Overprint plate making method

A printing plate, image technology, applied in the direction of editing/combining graphics or text, etc., can solve the problems of broken lines and jagged edges, affecting the quality of printed products, unable to meet the requirements of high quality of printed products, etc. Indentation and press accuracy errors, improving product quality and yield, reducing the effect of tonal depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

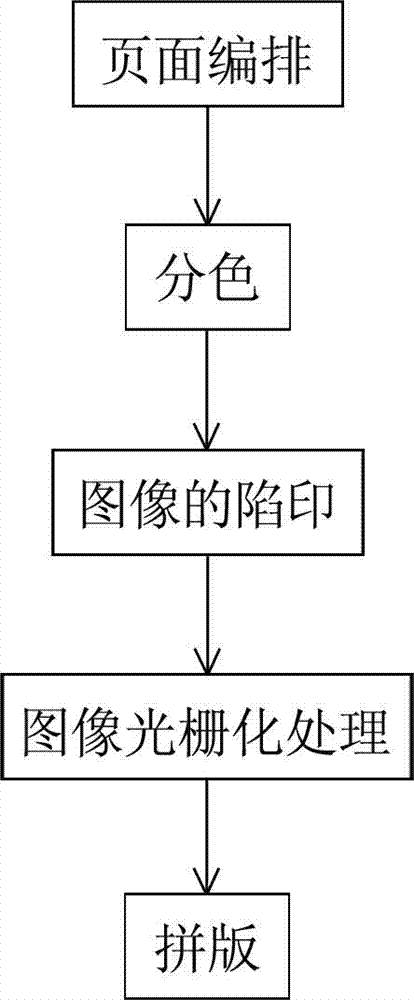

[0020] As shown in the accompanying drawings, this overprint plate-making method includes the following steps:

[0021] Step (1) Page layout: In the FreeHand typesetting software, the insertion of barcode graphics and images and the editing of texts such as smoking is harmful to health are completed to form a single page;

[0022] Step (2) Color separation: Complete the color separation of the image in the color separation software, which are eight printing colors such as white, black, cyan, magenta, yellow, special background color, dark brown and light brown;

[0023] Step (3) Image trapping: Dark brown and light brown are subjected to the trapping process of increasing net and reducing color, the light brown image is placed on the layer above the dark brown image, and the overprint size of the light brown image and the dark brown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com