Filter bag reinforced self-cleaning type centrifugal machine

A self-cleaning and enhanced technology, applied in the field of centrifuges, to avoid scratching the filter bag, improve the tensile strength, and improve the effect of centrifugation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, the technical solution of the present invention will be described in detail through specific embodiments.

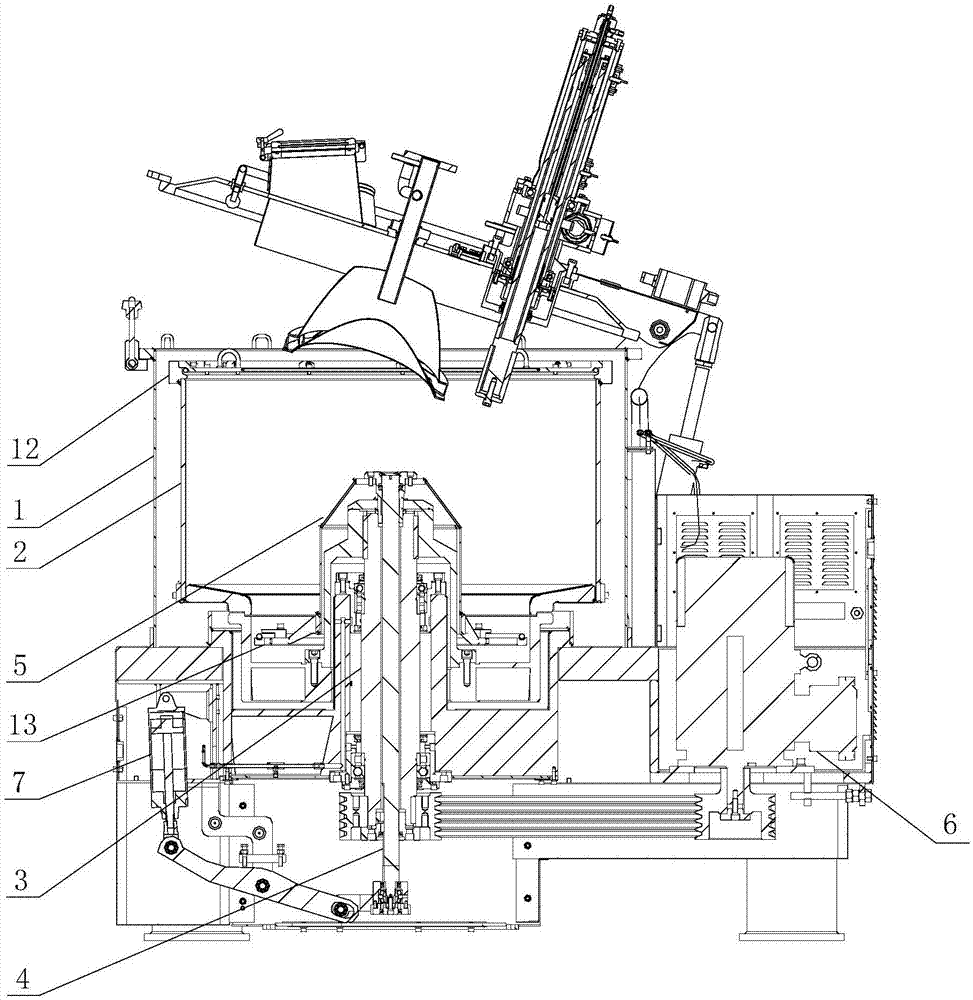

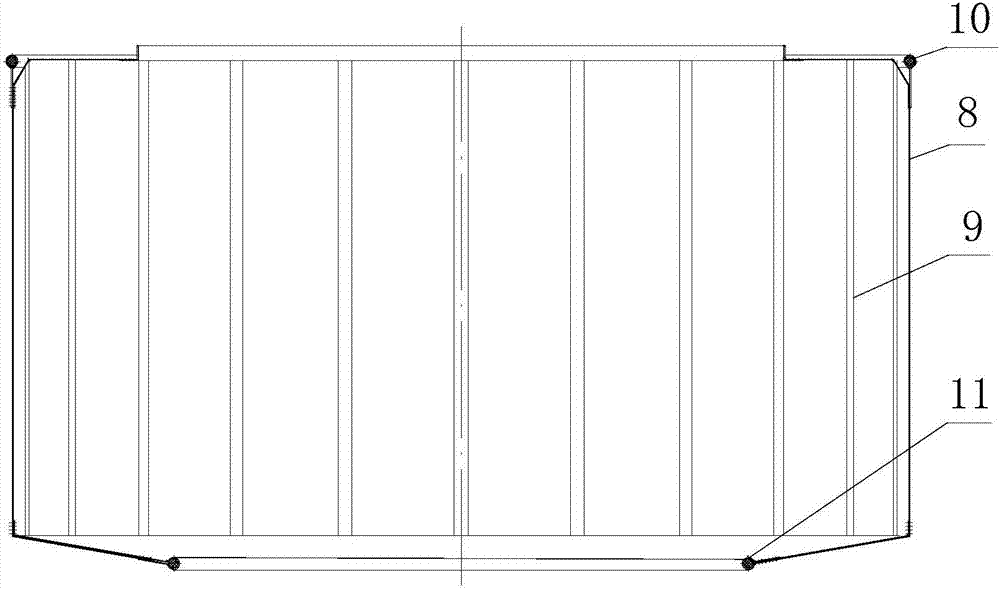

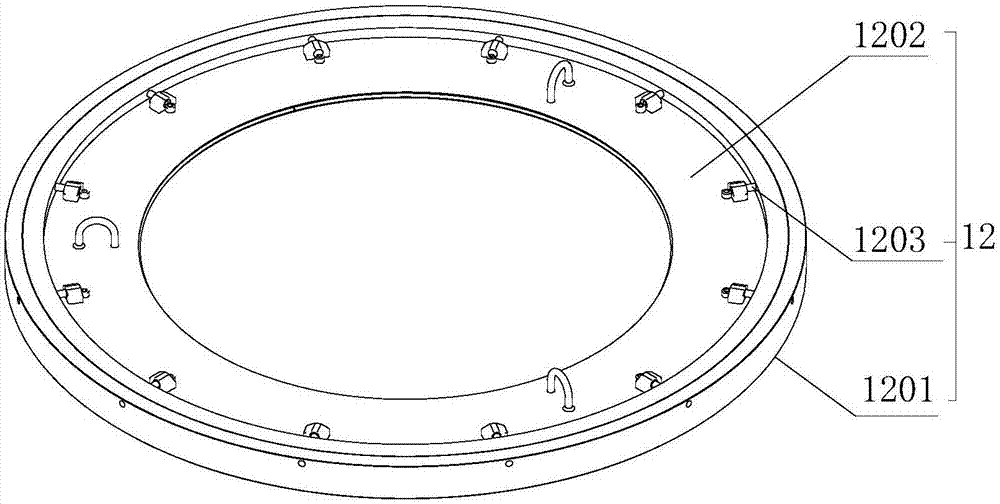

[0034] Such as Figure 1-6 As shown, figure 1 It is a schematic structural diagram of a filter bag reinforced self-cleaning centrifuge proposed by the present invention; figure 2 It is a schematic diagram of the structure of the filter bag in a filter bag reinforced self-cleaning centrifuge provided by the present invention; image 3 It is a structural schematic diagram of the fixing device on the filter bag in a filter bag reinforced self-cleaning centrifuge provided by the present invention; Figure 4 It is a partial cross-sectional view of the fixing device on the filter bag in a filter bag reinforced self-cleaning centrifuge provided by the present invention; Figure 5 It is a top view of the bottom fixing mechanism of the filter bag in a filter bag reinforced self-cleaning centrifuge provided by the present invention; Image 6 It is a diagram of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com