A light-reflecting heat-insulating coating

A technology of thermal insulation coating and light reflection, applied in the field of building exterior wall coatings, can solve the problems of high cost, poor reflection efficiency, poor thermal insulation effect of coatings, etc., and achieve the effect of low cost and high thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

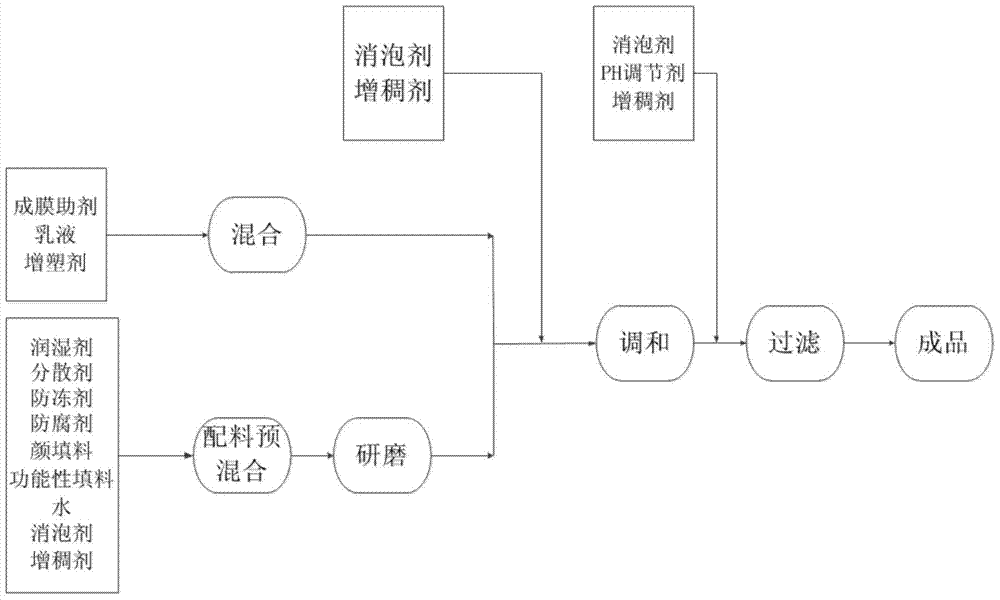

[0028] The present invention also provides a method for preparing the paint. First, add additives including wetting agent, dispersant, antifreeze, and preservative into water and stir at a low speed for 10 to 15 minutes;

[0029] Next, add pigments and fillers and functional fillers, stir at high speed for 15 to 20 minutes, add an appropriate amount of defoamer and thickener to pre-mix the ingredients during the stirring process, and grind the uniformly mixed pigments and fillers for 10 to 20 minutes;

[0030] Then, stir the ground slurry at a low speed, add the emulsion mixed with film-forming aids and plasticizers and mix evenly;

[0031] Finally, add a defoamer and a pH regulator, and add a thickener according to the required viscosity, stir well and filter to obtain a finished product.

[0032] In the above coatings, in order to better mix the components and achieve better physical and chemical properties,

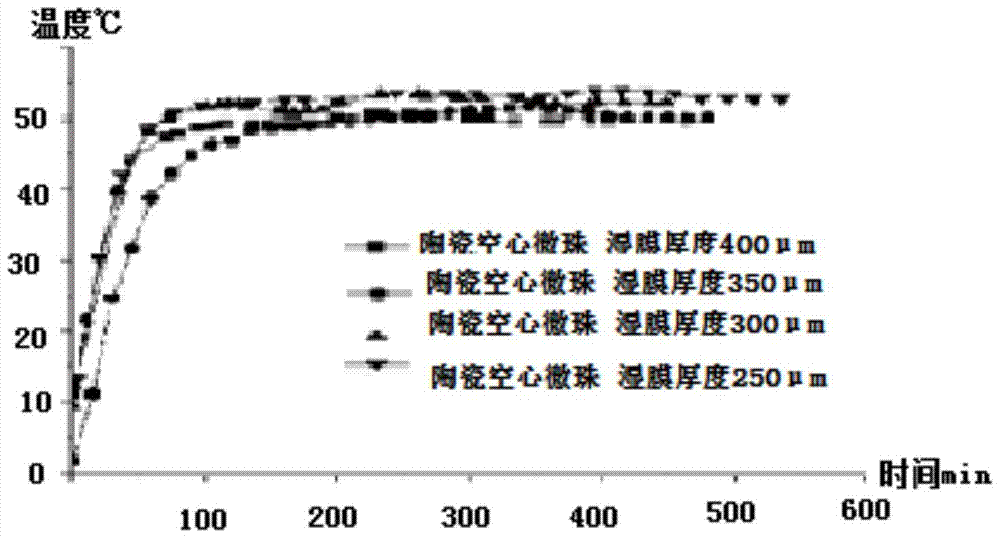

[0033] Preferably, when hollow ceramic microspheres are used as ...

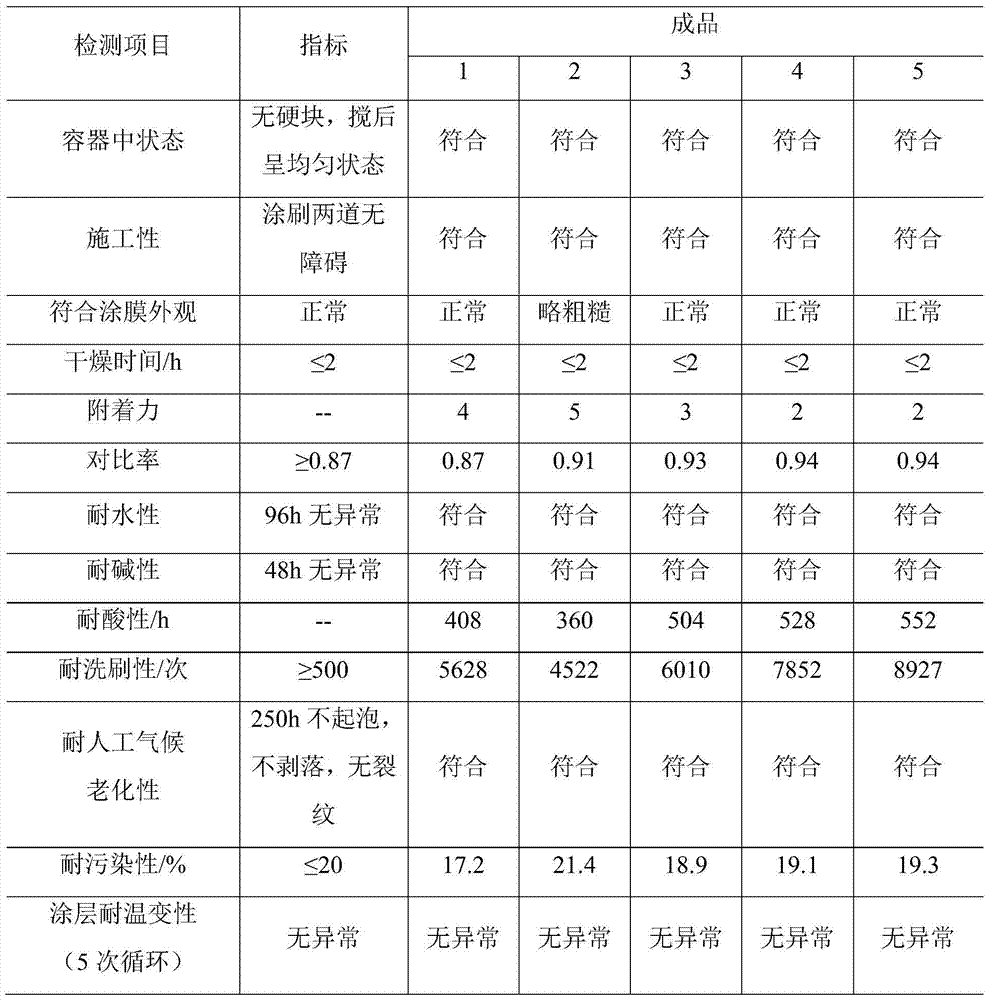

Embodiment 1

[0037] The specific components and weight ratio of the paint are: including 30% of emulsion, 30% of pigment and filler, 34% of functional filler, 1% of auxiliary agent and 5% of water;

[0038] The weight ratio of water-based polytetrafluoroethylene resin to water-based polyurethane resin in the emulsion is 0.2:1;

[0039] The pigments and fillers include titanium dioxide whose weight is 43% of the total weight of pigments and fillers; talcum powder whose weight is 57% of the total weight of pigments and fillers;

[0040] The functional fillers include hollow ceramic microsphere materials with a particle size of 150 mesh and a weight of 86% of the total weight of the functional filler; infrared ceramic powders with a particle size of 325 mesh and a weight of 14% of the total weight of the functional filler;

[0041] Described auxiliary agent comprises weight and is the dispersant of auxiliary agent gross weight 12%, the antifreezing agent of 2.5%, the thickening agent of 12.5%...

Embodiment 2

[0043] The specific components and weight ratio of the paint are: including 30% of emulsion, 30% of pigment and filler, 38% of functional filler, 0.8% of auxiliary agent and 1.2% of water;

[0044] Water-based polytetrafluoroethylene resin and water-based polyurethane resin weight ratio in the emulsion are 1.2:1;

[0045] The pigments and fillers include titanium dioxide whose weight is 71% of the total weight of pigments and fillers; talcum powder whose weight is 29% of the total weight of pigments and fillers;

[0046] The functional filler includes a hollow ceramic bead material with a particle size of 800 mesh and a weight of 91% of the total weight of the functional filler; an infrared ceramic powder with a particle size of 800 mesh and a weight of 9% of the total weight of the functional filler;

[0047] Described auxiliary agent comprises that weight is the dispersant of auxiliary agent gross weight 11%, 3% antifreezing agent, 12% thickening agent, 9% wetting agent, 17%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com