Screen printing method with tag adhering in mould

A screen printing and labeling technology, used in screen printing machines, printing, printing machines, etc., can solve the problems of inaccurate screen clamping, the last one may be biased, and poor reliability, and achieve a high yield rate. , reducing the number of times, and the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, the present invention will be further described in detail based on the drawings and embodiments:

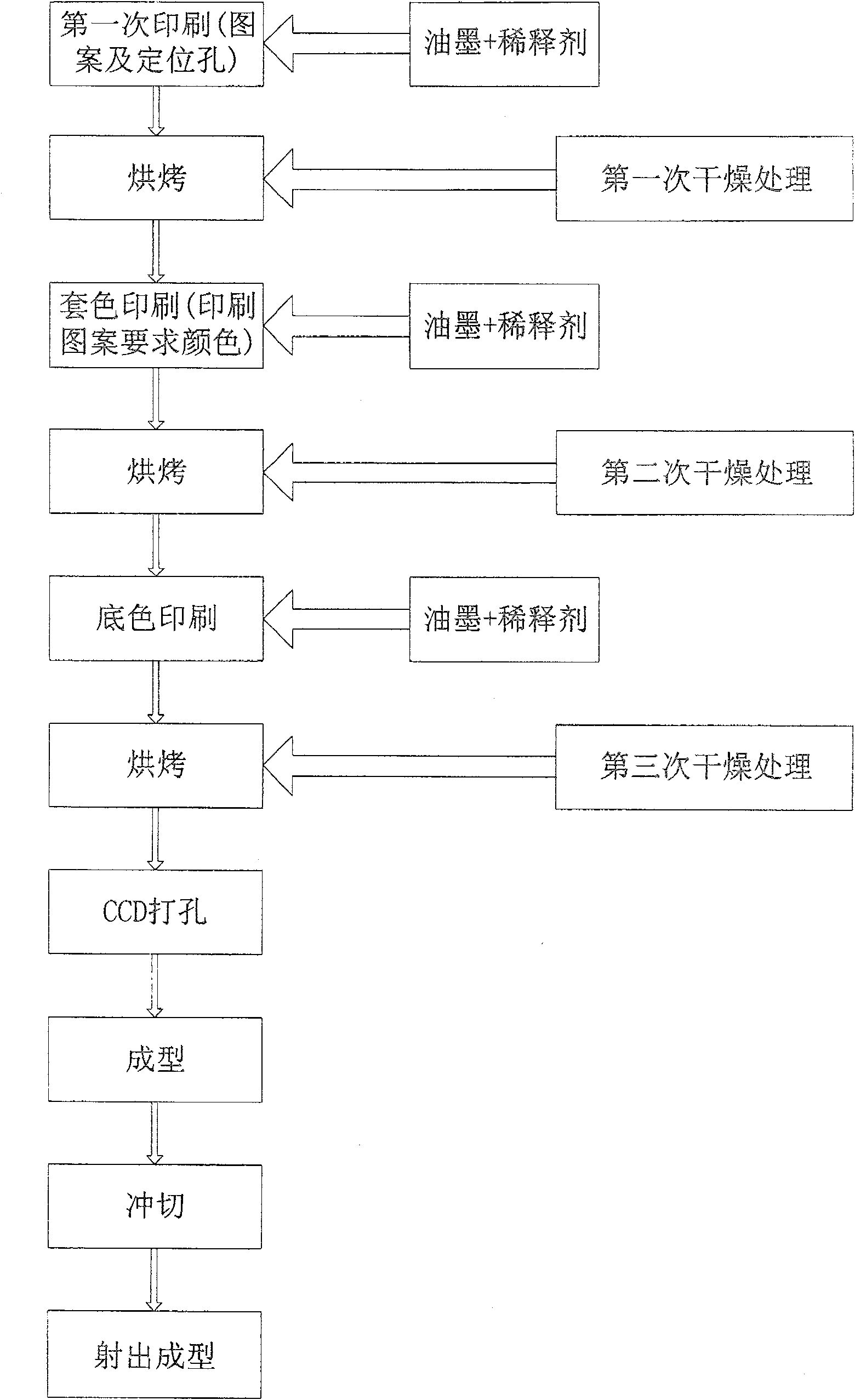

[0018] according to figure 1 As shown, the screen printing method of the present invention adopts the following steps:

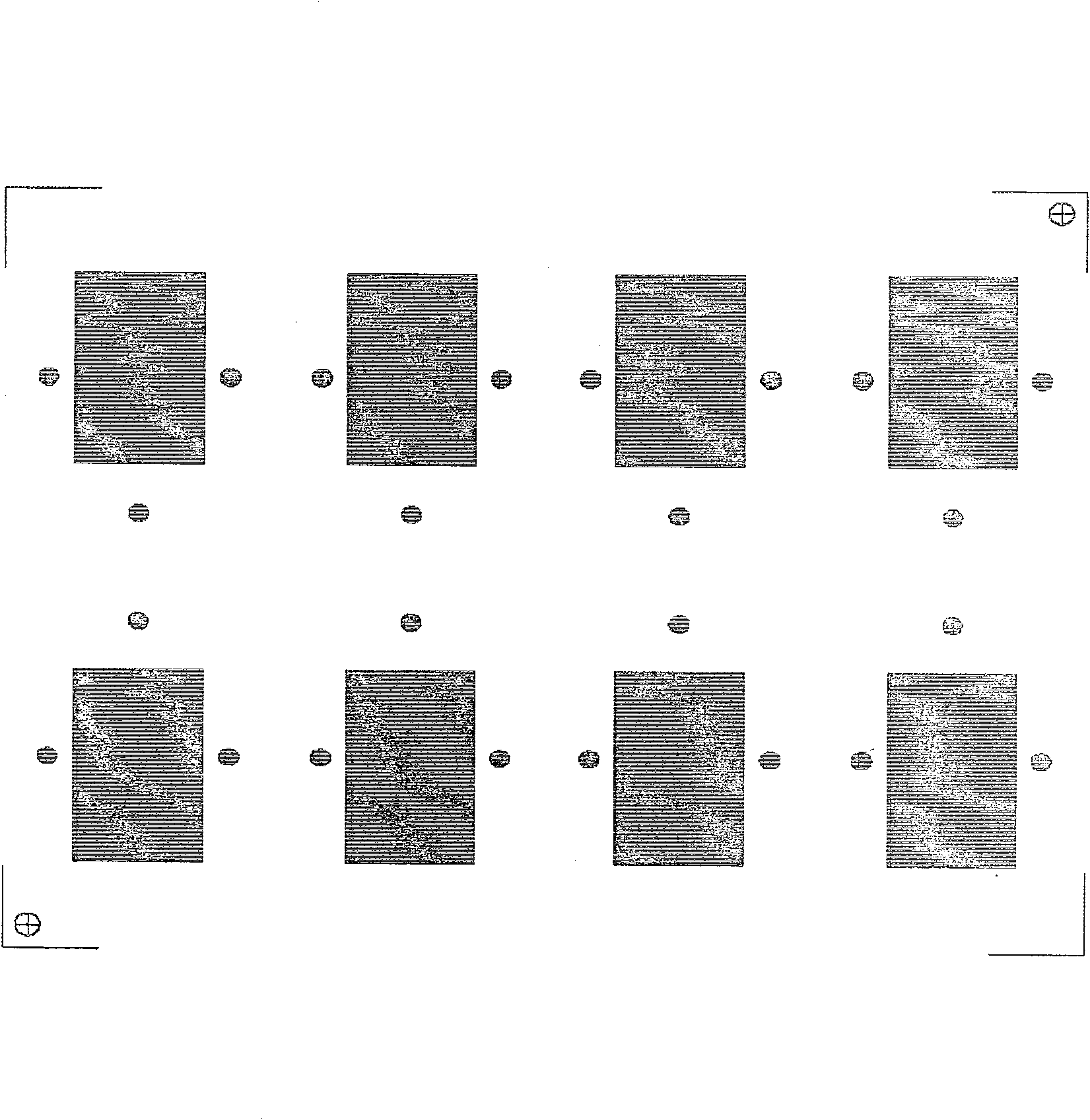

[0019] 1. Use an automatic screen printing machine to perform the first screen printing. Use ink and thinner to print the printing pattern together with positioning holes and screen alignment holes on the sheet, such as figure 2 As shown, the solid rectangle is the printing pattern, the solid circle is the positioning hole, and the screen alignment hole is located at the opposite corners of the screen, and it is a circle with a cross in the middle.

[0020] 2. Carry out the first drying process for baking.

[0021] 3. The used screen is positioned through the alignment holes of the screen, and ink and thinner are used for the second color printing.

[0022] 4. Carry out the second drying process for baking.

[0023] 5. The screen used is positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com