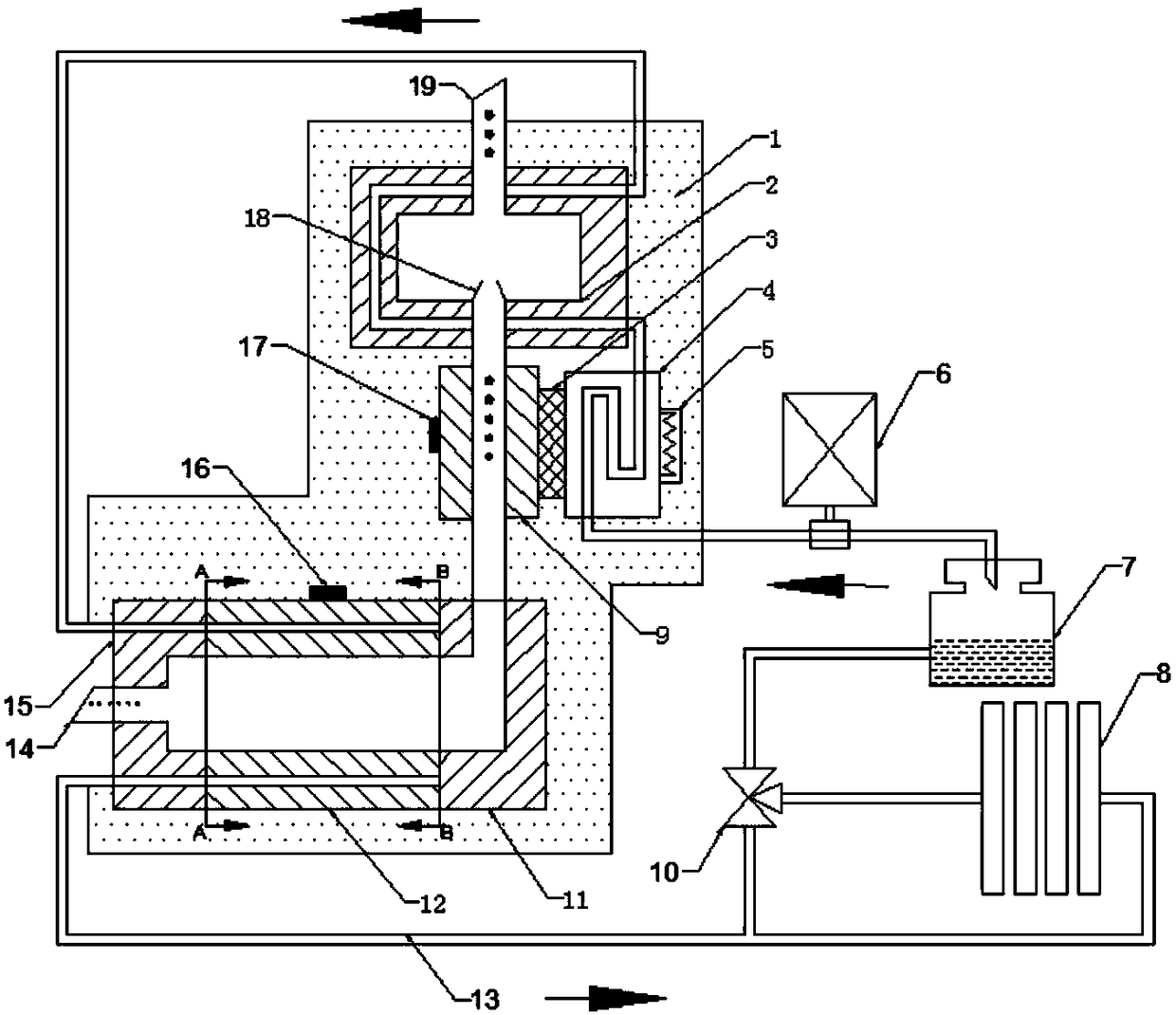

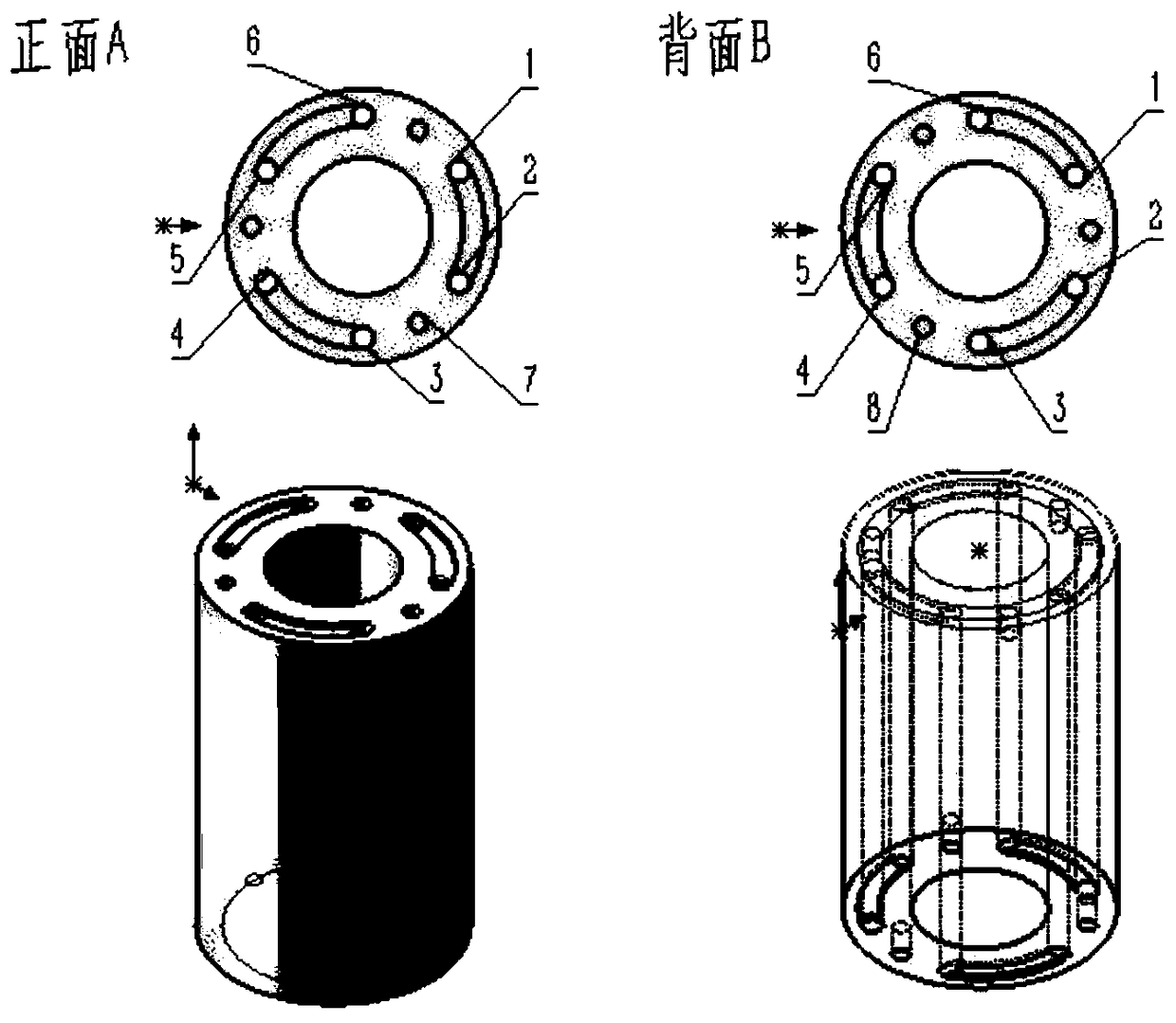

Temperature control device for condensation particle counter

A particle counter and temperature control device technology, applied in the direction of temperature control, measuring devices, instruments, etc., can solve the problems of poor applicability, large volume and power consumption of the temperature control system, and achieve uniformity of diffusion, uniform heating, and reduced power consumption. The effect of consumption and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the objectives, technical solutions, and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be described clearly and completely in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of the embodiments of the present invention, not all the embodiments.

[0020] Because in butanol CPC, particles with a measurable diameter are generated by extracting particles in the air and making them sequentially enter the saturation chamber and the condensation chamber. The working temperature of the saturated cavity is between 35℃-40℃ and needs to be heated by a heating plate. The working temperature of the optical cavity is around 40℃ and also needs to be heated by a heating plate. The condensing cavity works at around 10℃ and needs to be heated by Parr. The three temperature control systems usually ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com