Method and assembly comprising condensation particle counter, operating fluid, and carrier gas

A particle counter and moving object technology, applied in sampling devices, measuring devices, instruments, etc., can solve problems such as reducing the measurement accuracy and service life of HT-CPC, saturator damage, and not allowing stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

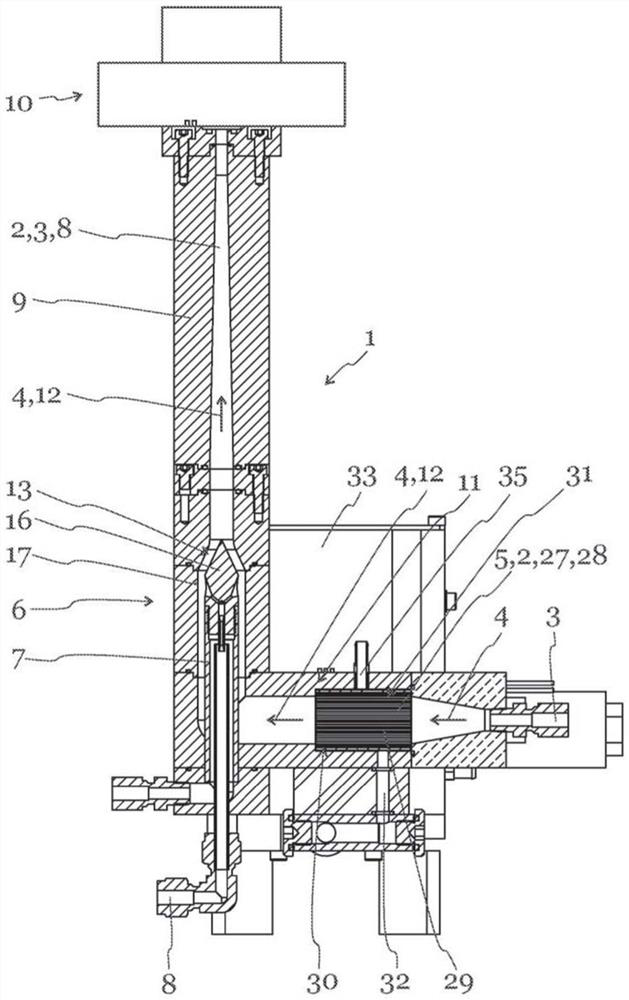

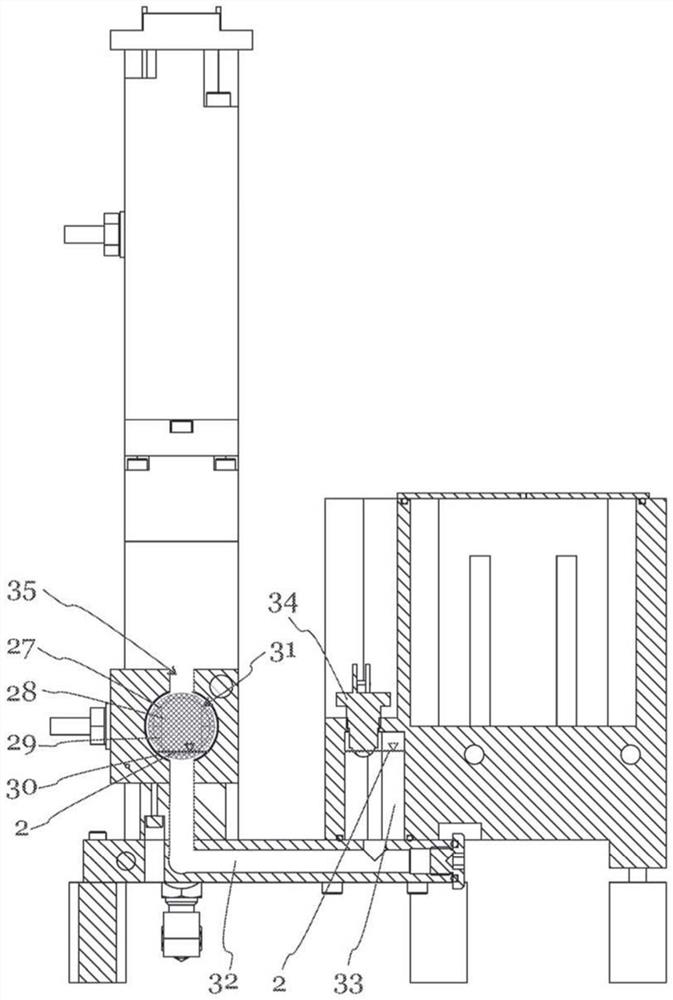

[0043] figure 1 A possible embodiment of a condensation particle counter 1 or a design of a condensation particle counter 1 with operating object 2 , carrier gas 3 and / or measurement aerosol 8 is shown.

[0044] During normal operation, carrier gas 3 flows through condensation particle counter 1 along main flow path 4 . The carrier gas 3 is a waste gas-free and oxygen-free gas or gas mixture.

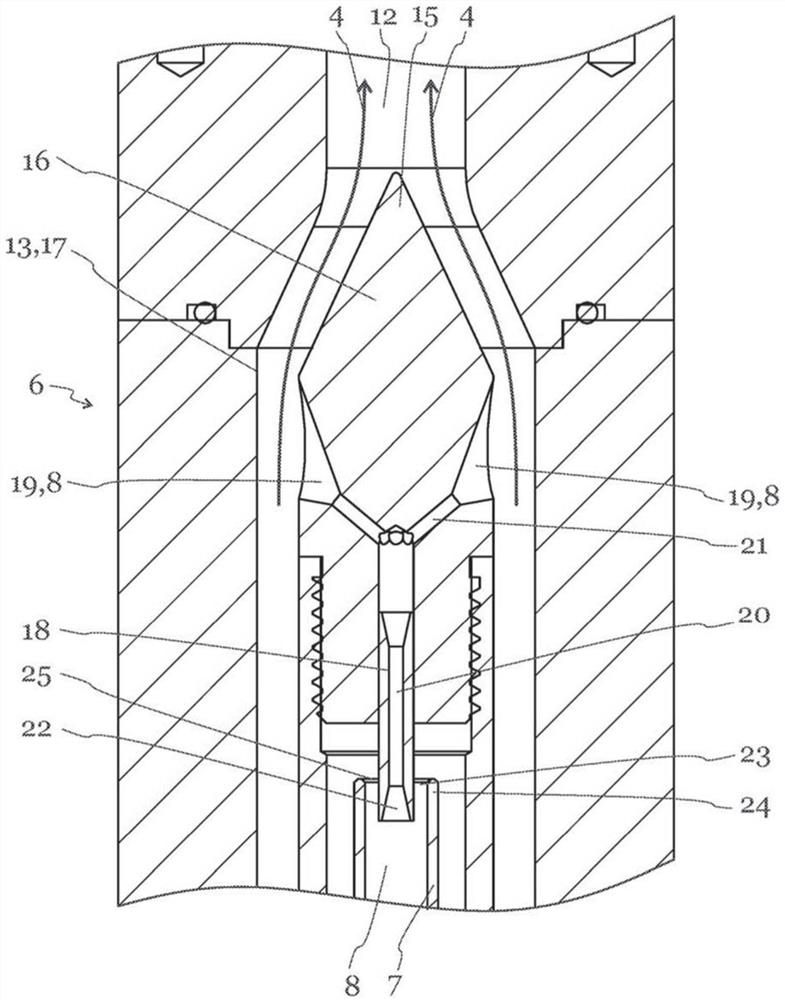

[0045] Here, the carrier gas 3 flows through a saturator 5 in which the carrier gas 3 is enriched or saturated with the operating substance 2 . In the present embodiment, a nozzle arrangement 6 is arranged downstream of the saturator 5 along the main flow path 4 . The nozzle arrangement 6 comprises a measuring aerosol feed line 7 for feeding a measuring aerosol 8 into the enriched or saturated carrier gas 3 . In an advantageous embodiment, the measurement aerosol 8 is an unconditioned partial flow of the exhaust gas of a test object, for example an internal combustion engine, an inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com