Patents

Literature

35 results about "Condensation particle counter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A condensation particle counter or CPC is a particle counter that detects and counts aerosol particles by first enlarging them by using the particles as nucleation centers to create droplets in a supersaturated gas.

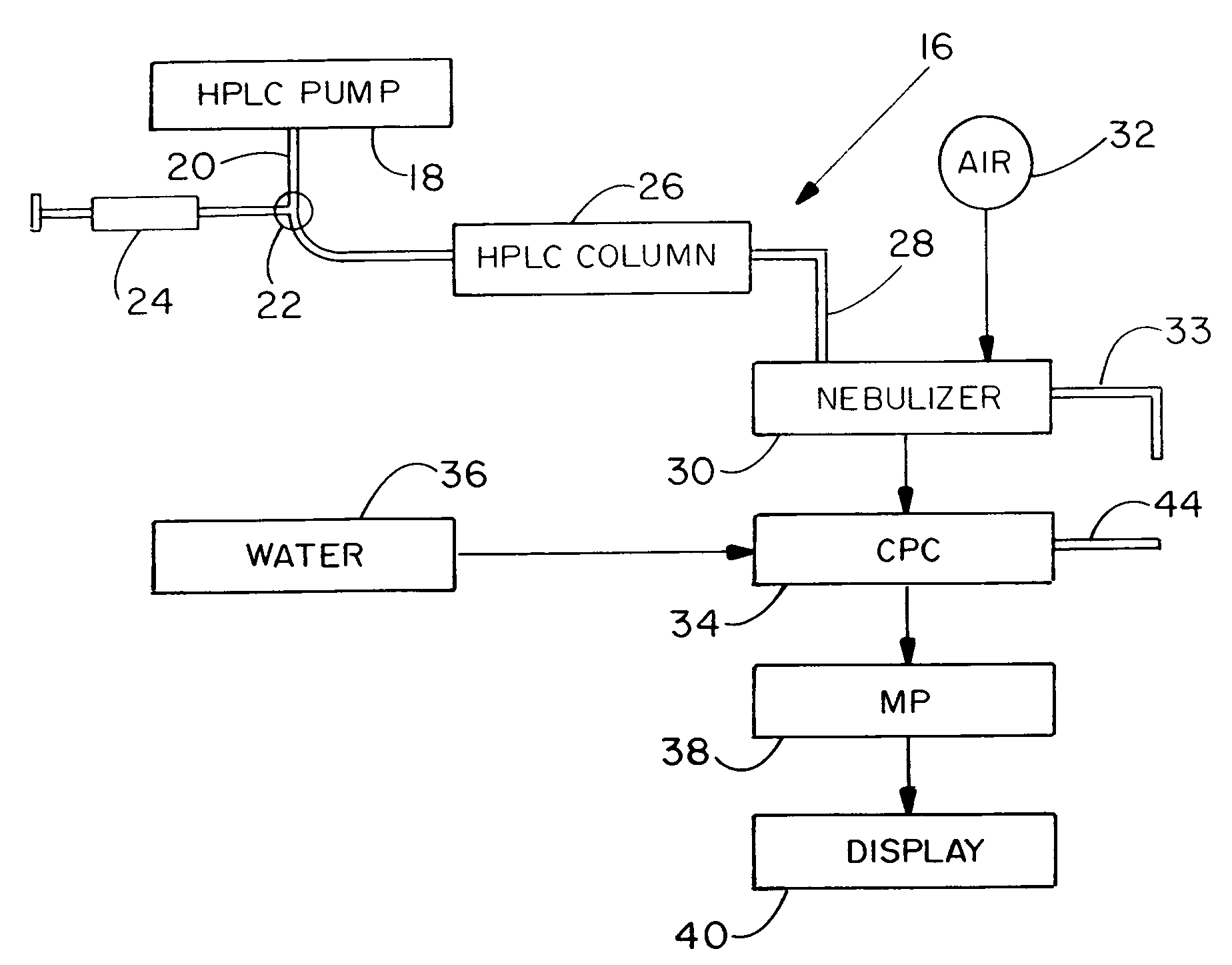

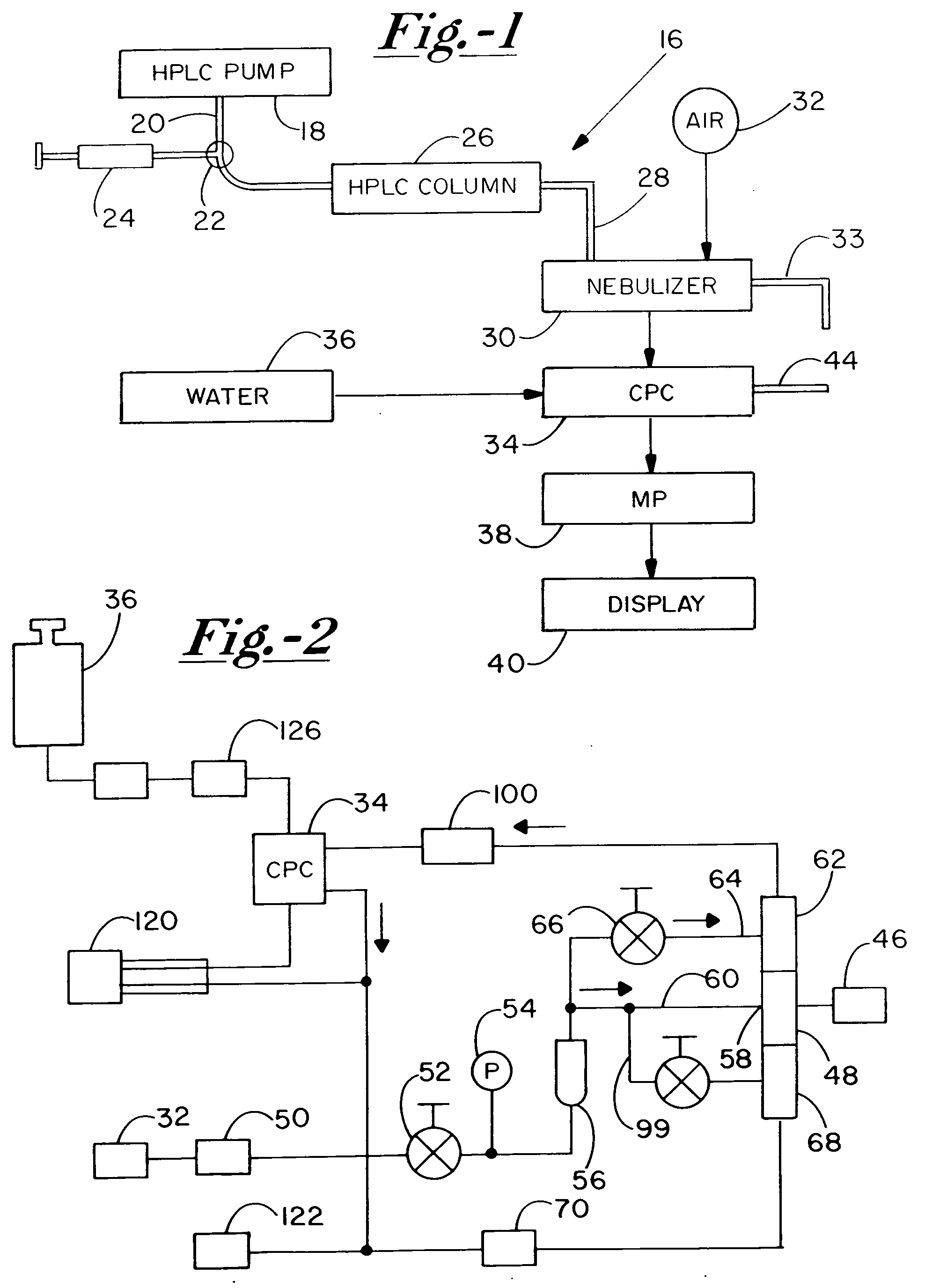

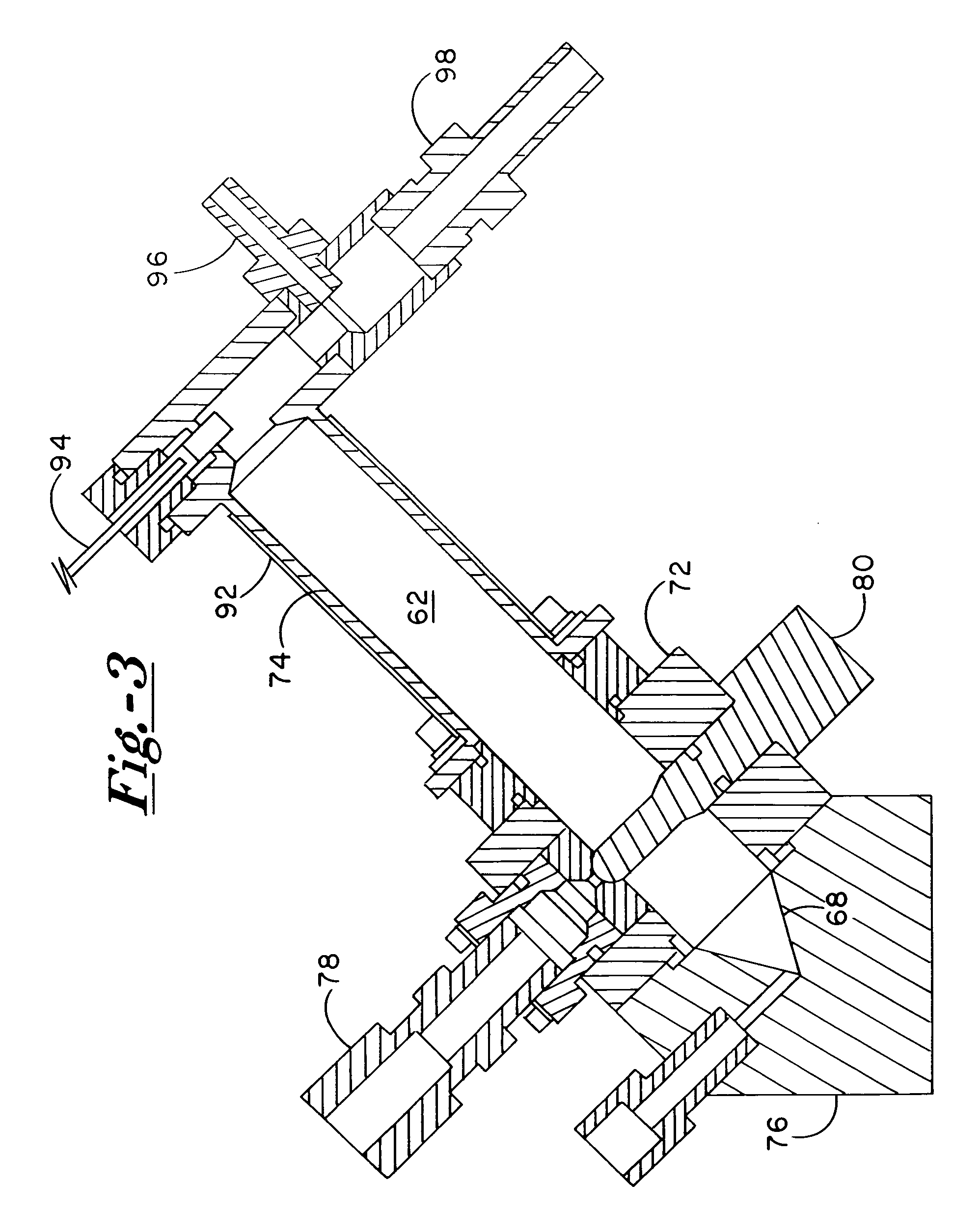

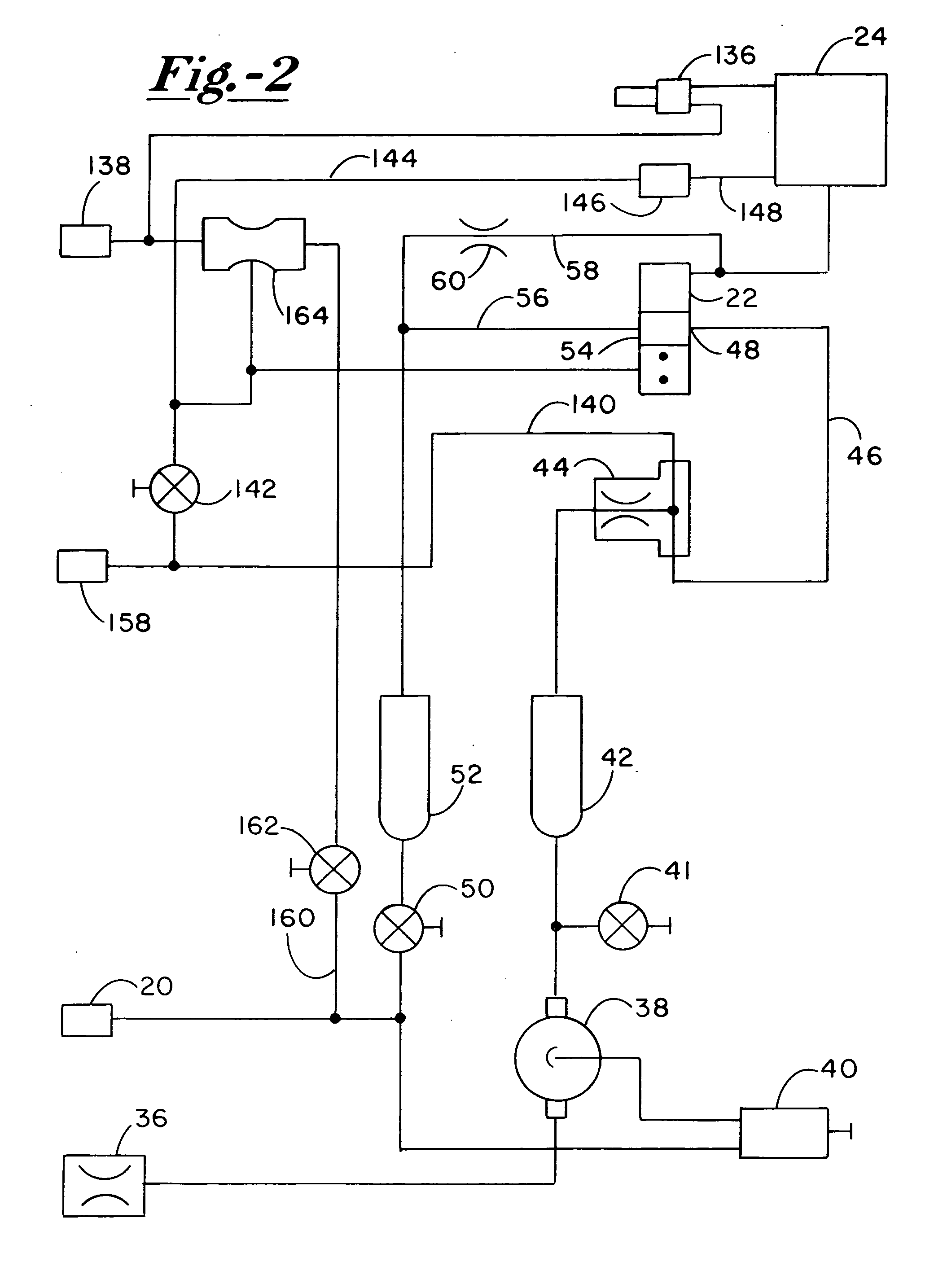

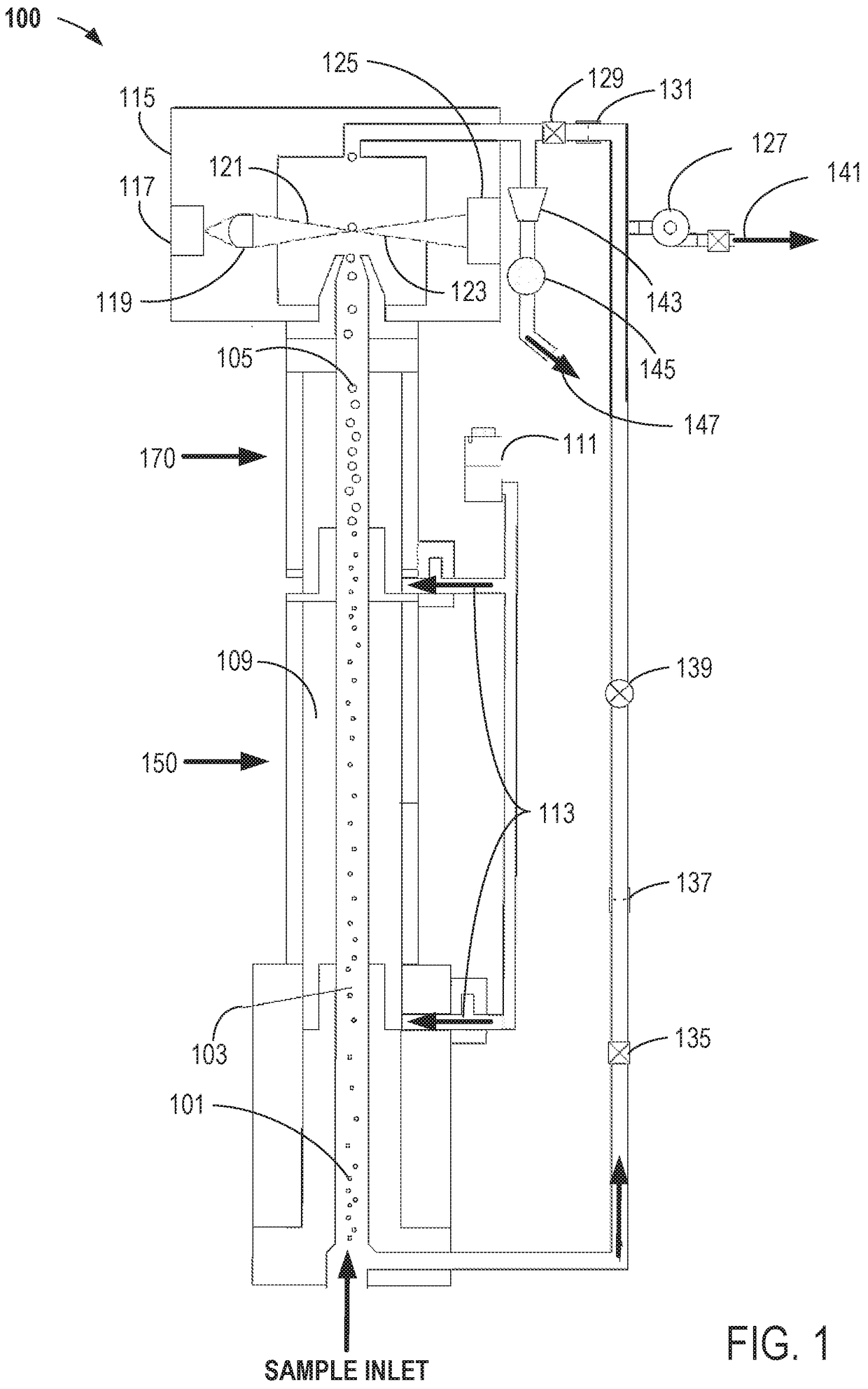

Measuring Analyte Concentrations in Liquids

InactiveUS20080137065A1Higher kinetic energy mixingSmall dropletSamplingComponent separationElectrical mobilityDroplet size

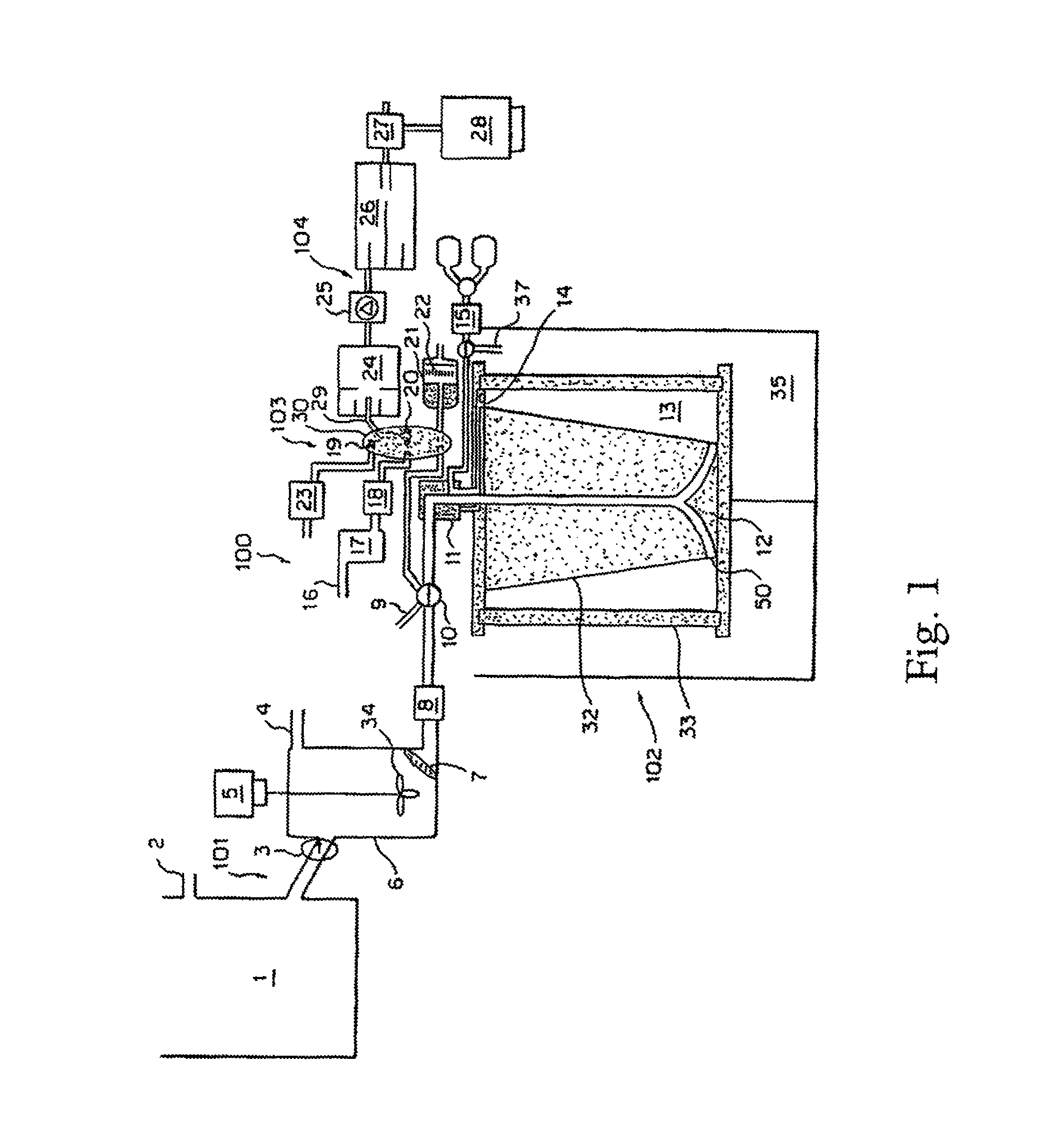

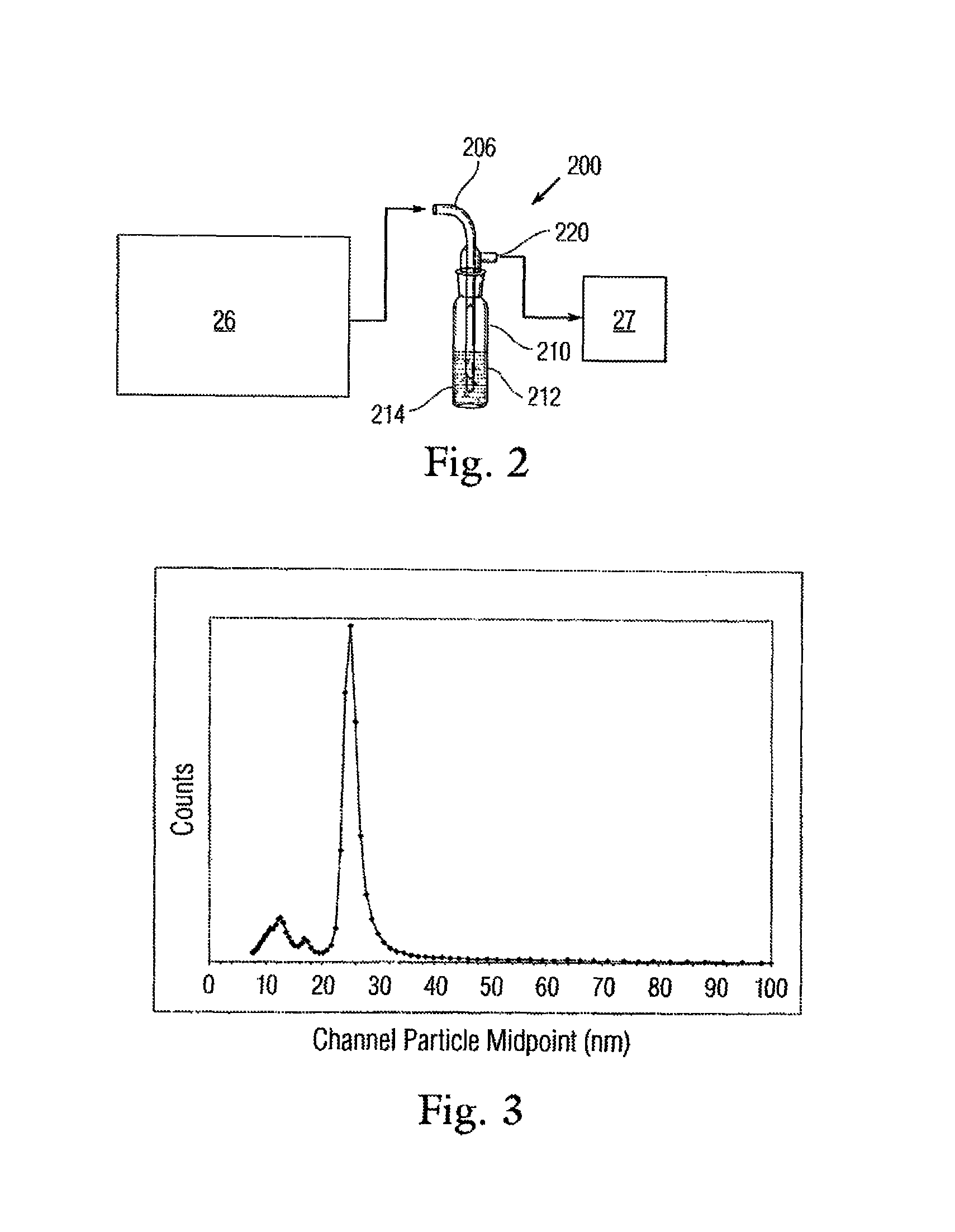

A high performance liquid chromatography system employs a nebulizer with a flow restriction at the exit of its mixing chamber to produce finer droplets, and an adjustable impactor for increased control over droplet sizes. Downstream of the mixing chamber, the nebulizer can incorporate tubing that is permeable to the sample liquid, to promote aerosol drying through perevaporation. A condensation particle counter downstream of the nebulizer uses water as the working medium, and is adjustable to control threshold nucleation sizes and droplet growth rates. A particle size selector employing diffusion, electrostatic attraction or selection based on electrical mobility, is advantageously positioned between the nebulizer and the CPC.

Owner:TSI INC

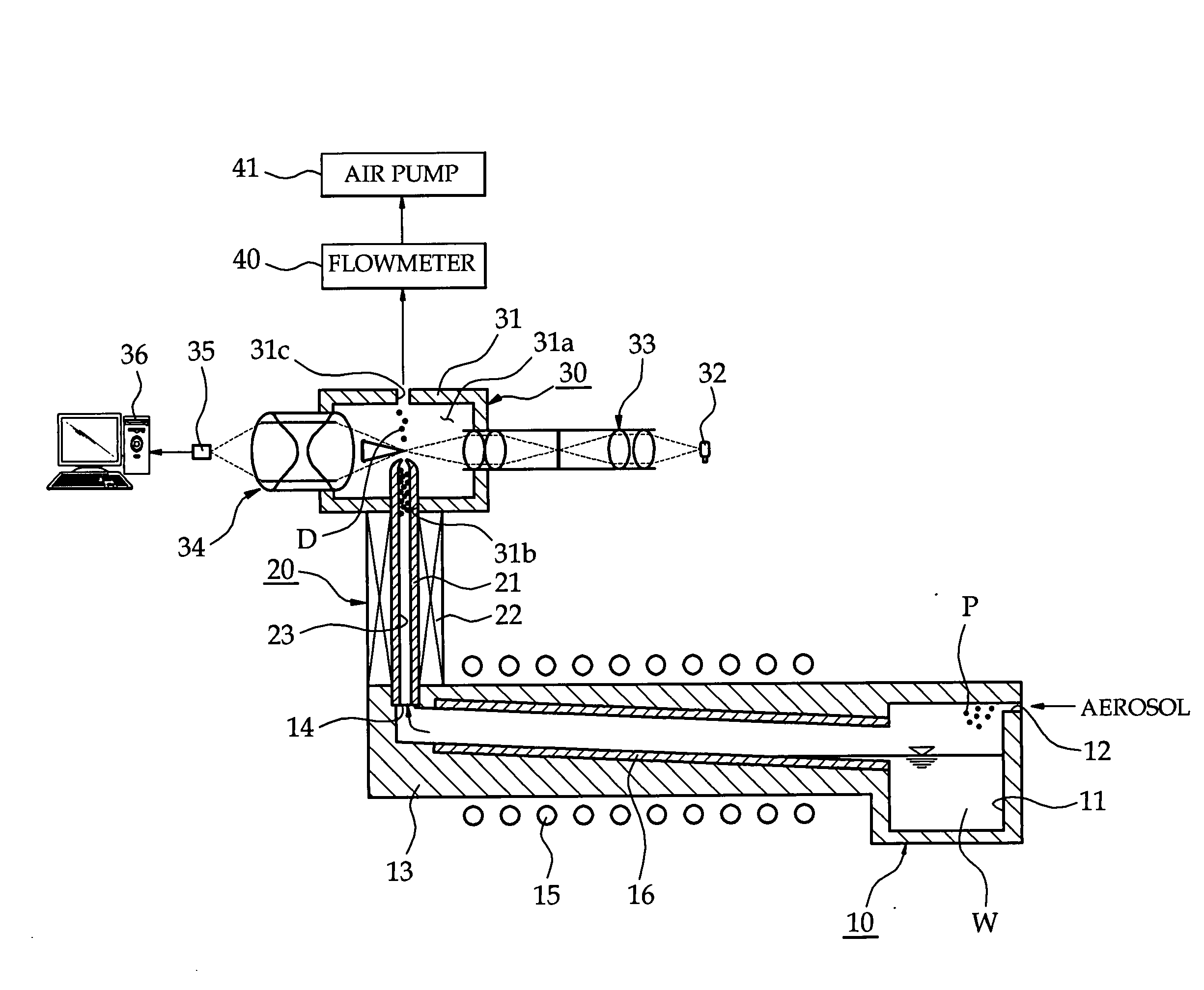

Condensation particle counter

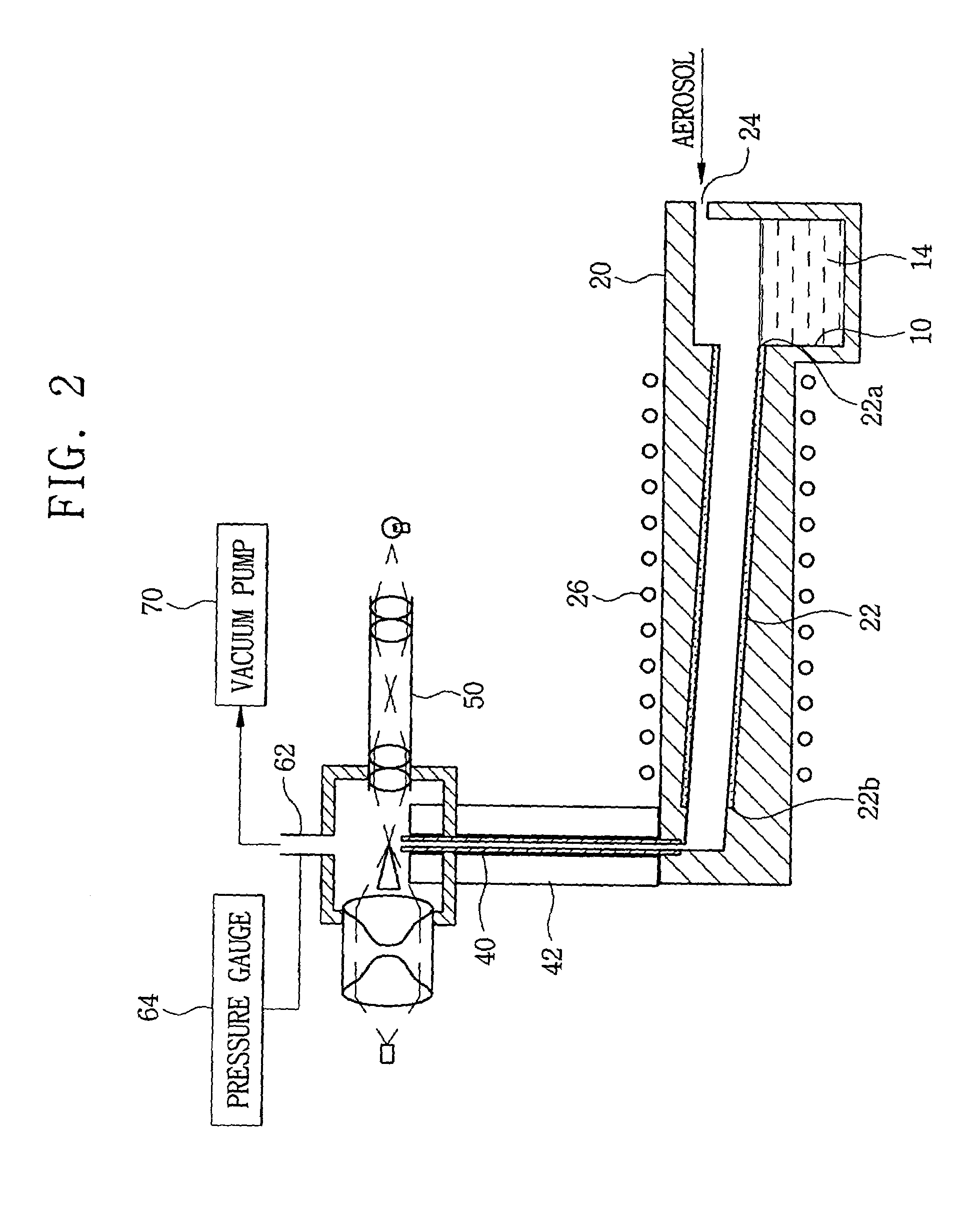

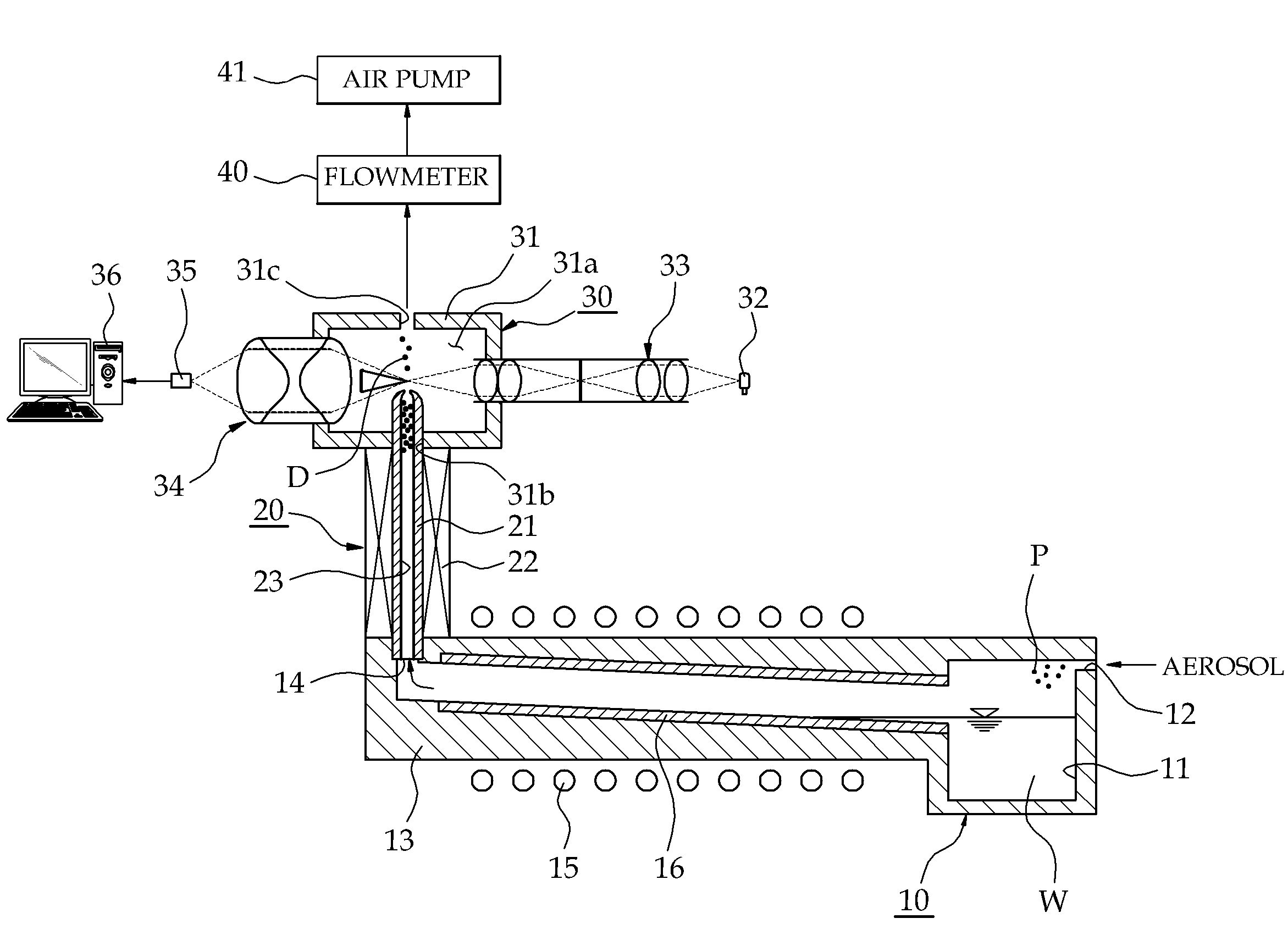

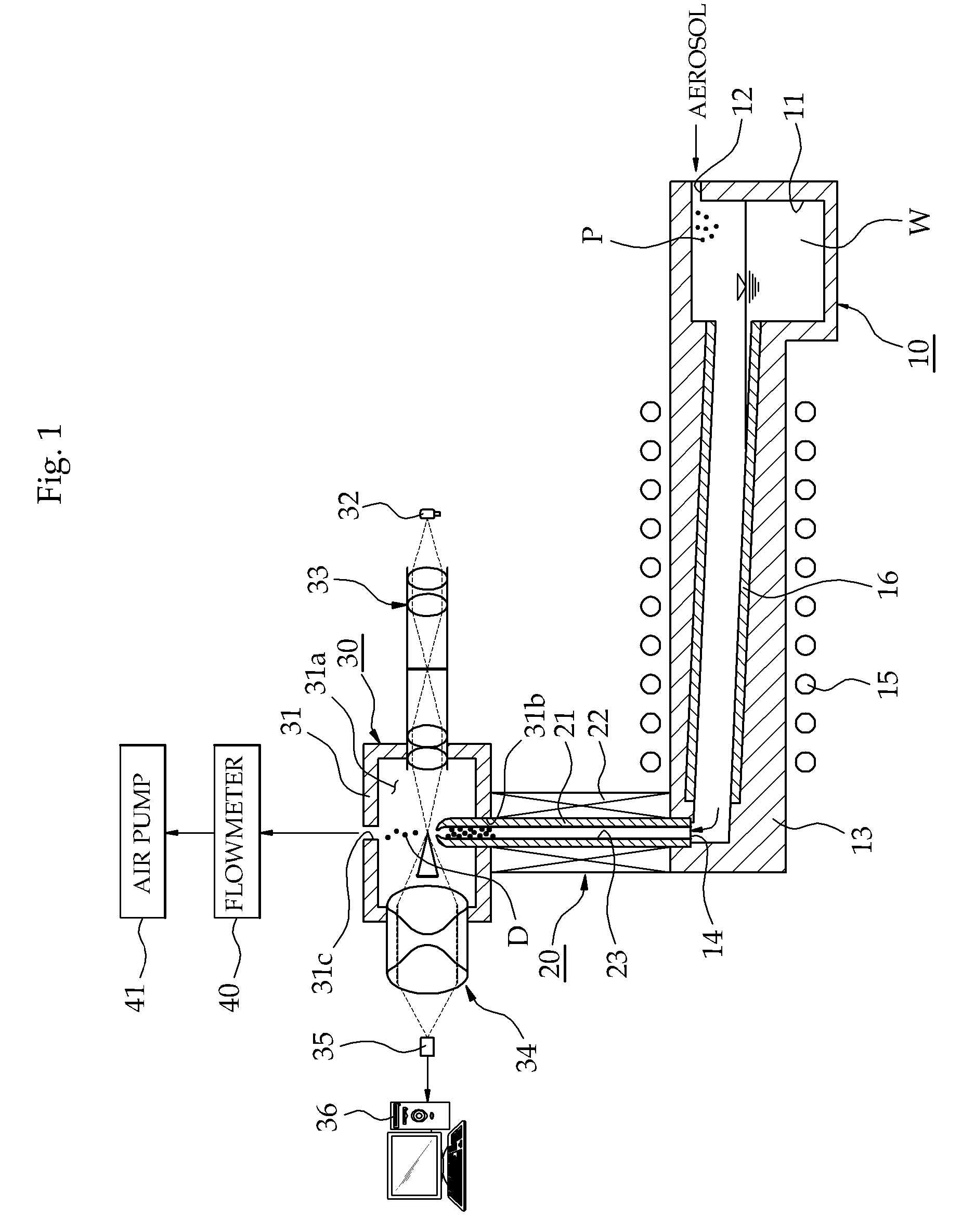

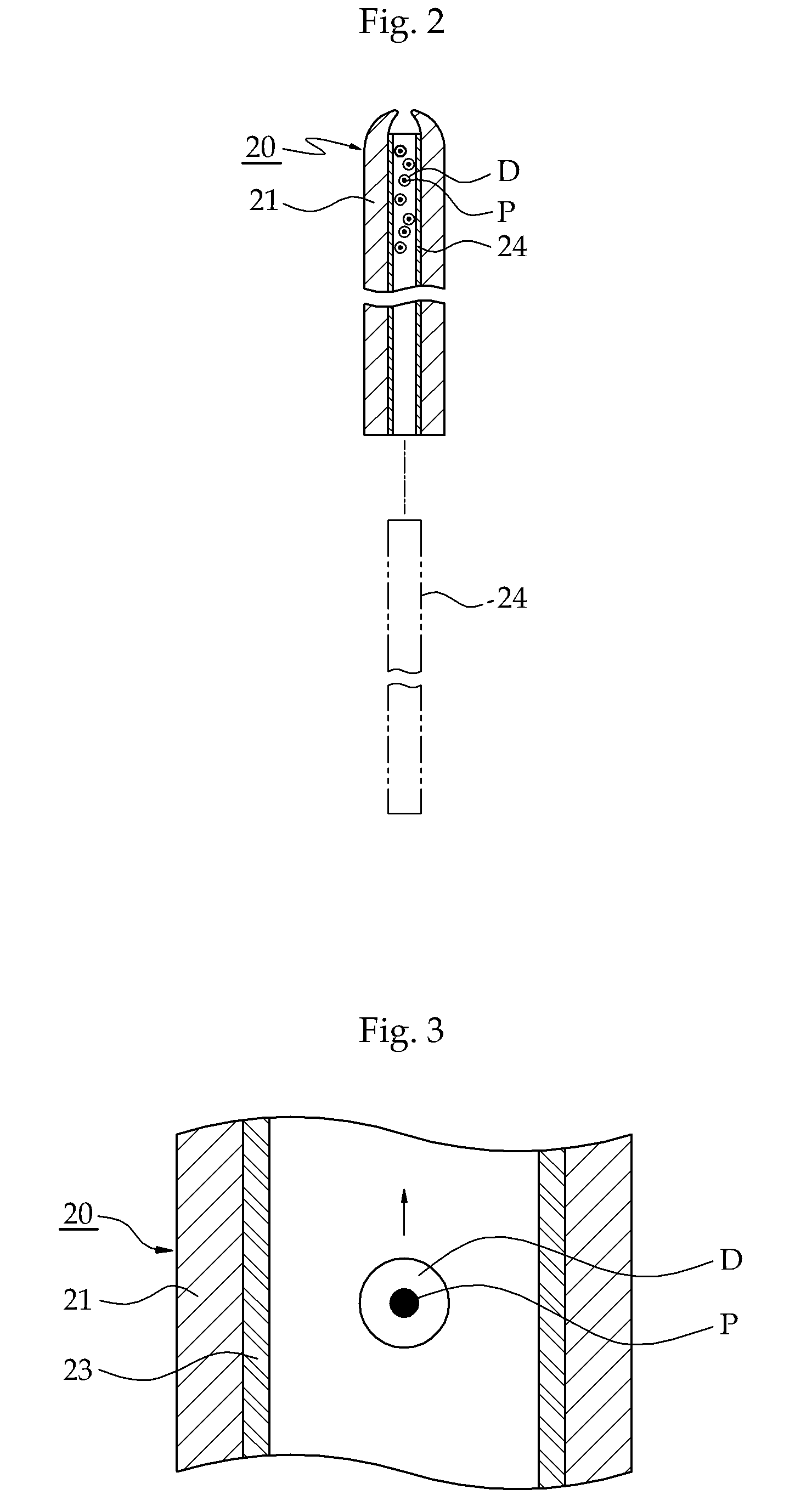

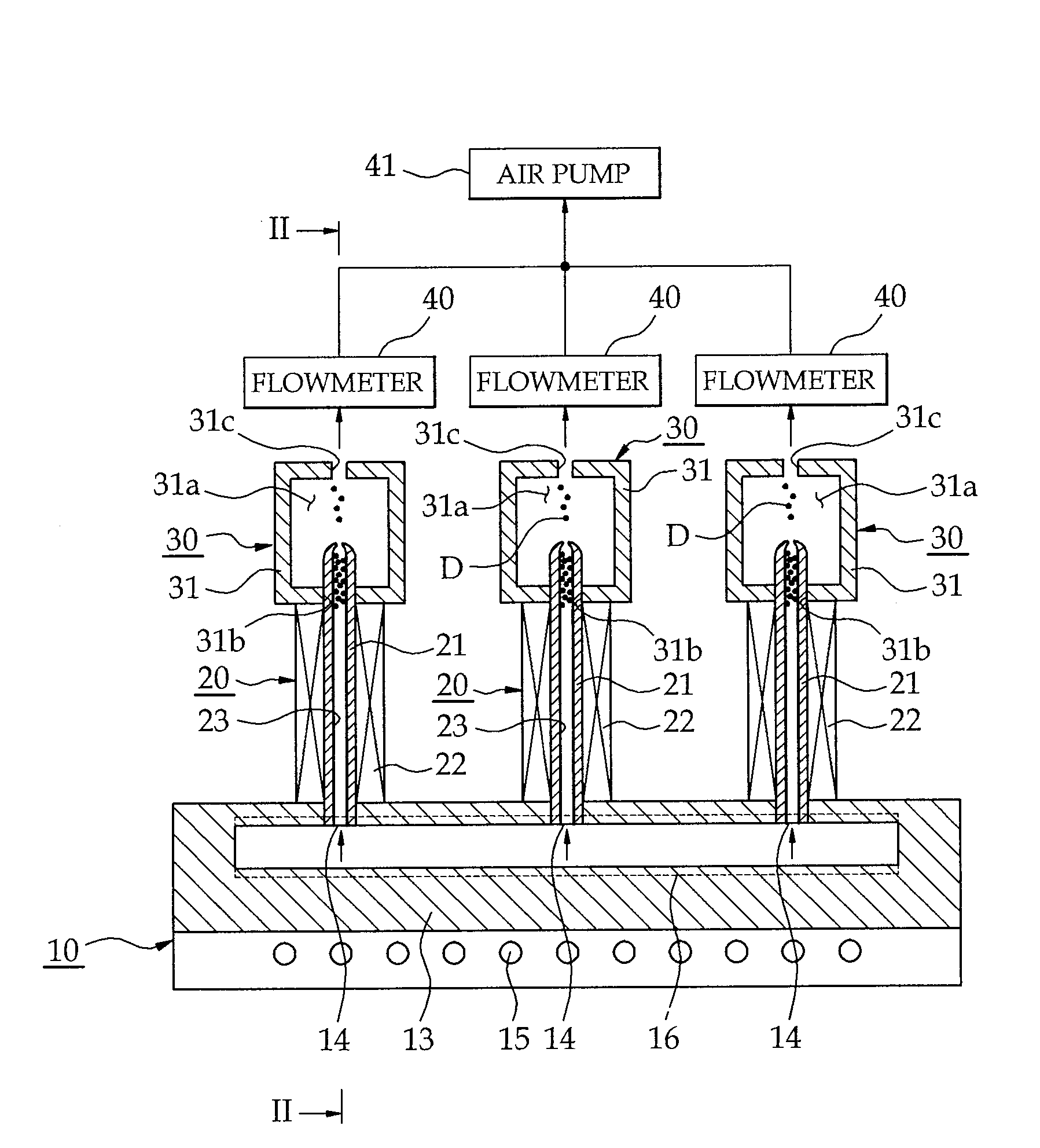

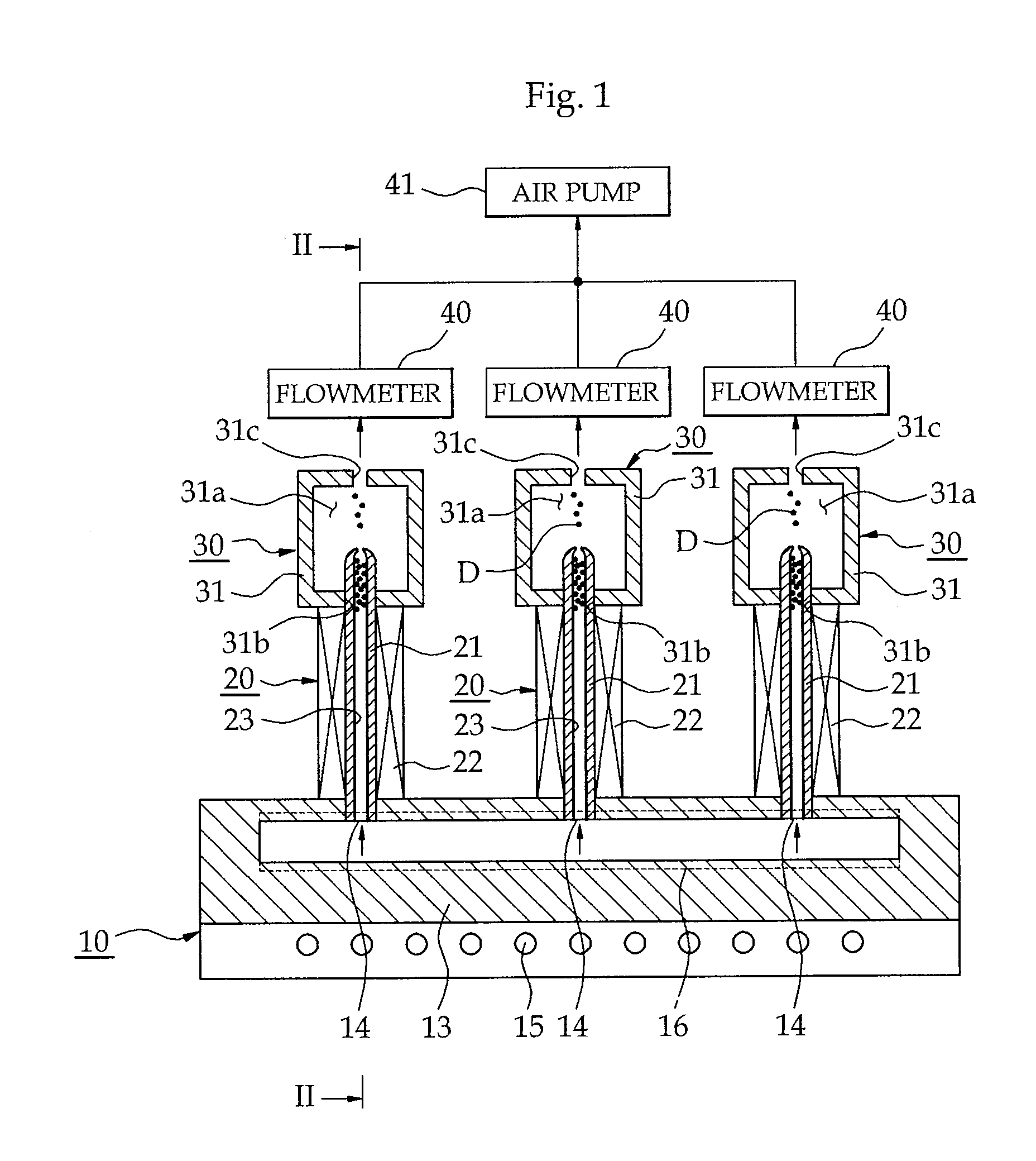

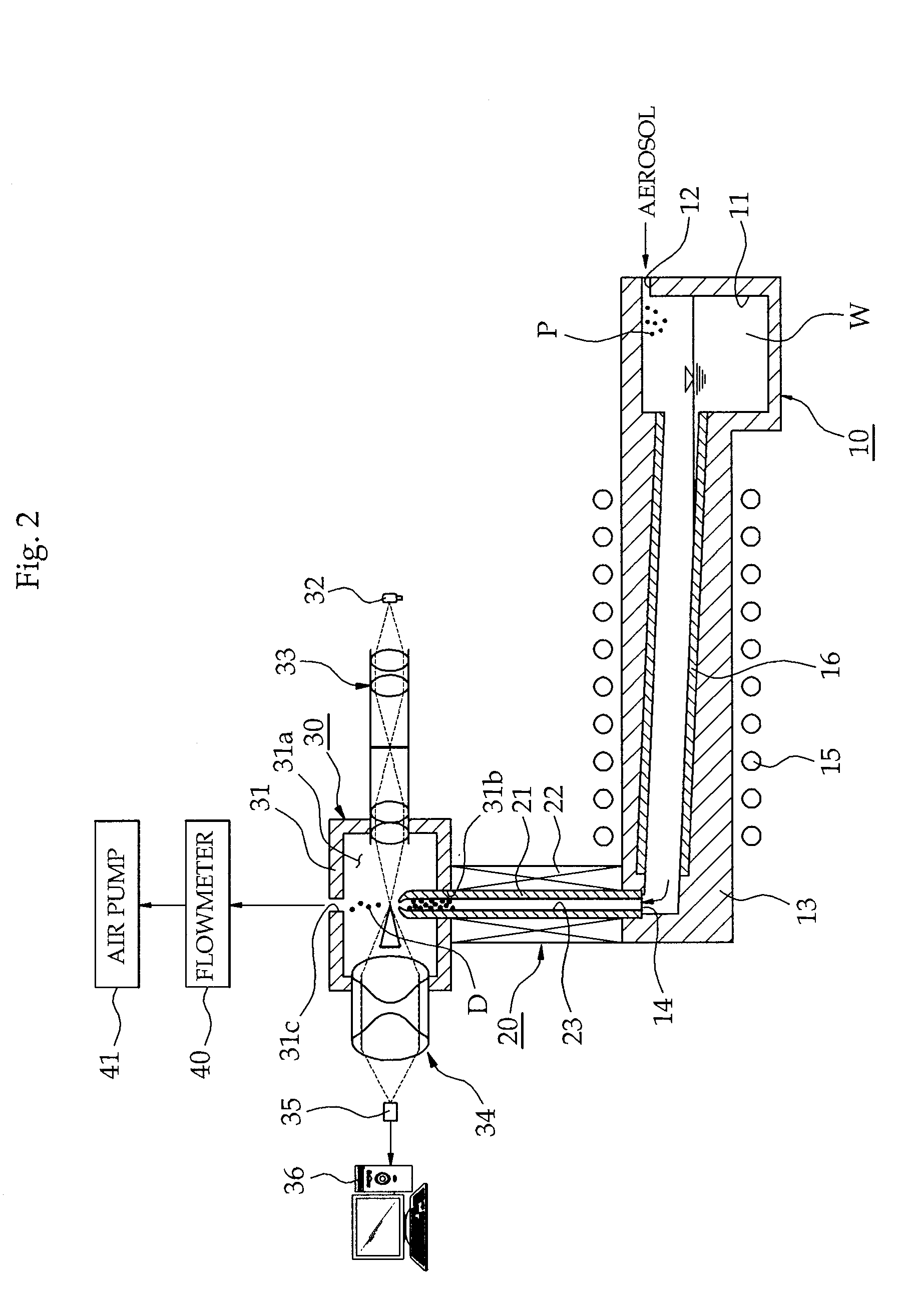

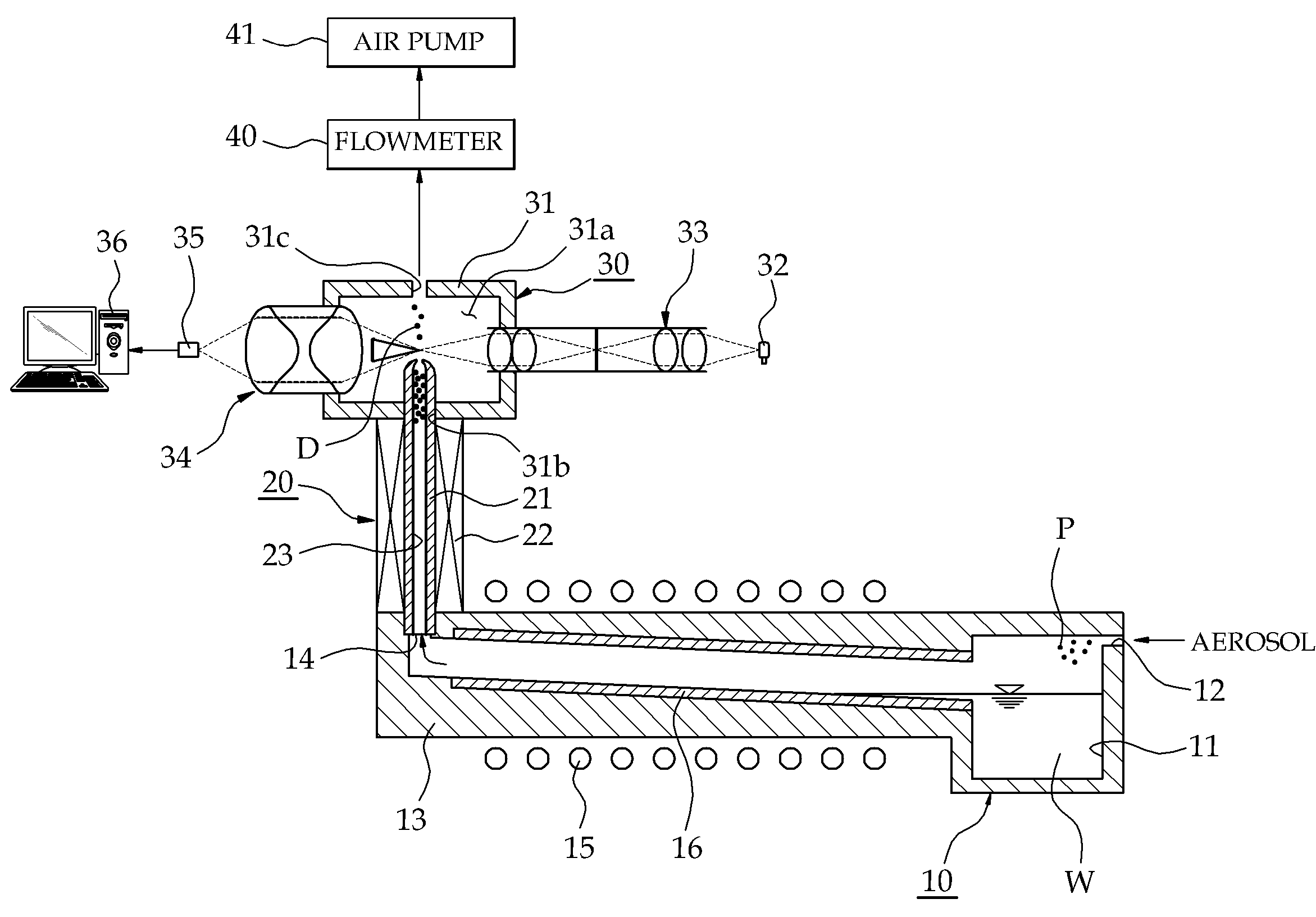

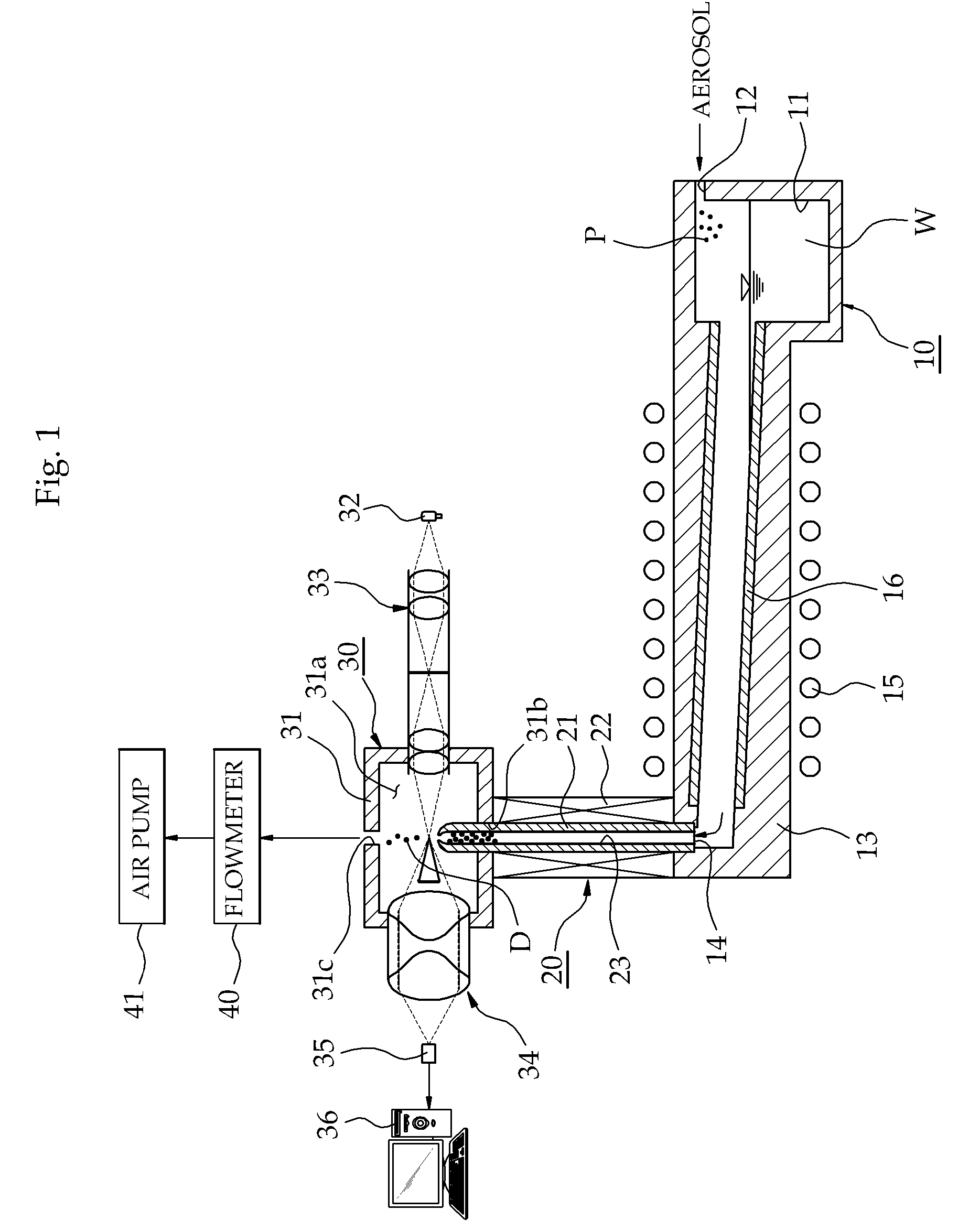

ActiveUS20080186489A1Efficient measurementMaterial analysis by optical meansIndividual particle analysisWorking fluidSurface layer

A condensation particle counter is capable of efficiently measuring the number and size of fine particles. The condensation particle counter includes a saturator, a plurality of condensers and a plurality of optical particle counters. The saturator is designed to generate a saturated gas by saturating a gas in which fine particles are suspended with working fluid. The condensers are connected to a downstream side of the saturator to condense the saturated gas so that liquid droplets can grow around the fine particles. The optical particle counters are connected to downstream sides of the condensers to optically detect the liquid droplets supplied from the condensers. Each of the condensers has a condenser tube for interconnecting the saturator and each of the optical particle counters. The condenser tube is provided with a hydrophilic inner surface layer.

Owner:AHN IN +1

Condensation particle counter

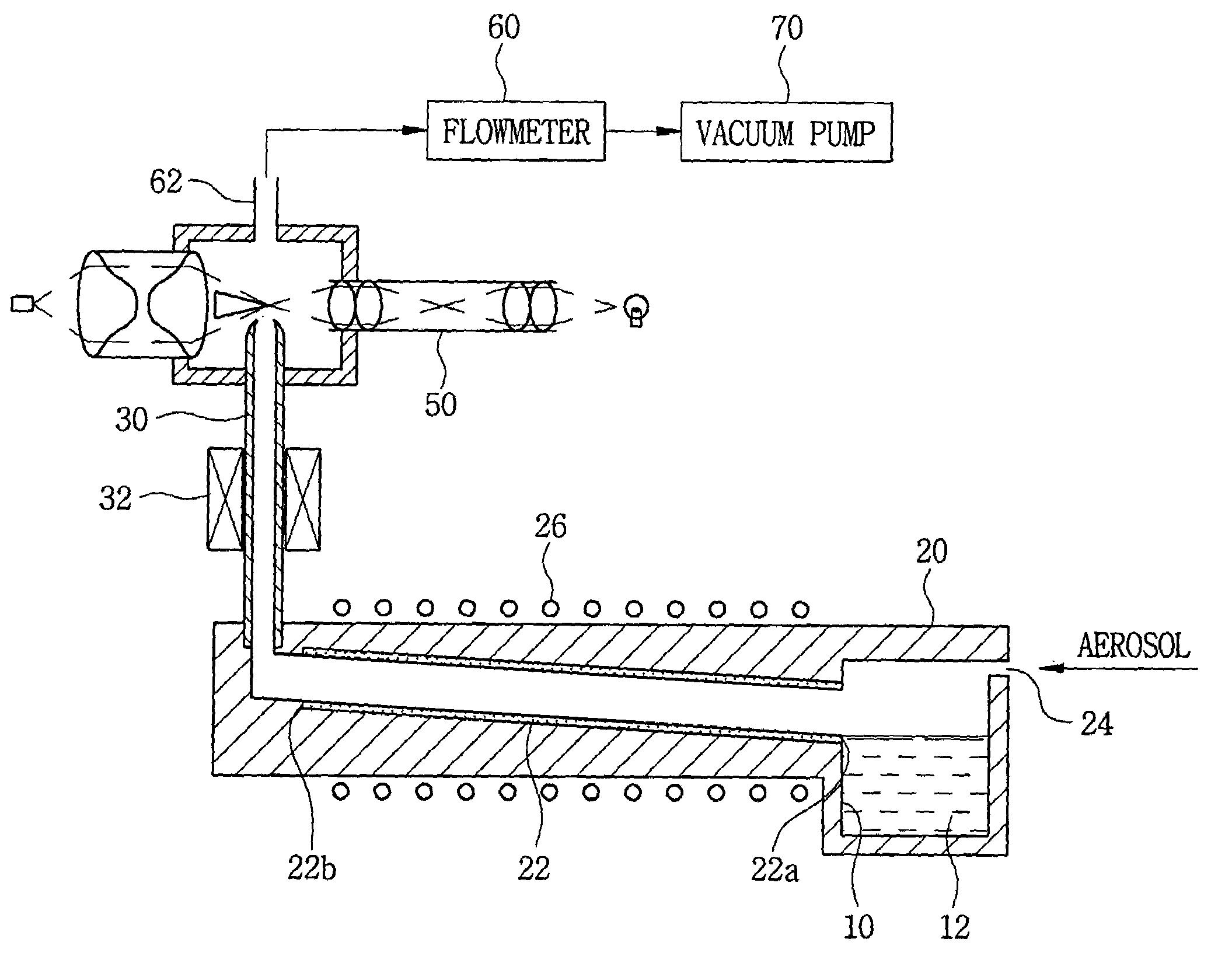

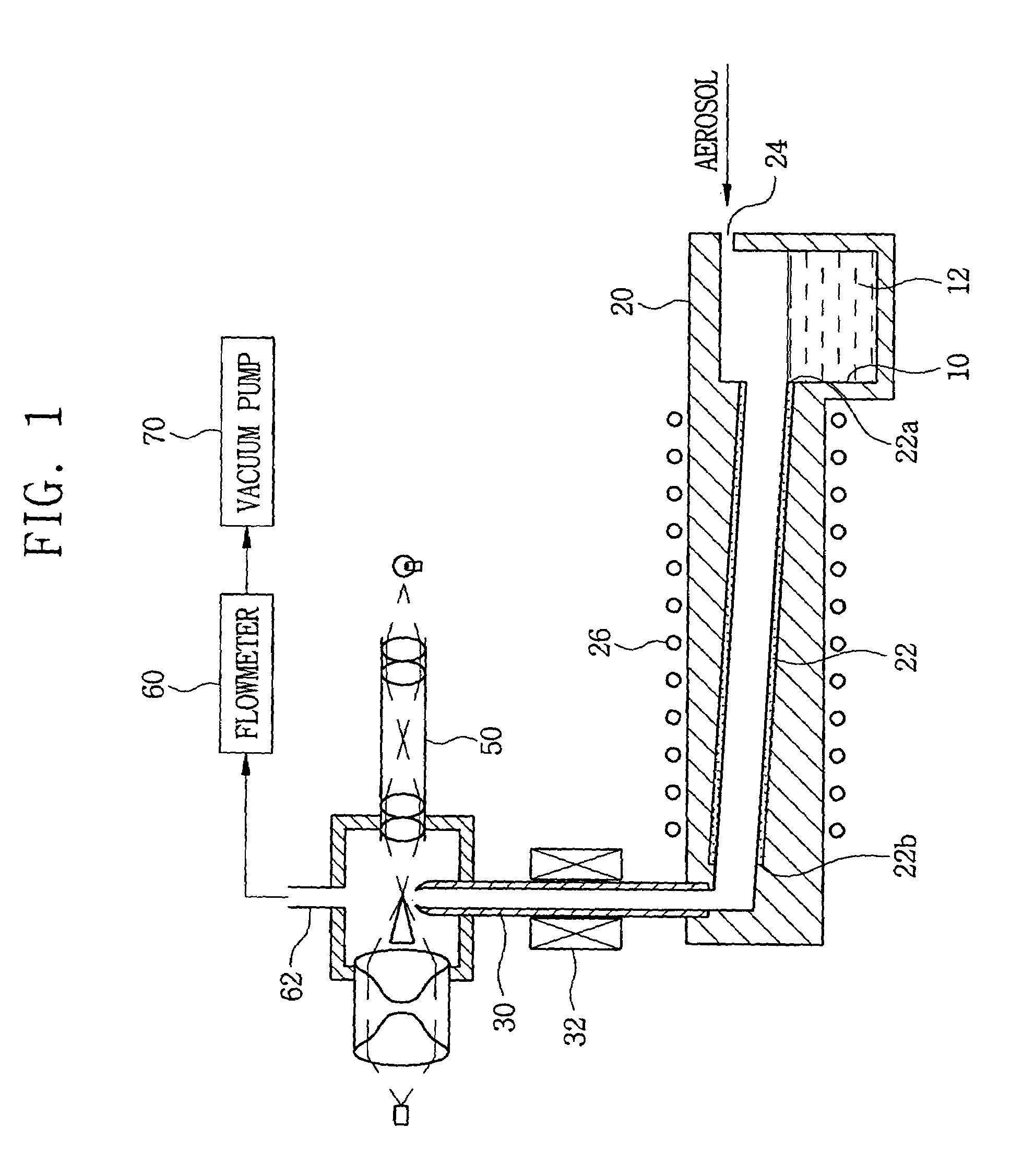

InactiveUS6980284B2Readily and quickly countingIncrease flow rateSamplingSemiconductor/solid-state device manufacturingAlcoholHeat flow

A condensation particle counter measures the number of ultra-fine particles by growing the ultra-fine particles through a condensing process. The counter includes a capillary in which vapor of operating liquid is condensed and the ultra-fine particles grow. An insulating material surrounds the capillary to shut out heat flow between the capillary and the environment. The condensation particle counter can use various operating liquids including alcohol and water, and can be also applied to semiconductor clean rooms.

Owner:HYUNDAI CALIBRATION & CERTIFICATION TECH CO LTD

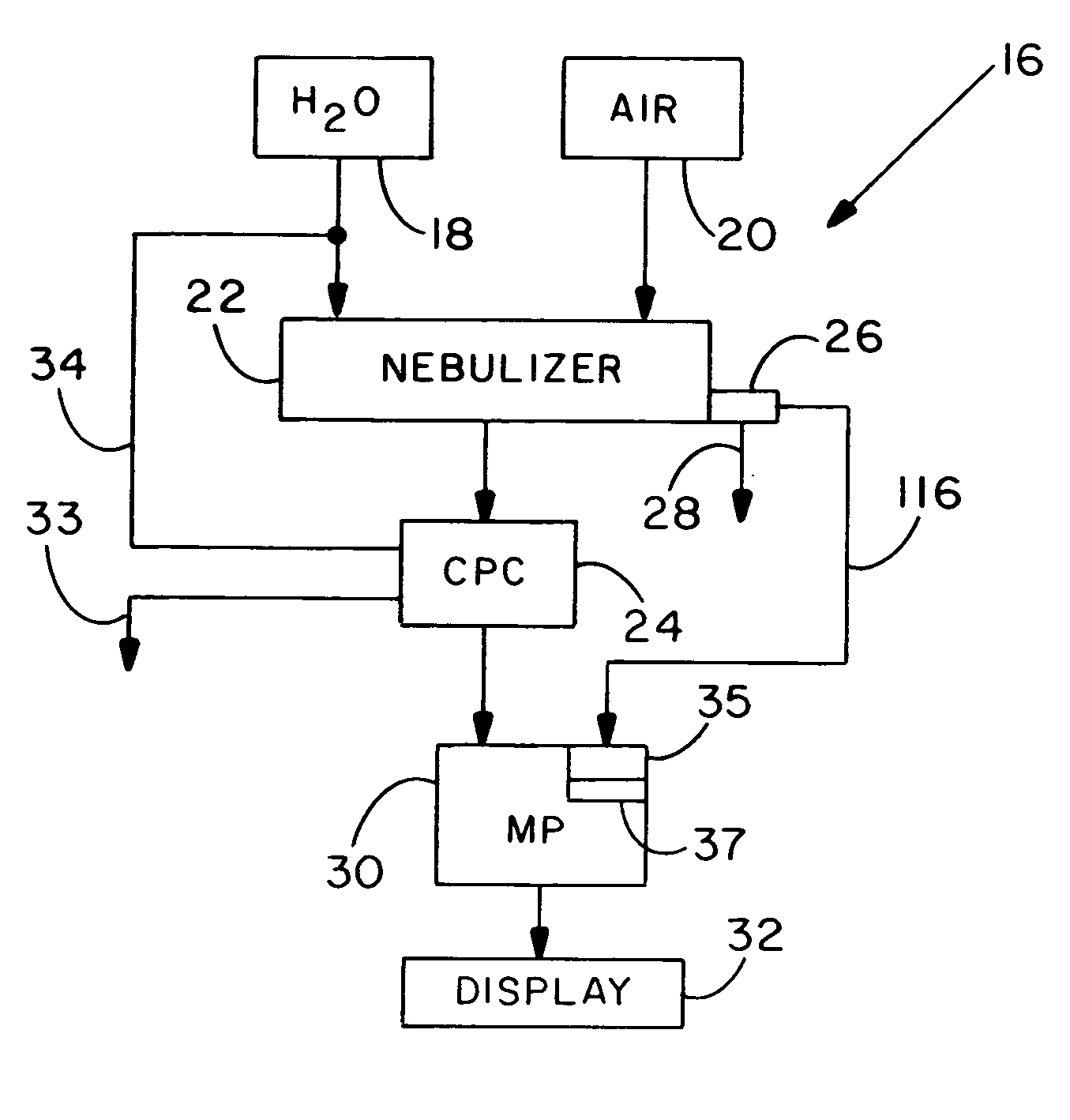

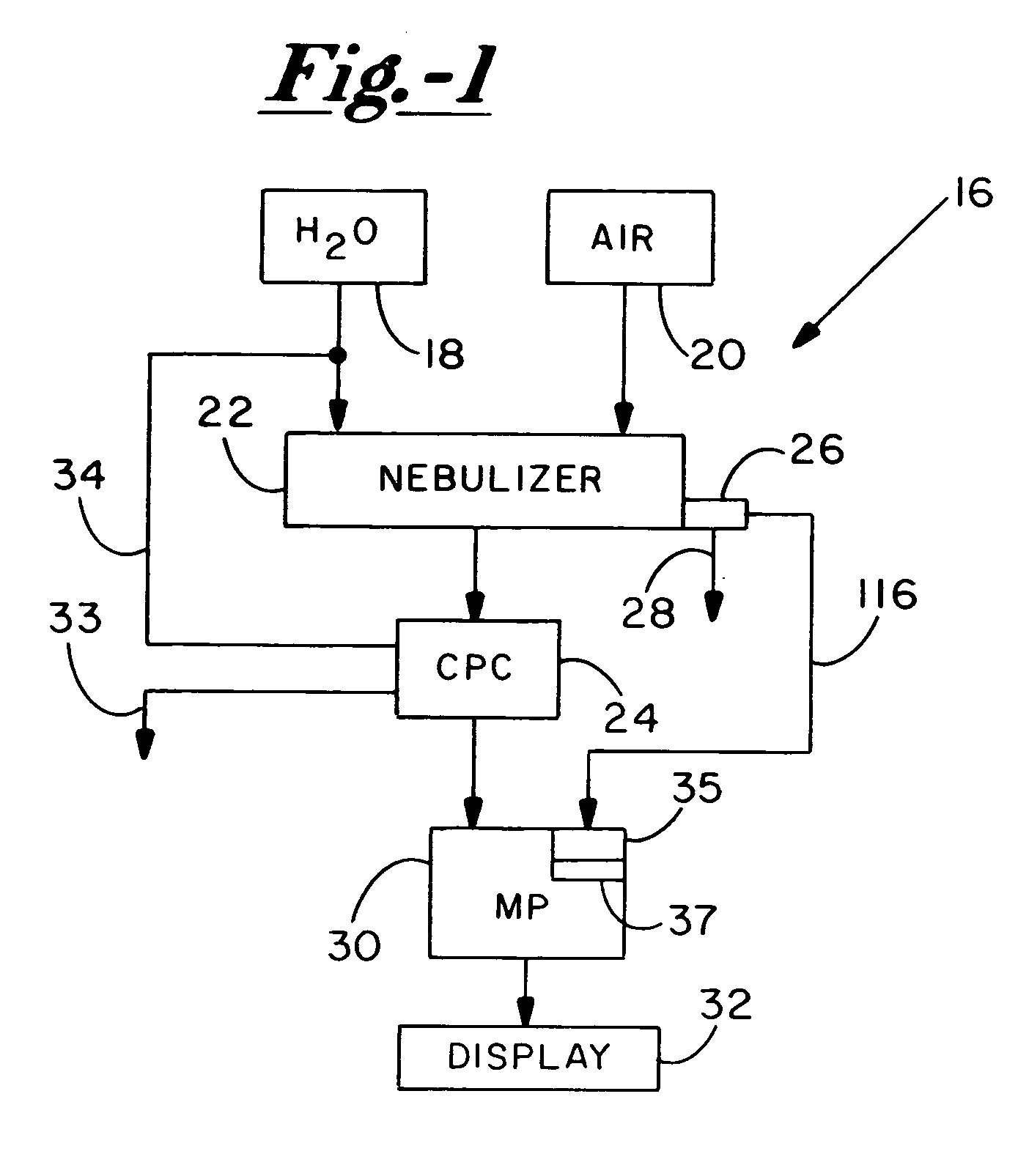

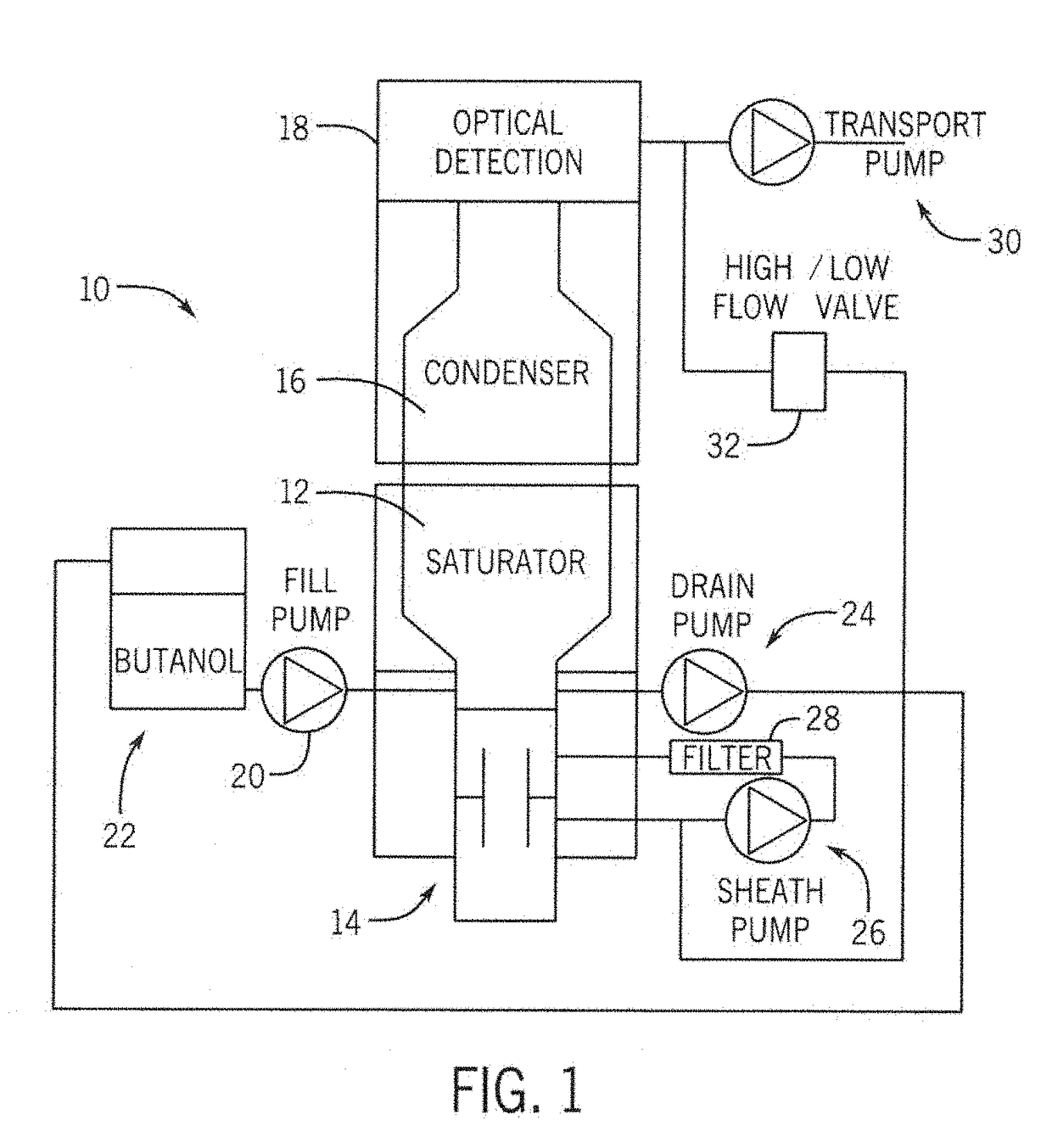

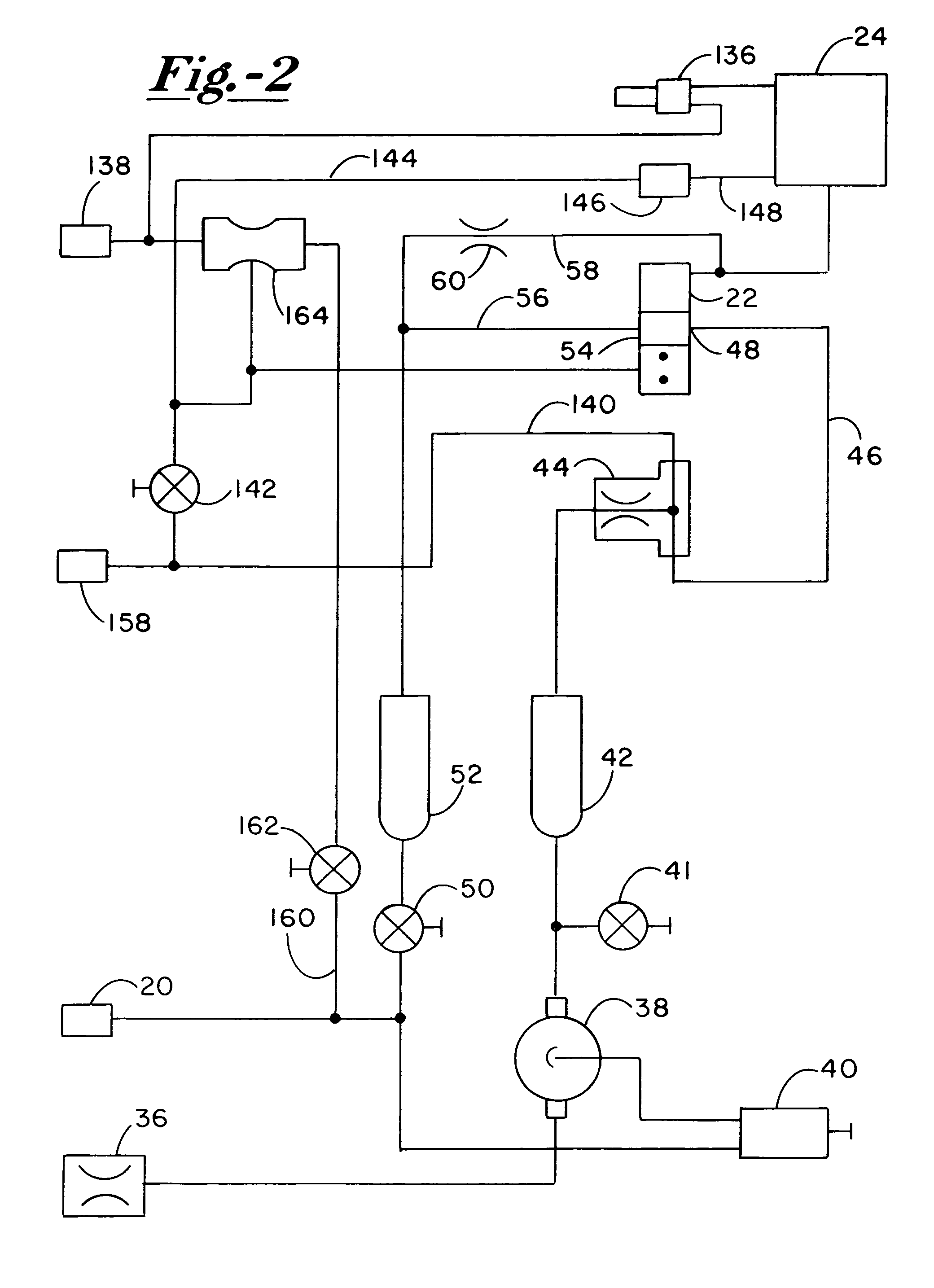

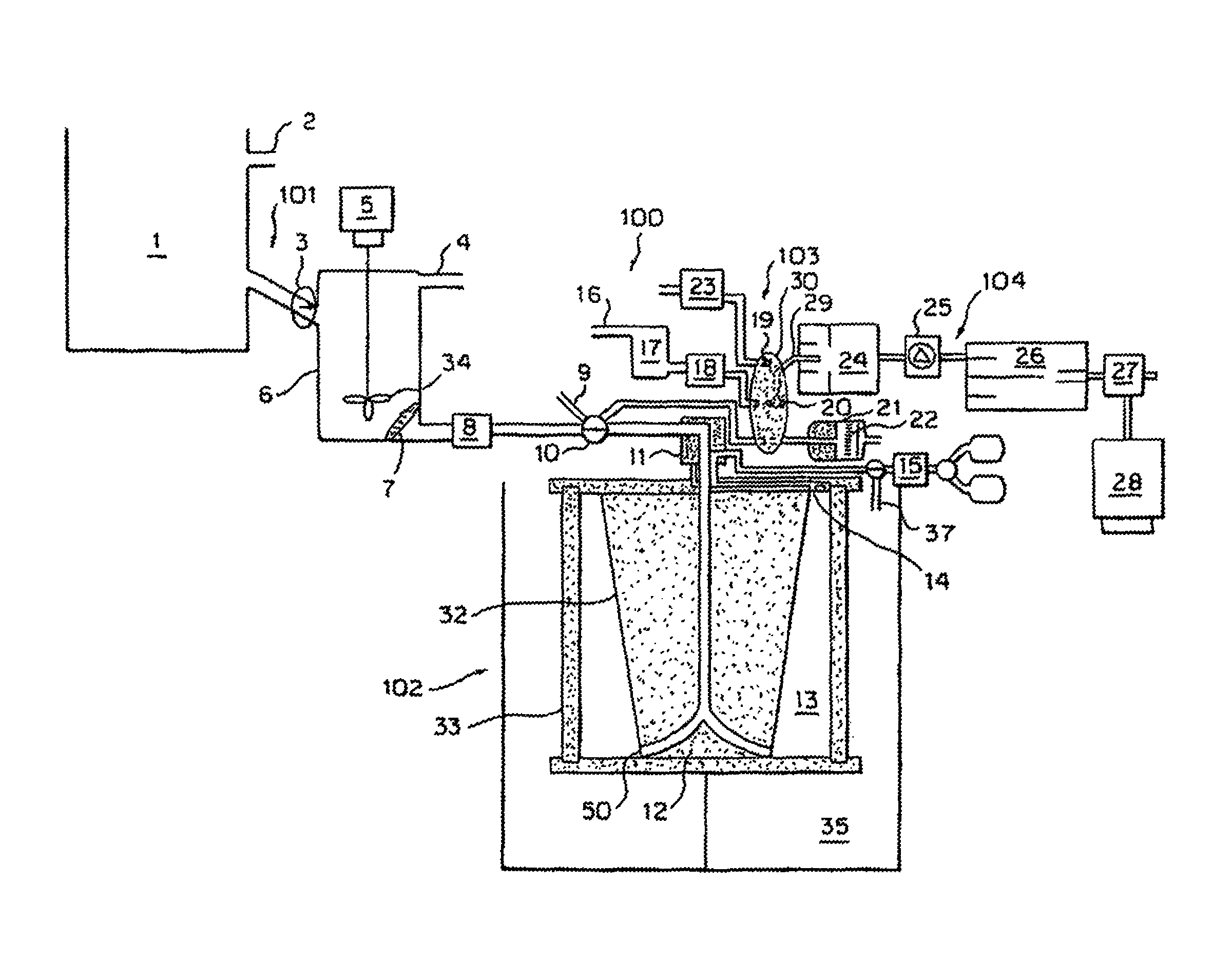

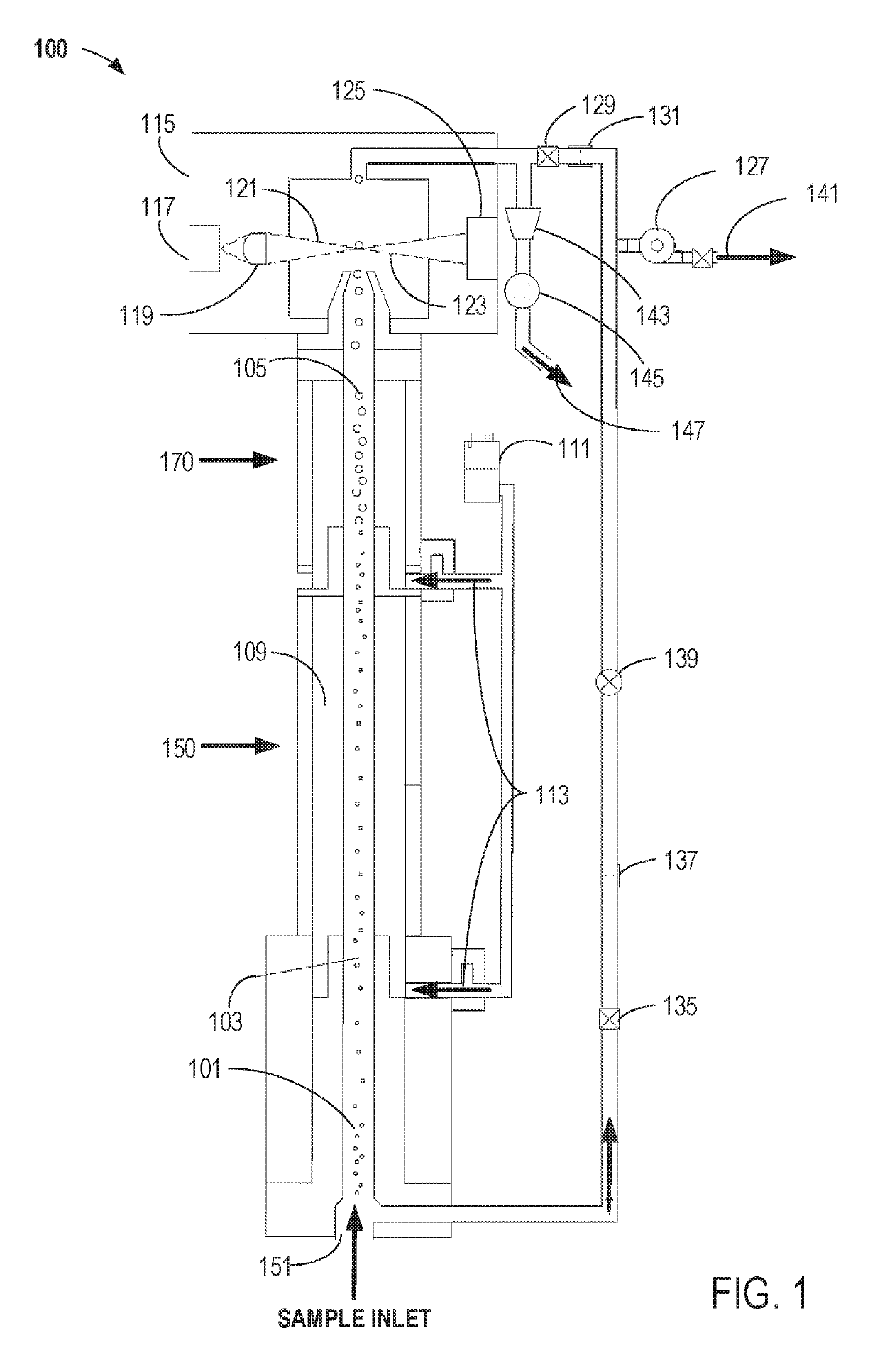

System for Measuring Non-Volatile Residue in Ultra Pure Water

ActiveUS20080144003A1Reduce water pressureAvoid residueSamplingComponent separationWastewaterWater flow

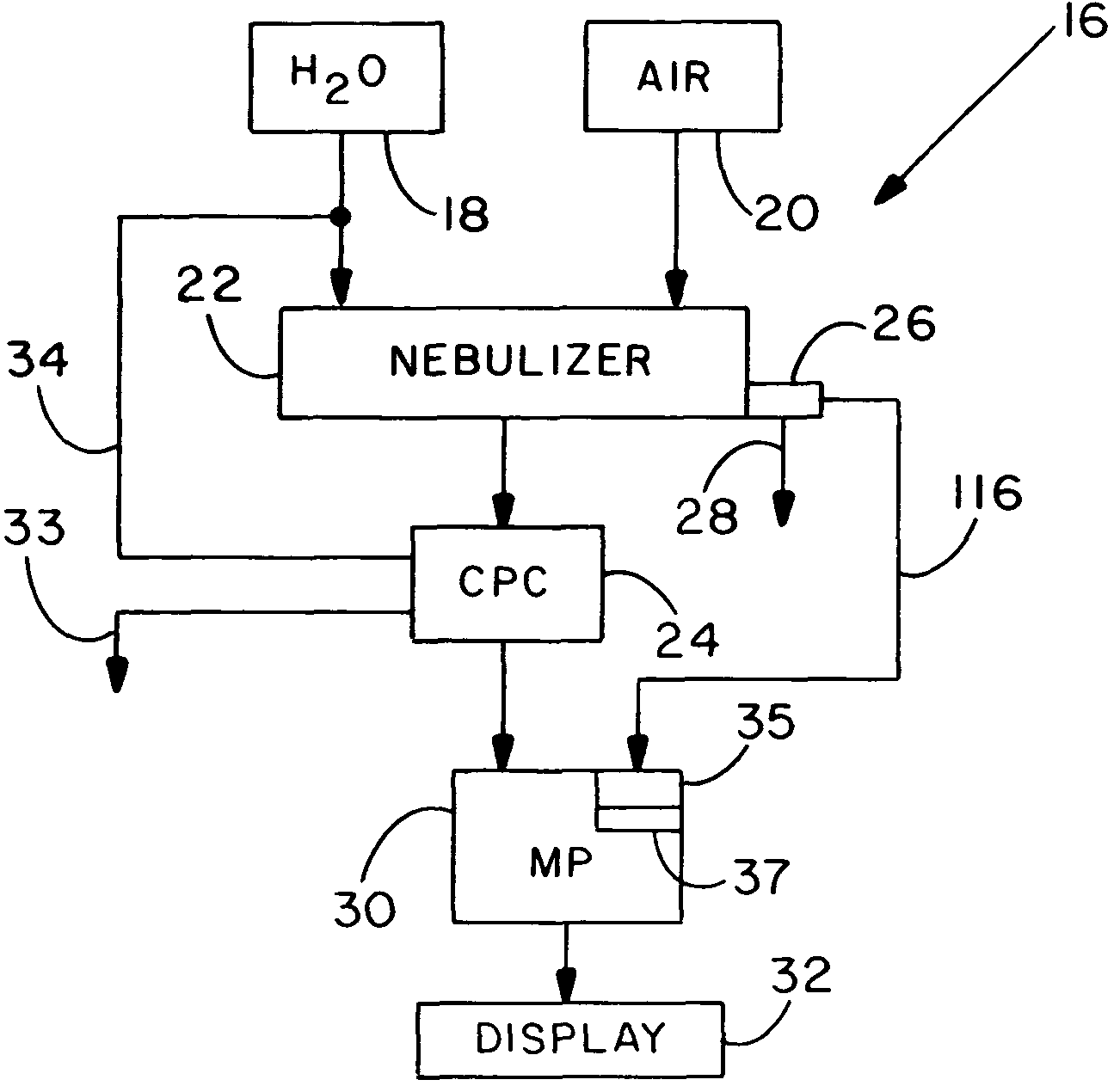

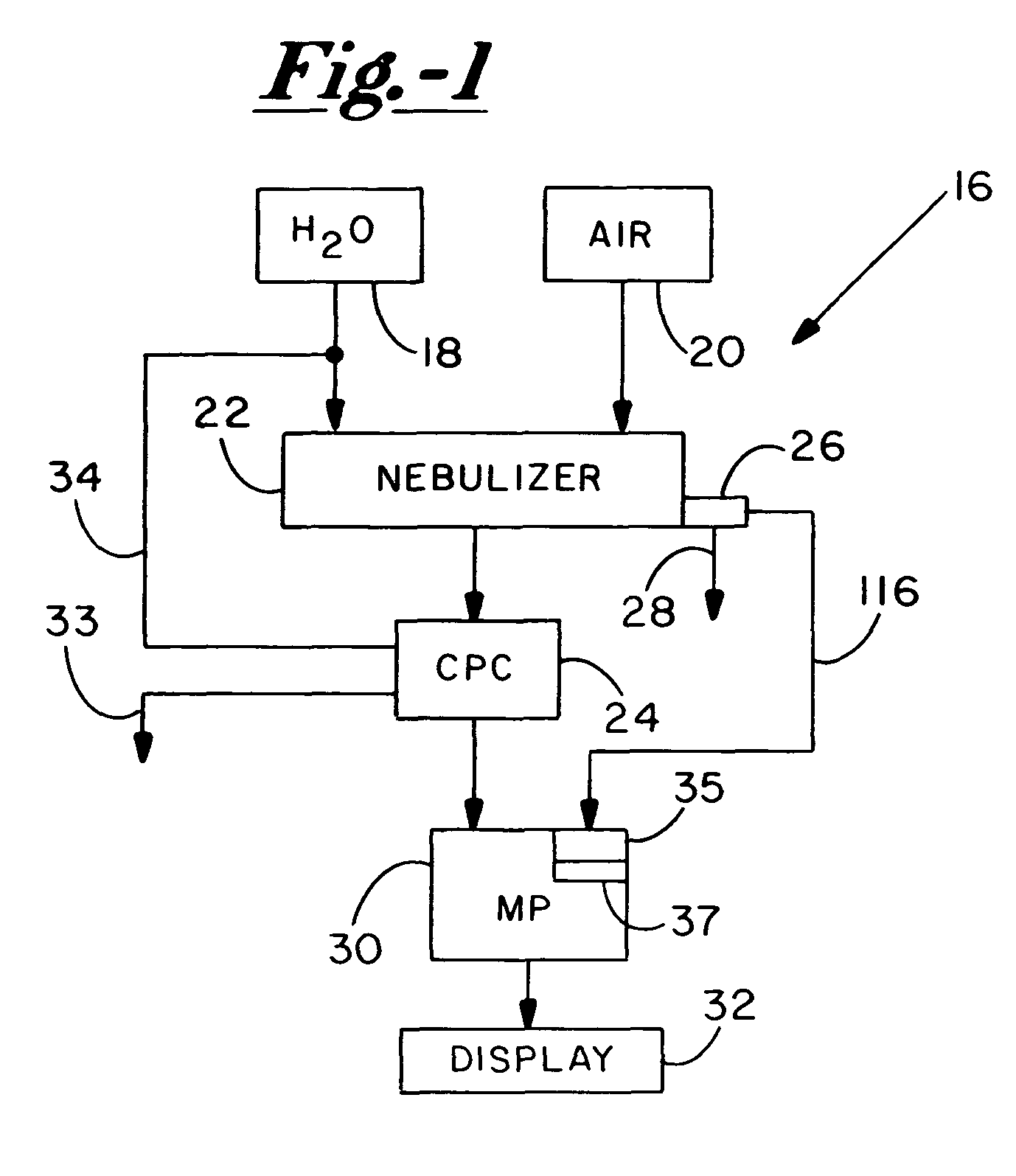

A system for monitoring non-volatile residue concentrations in ultra pure water includes a nebulizer for generating an aerosol composed of multiple water droplets, a heating element changing the aerosol to a suspension of residue particles, and a condensation particle counter to supersaturate the dried aerosol to cause droplet growth through condensation of a liquid onto the particles. The nebulizer incorporates a flow dividing structure that divides exiting waste water into a series of droplets. The droplets are counted to directly indicate a waste water flow rate and indirectly indicate an input flow rate of water supplied to the nebulizer. The condensation particle counter employs water as the condensing medium, avoiding the need for undesirable chemical formulations and enabling use of the ultra pure water itself as the condensing medium.

Owner:FLUID MEASUREMENT TECH

Condensation particle counter

A condensation particle counter is capable of efficiently measuring the number and size of fine particles. The condensation particle counter includes a saturator, a condenser and an optical particle counters. The saturator is designed to generate a saturated gas by saturating a gas in which fine particles are suspended with working fluid. The condenser is connected to a downstream side of the saturator to condense the saturated gas so that liquid droplets can grow around the fine particles. The optical particle counter is connected to downstream sides of the condenser to optically detect the liquid droplets supplied from the condensers. The condenser has a condenser tube for interconnecting the saturator and the optical particle counter. The present condensation particle counter can use water as working fluid and also can optically measure fine particles in an easy and accurate manner by forming or installing an inner surface of a condenser tube with a hydrophilic tube.

Owner:HCTM +1

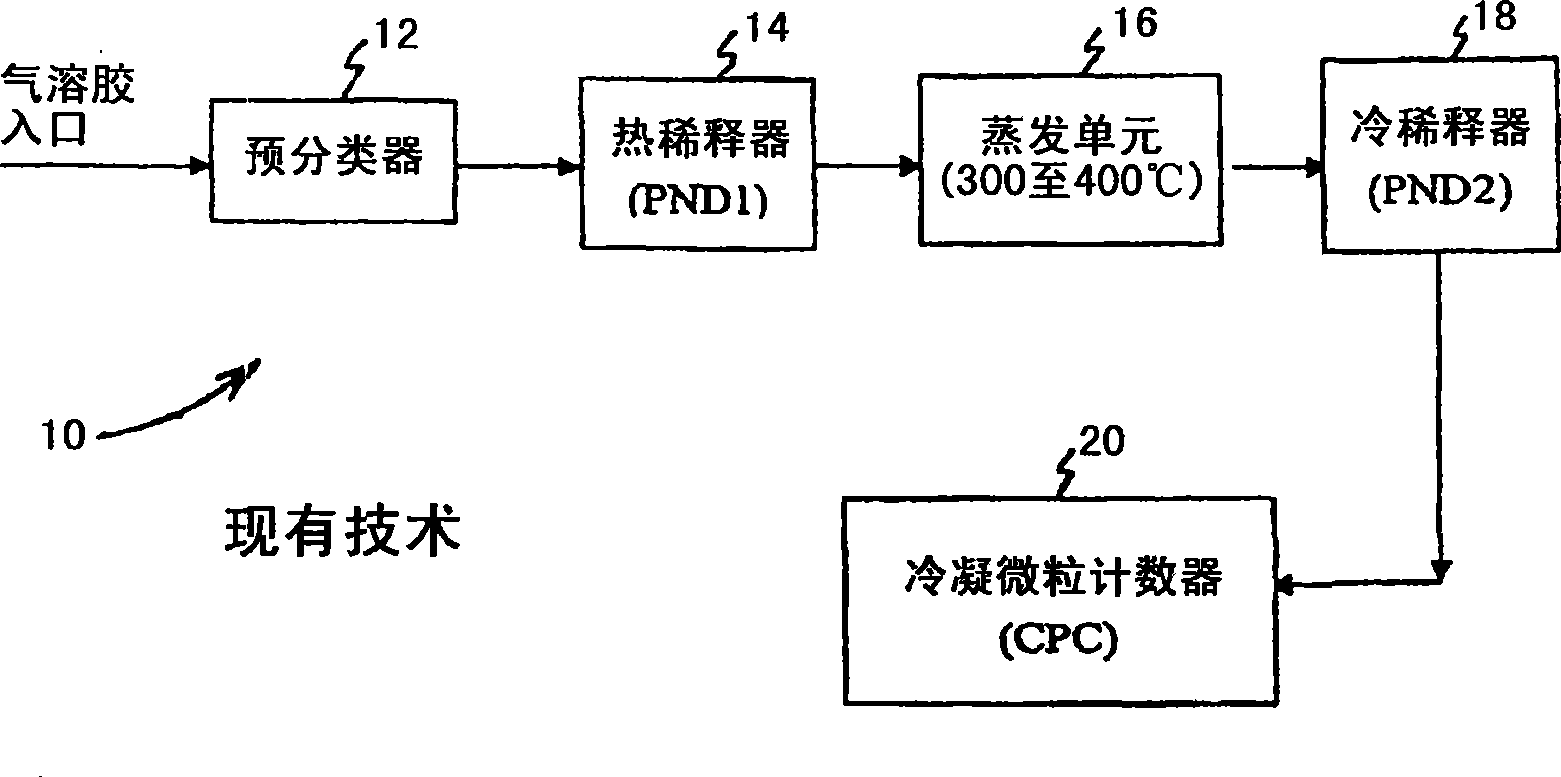

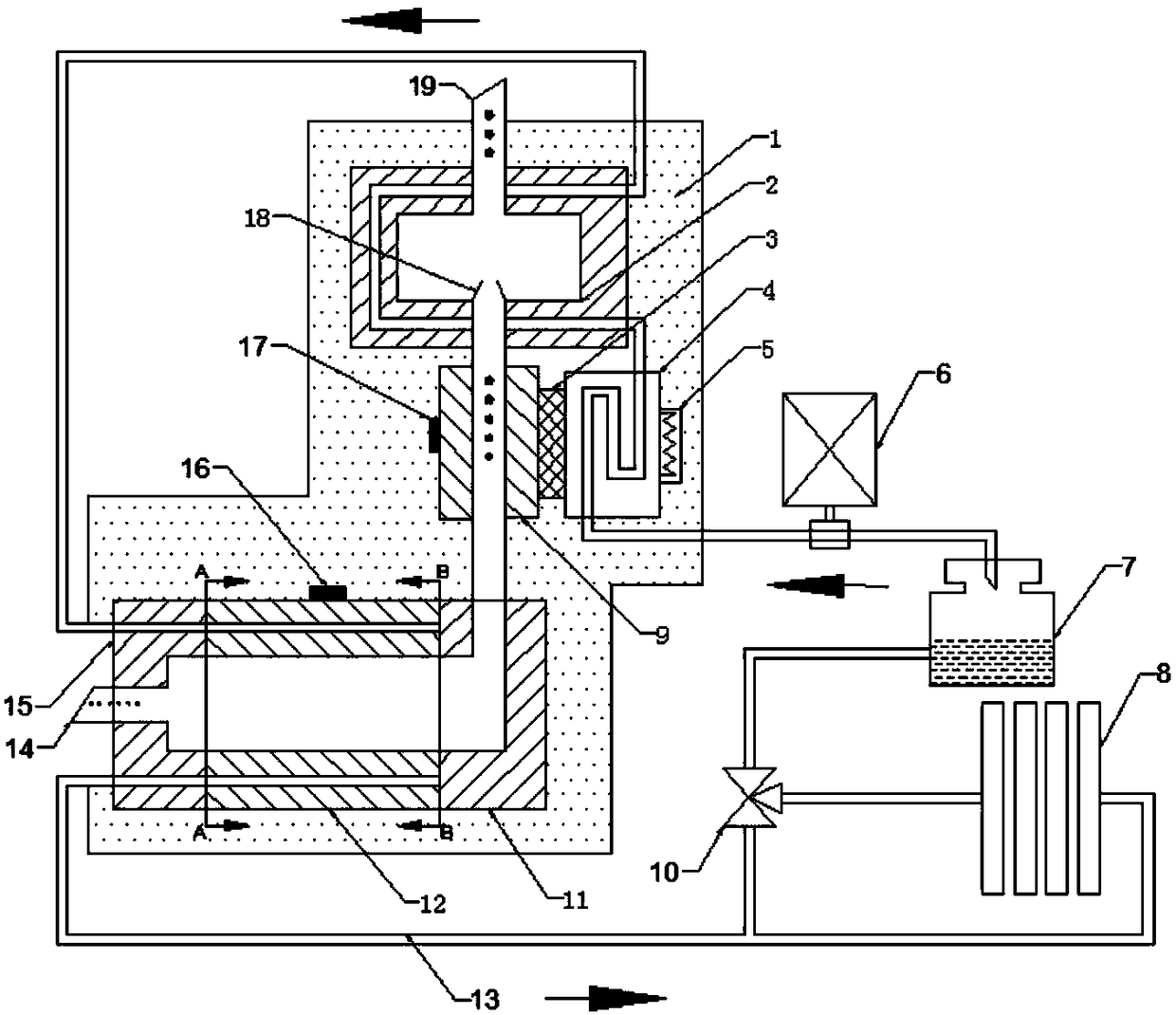

Real-time particulate matter measuring system

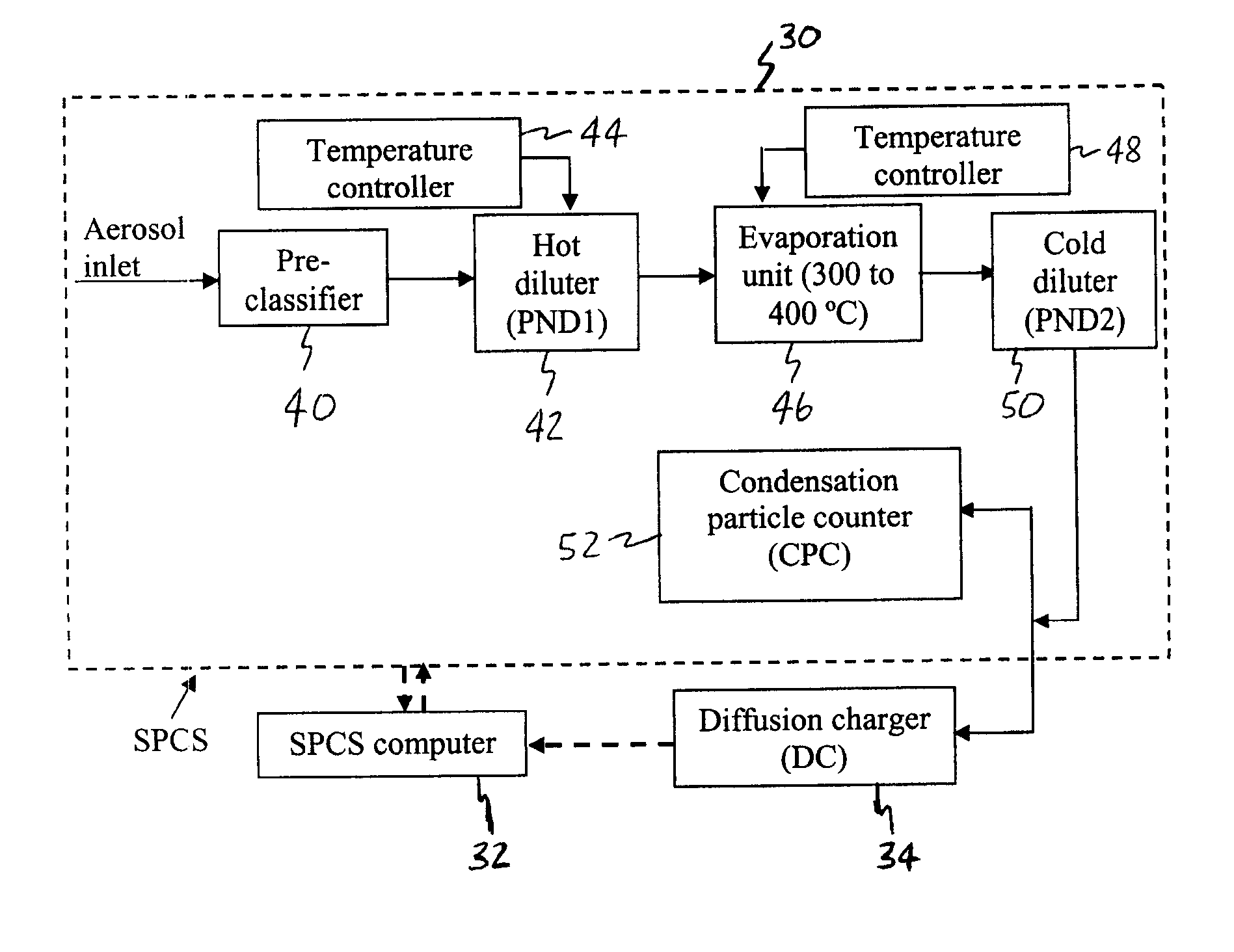

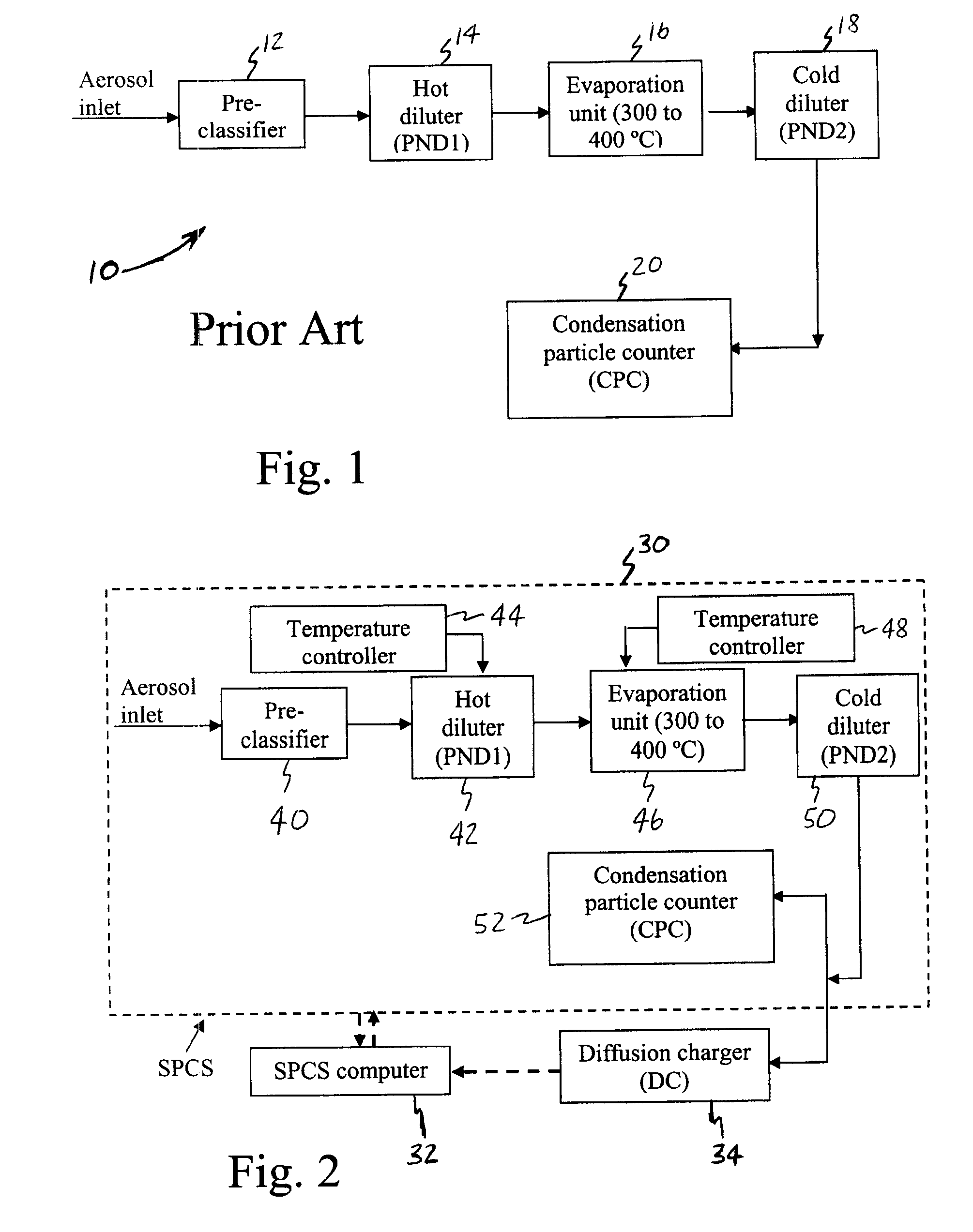

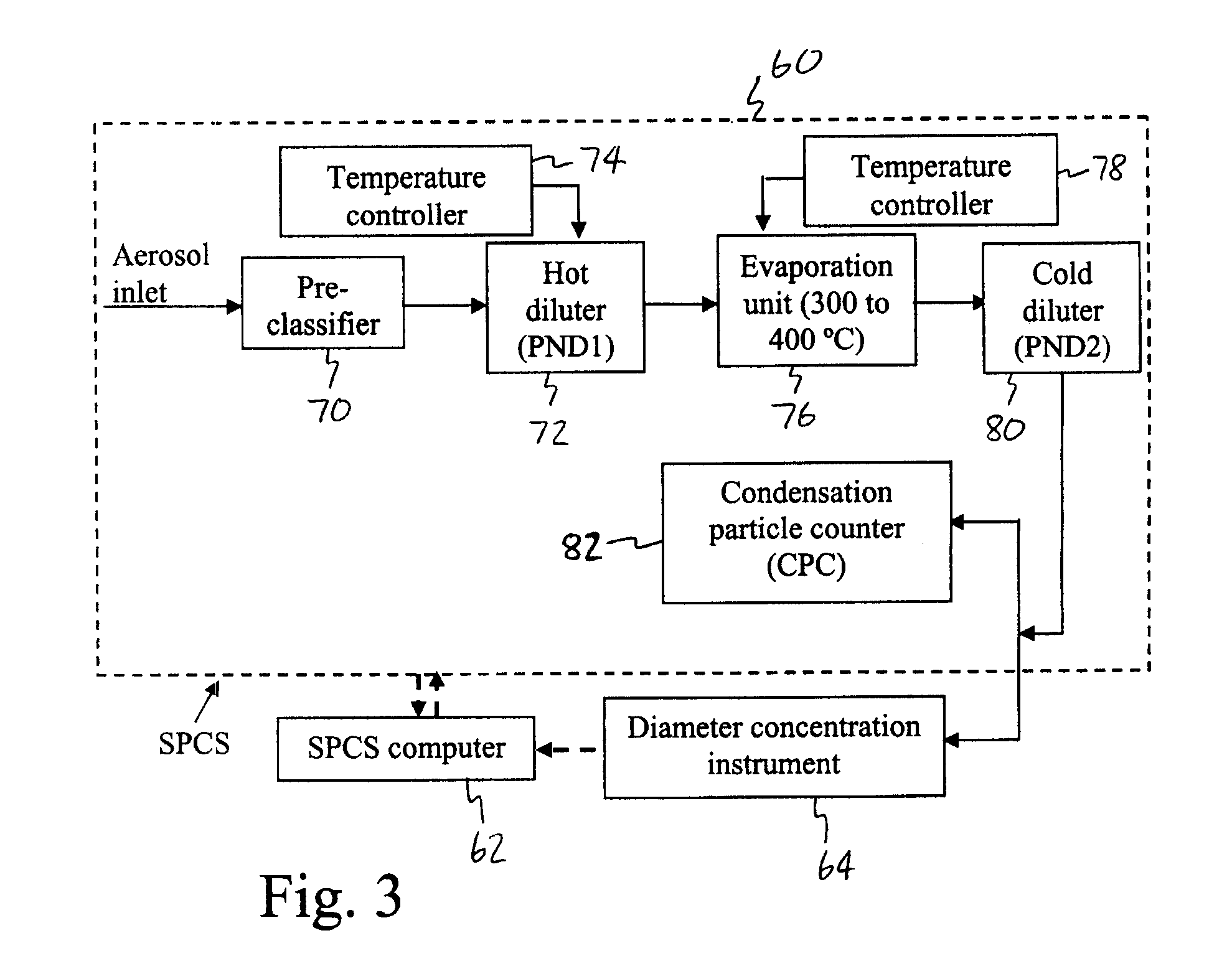

InactiveUS20070131038A1Function increasePowerful toolWithdrawing sample devicesParticle suspension analysisParticulatesChemical physics

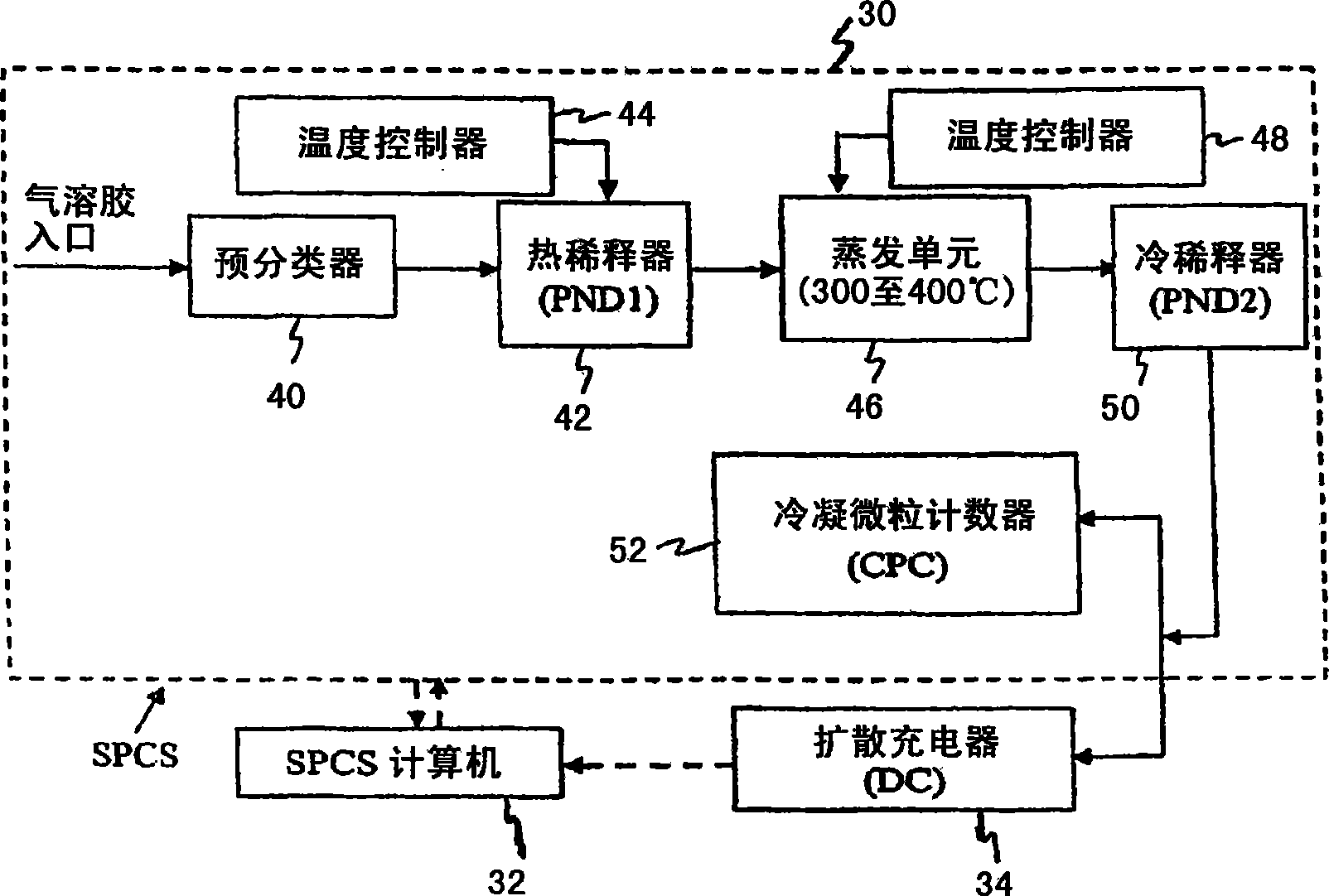

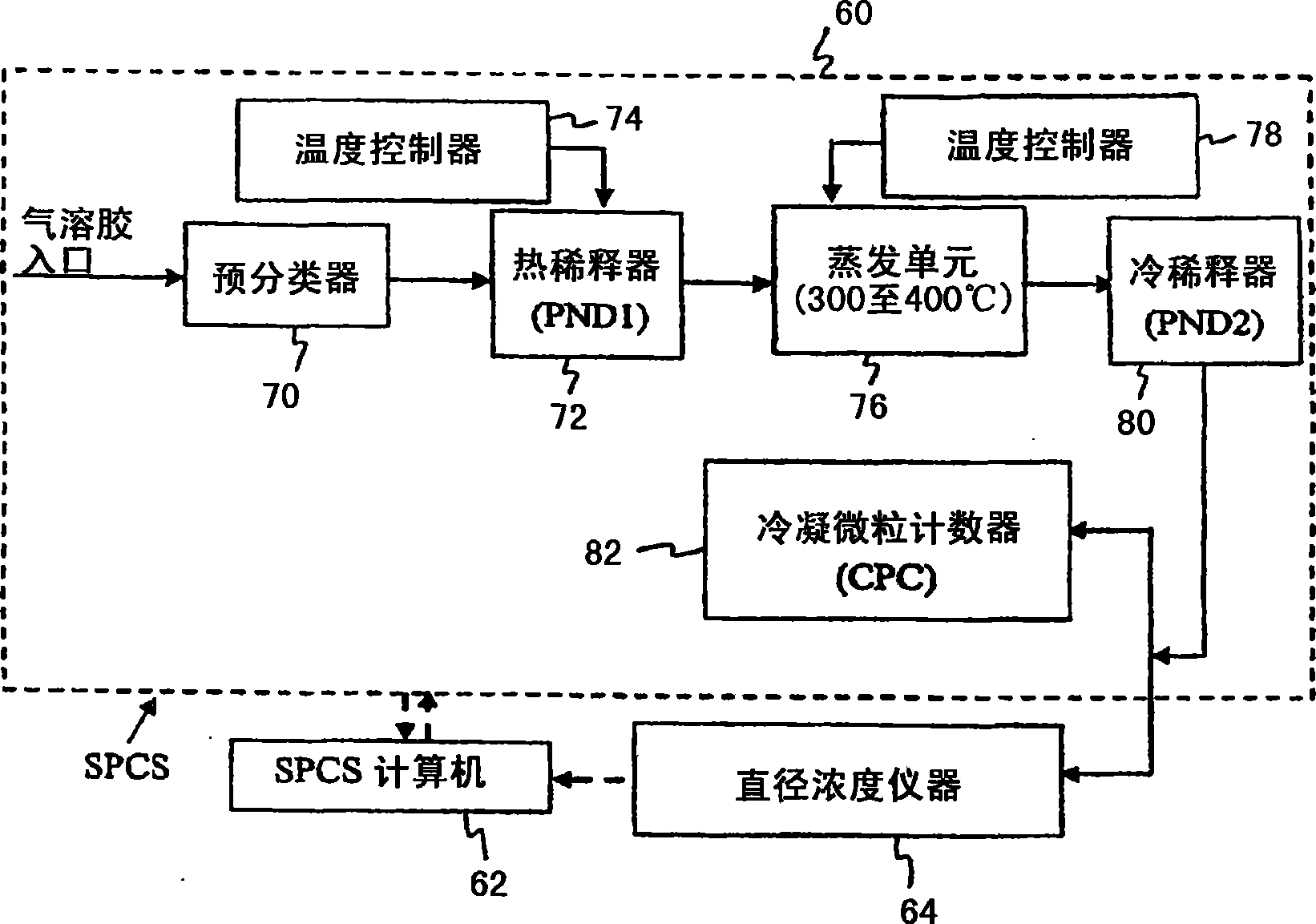

A real-time particulate matter measuring system includes a hot diluter for receiving and diluting aerosol. An evaporation unit receives the diluted aerosol. A cold diluter receives and dilutes the output flow from the evaporation unit. A condensation particle counter receives the diluted output flow and measures the particle number concentration. An integrated device also receives the diluted output flow. The integrated device measures at least one of particle diameter concentration and particle surface area. The integrated device also measures mass concentration.

Owner:HORIBA LTD

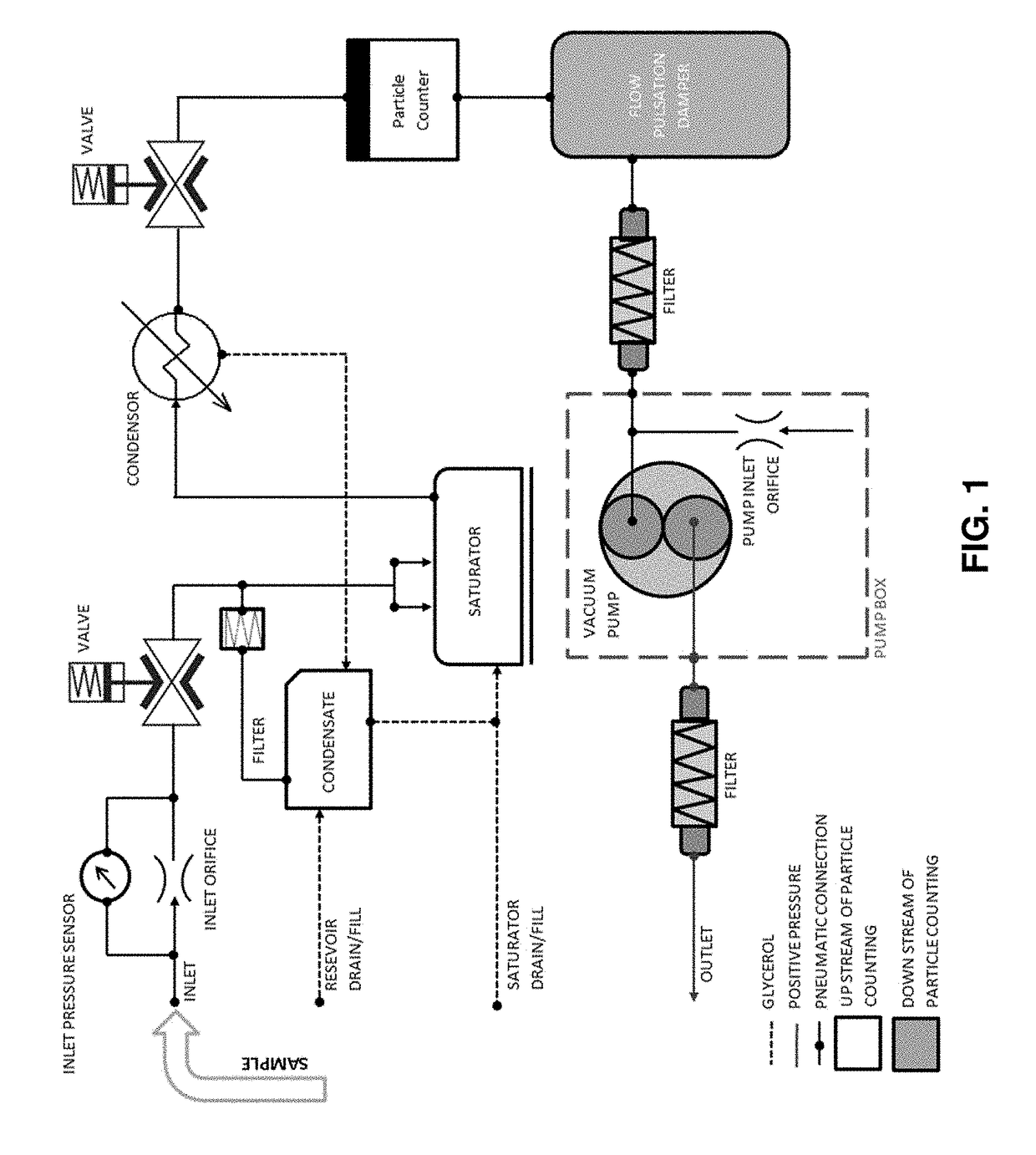

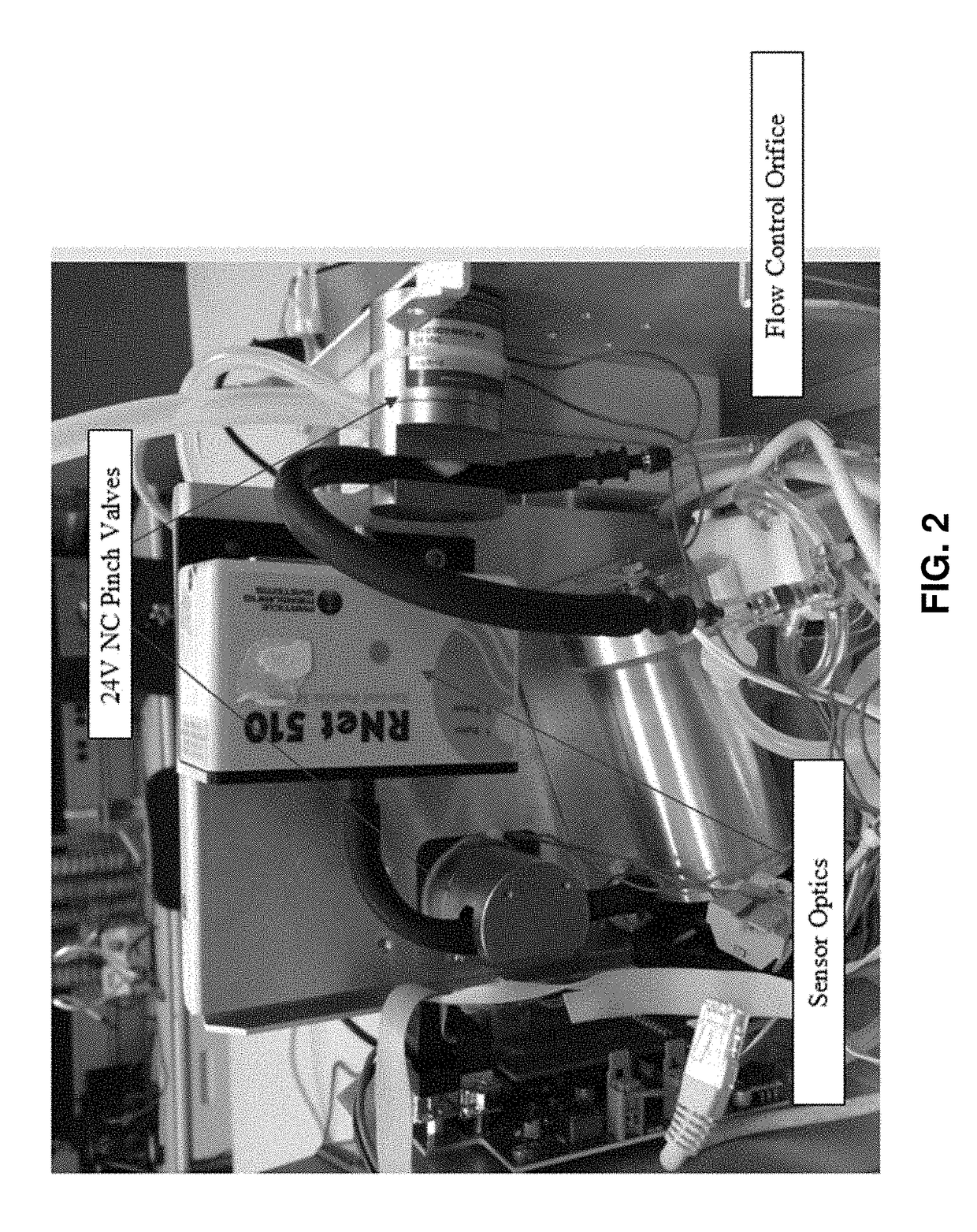

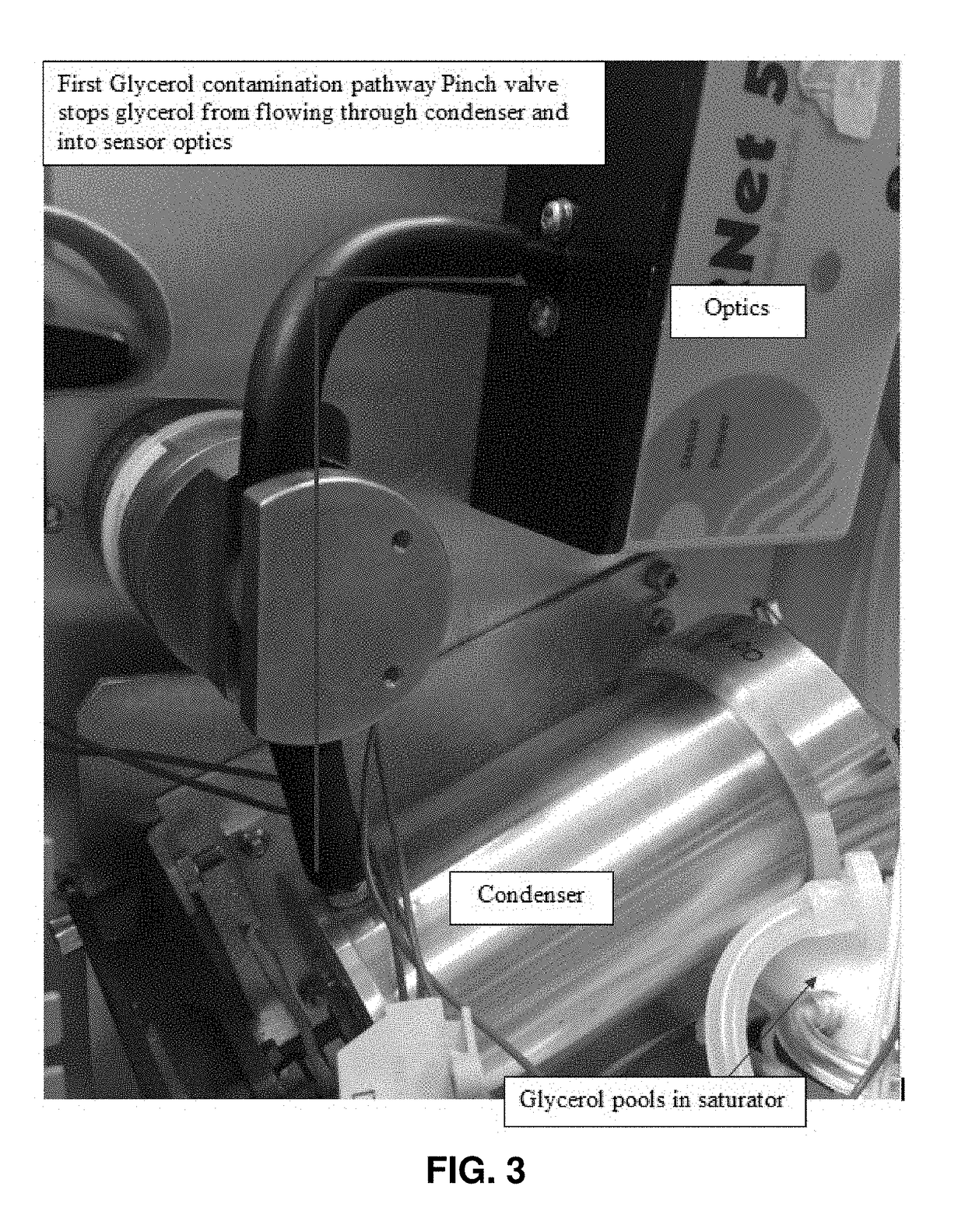

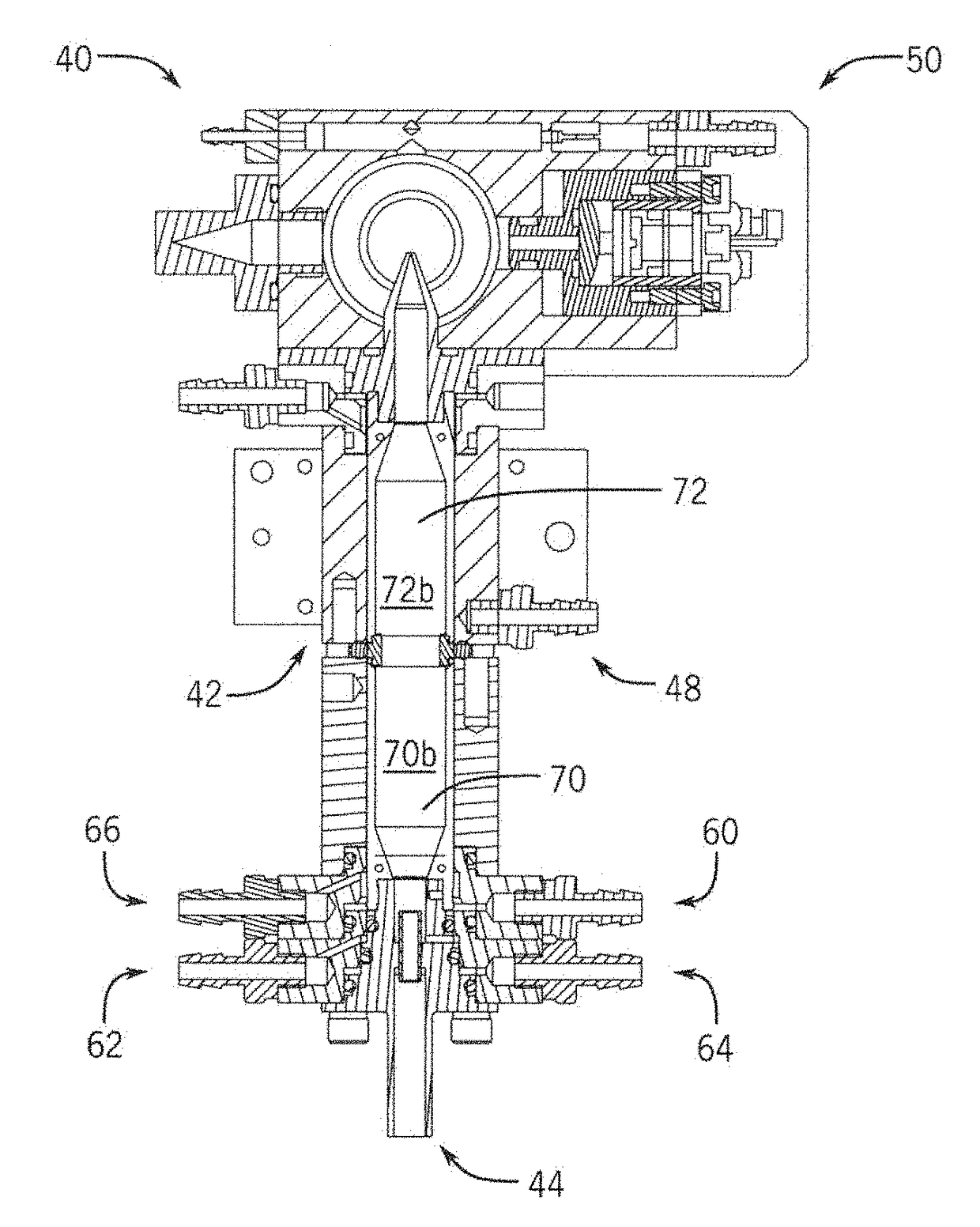

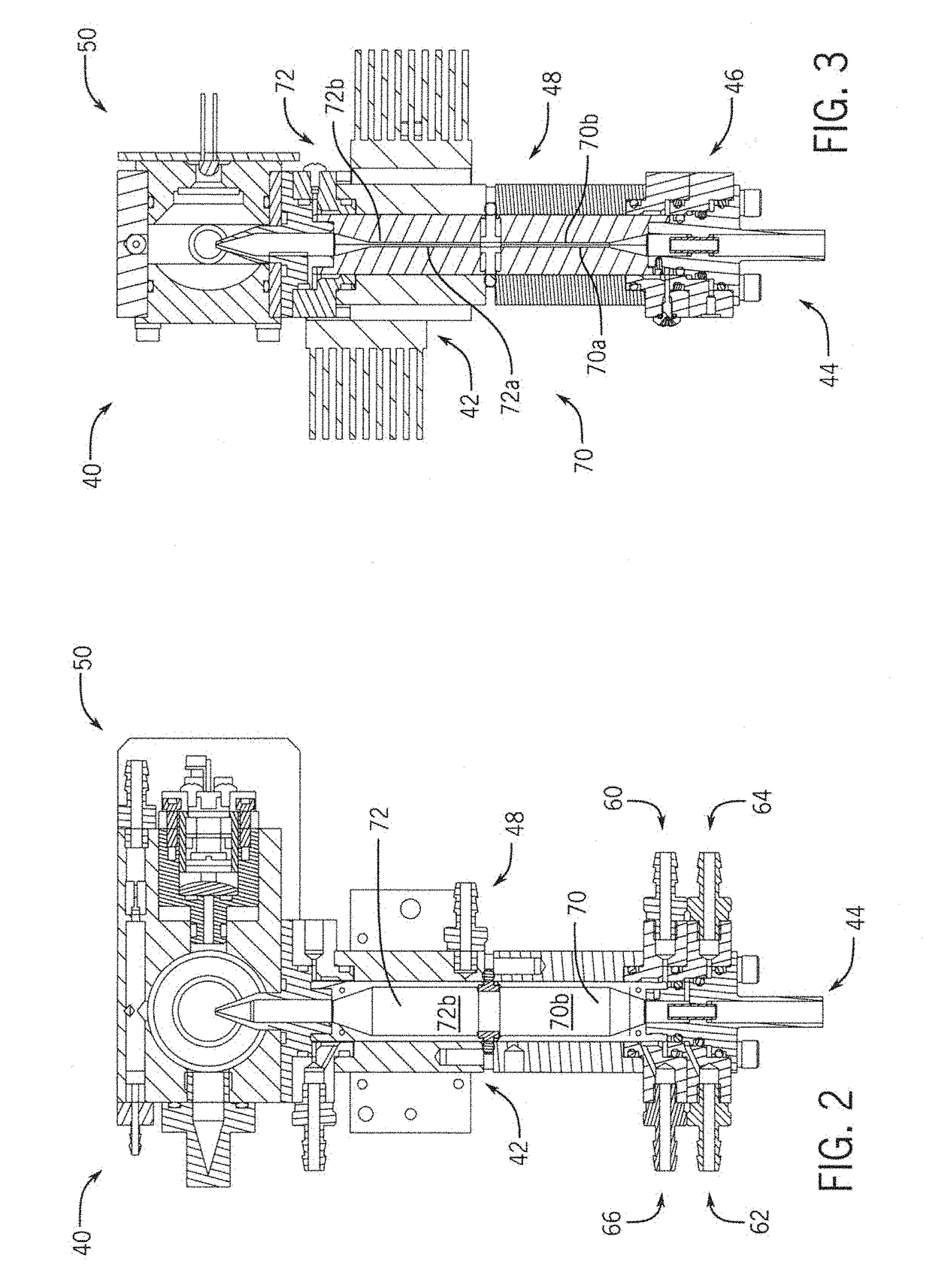

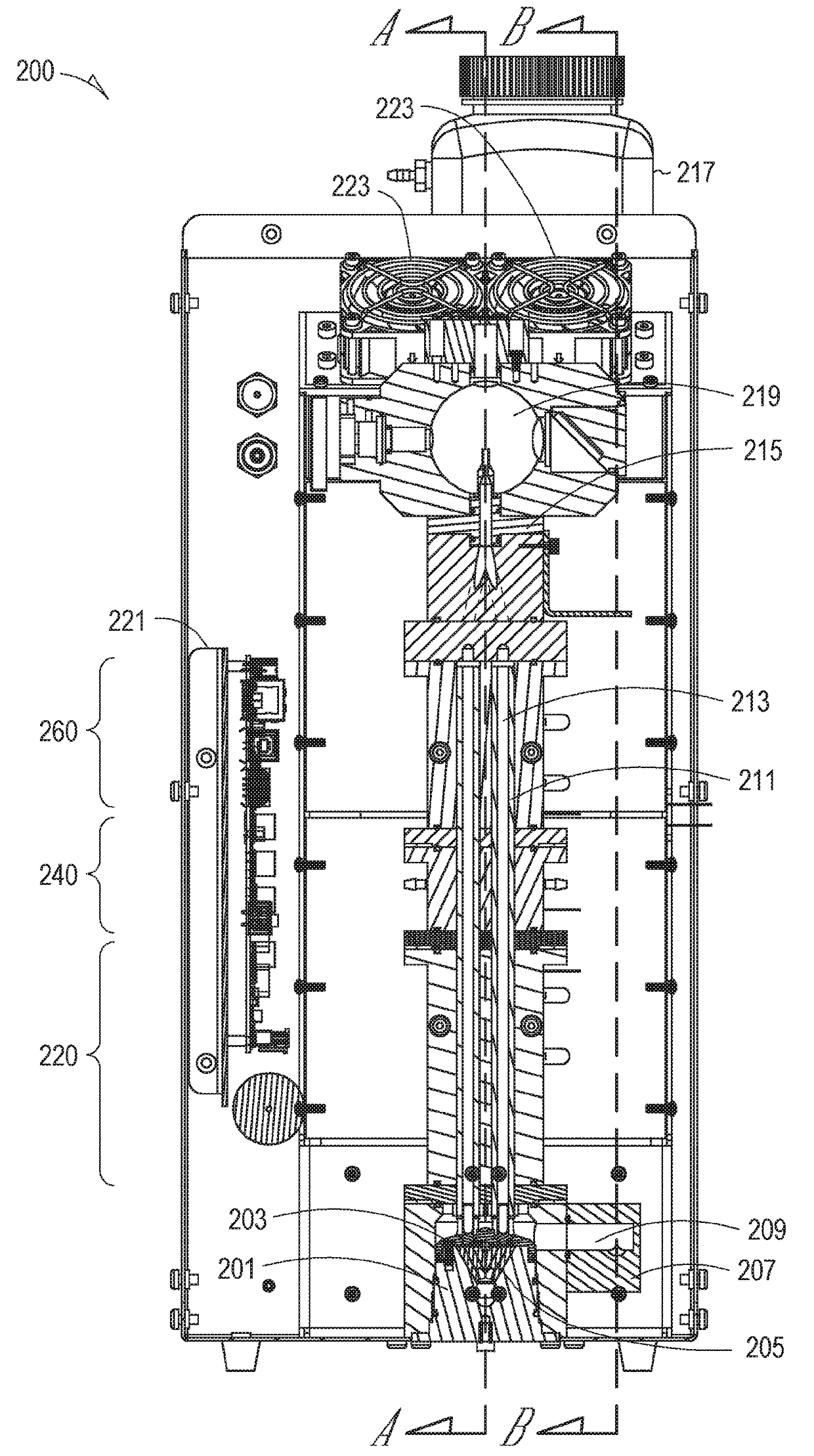

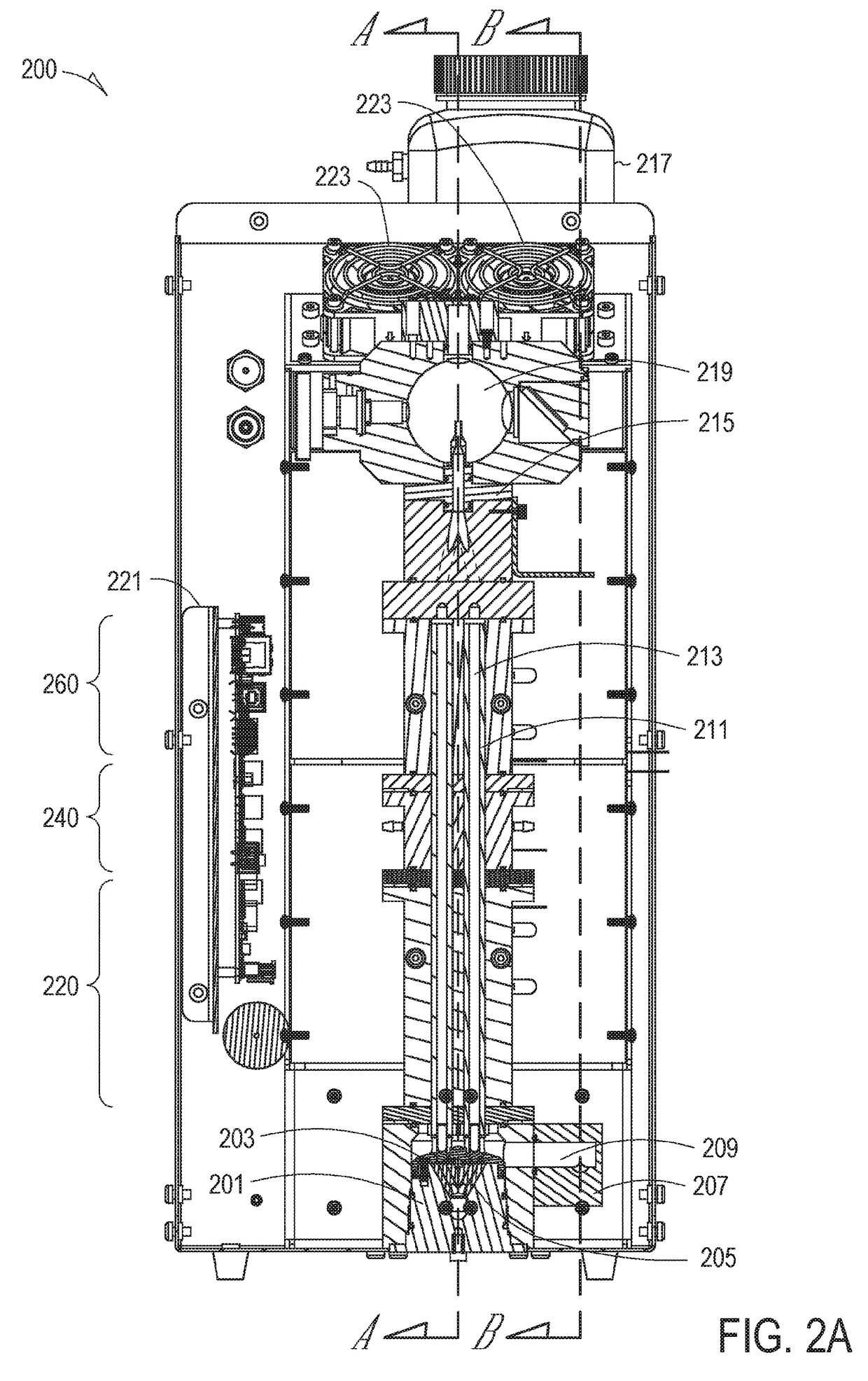

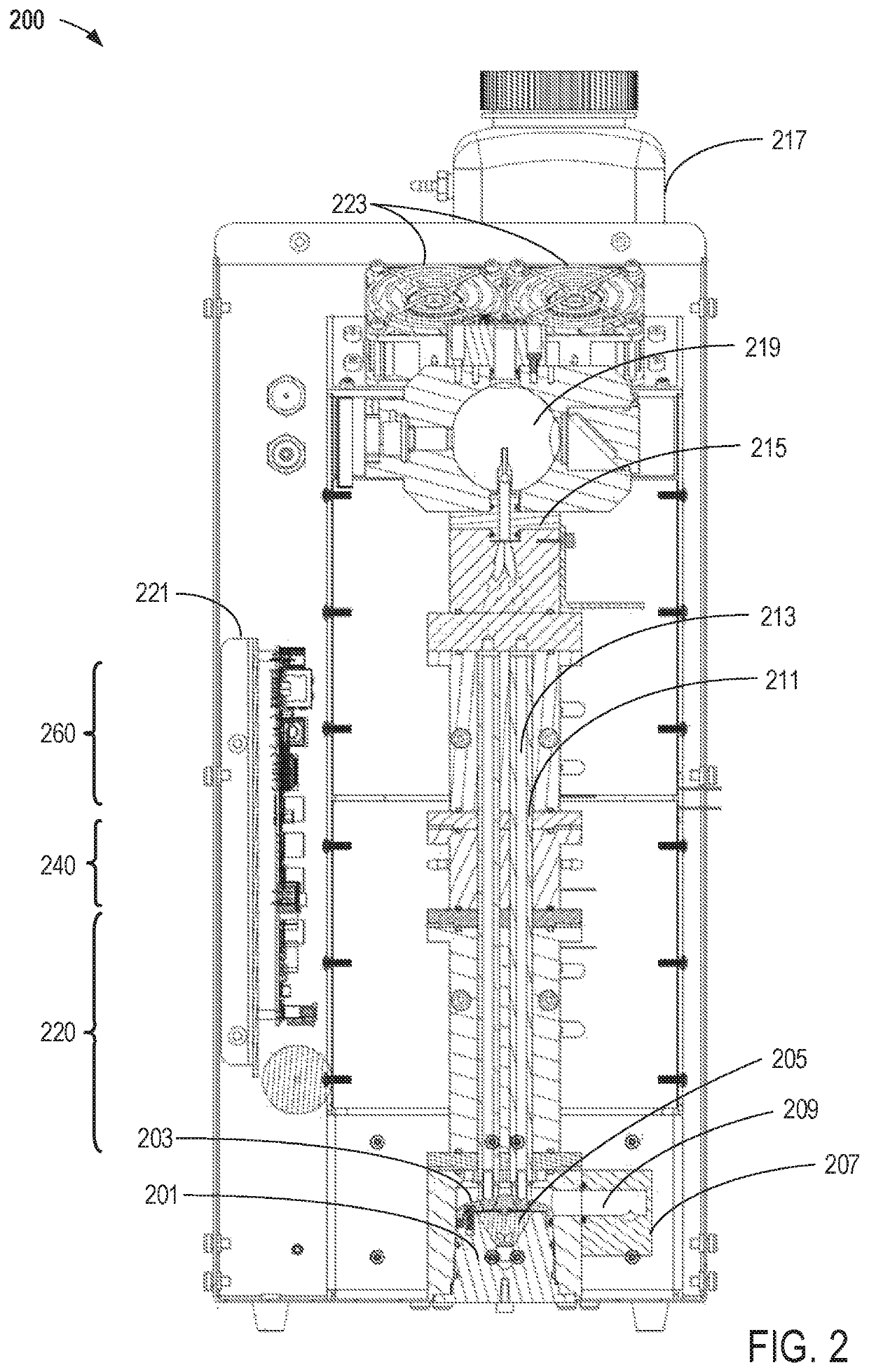

Systems and methods for isolating condensate in a condensation particle counter

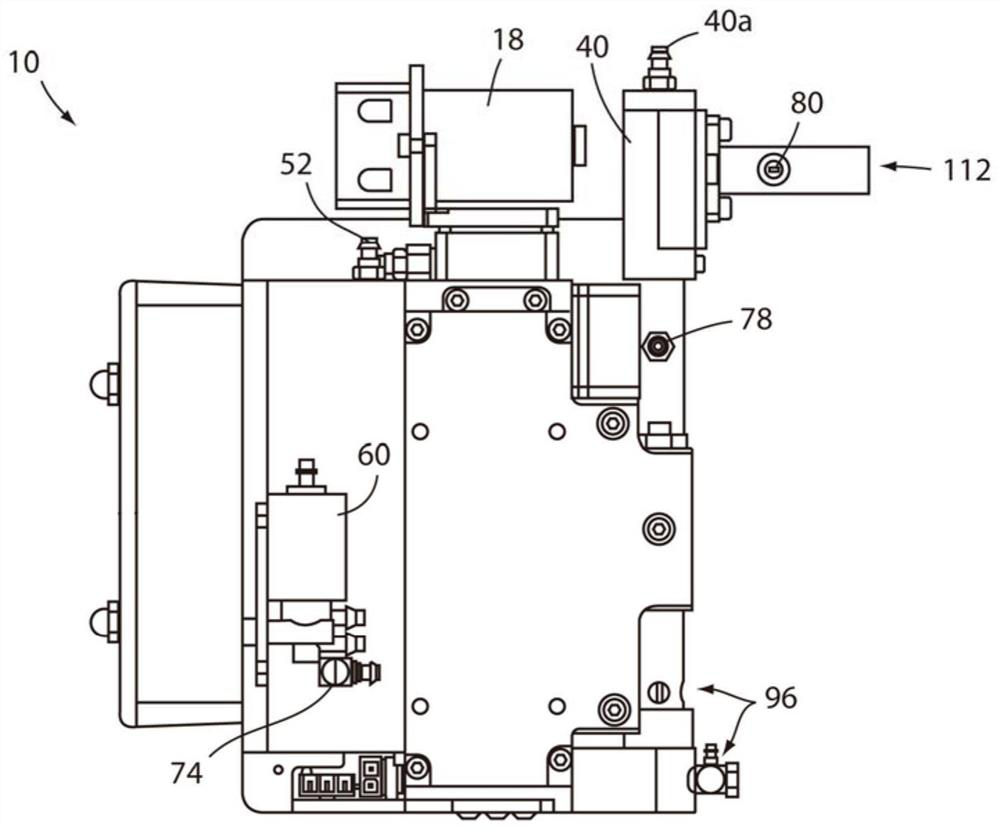

ActiveUS10197487B2Inhibit migrationEliminate needSamplingIndividual particle analysisEngineeringCondensation particle counter

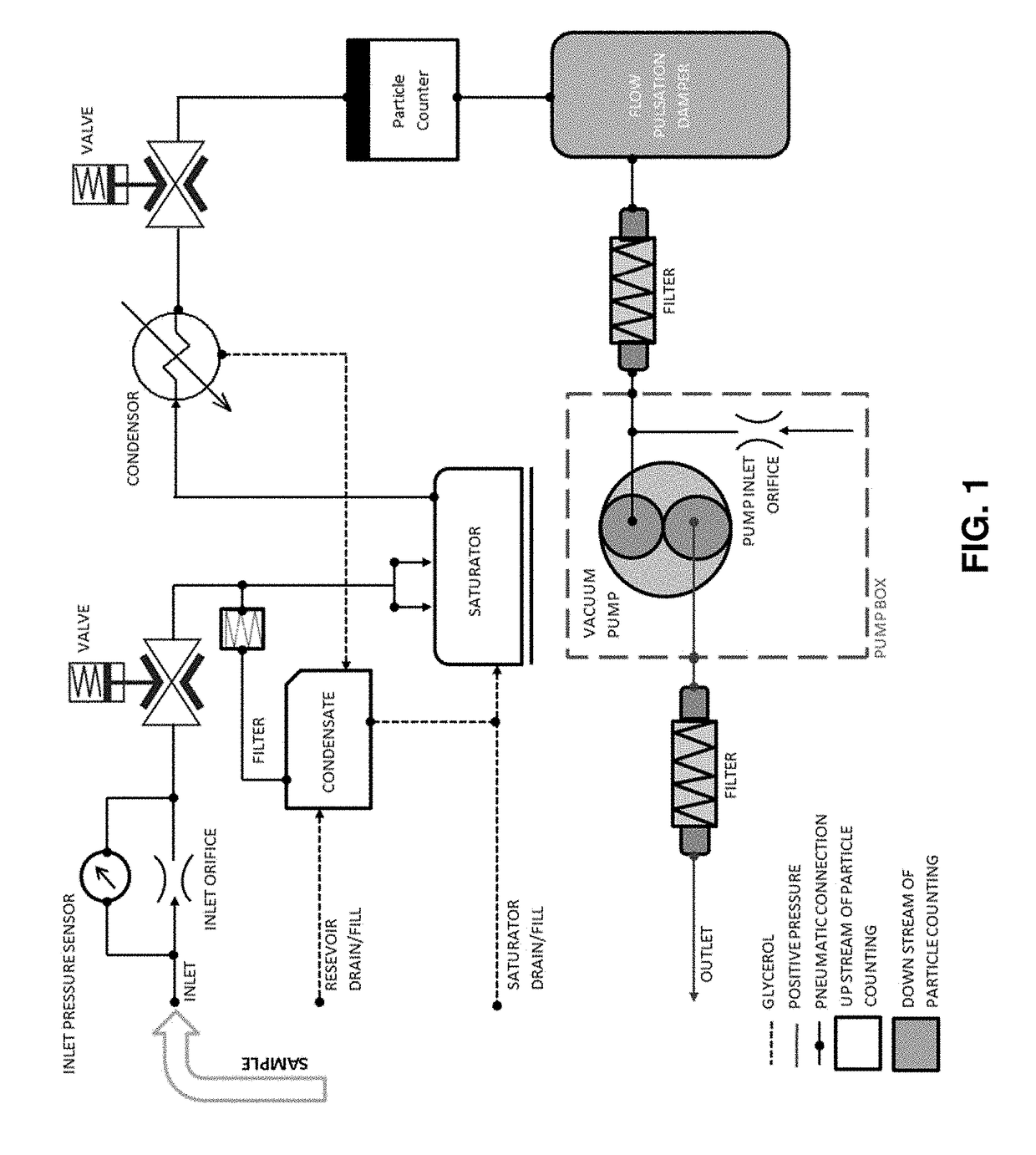

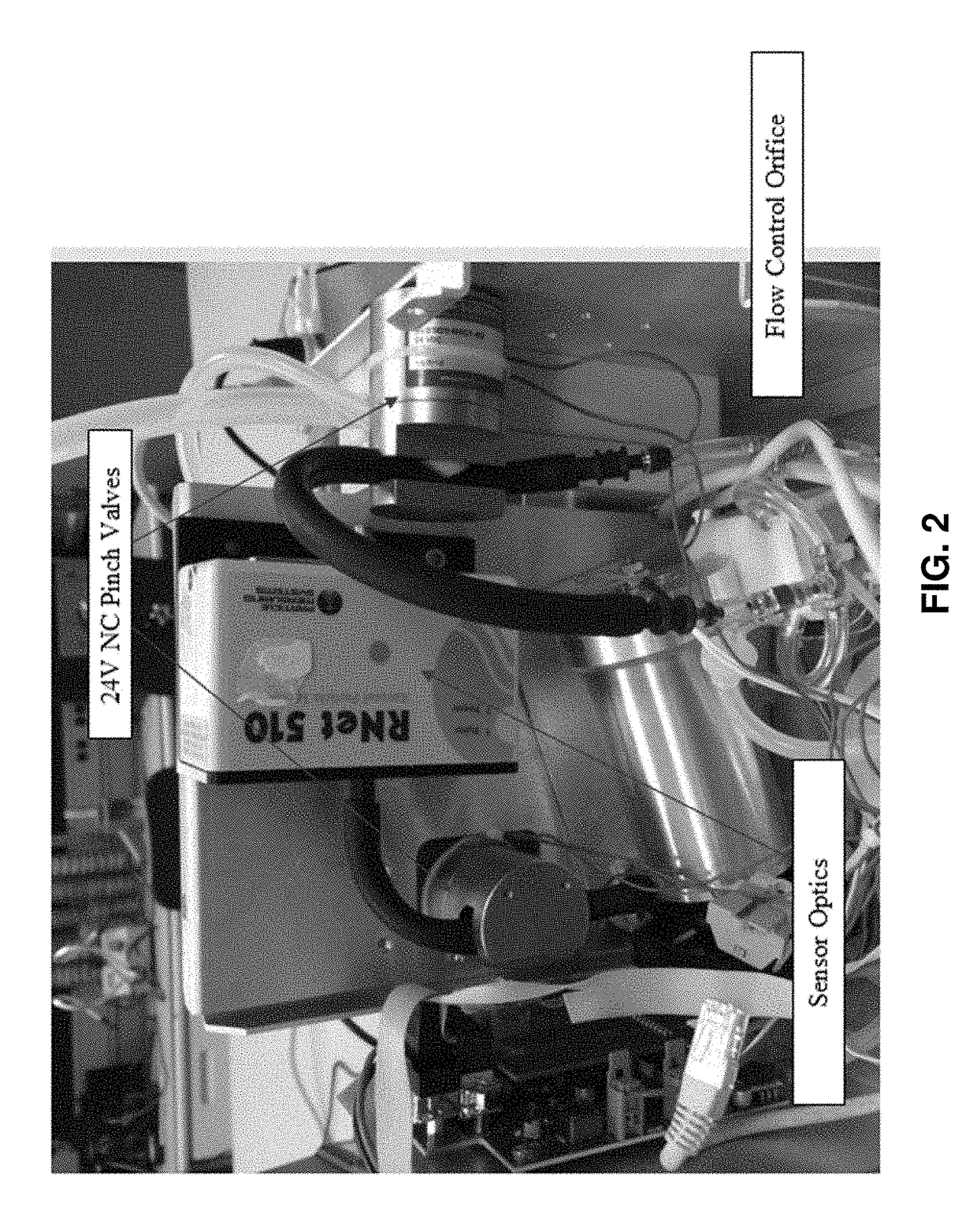

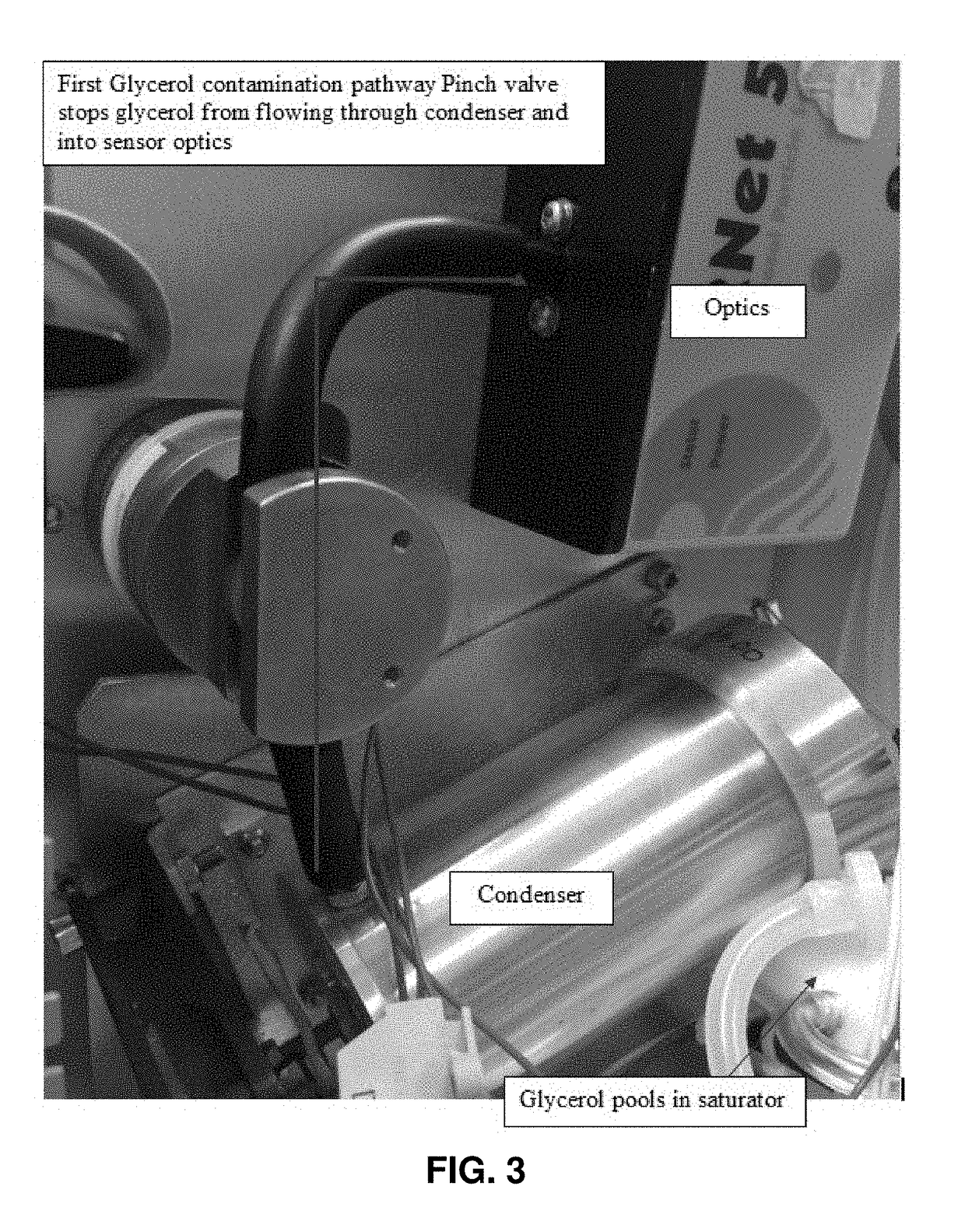

The systems and methods provided herein relate generally to the prevention of migration of condensate in a condensation particle counter between components designed to handle condensate (e.g. saturator, condenser, condensate reservoir) and components which may be damaged by the condensate (e.g. detection and flow control devices).

Owner:PARTICLE MEASURING SYST

Condensation particle counter

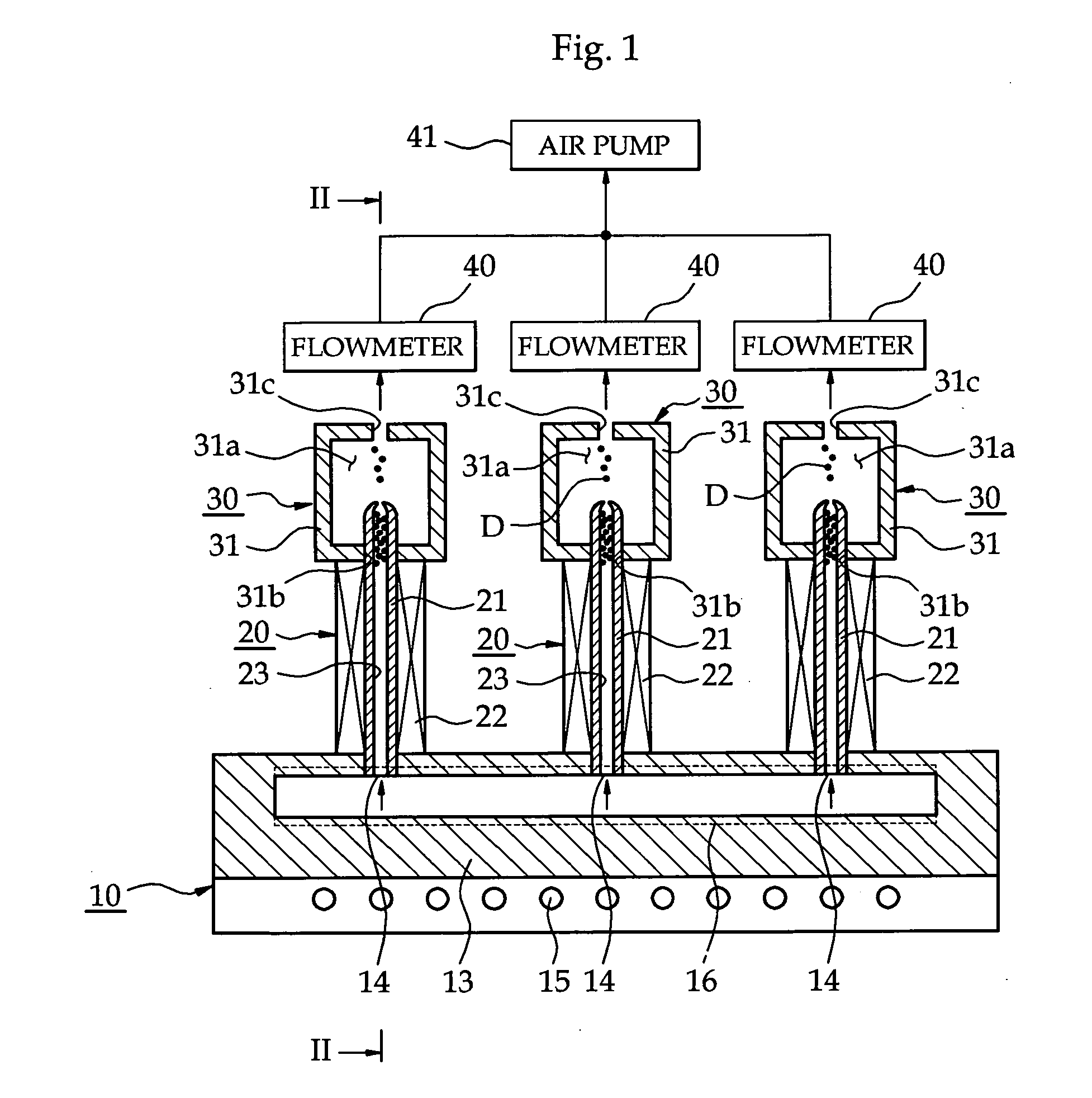

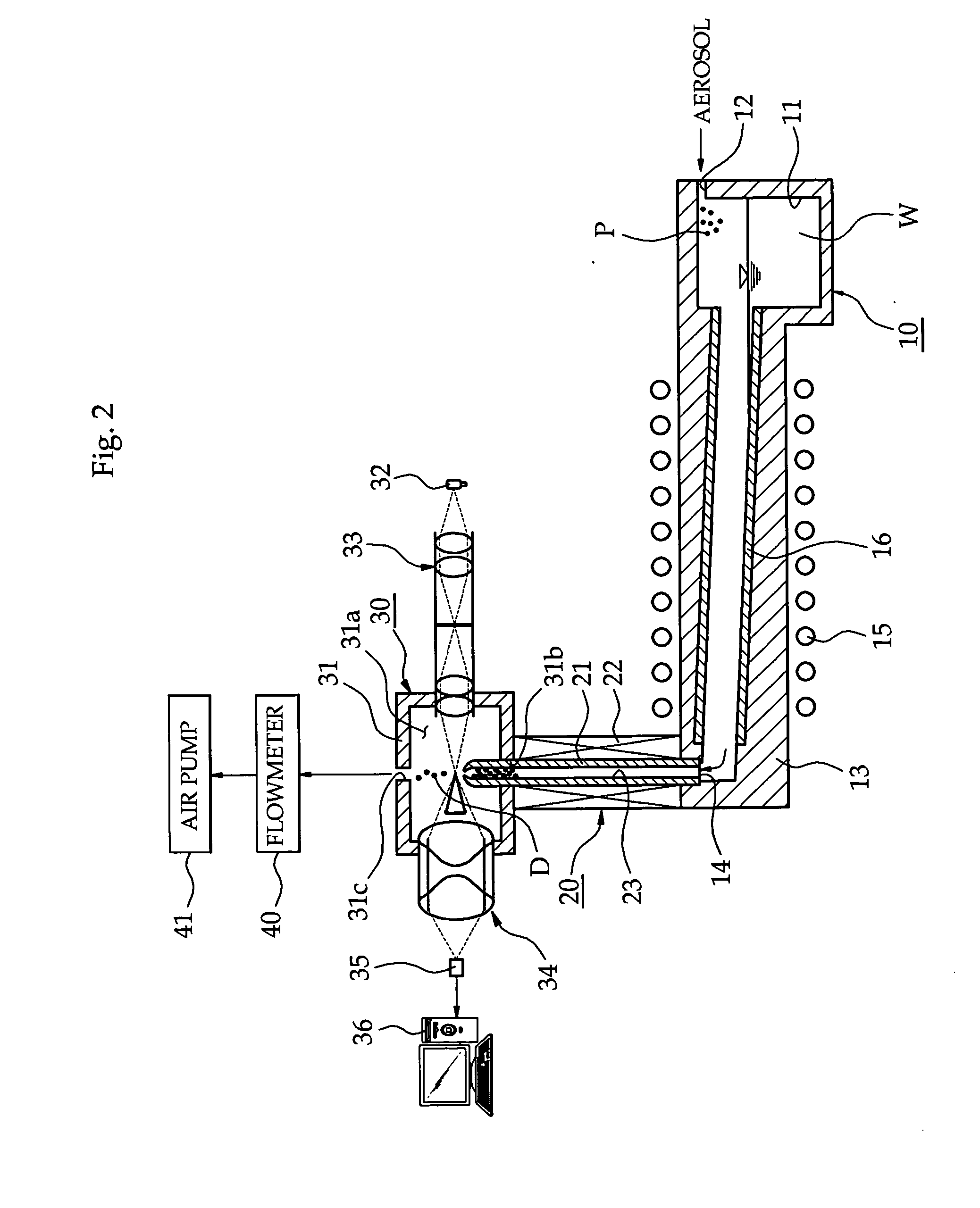

ActiveUS20090009748A1Efficient measurementSamplingParticle size analysisWorking fluidParticle counter

A condensation particle counter is capable of efficiently measuring the number and size of fine particles. The condensation particle counter includes a saturator, a plurality of condensers and a plurality of optical particle counters. The saturator is designed to generate a saturated gas by saturating a gas in which fine particles are suspended with working fluid. The condensers are connected to a downstream side of the saturator to condense the saturated gas so that liquid droplets can grow around the fine particles. The optical particle counters are connected to downstream sides of the condensers to optically detect the liquid droplets supplied from the condensers. Each of the condensers has a condenser tube for interconnecting the saturator and each of the optical particle counters. The condenser tube is provided with a hydrophilic tube installed inside surface of the condenser tube.

Owner:AHN KANG HO +1

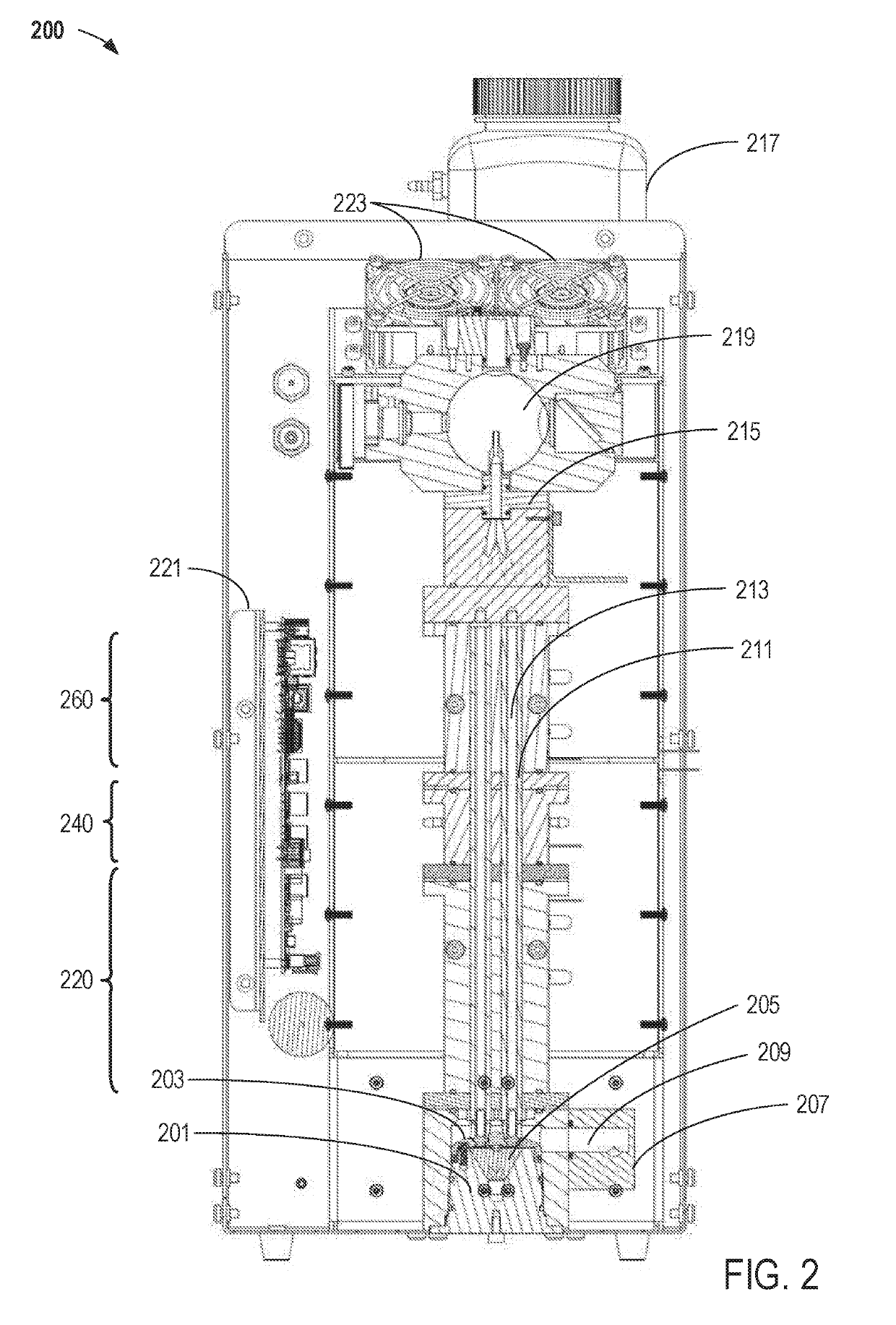

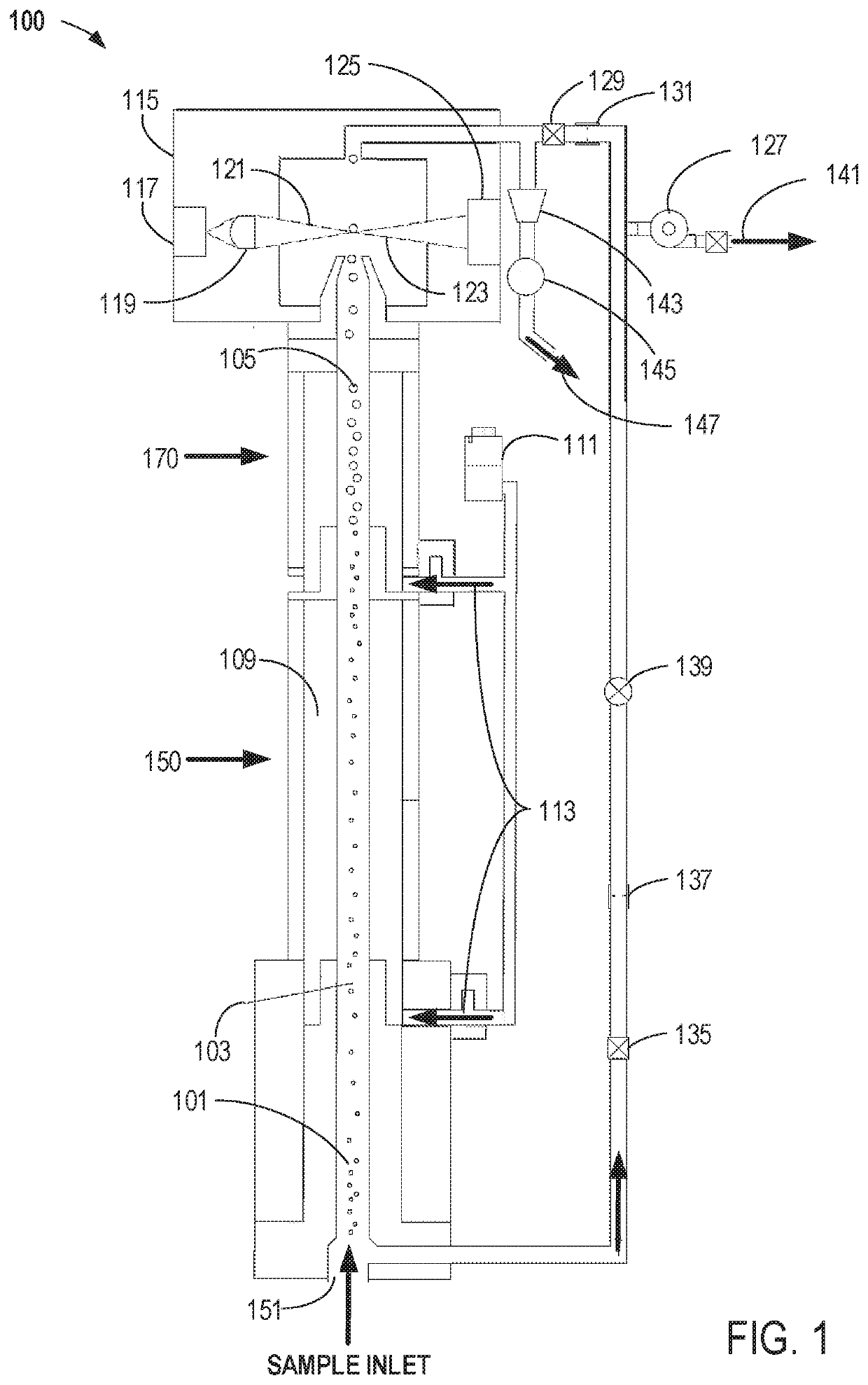

Compact condensation particle counter technology

ActiveUS20170276589A1Practical and reliable and accurate and efficientAdvanced technologyNanoparticle analysisLaboratory glasswaresEngineeringCondensation particle counter

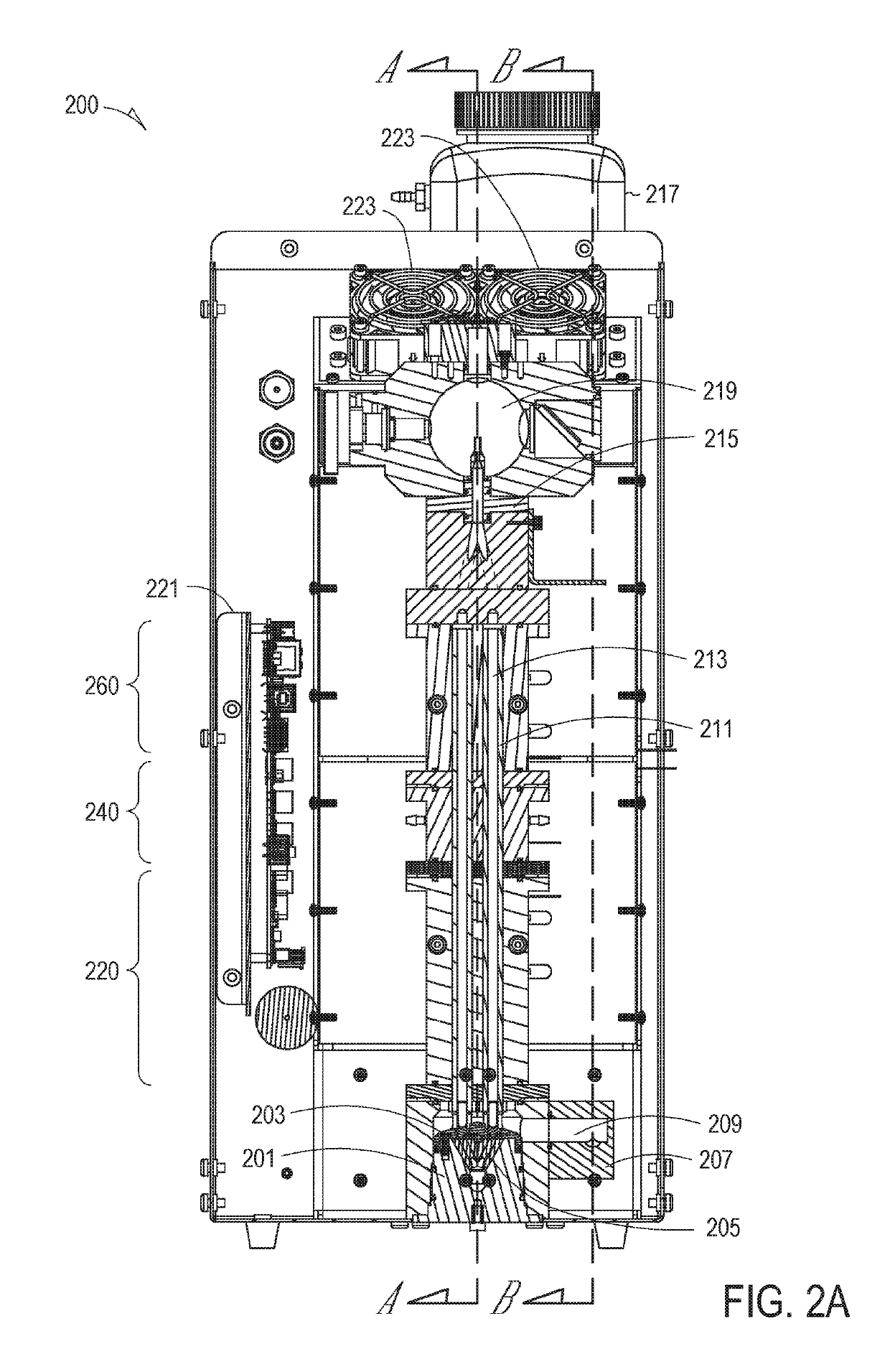

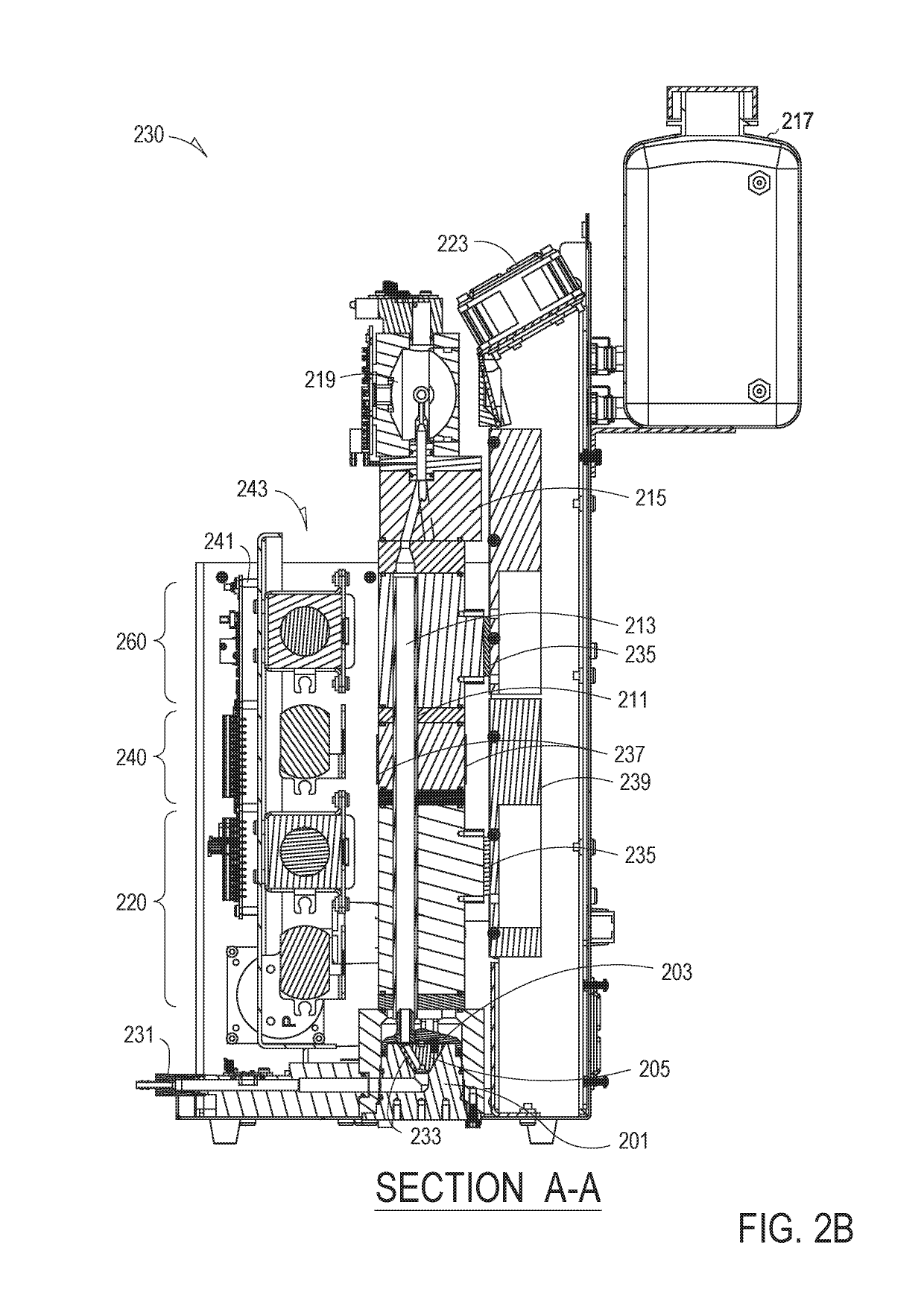

A particle vapor reactor (PVR) includes a reactor body with a fluid flow conduit having an inlet end and an outlet end, the crossection of the conduit having a circular geometry at the inlet end, a rectangular geometry at its midsection, and a circular geometry at its outlet end. The PVR conduit defines a saturator section and a condenser section. A compact condensation particle counter (CPC) including the reactor is also disclosed. The CPC also includes a sample inlet, a fluid inlet section, a heater section, and a detector section.

Owner:KANOMAX FMT INC

Real-time particulate matter measuring system

InactiveCN101375149AImprove functionalitySamplingParticle suspension analysisParticulatesChemical physics

A real-time particulate matter measuring system includes a hot diluter for receiving and diluting aerosol . An evaporation unit receives the diluted aerosol. A cold diluter receives and dilutes the output flow from the evaporation unit. A condensation particle counter receives the diluted output flow and measures the particle number concentration. An integrated device also receives the diluted output flow. The integrated device measures at least one of particle diameter concentration arid particle surface area. The integrated device also measures mass concentration.

Owner:HORIBA LTD

System for measuring non-volatile residue in ultra pure water

A system for monitoring non-volatile residue concentrations in ultra pure water includes a nebulizer for generating an aerosol composed of multiple water droplets, a heating element changing the aerosol to a suspension of residue particles, and a condensation particle counter to supersaturate the dried aerosol to cause droplet growth through condensation of a liquid onto the particles. The nebulizer incorporates a flow dividing structure that divides exiting waste water into a series of droplets. The droplets are counted to directly indicate a waste water flow rate and indirectly indicate an input flow rate of water supplied to the nebulizer. The condensation particle counter employs water as the condensing medium, avoiding the need for undesirable chemical formulations and enabling use of the ultra pure water itself as the condensing medium.

Owner:FLUID MEASUREMENT TECH

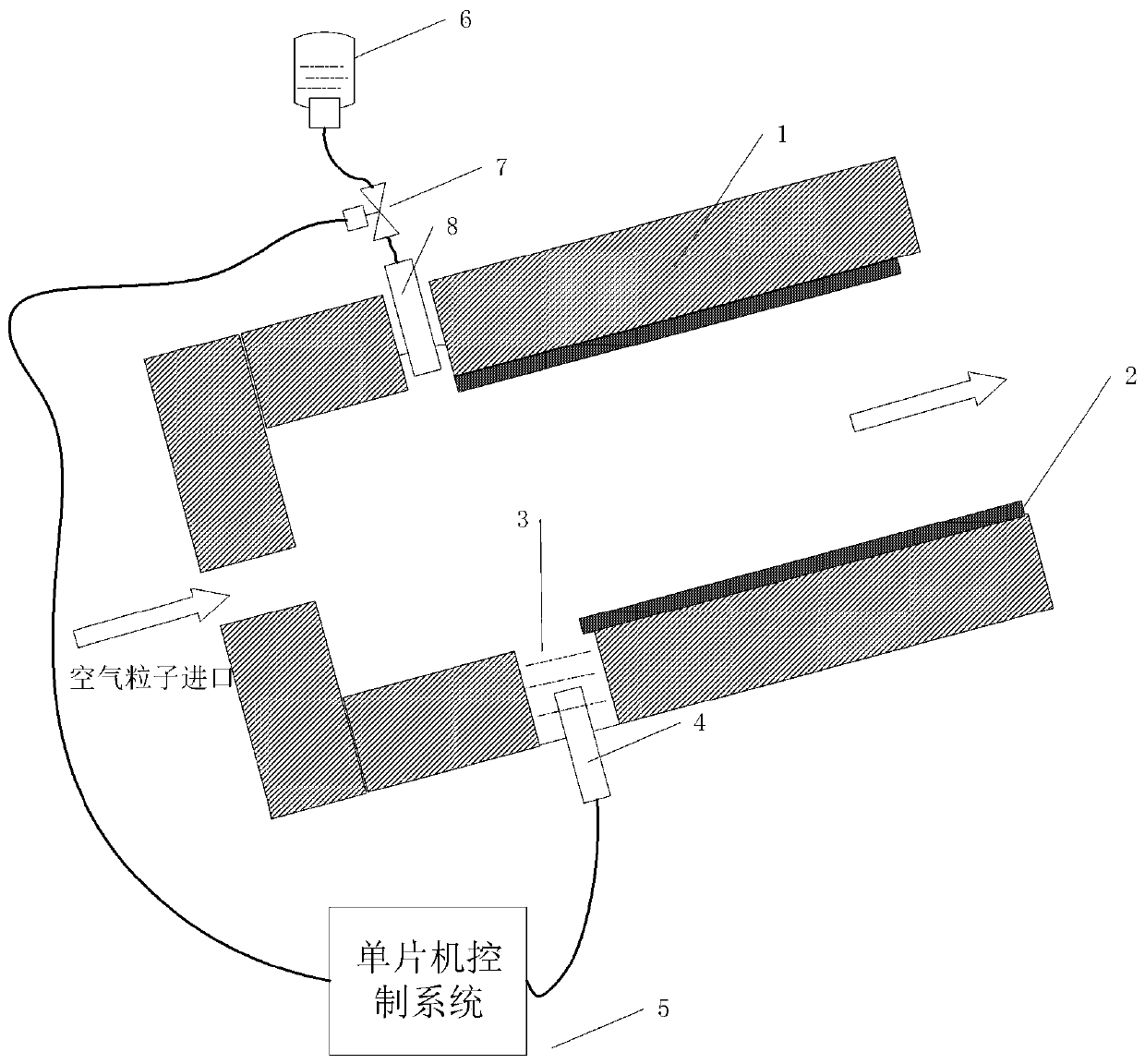

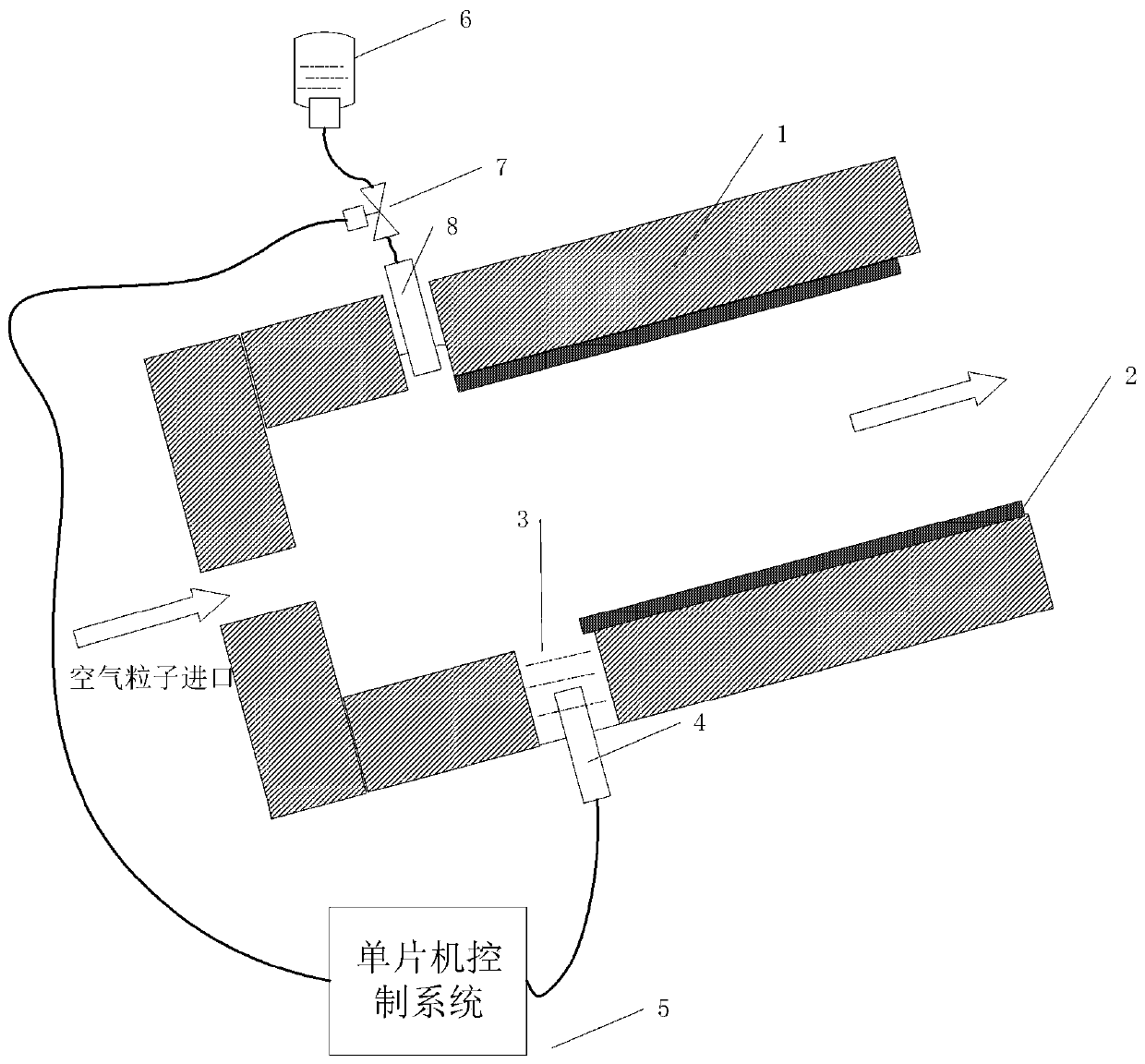

Small-size particle condensation growth counter

PendingCN108535168AMiniaturizationReduce wasteIndividual particle analysisParticulatesMeasuring instrument

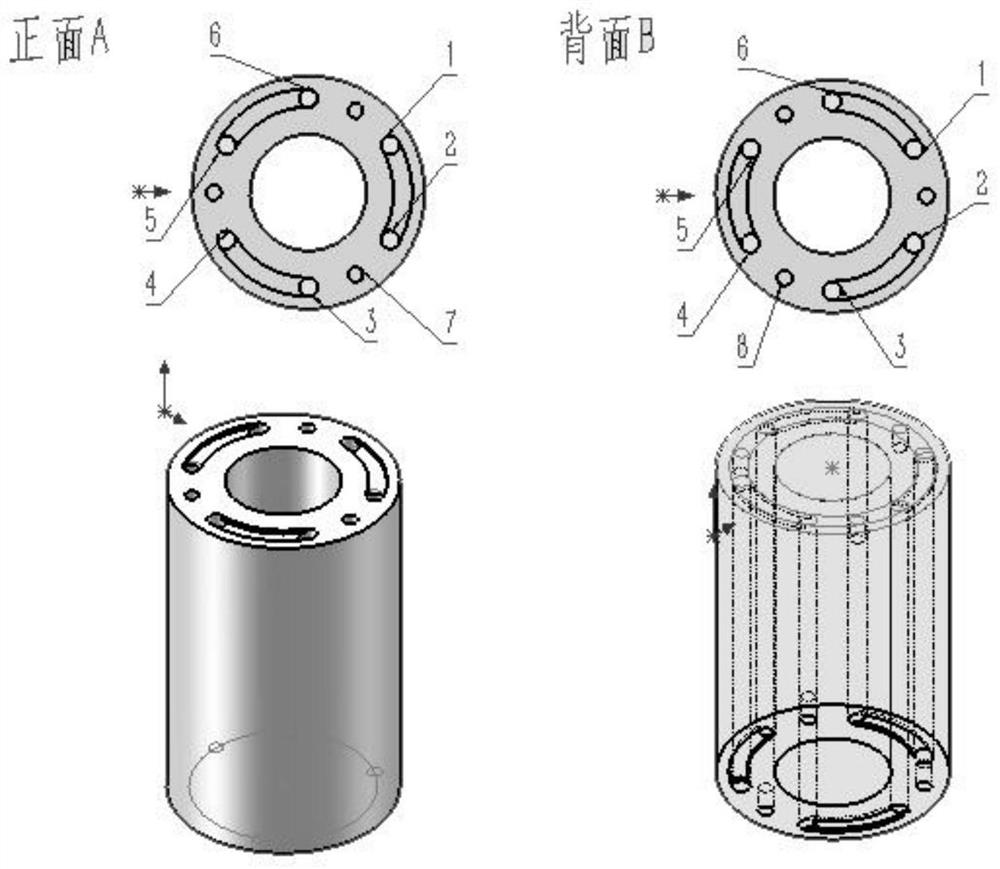

The invention discloses a small-size particle condensation growth counter. The small-size condensation particle counter comprises a flow splitting system, a filtering device, an evaporation chamber, aheat insulation device, a refrigeration sheet, an aerosol inlet and working solution recycling device, a working solution recycling pump, a working solution storage bottle, a condensation chamber, apressure measuring device, a light scattering measuring instrument, a flow limiting hole, a tee joint, a gas pump and a liquid inlet pump, wherein an inlet of the flow splitting system is connected with an object to be sampled; an outlet A of the flow splitting system is connected with the inlet of the filtering device through a hose; the outlet of the filtering device is connected with the evaporation chamber through a hose; a water absorption material is fixed in a middle cavity of the evaporation chamber. The counter disclosed by the invention adopts a back-to-back type design, and the arrangement manner of the evaporation chamber and the condensation chamber is changed into parallel arrangement from traditional axial arrangement, so that the space is effectively utilized and saved andthe miniaturization of a device is realized; the refrigeration sheet is arranged between the evaporation chamber and the condensation chamber and the heat generated by the refrigeration sheet in a refrigeration process is used for heating the evaporation chamber so that wastes of heat dissipation are reduced and a heat rejection fan is omitted.

Owner:TSINGHUA UNIV

Condensation particle counter false count performance

ActiveUS20180045636A1Investigating moving fluids/granular solidsParticle suspension analysisWater basedParticle counter

Various embodiments include methods of reducing false-particle counts in a water-based condensation particle counter (CPC). One embodiment of a method includes delivering water into one or more wicks, sensing an excess volume of water delivered to the wicks, collecting the excess volume of water into a collection reservoir, and draining the excess volume of water from the collection reservoir. Other methods and apparatuses are disclosed.

Owner:TSI INC

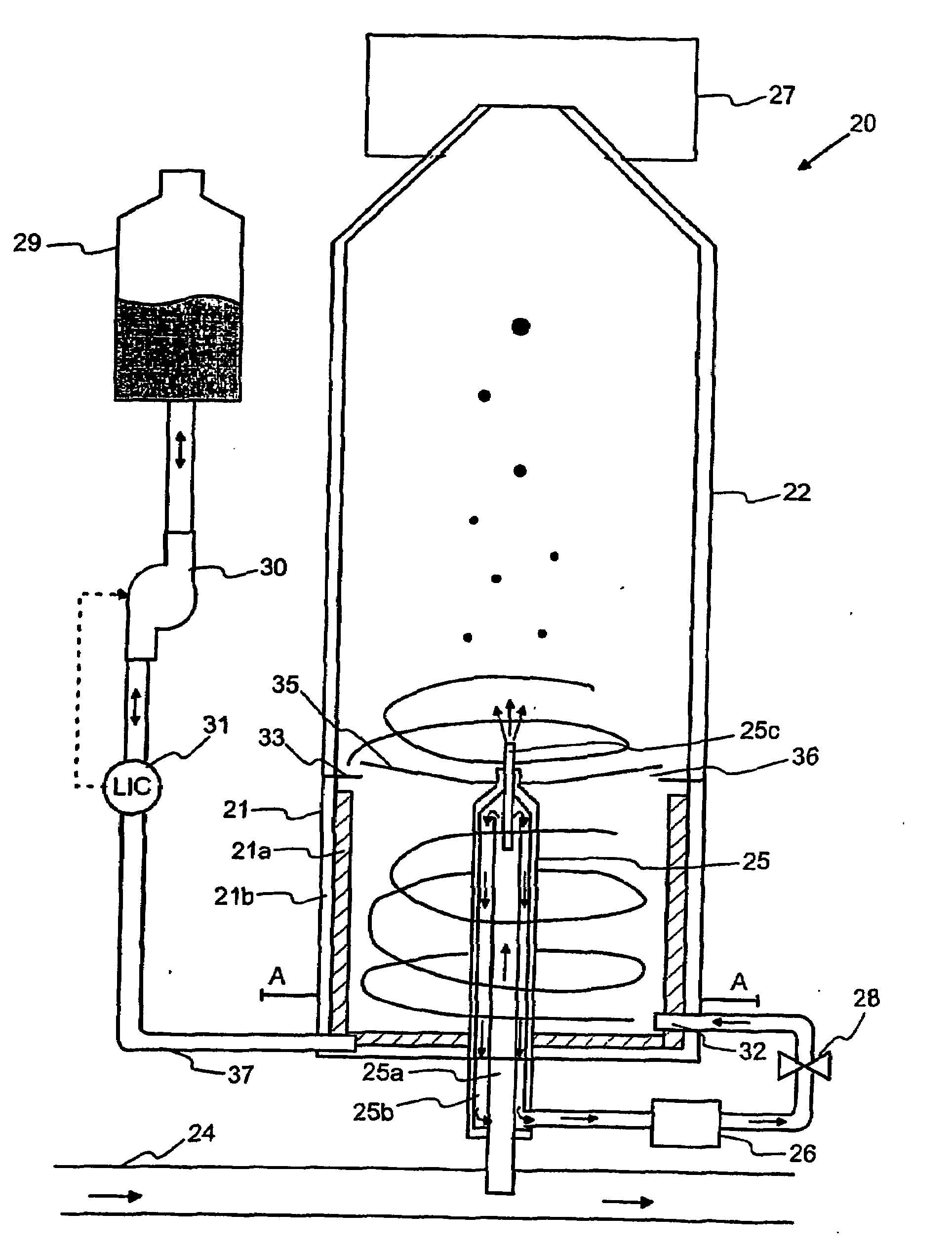

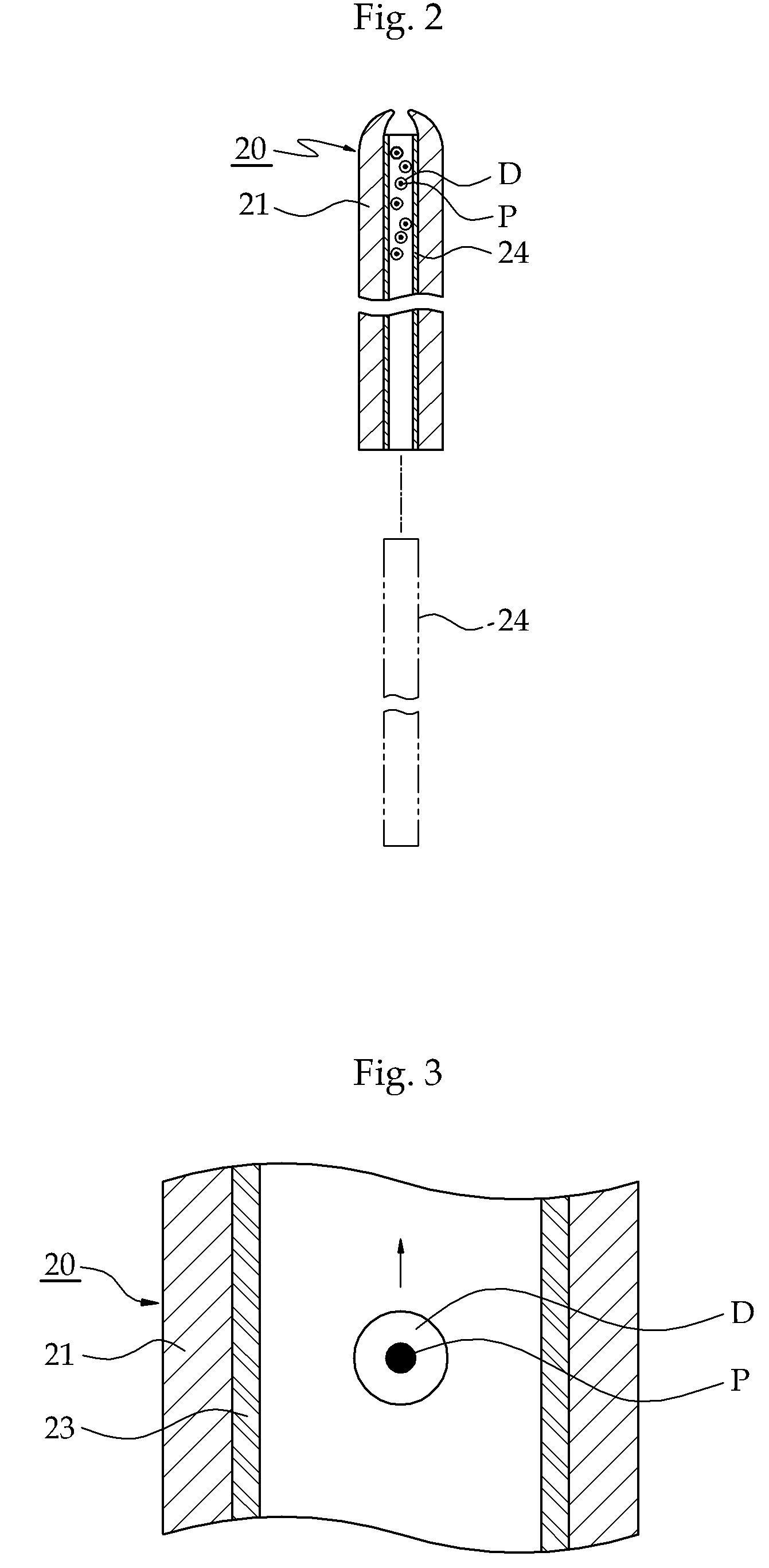

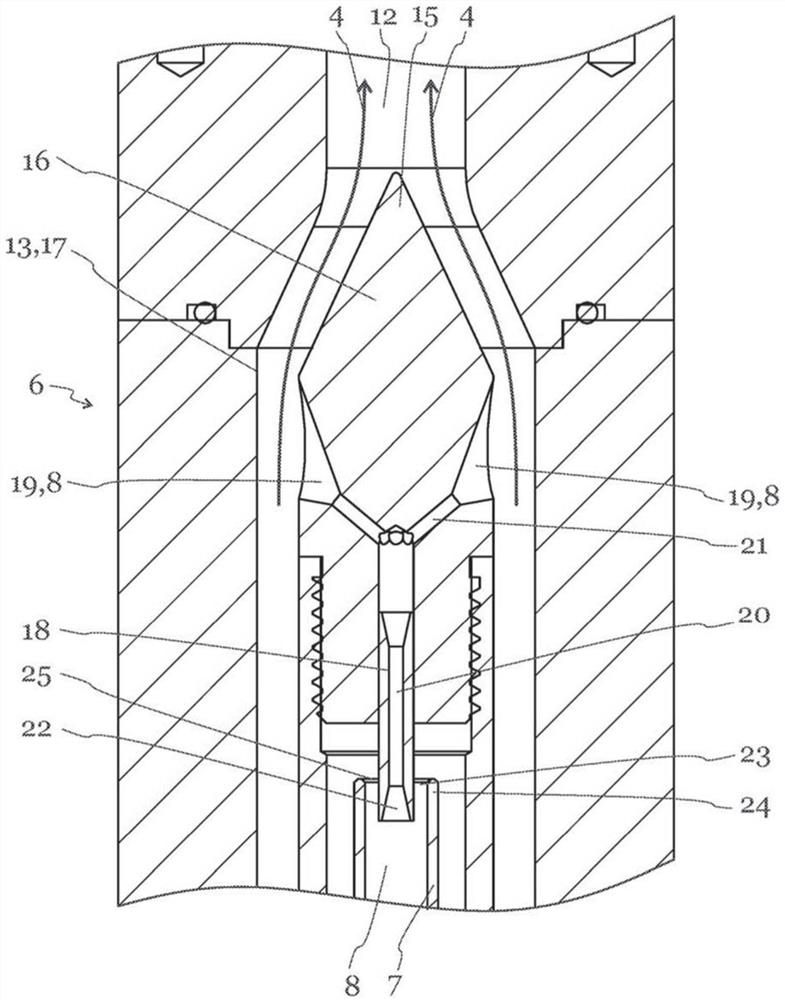

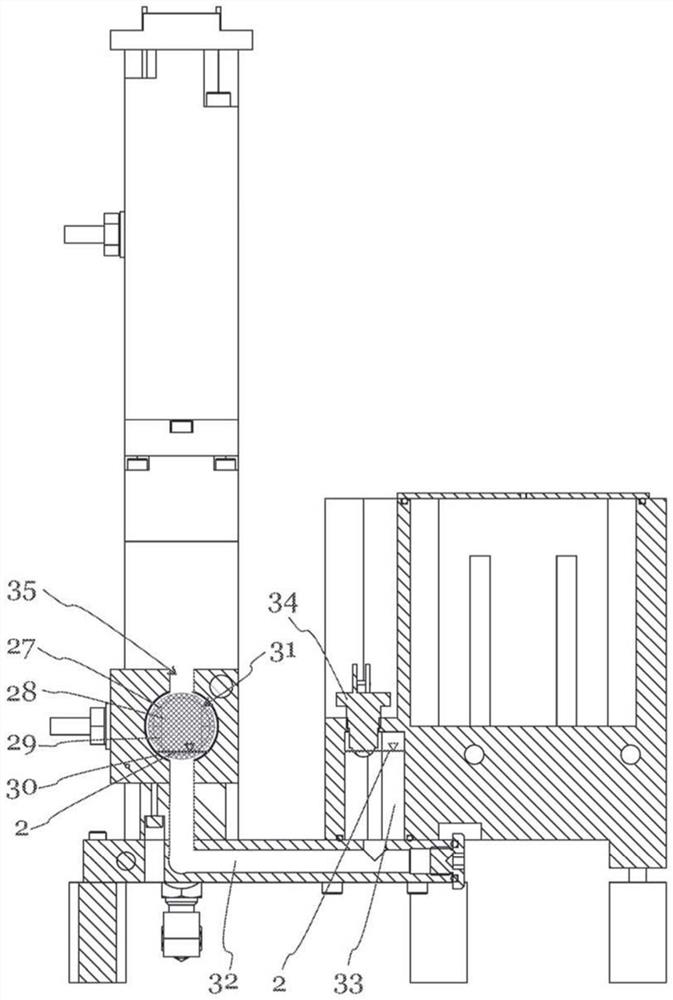

Method and apparatus for increasing the size of small particles

InactiveUS20090031828A1Increase in sizeReduce latencyWithdrawing sample devicesPreparing sample for investigationChemical physicsSmall particles

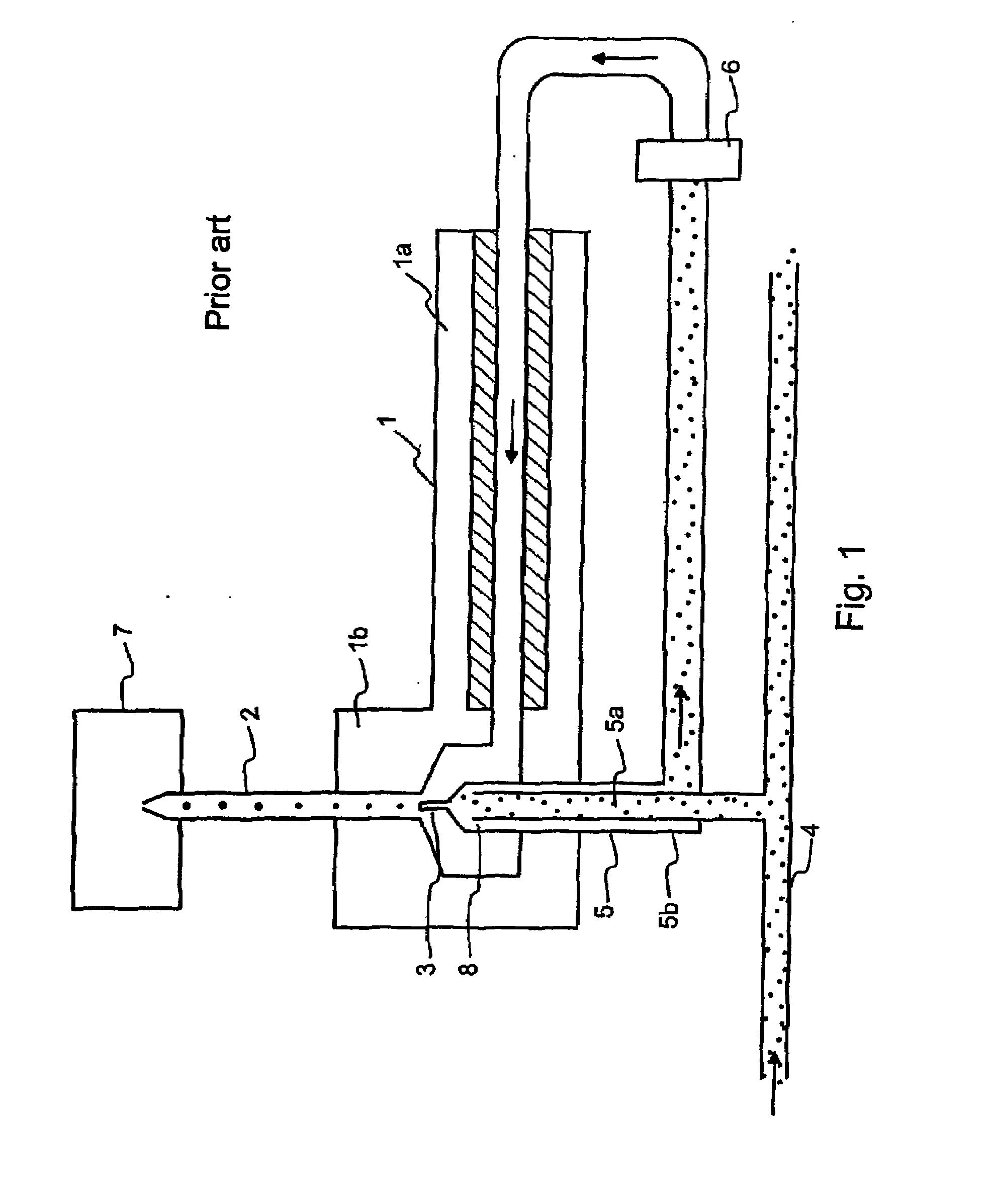

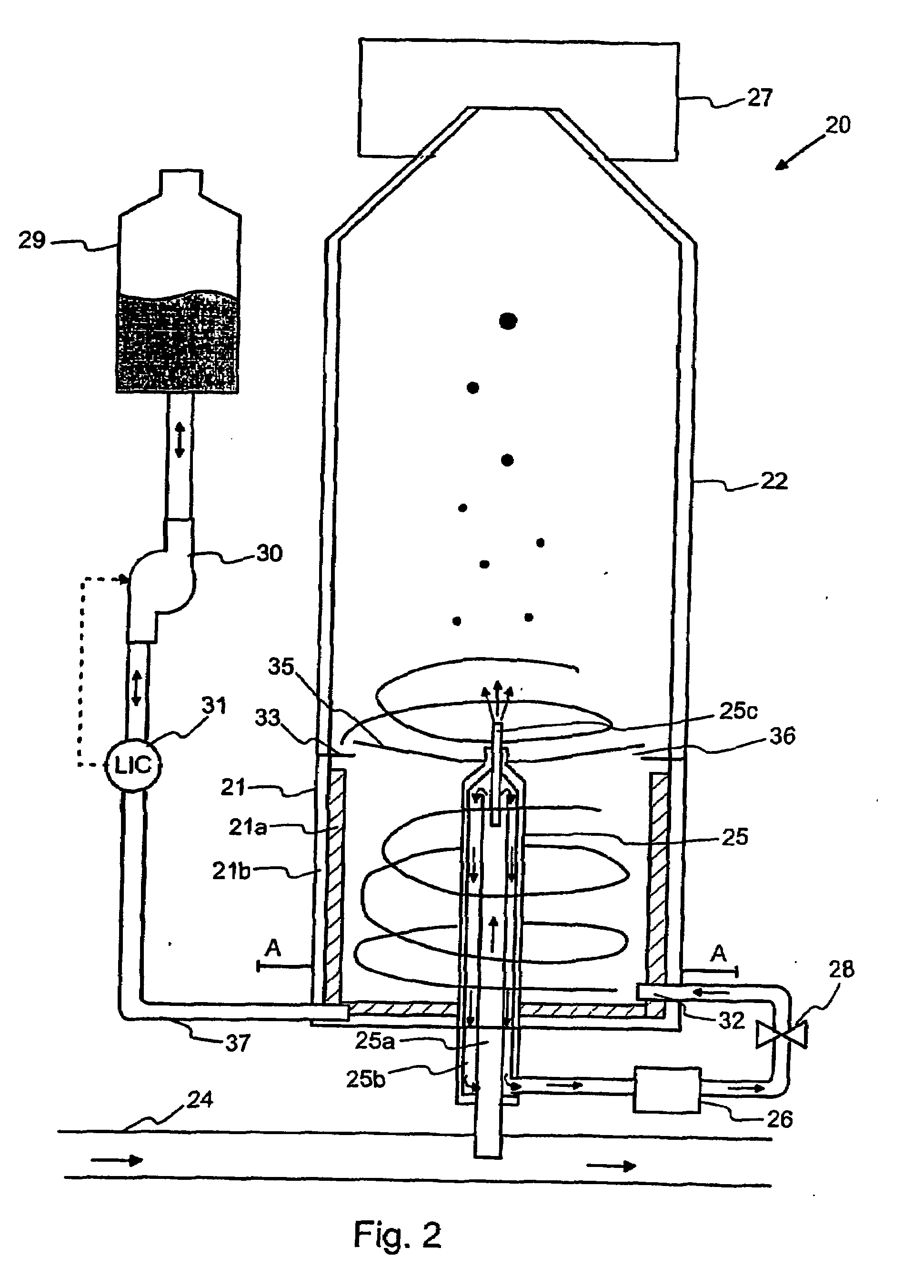

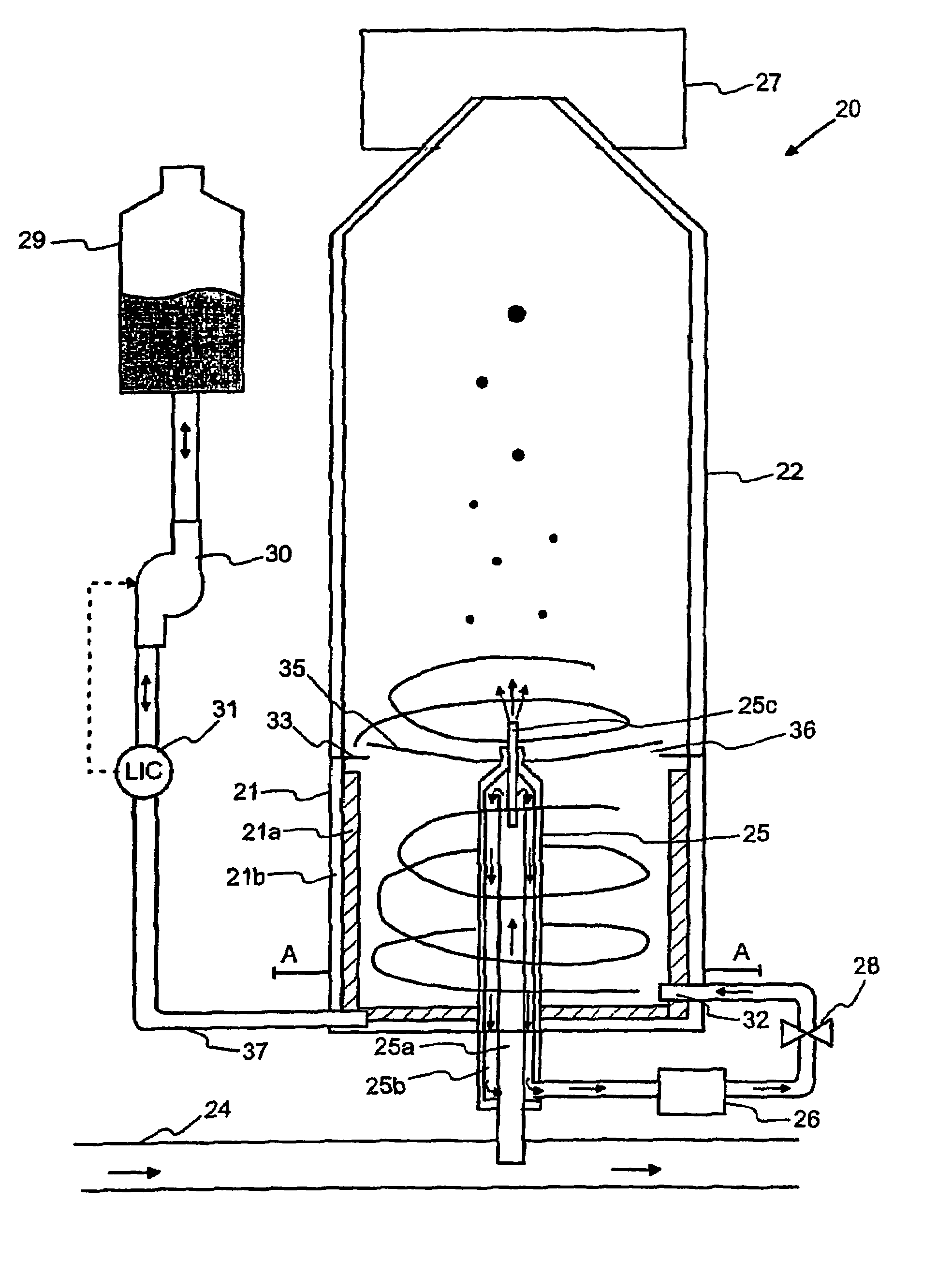

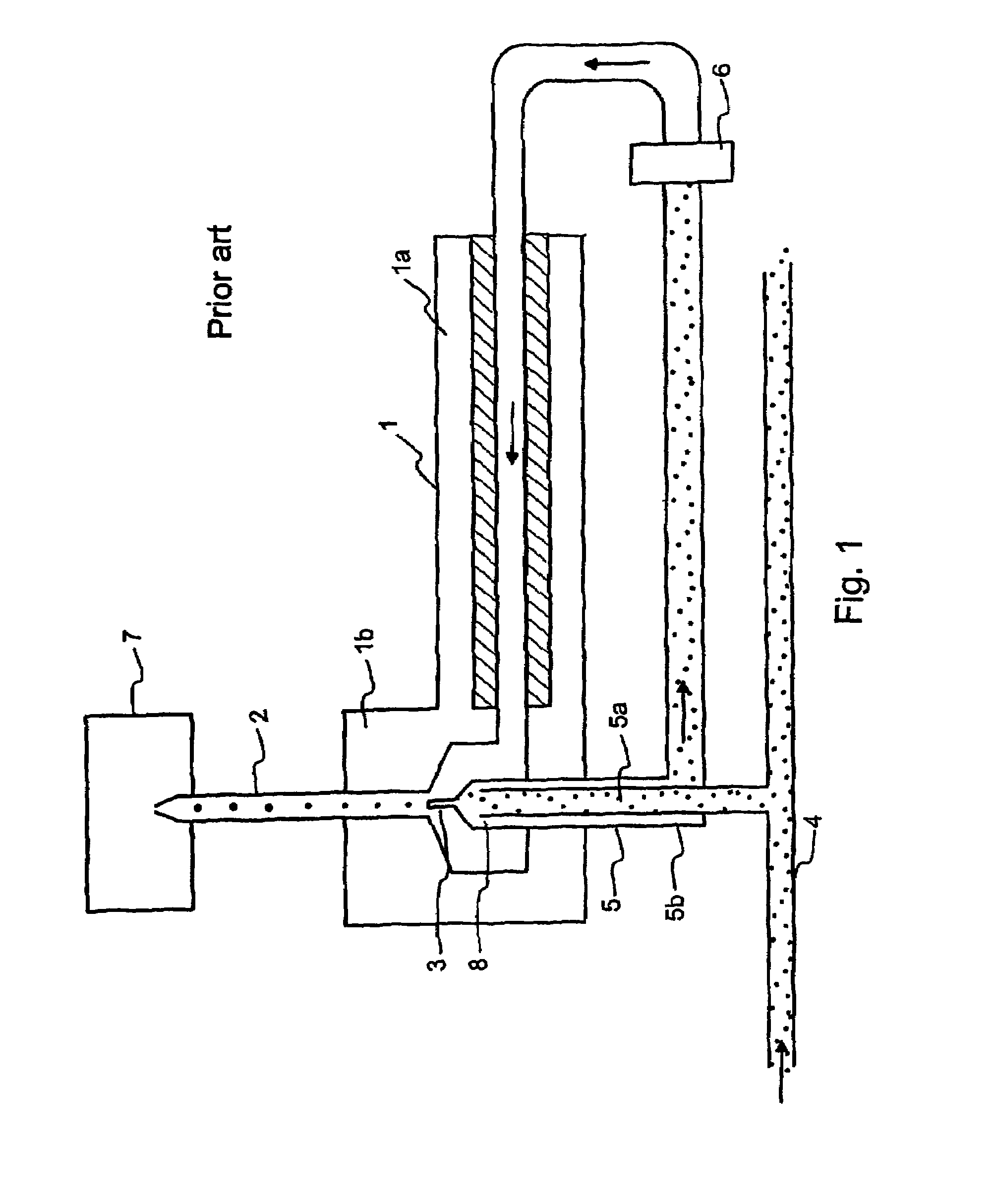

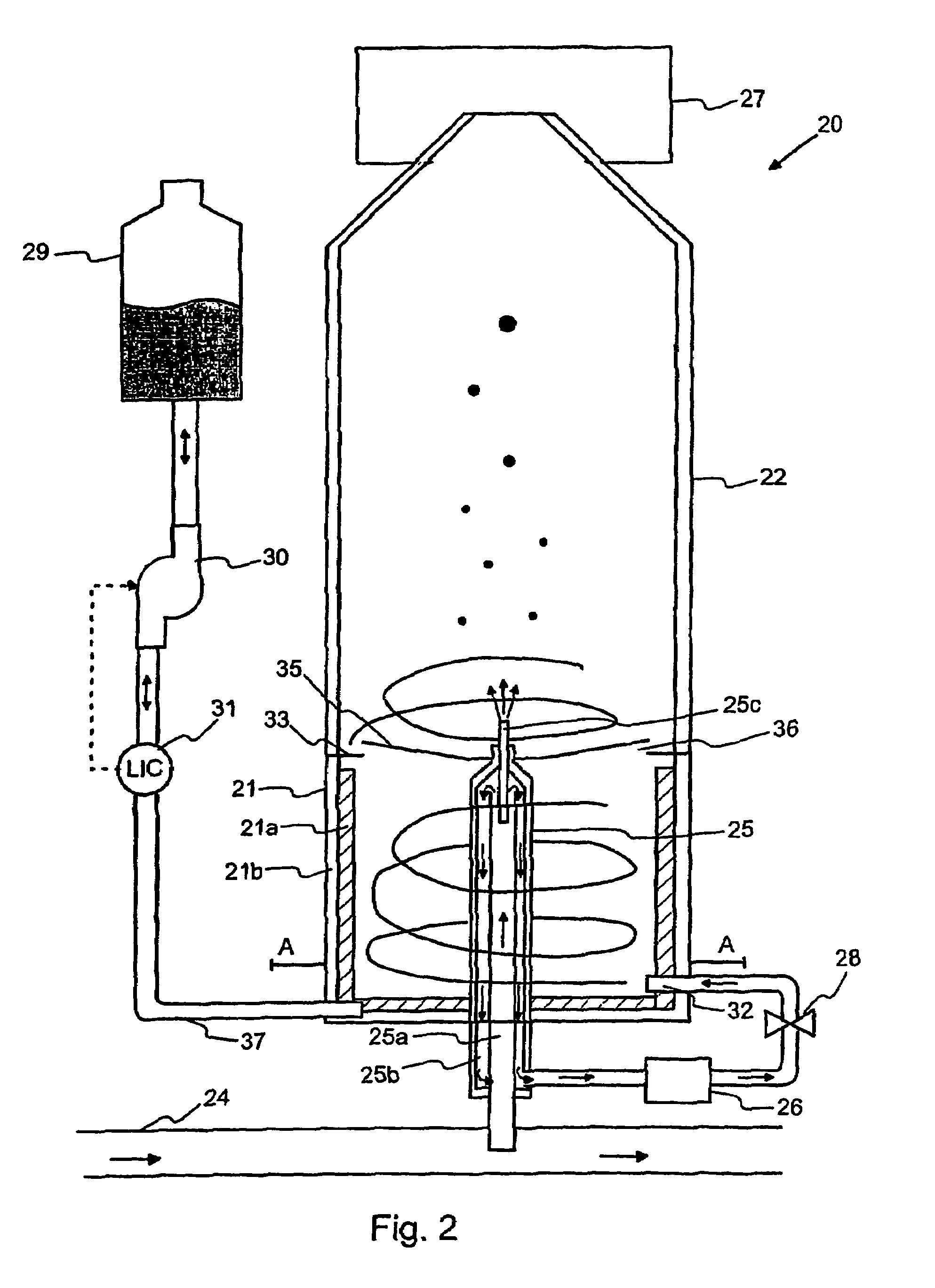

A method and apparatus for increasing the size of small particles for a condensation particle counter, in which method a particle containing aerosol flow is divided into a sample flow and a sheath flow. The sheath flow is filtered, saturated with vapor and formed to a vortex flow in a saturator which vortex-flow continues in a condenser. The sample flow is introduced to the centre of the vortex flow of the saturated sheath flow in the condenser for causing the vapor in the saturated sheath flow to condense on the particles in the sample flow thus increasing the size of the particles.

Owner:DEKATI

Condensation particle counter

A condensation particle counter is capable of efficiently measuring the number and size of fine particles. The condensation particle counter includes a saturator, a condenser and an optical particle counters. The saturator is designed to generate a saturated gas by saturating a gas in which fine particles are suspended with working fluid. The condenser is connected to a downstream side of the saturator to condense the saturated gas so that liquid droplets can grow around the fine particles. The optical particle counter is connected to downstream sides of the condenser to optically detect the liquid droplets supplied from the condensers. The condenser has a condenser tube for interconnecting the saturator and the optical particle counter. The present condensation particle counter can use water as working fluid and also can optically measure fine particles in an easy and accurate manner by forming or installing an inner surface of a condenser tube with a hydrophilic tube.

Owner:HCTM +1

Temperature control device for condensation particle counter

ActiveCN109323976ASolution volumeAddress usability issuesTemperatue controlIndividual particle analysisLiquid storage tankThermistor

The invention discloses a temperature control device for a condensation particle counter, and can solve the technical problem that a temperature control system for the condensation particle counter isrelatively large in volume and relatively high in power consumption and is low in applicability. Peltier is arranged inside a condensation cavity, the condensation cavity is internally provided witha condensation cavity thermistor, a saturation cavity is internally provided with a saturation cavity thermistor, and the hot surface of the Peltier is provided with a cooling fin. The temperature control device also comprises a cooling liquid loop system, the cooling liquid loop system comprises a cooling liquid storage tank, a liquid pump and a return line, the cooling liquid storage tank is connected to the liquid pump through the return line, the return line is guided out from the liquid pump, passes through the cooling fin and then runs through an optical cavity to be connected into the saturation cavity. The temperature control device also comprises a temperature control circuit, and the condensation cavity thermistor, the condensation cavity thermistor, the Peltier and the liquid pump are connected with the temperature control circuit respectively. According to the temperature control device, the temperature control speed is high, the saturation cavity and the optical cavity areheated uniformly, the diffusion uniformity of butyl alcohol steam is facilitated, the uniformity of particle growth is controlled, and the power consumption and volume are further greatly reduced.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Virus and particulate separation from solution

InactiveUS8524155B1Minimizes background countSamplingComponent separationParticle physicsDifferential mobility analyzer

An improved system for collecting, detecting, and classifying submicron-sized particles in a sample comprising an Integrated Virus Detection System (IVDS) of the type wherein the detecting means includes a differential mobility analyzer (DMA) and condensation particle counter (CPC), the improvement comprising positioning an aerosol collector or an electrostatic collector between the differential mobility analyzer and the condensation particle counter wherein submicron-sized particles from the environmental sample are collected for further analysis.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Method and apparatus for increasing the size of small particles

InactiveUS7975564B2Increase in sizeReduce latencyWithdrawing sample devicesParticle suspension analysisMechanicsSmall particles

A method and apparatus for increasing the size of small particles for a condensation particle counter, in which method a particle containing aerosol flow is divided into a sample flow and a sheath flow. The sheath flow is filtered, saturated with vapor and formed to a vortex flow in a saturator which vortex-flow continues in a condenser. The sample flow is introduced to the center of the vortex flow of the saturated sheath flow in the condenser for causing the vapor in the saturated sheath flow to condense on the particles in the sample flow thus increasing the size of the particles.

Owner:DEKATI

Systems and methods for isolating condensate in a condensation particle counter

ActiveUS20170350801A1Inhibit migrationEliminate needIndividual particle analysisParticle suspension analysisEngineeringCondensation particle counter

The systems and methods provided herein relate generally to the prevention of migration of condensate in a condensation particle counter between components designed to handle condensate (e.g. saturator, condenser, condensate reservoir) and components which may be damaged by the condensate (e.g. detection and flow control devices).

Owner:PARTICLE MEASURING SYST

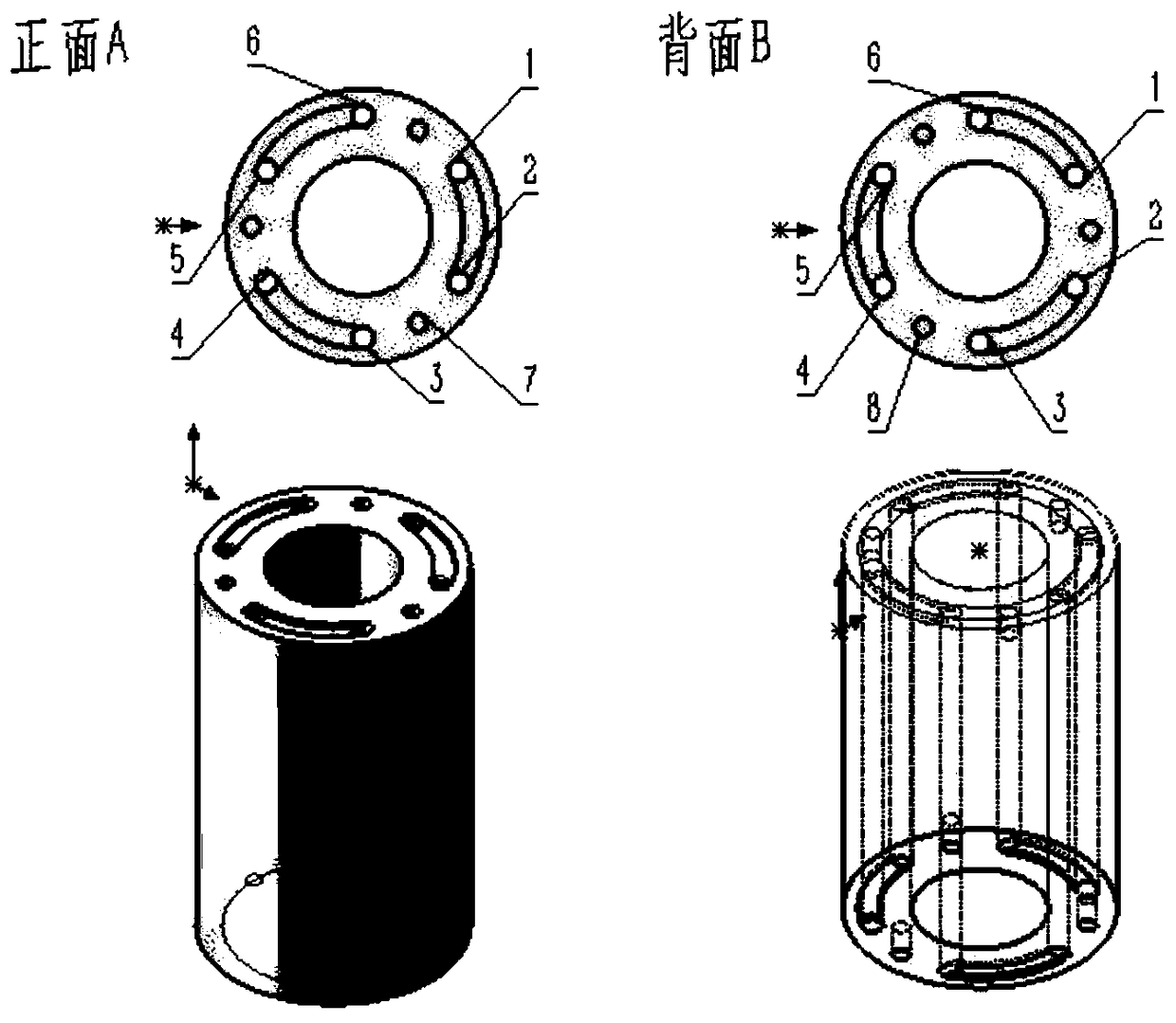

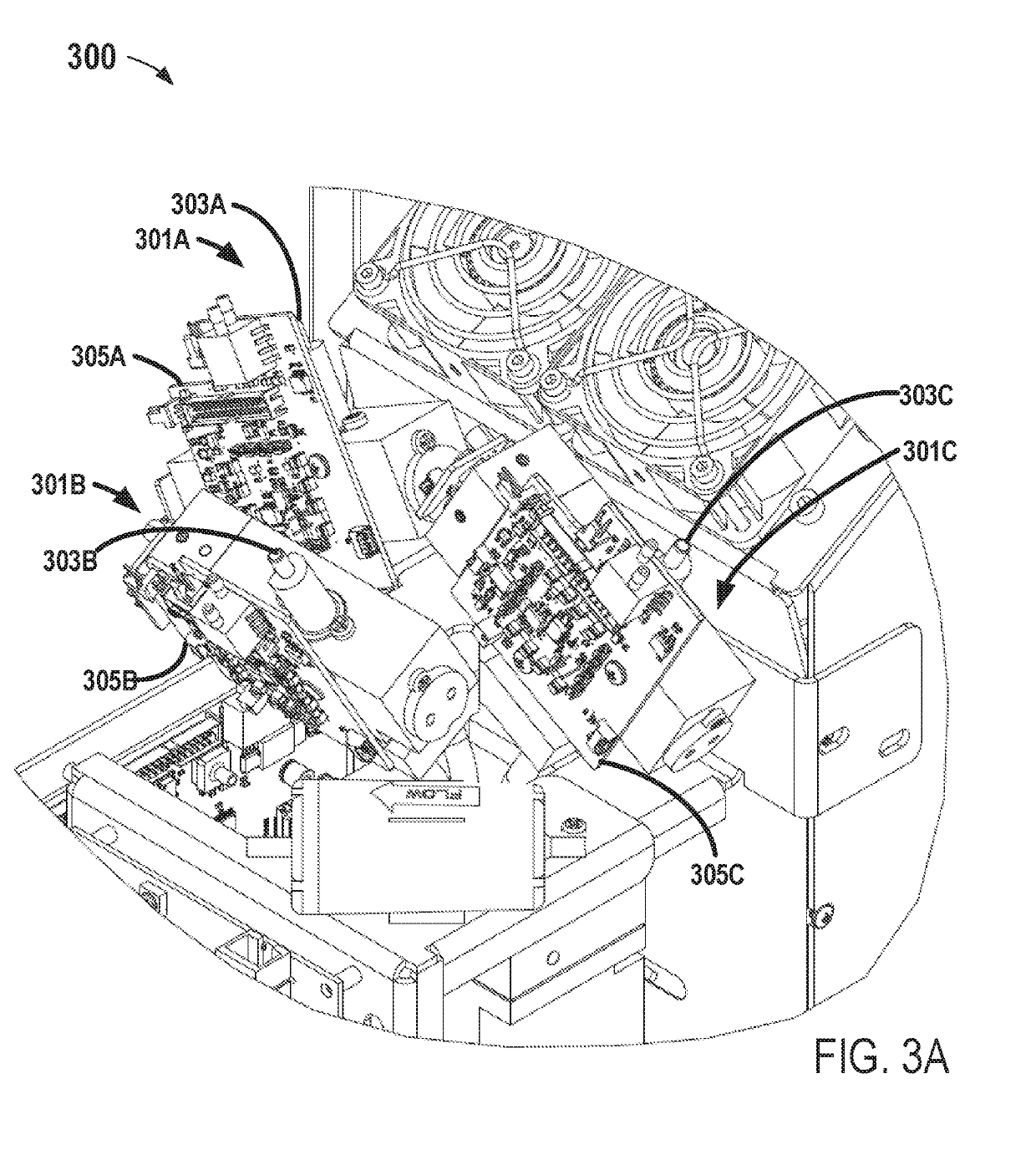

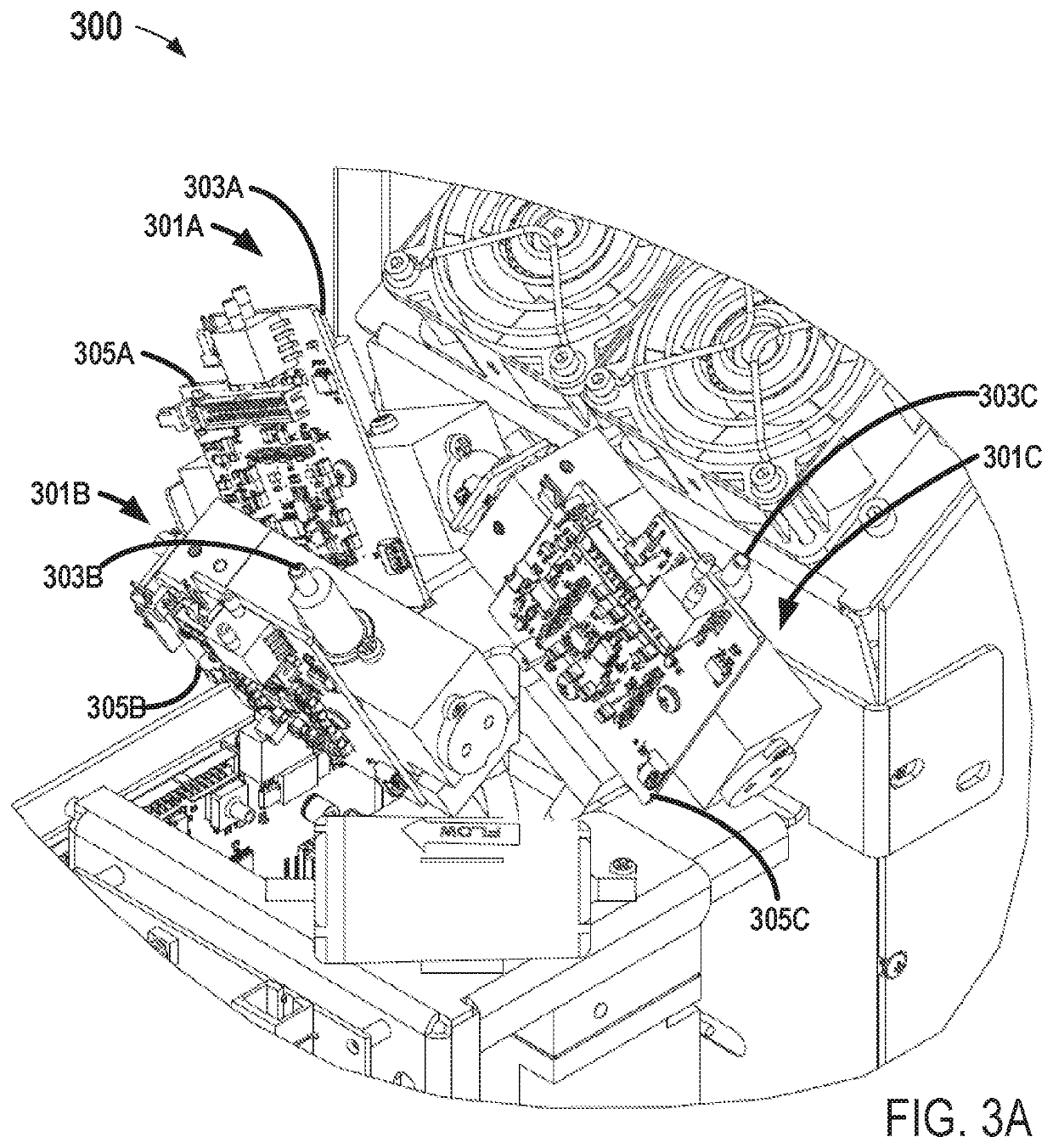

Reducing false counts in condensation particle counters

ActiveUS20190339186A1Individual particle analysisParticle suspension analysisWater basedParticle physics

Various embodiments include methods and apparatuses to reduce false-particle counts in a water-based condensation particle counter (CPC). In one embodiment, a cleanroom CPC has three parallel growth tube assemblies. A detector is coupled to an outlet of each of the three parallel growth tube assemblies, and is used to compare the particle concentrations measured from each of the three growth tube assemblies. An algorithm compares the counts from the three detectors and determines when the particles counted are real and when they are false counts. Any real particle event shows up in all three detectors, while false counts will only be detected by one detector. Statistics are used to determine at which particle count levels the measured counts are considered to be real versus false. Other methods and apparatuses are disclosed.

Owner:TSI INC

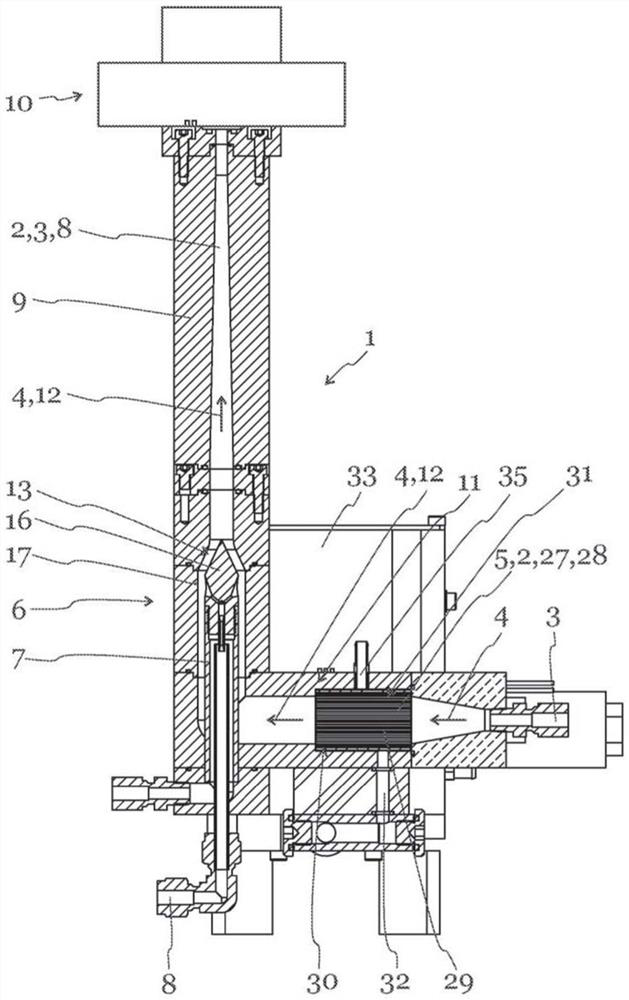

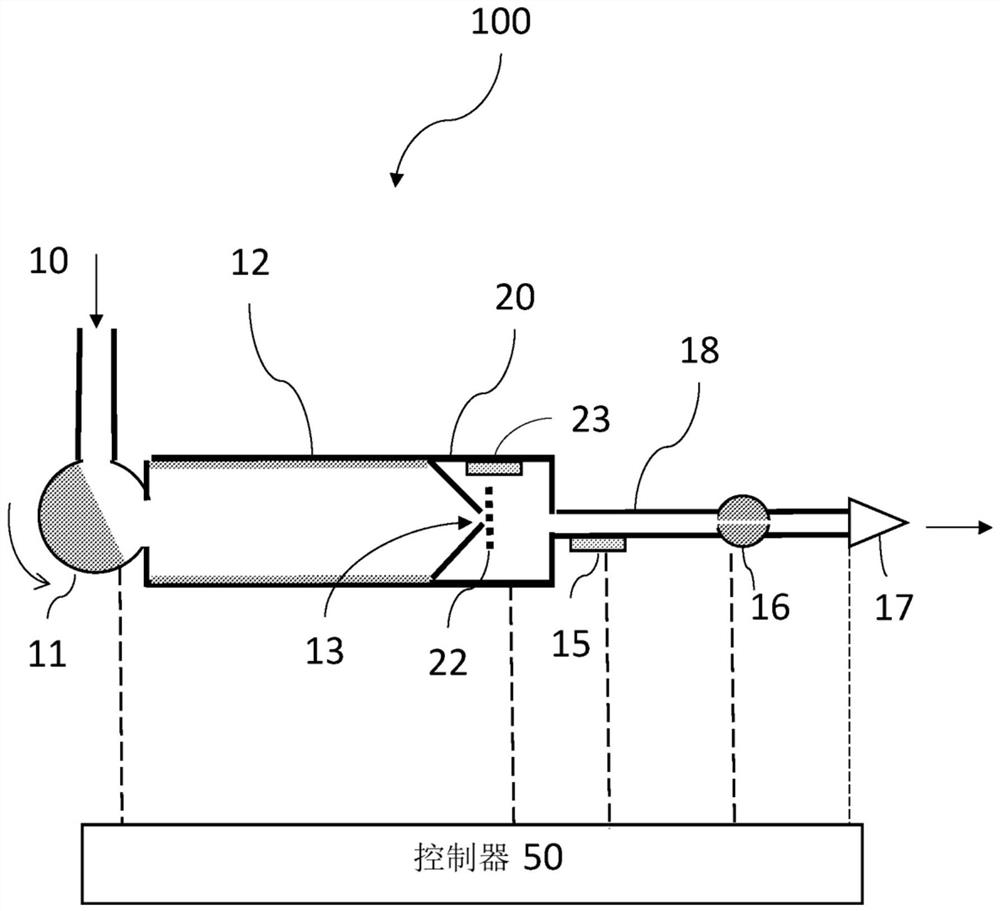

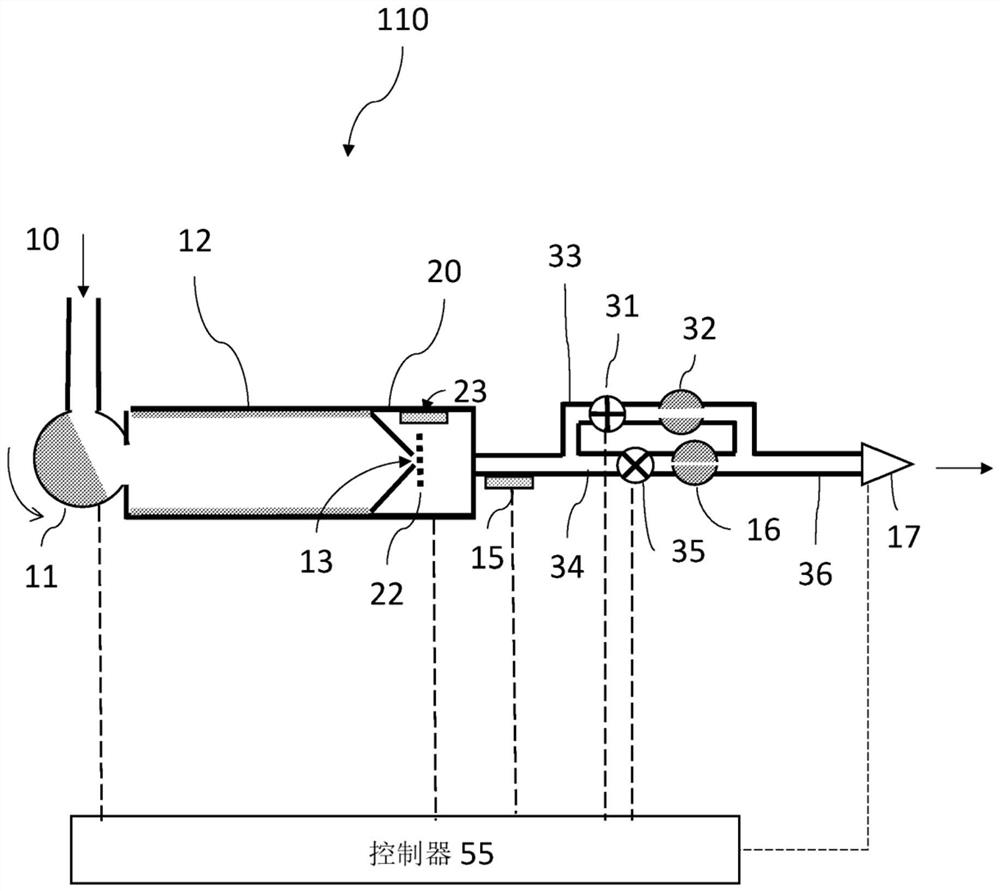

Method and assembly comprising condensation particle counter, operating fluid, and carrier gas

PendingCN111670353AAvoid lostReduce pollutionWithdrawing sample devicesPreparing sample for investigationAlkaneCondensation temperature

The invention relates to a method and an assembly comprising a condensation particle counter (1), an operating fluid (2), and a carrier gas (3) which flows through the condensation particle counter (1) along a main flow path (4) during a measurement operation. The condensation particle counter (1) has a saturator (5) and a nozzle device (6) which is arranged downstream of the saturator (5) along the main flow path (4) of the carrier gas (3) and opens into the enriched carrier gas (3), wherein the condensation particle counter (1) has a condensation region (9) which is arranged downstream of the nozzle device (6) for oversaturating the mixture containing the carrier gas (3), the operating fluid (2), and a measurement aerosol (8), and the condensation particle counter (1) has a measuring device (10) which is arranged downstream of the condensation region (9) along the main flow path (4) for detecting the measurement aerosol (8) particles enlarged by the condensed operating fluid (2). According to the invention, the carrier gas (3) is an inert gas, the operating fluid (2) is an alkane with the structural formula CnH2n+2 and an ordinal number n between 16 and 24, and the temperature ofthe carrier gas (3) is controlled to a condensation temperature of over 150 DEG C by the temperature-control assembly (11) in the condensation region (9) during a measurement operation.

Owner:AVL LIST GMBH

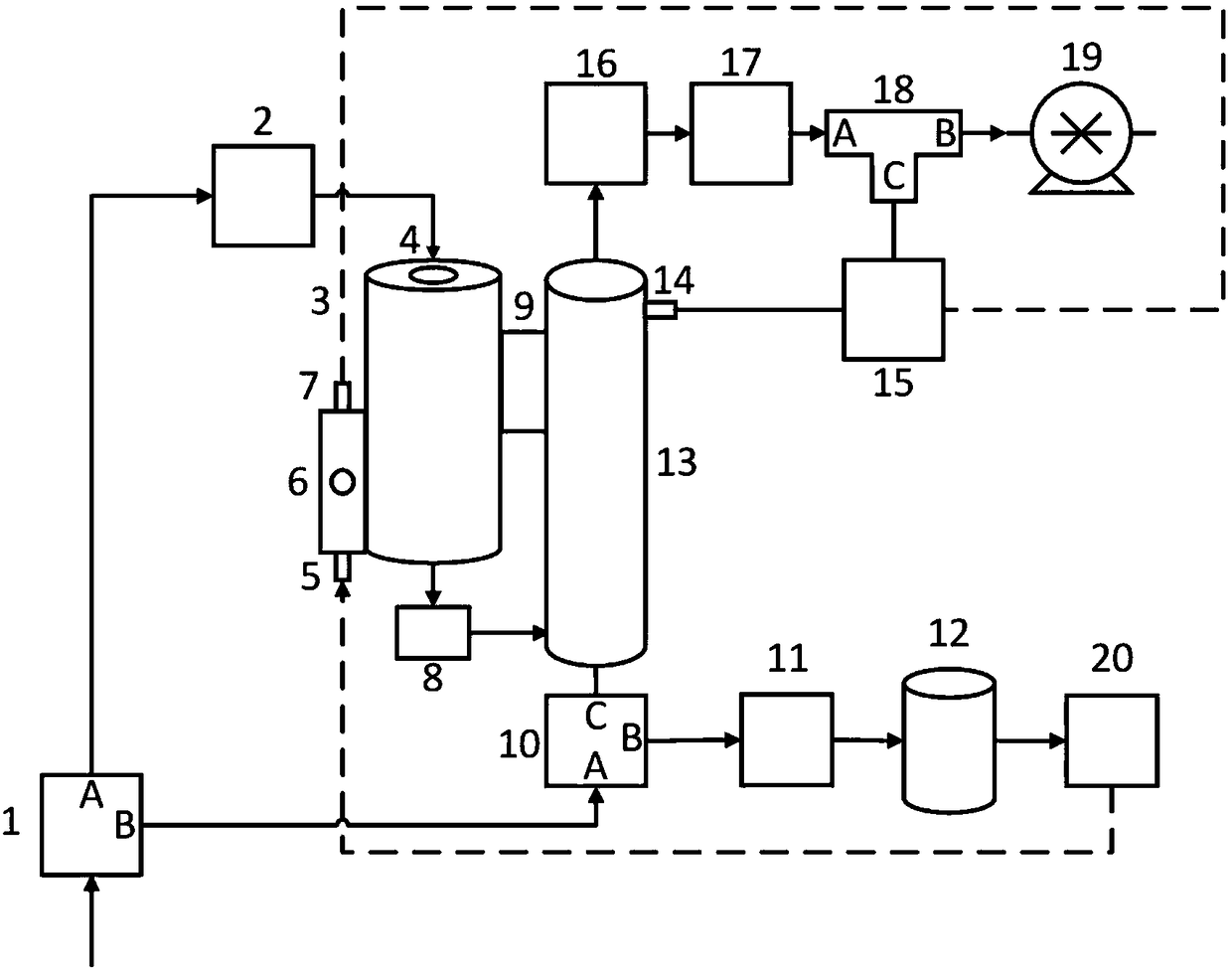

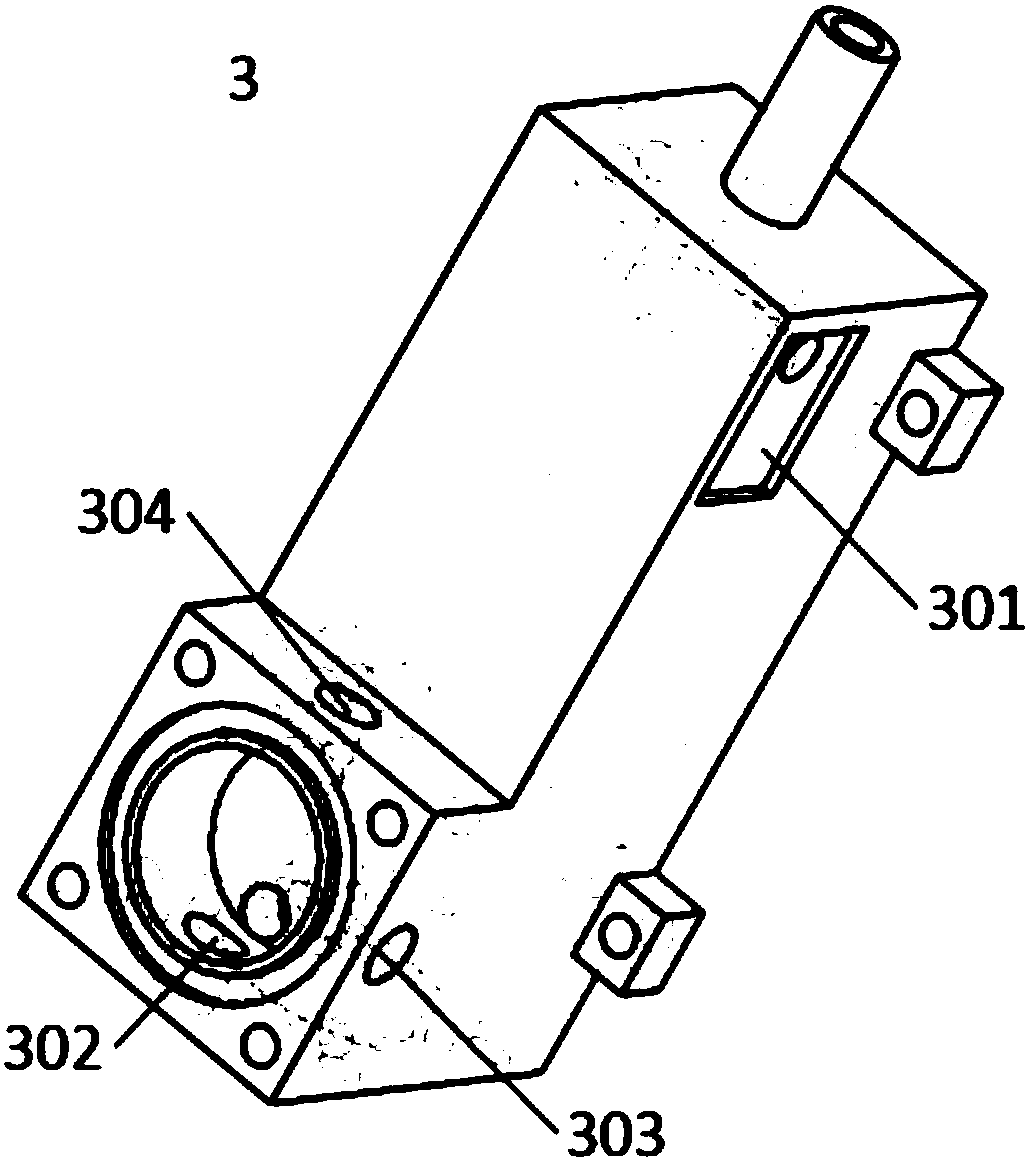

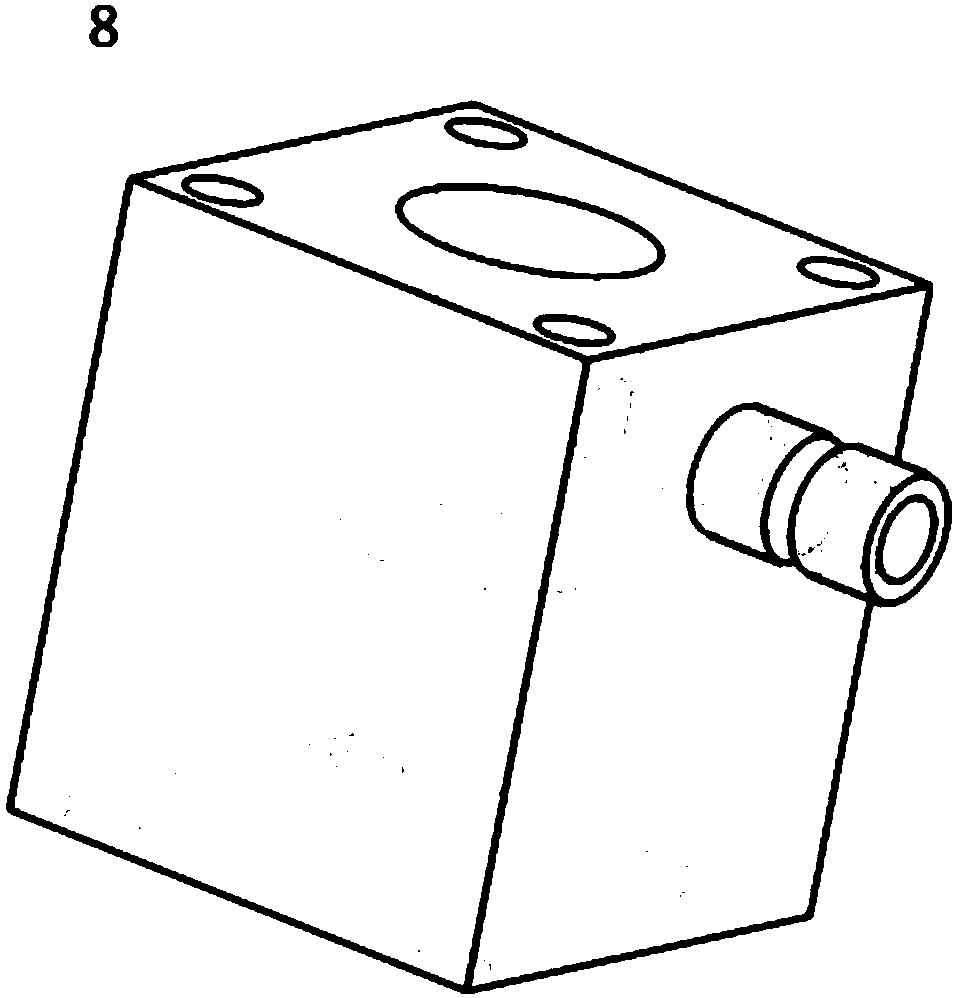

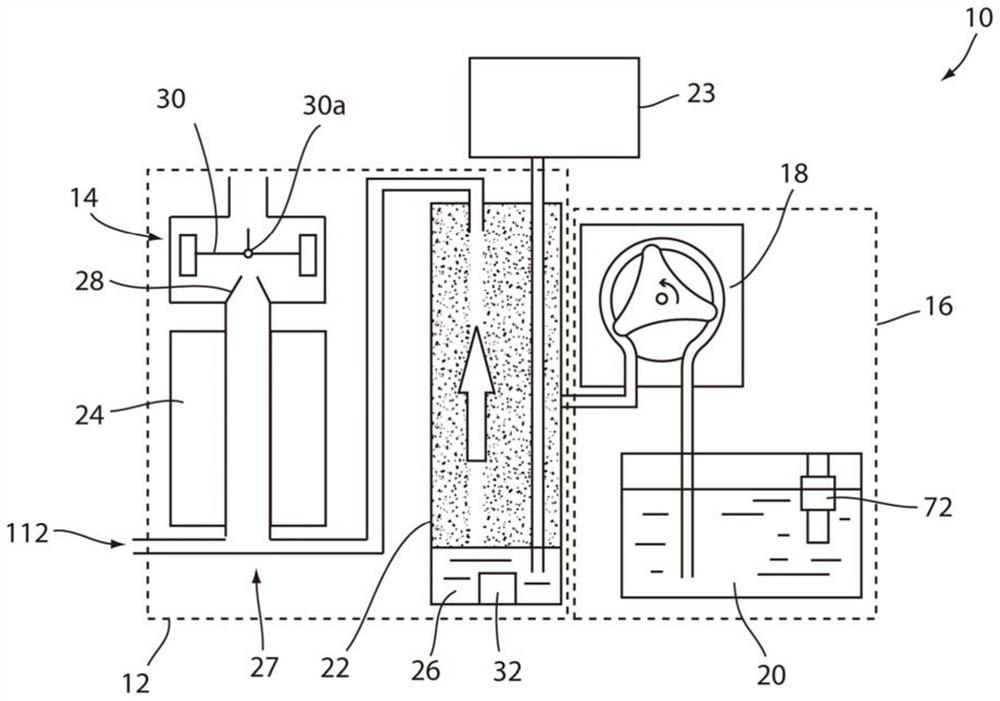

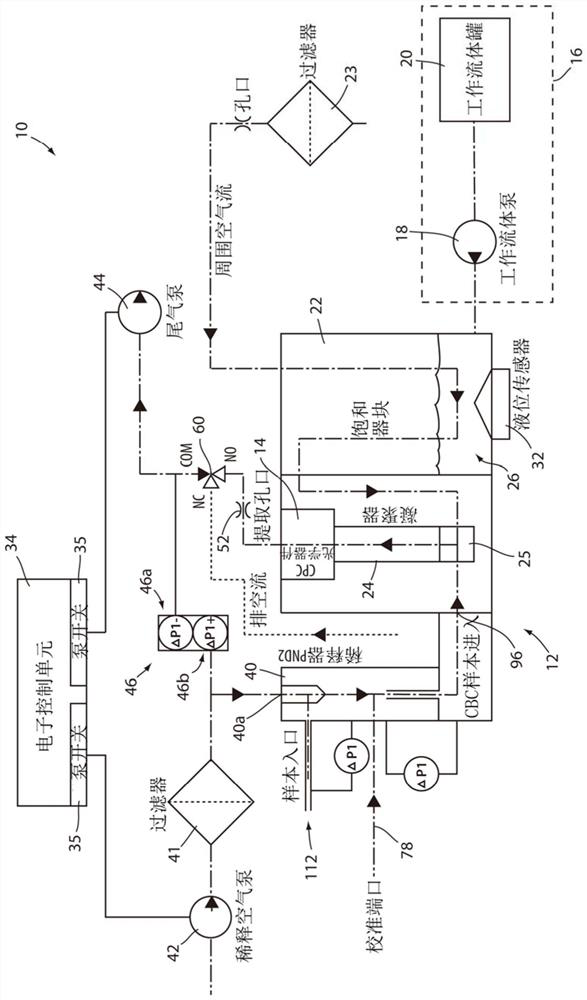

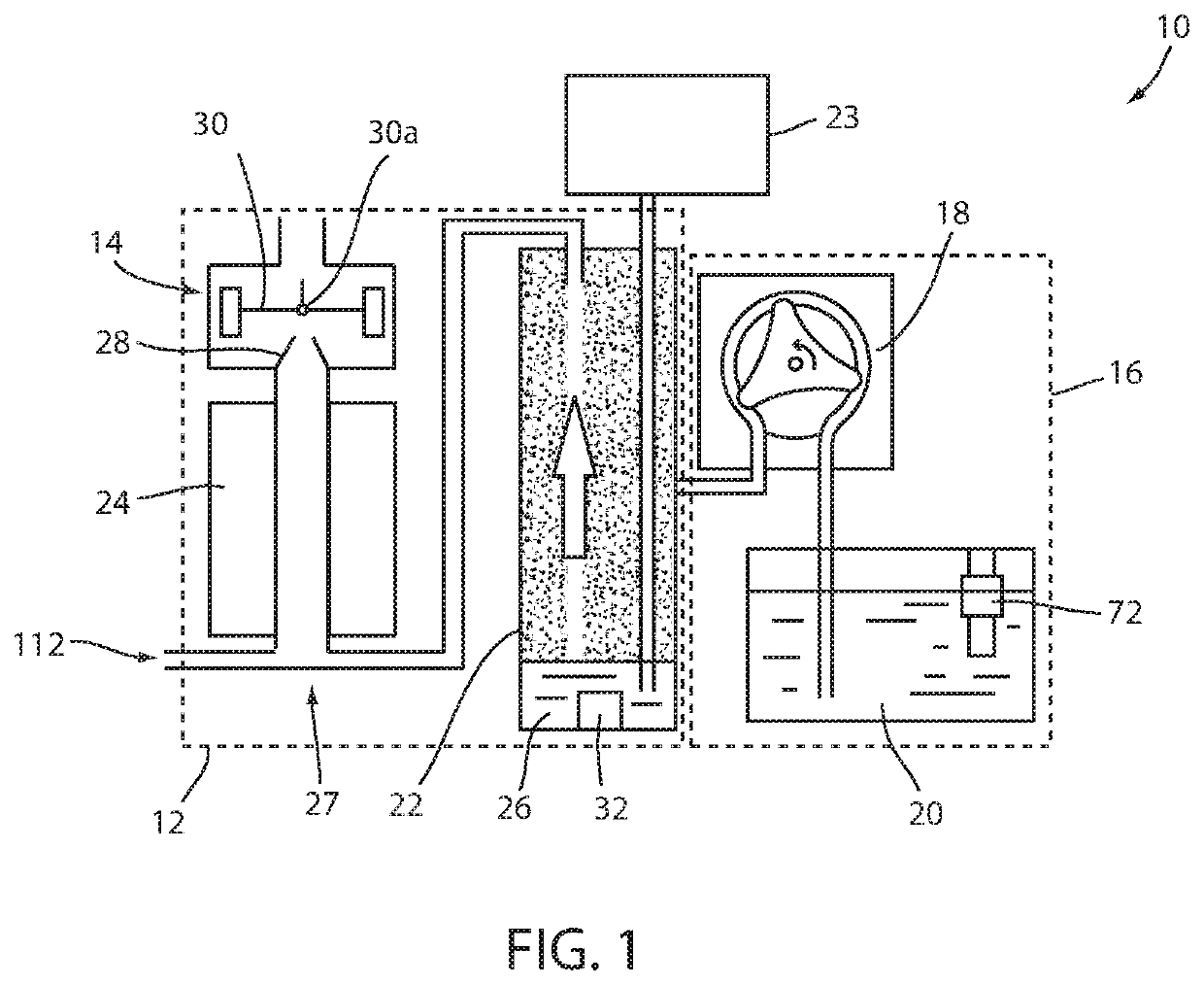

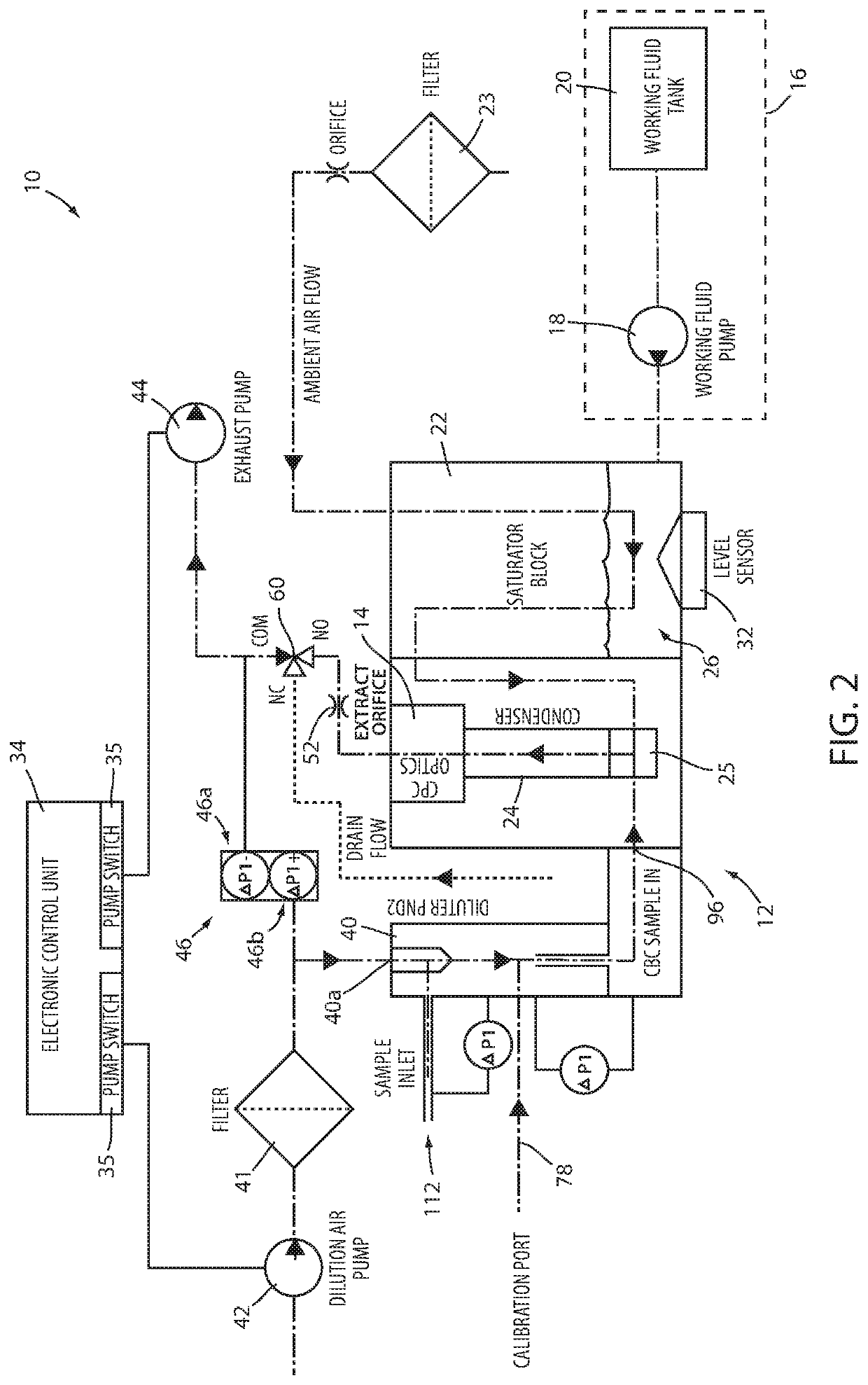

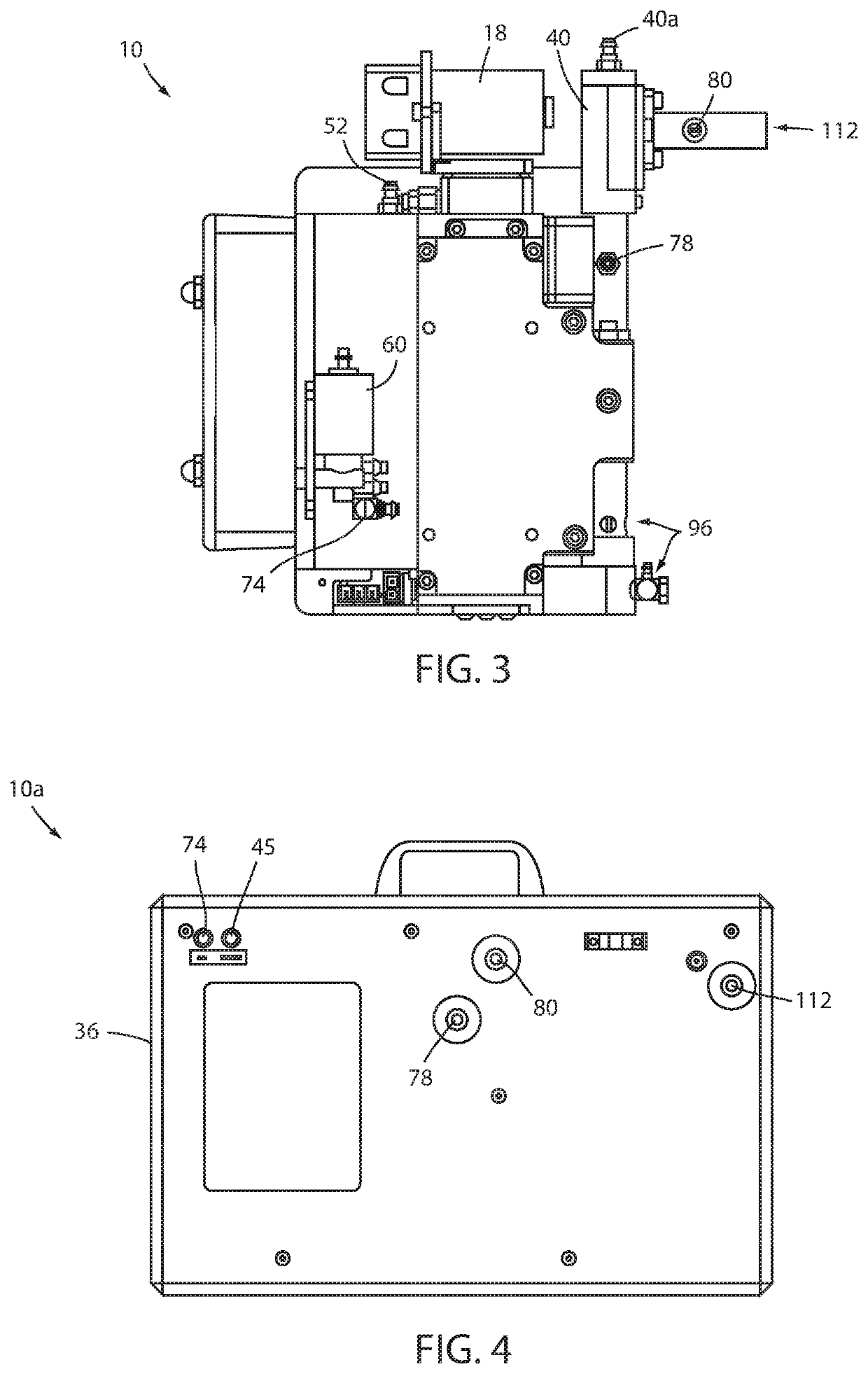

Particle concentration analyzing system and method

A particle concentration analyzing system for testing particle concentrations in a fluid sample, such as engine emission particle concentration present in the exhaust of an engine. The particle concentration analyzing system includes a condensation particle counter having a saturation chamber, a condenser, and a laser optic particle counter. The analyzing system further includes a working fluid tank, a working fluid pump, and a sampling probe. The system provides a robust analysis system for a user to test vehicle emissions without being highly trained on the device, as the device is protectedfrom misuse. A position sensitive sensor is used to ensure that the system is not damaged if the system is tipped over or placed in a position that would produce false results. Additional features include differential pressure sensors, a sealed and replaceable tamper resistant working fluid tank, a solvent recovery system, an anti-cheat device, and fluid purity sensors.

Owner:SENSITIVE OBJECT

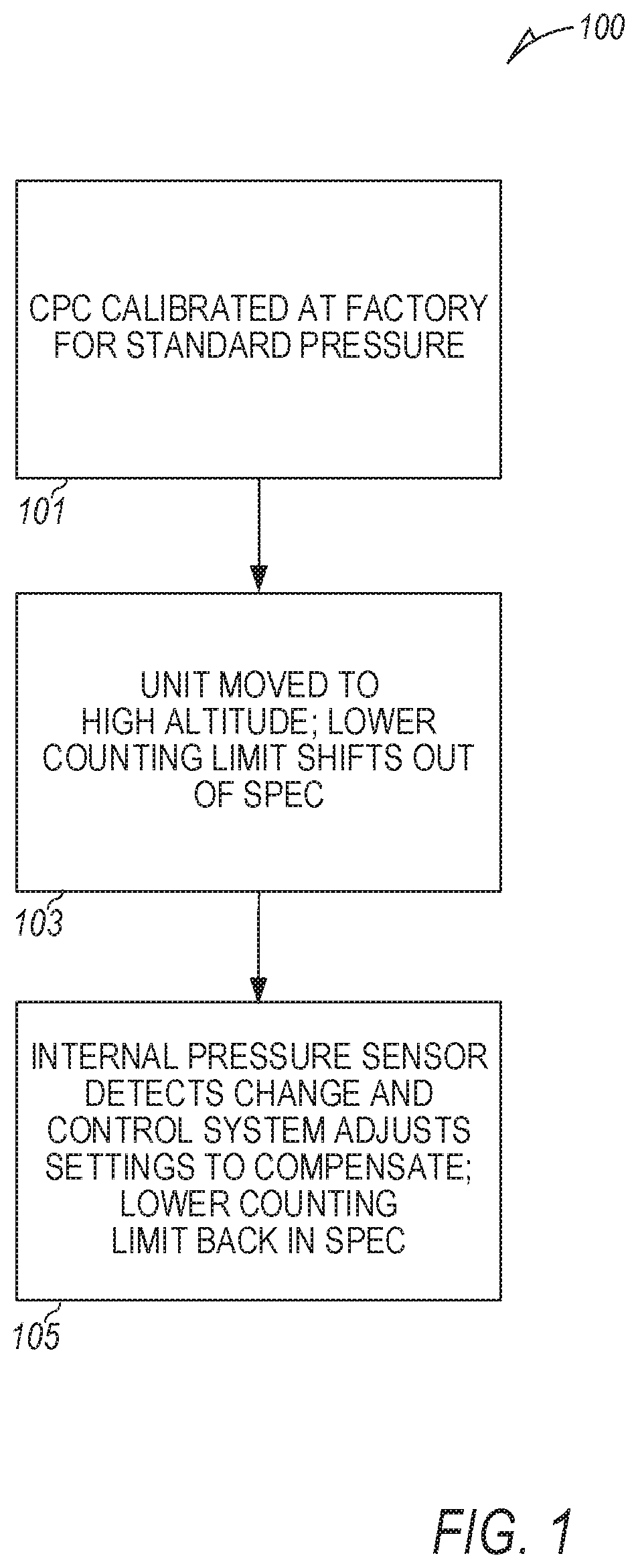

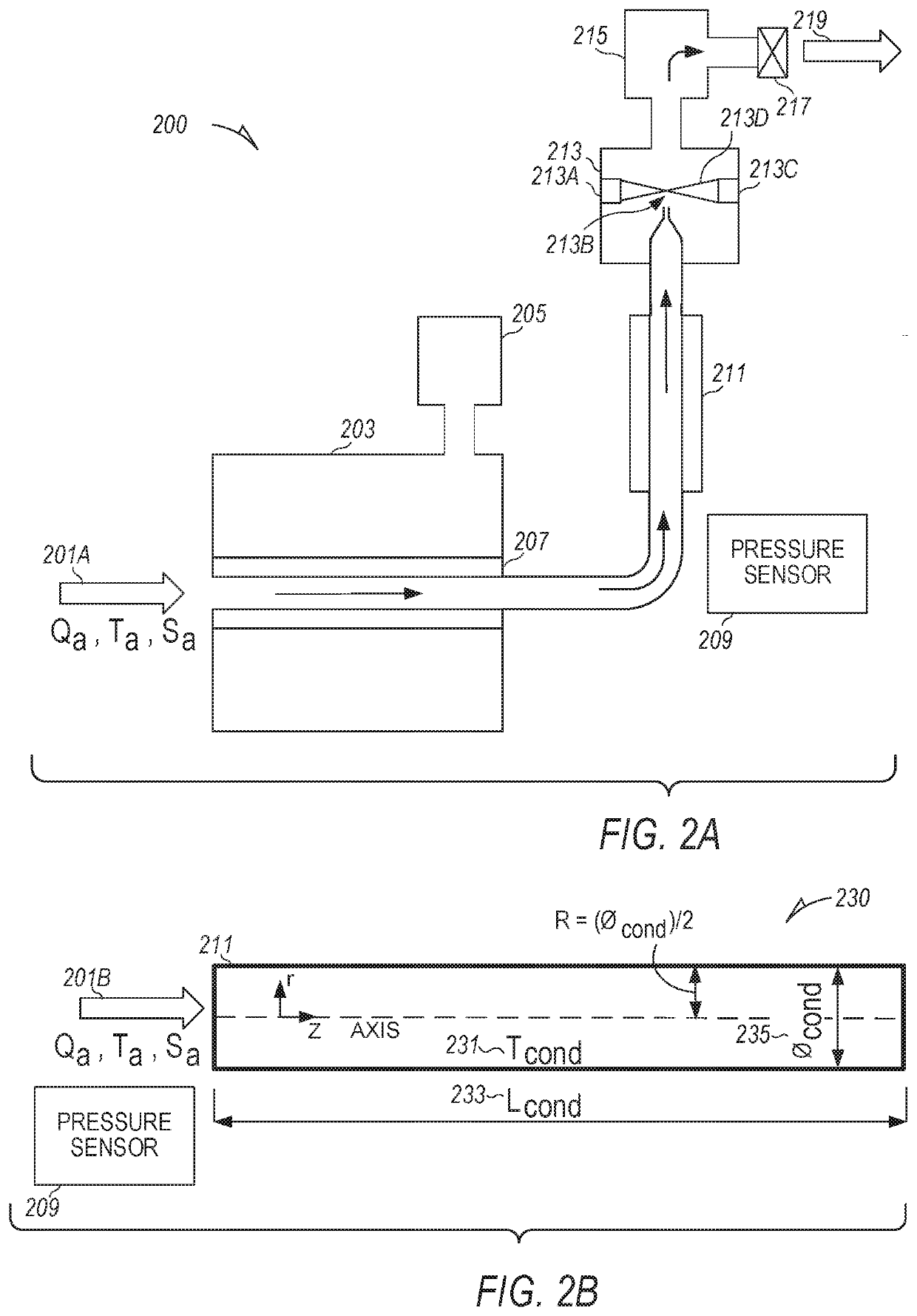

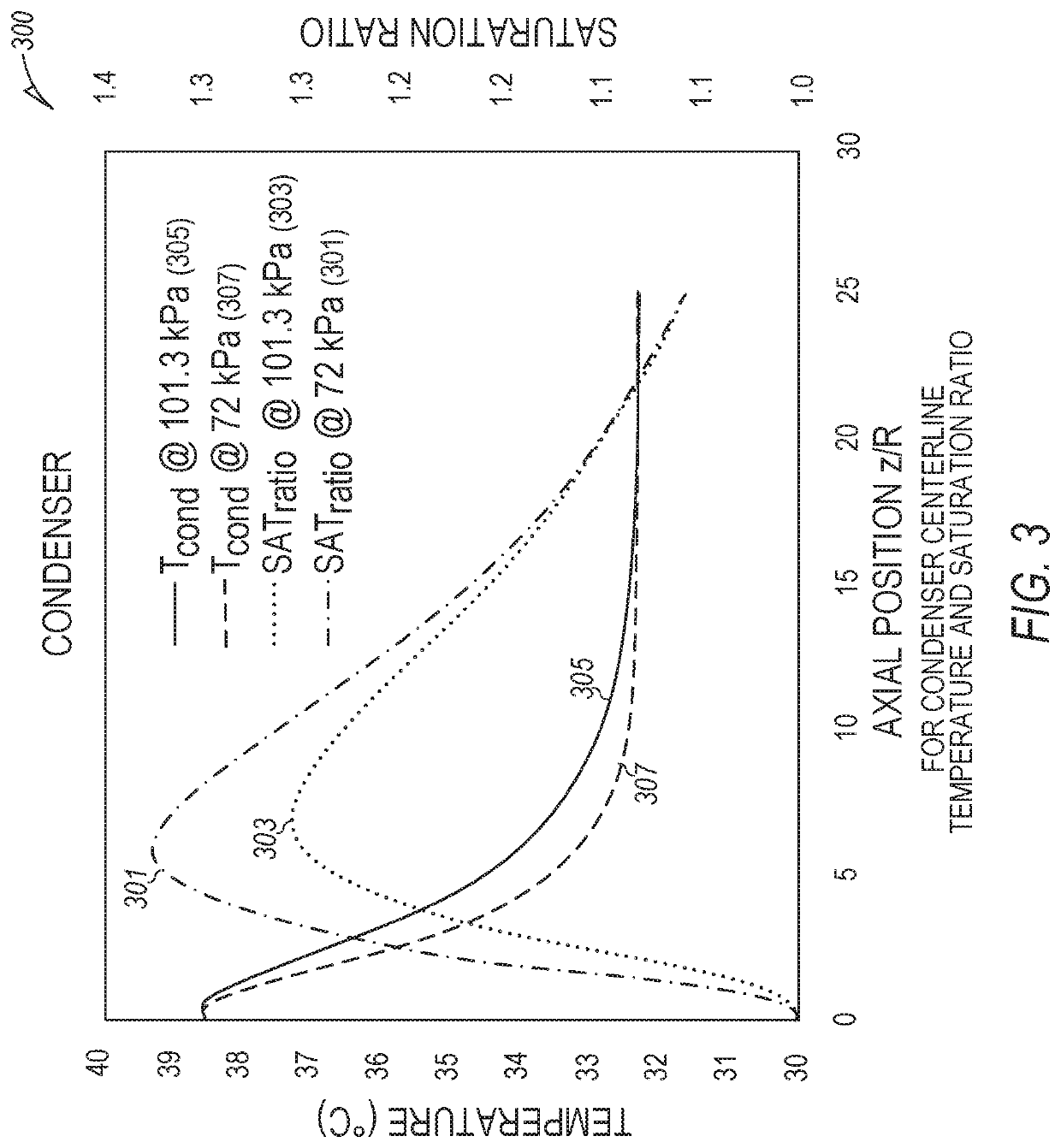

Condensation particle counter efficiency compensation for altitude

ActiveUS20190368996A1Nanoparticle analysisParticle suspension analysisSubject matterParticle physics

The disclosed subject matter compensates or corrects for errors that otherwise would be present when a measurement is made on a condensation particle counting system with the only difference causing the errors being absolute pressure. The difference in absolute pressure may be due to, for example, a change in altitude in which the condensation particle counting system is located. Techniques and mechanisms are disclosed to compensate for changes in particle count, at a given particle diameter, for changes in sampled absolute pressure at which measurements are taken. Other methods and apparatuses are disclosed.

Owner:TSI INC

Condensation particle counter

PendingCN111122419ASolve technical problems with complex mechanical structures and expensive pricesPrecise raiseIndividual particle analysisLevel indicators by physical variable measurementControl systemEngineering

A condensation particle counter can solve the technical problems that in an existing commercial CPC, a special liquid level instrument needs to be adopted, the mechanical structure is complex and theprice is high. The condensation particle counter is based on a saturation cavity, two ends of the saturation cavity comprise a gas inlet and a gas outlet respectively, and the condensation particle counter further comprises a butanol storage tank; the butanol storage tank is arranged on the bottom wall of the saturation cavity at a position close to the gas inlet; the condensation particle counterfurther comprises a thermistor and a control system, the thermistor is placed in the butanol storage tank, and the control system is arranged outside the saturation cavity; the butanol storage tank is arranged outside the saturation cavity; a butanol filling nozzle is used for filling butanol liquid, and the butanol filling nozzle is communicated with the butanol storage tank by arranging a liquid valve; the butanol filling nozzle is arranged on the top wall of the saturation cavity and is communicated with the interior of the saturation cavity; and the liquid valve is connected with the control system which controls the liquid valve to be opened and closed. By arranging the thermistor and the butanol storage tank, the detection and control functions of the liquid level can be completed;and the condensation particle counter has the advantages of simple structure, low cost and stable performance.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

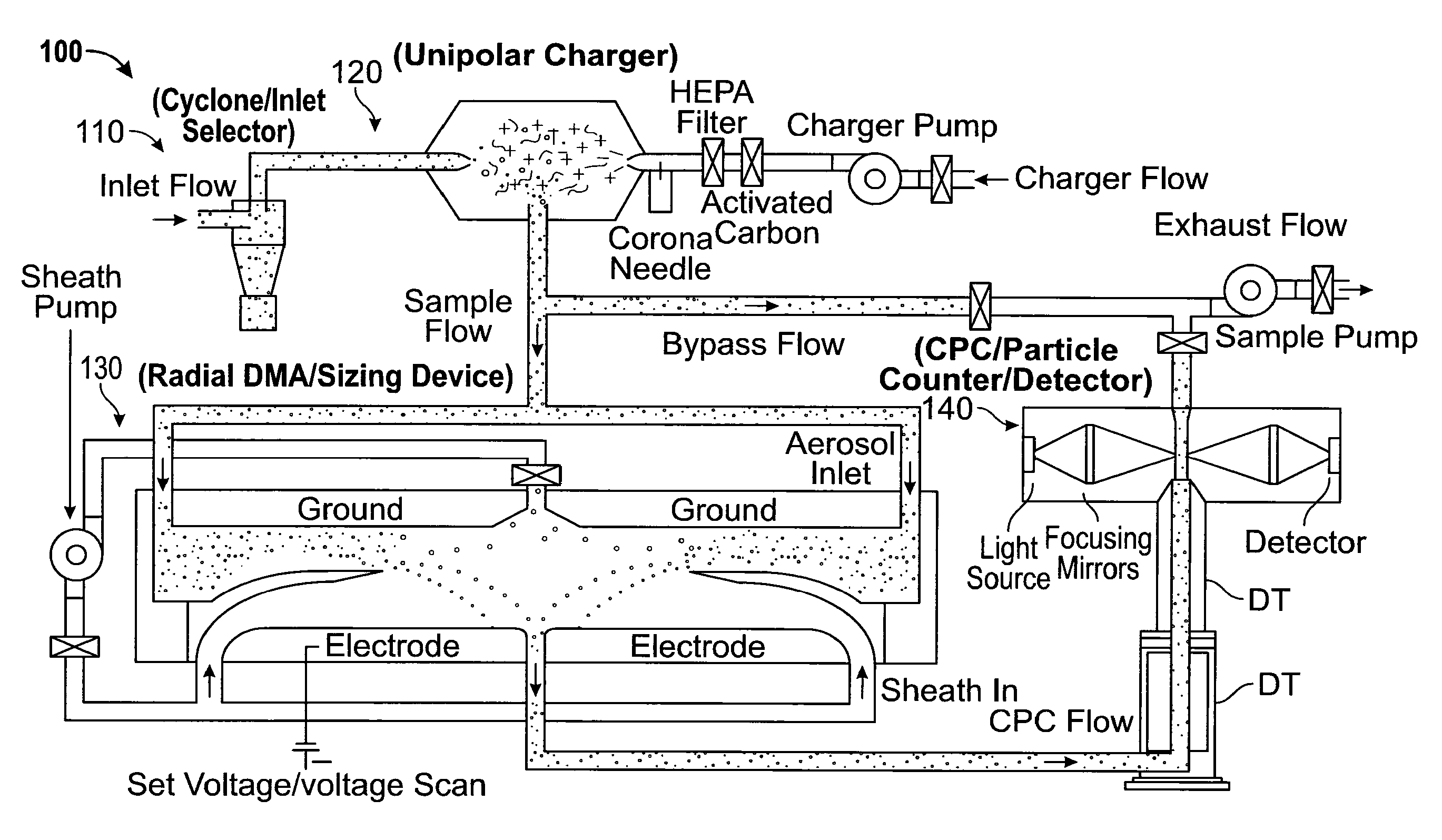

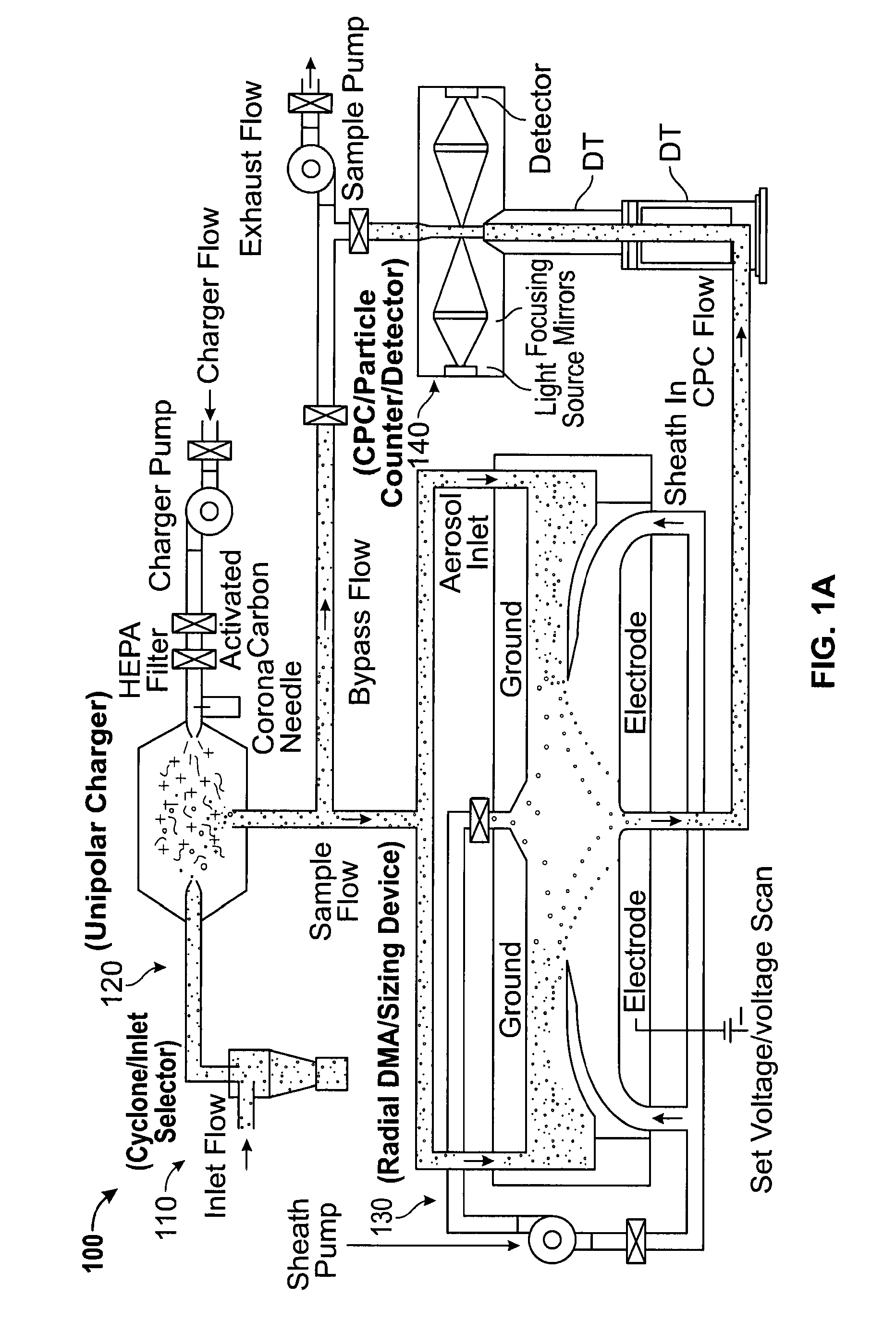

Instrument for sizing nanoparticles and a component therefor

ActiveUS9035242B2Easy to operateImprove portabilityTime-of-flight spectrometersNanoparticle analysisElectrical batteryEngineering

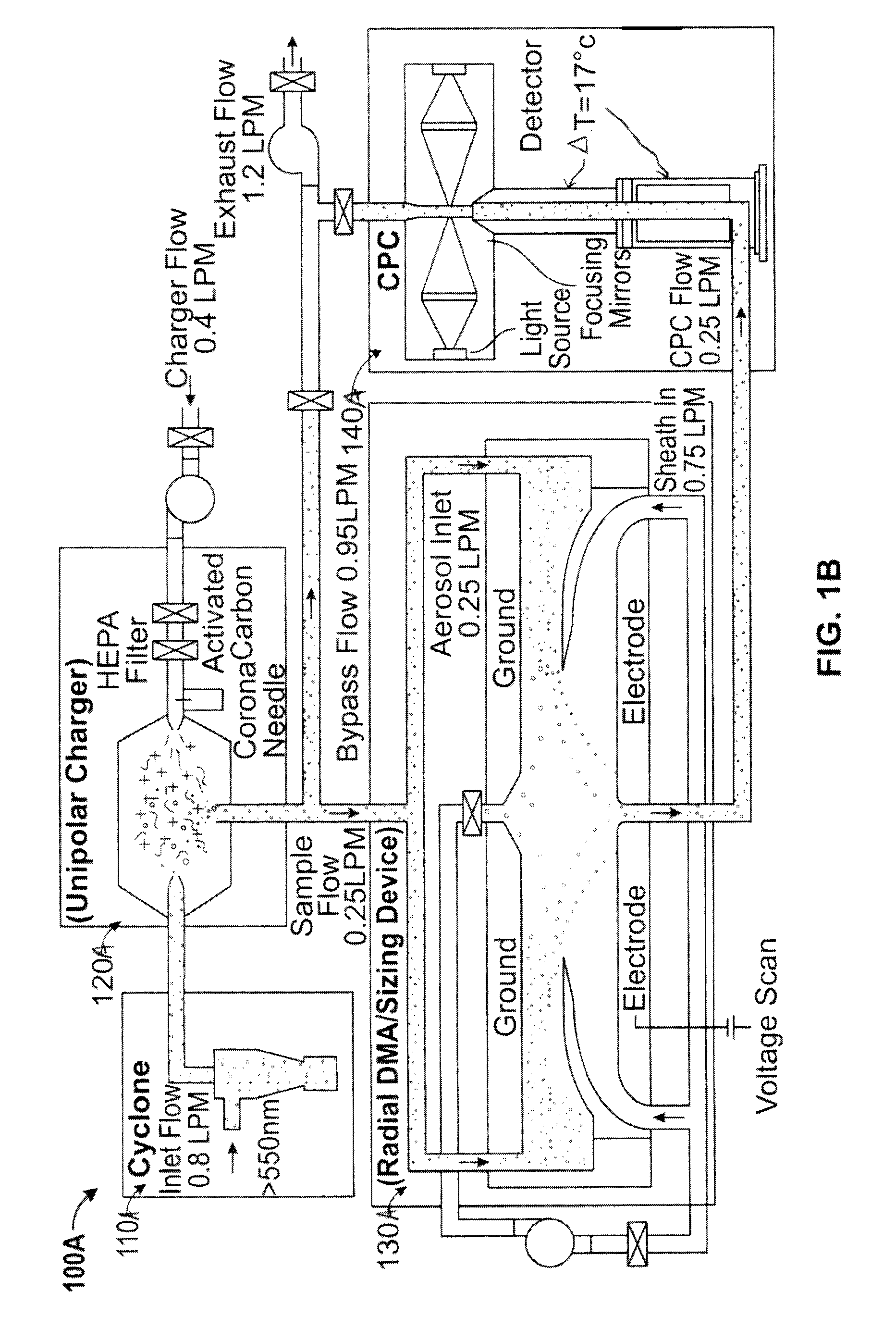

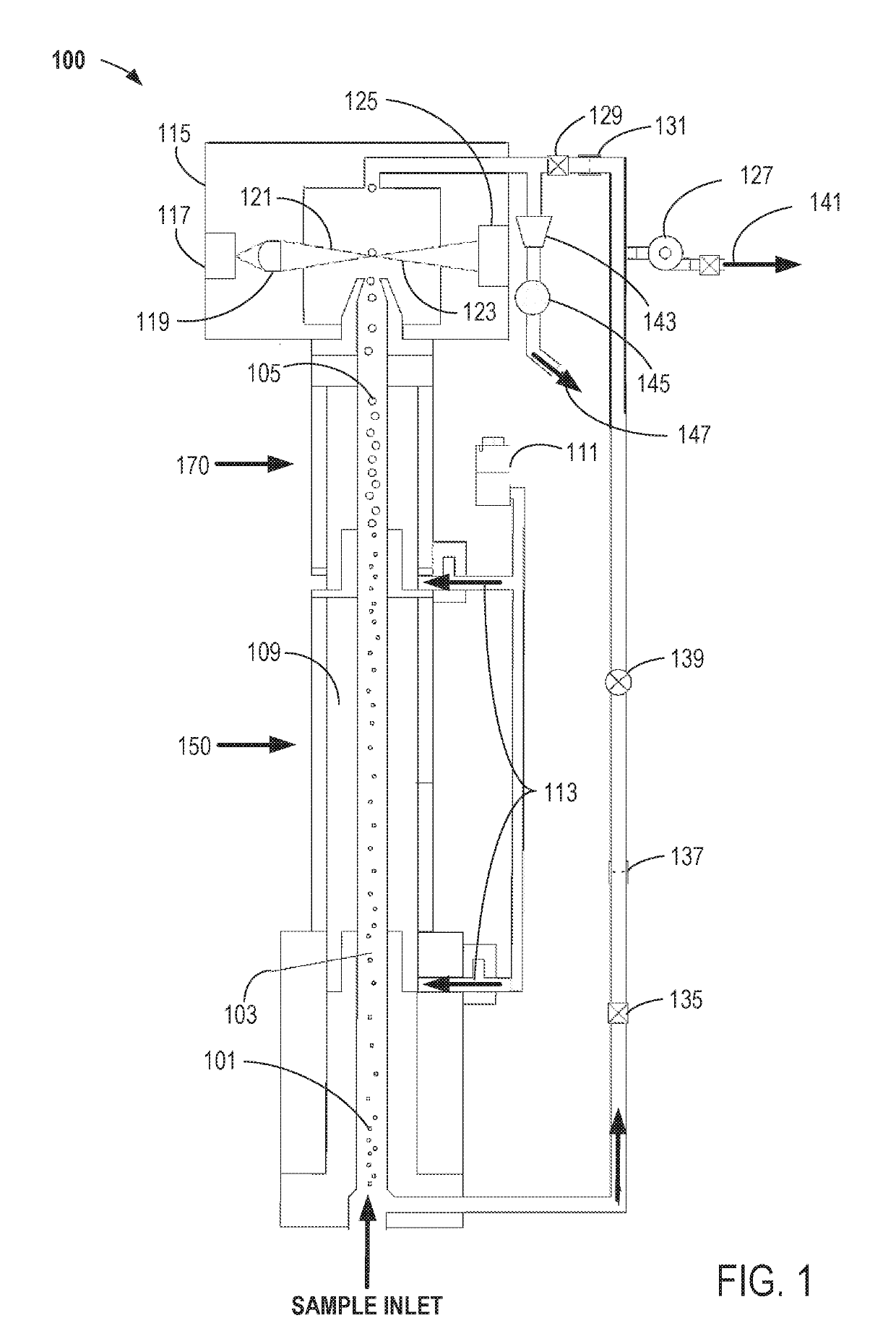

An improved nanoparticle sizing apparatus comprised of a unipolar charger operatively coupled to a radial differential mobility analyzer in combination with a condensation particle counter and powered by a power source such as a battery or solar cell, thereby providing a portable sizing device.

Owner:TSI INC

Condensation particle counter false count performance

ActiveUS10520414B2Investigating moving fluids/granular solidsParticle suspension analysisWater basedParticle counter

Various embodiments include methods of reducing false-particle counts in a water-based condensation particle counter (CPC). One embodiment of a method includes delivering water into one or more wicks, sensing an excess volume of water delivered to the wicks, collecting the excess volume of water into a collection reservoir, and draining the excess volume of water from the collection reservoir. Other methods and apparatuses are disclosed.

Owner:TSI INC

Particle concentration analyzing system and method

A particle concentration analyzing system for testing particle concentrations in a fluid sample, such as engine emission particle concentration present in the exhaust of an engine. The particle concentration analyzing system includes a condensation particle counter having a saturation chamber, a condenser, and a laser optic particle counter. The analyzing system further includes a working fluid tank, a working fluid pump, and a sampling probe. The system provides a robust analysis system for a user to test vehicle emissions without being highly trained on the device, as the device is protected from misuse. A position sensitive sensor is used to ensure that the system is not damaged if the system is tipped over or placed in a position that would produce false results. Additional features include differential pressure sensors, a sealed and replaceable tamper resistant working fluid tank, a solvent recovery system, an anti-cheat device, and fluid purity sensors.

Owner:SENSORS

Reducing false counts in condensation particle counters

ActiveUS10578539B2Individual particle analysisParticle suspension analysisEngineeringComputational physics

Various embodiments include methods and apparatuses to reduce false-particle counts in a water-based condensation particle counter (CPC). In one embodiment, a cleanroom CPC has three parallel growth tube assemblies. A detector is coupled to an outlet of each of the three parallel growth tube assemblies, and is used to compare the particle concentrations measured from each of the three growth tube assemblies. An algorithm compares the counts from the three detectors and determines when the particles counted are real and when they are false counts. Any real particle event shows up in all three detectors, while false counts will only be detected by one detector. Statistics are used to determine at which particle count levels the measured counts are considered to be real versus false. Other methods and apparatuses are disclosed.

Owner:TSI INC

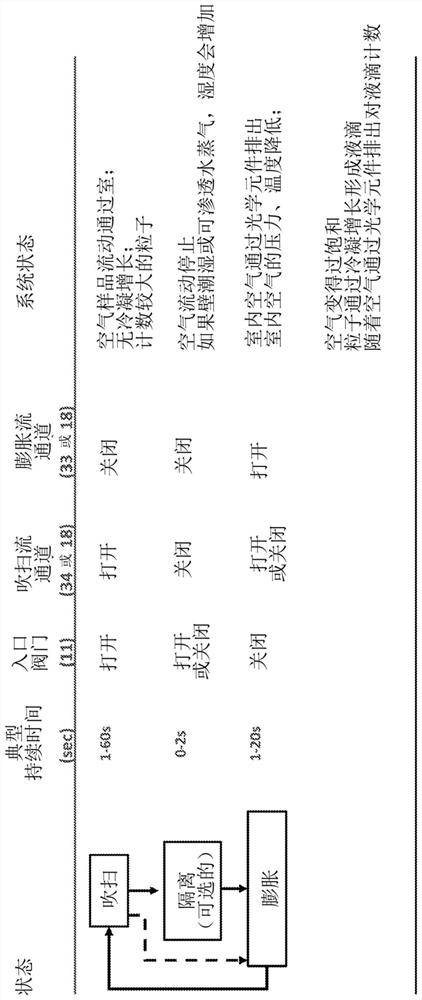

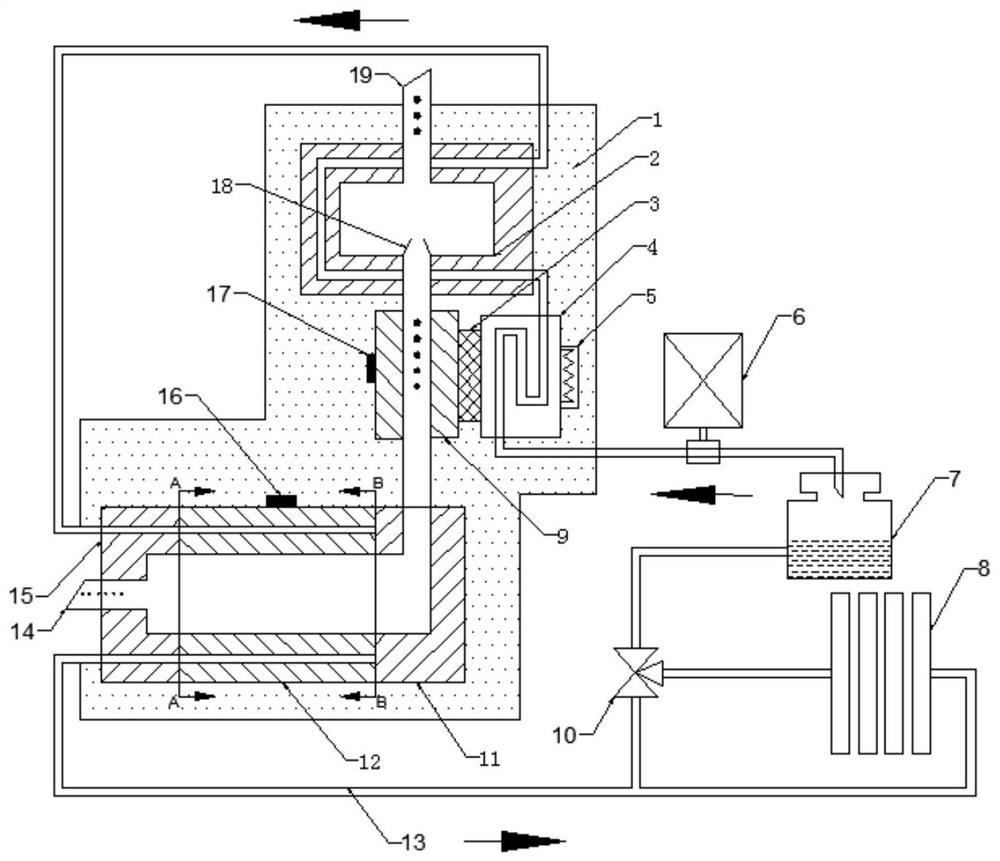

Pulsed condensation particle counter

A method and apparatus to create water vapor supersaturation and particulate counts from an air sample. The method and apparatus include introducing an air sample into a chamber by passing a flow into the chamber through the inlet by pumping at the outlet. The method further includes closing the inlet while continuing the pumping to exhaust the air sample from the chamber through the outlet. The pumping is performed at a rate operable to reduce pressure inside the chamber such that the air sample in the central portion of the chamber cools, and water vapor from walls of the chamber has time to diffuse into the air sample in the chamber from the walls. The cycles are repeated by continuously repeating the introducing and closing. The walls of the chamber may be wetted or dry.

Owner:AEROSOL DYNAMICS INC

A temperature control device for condensation particle counter

ActiveCN109323976BGood for uniformity of diffusionControl consistencyTemperatue controlIndividual particle analysisTemperature controlOptical cavity

A temperature control device for a condensation particle counter can solve the technical problems of large volume and power consumption of the temperature control system of the condensation particle counter and poor applicability. A Peltier is arranged in the condensation chamber, a condensation chamber thermistor is arranged in the condensation chamber, a saturation chamber thermistor is arranged in the saturation chamber, a heat sink is arranged on the hot surface of the Peltier; a cooling liquid circuit is also included system, the cooling liquid loop system includes a cooling liquid storage tank, a liquid pump and a return line, the cooling liquid storage tank is connected to the liquid pump through the return line, and the return line is drawn from the liquid pump, passes through the heat sink, and then passes through the The optical cavity is connected to the saturation cavity; a temperature control circuit is also included, and the condensation cavity thermistor, the cavity thermistor, the Peltier and the liquid pump are respectively connected with the temperature control circuit. The invention not only has a fast temperature control speed, uniform heating of the saturation chamber and the optical chamber, is beneficial to the uniformity of the diffusion of the butanol vapor, controls the consistency of particle growth, and greatly reduces power consumption and volume.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com