Method for manufacturing plane surface medium resistance discharging light source

A technology of dielectric barrier discharge and manufacturing method, applied in the field of electric vacuum, can solve the problems of uneven thickness and complicated process, and achieve the effect of simple and accurate manufacturing process and reduction of printing times.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] a. Fabrication of the lower glass substrate 1:

[0031] 1) Use 2g of decontamination powder, analytically pure alcohol, and deionized water to perform ultrasonic cleaning on the glass substrate. There is no strict ratio requirement for alcohol and deionized water. After cleaning, the glass surface does not leave oil stains or stains, and the surface is smooth. The water film is required to be intact.

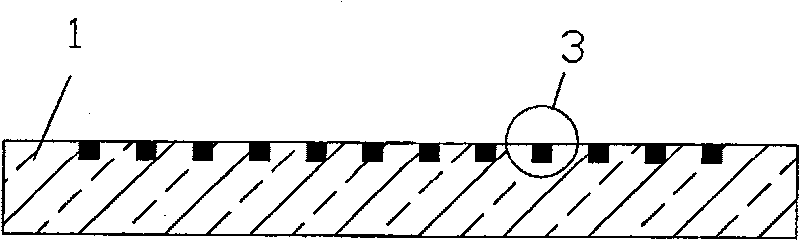

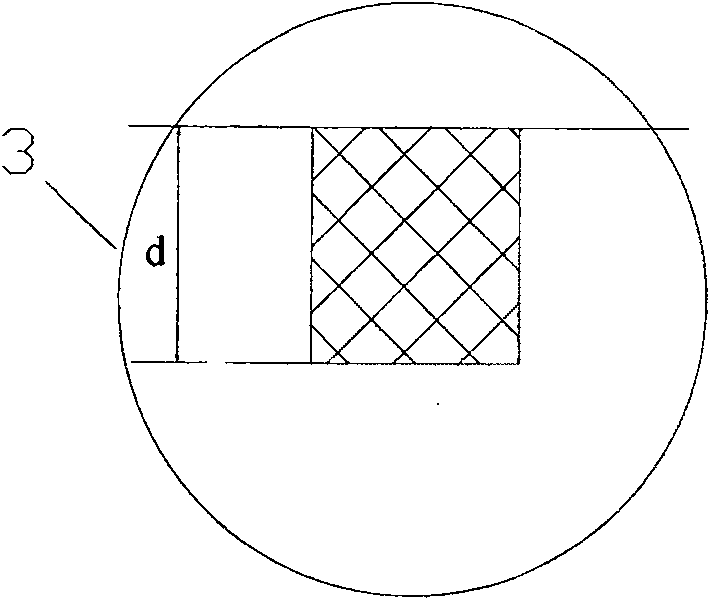

[0032] 2) On the lower glass substrate 1 glass, coat a layer of photosensitive glue with a thickness of 20 microns to resist the corrosion of glass etching solution, expose and develop through a mask plate, and form an electrode pattern, as shown in the attached image 3 shown;

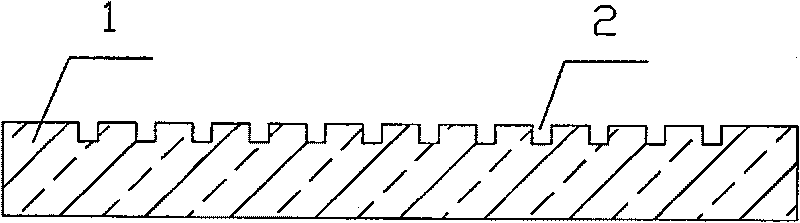

[0033] 3) Etching the lower substrate glass with a mixture of 40% hydrofluoric acid and pure water in a weight ratio of 4:1, and then peeling off the remaining photosensitive adhesive with a degumming solution, forming a and Groove 2 with consistent electrode pattern, as attached figure 1 show...

Embodiment 2

[0048] a. Fabrication of the lower glass substrate 1:

[0049] 1) Use 2 g of decontamination powder, analytically pure alcohol, and deionized water in sequence to ultrasonically clean the lower glass substrate.

[0050] 2) Coating a layer of 30 micron-thick photosensitive glue resistant to corrosion by glass etching solution on the glass of the lower glass substrate 1, exposing and developing through a mask to form an electrode pattern;

[0051] 3) Etching the glass of the lower glass substrate 1 with a mixture of 40% hydrofluoric acid and pure water in a weight ratio of 4:1, and then peeling off the remaining photosensitive adhesive with a degumming solution to form a Groove 2 consistent with the electrode pattern;

[0052] 4) After aligning the screen plate with the electrode pattern and the etched lower glass substrate with the “cross” alignment code, print the electrode in the groove 2 of the etched lower glass substrate, and place the printed electrode The lower glass s...

Embodiment 3

[0066] a. Fabrication of the lower glass substrate 1:

[0067] 1) Use 2 g of decontamination powder, analytically pure alcohol, and deionized water in sequence to ultrasonically clean the lower glass substrate.

[0068] 2) Coating a layer of 25 micron-thick photosensitive glue resistant to corrosion by glass etching solution on the glass of the lower glass substrate 1, exposing and developing through a mask to form an electrode pattern.

[0069] 3) Etching the lower glass substrate 1 glass with a mixture of 40% hydrofluoric acid and pure water in a weight ratio of 4:1, then peeling off the remaining photosensitive adhesive with a degumming solution, and placing it on the lower glass substrate A groove 2 consistent with the electrode pattern is formed;

[0070] 4) After aligning the screen plate with the electrode pattern and the etched lower glass substrate with the “cross” alignment code, print the electrode in the groove 2 of the etched glass substrate, and place the printe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com