Ultrasonic vibration atomizer

A technology of ultrasonic vibration and atomizer, applied in the direction of spraying device, liquid spraying device, etc., can solve the problems of uneven droplet diameter, large atomized particle diameter, low atomization efficiency, etc., and achieve adjustable atomization volume , large power capacity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

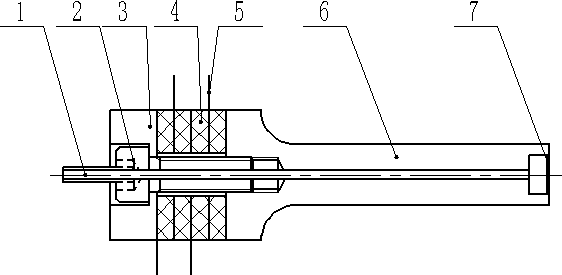

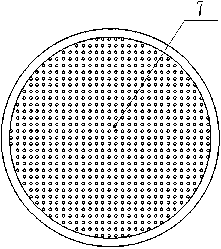

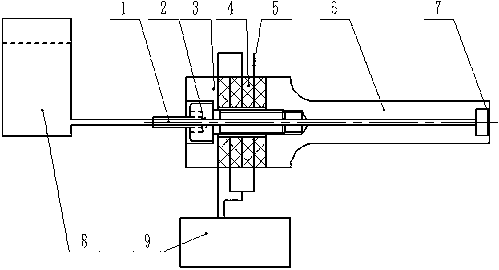

[0033] like image 3 As shown, the embodiment of the present invention adopts piezoelectric ceramic sandwich structure, including liquid delivery pipe (1), bolt (2), rear cover plate (3), electrode sheet (4), piezoelectric ceramic sheet (5) , the horn (6) and the mesh vibrating plate (7), the rear cover (3), the electrode sheet (4), the piezoelectric ceramic sheet (5) and the variable The rod (6) is sequentially sleeved on the bolt (2), the rear cover (3), the electrode sheet (4), the piezoelectric ceramic sheet (5) and the The horn (6) is connected and clamped by the bolt (2), the liquid delivery pipe (1) is connected to the rear end of the bolt (2), and the mesh vibrating plate (7) is set on The front end of the horn (6). The liquid delivery pipeline (1) is connected with a certain amount of liquid supply device (8). The electrode sheet of the ultrasonic vibrating nebulizer is connected with an ultrasonic power supply (9).

[0034] The piezoelectric ceramic transducer se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com