Printer and paper conveying mechanism thereof

A paper feeding mechanism and printing machine technology, applied in the field of cardboard printing, can solve the problems of high energy consumption and unfavorable energy saving, and achieve the effect of improving the printing yield, reducing waste, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

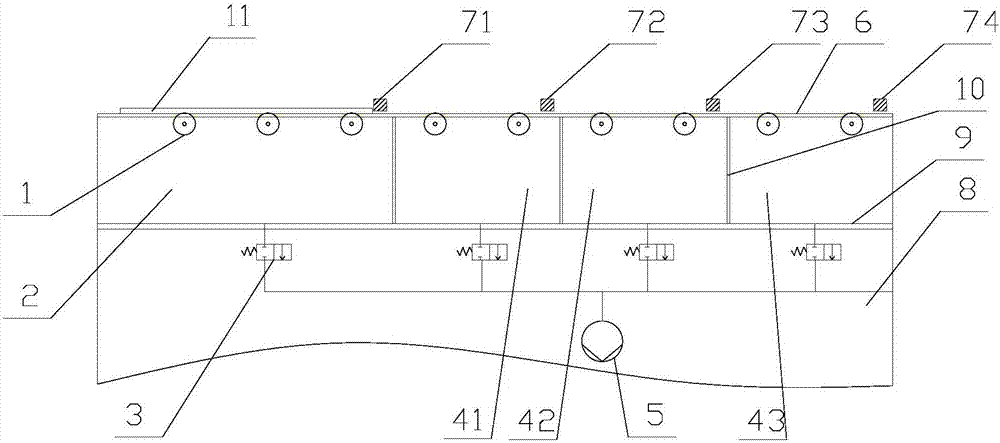

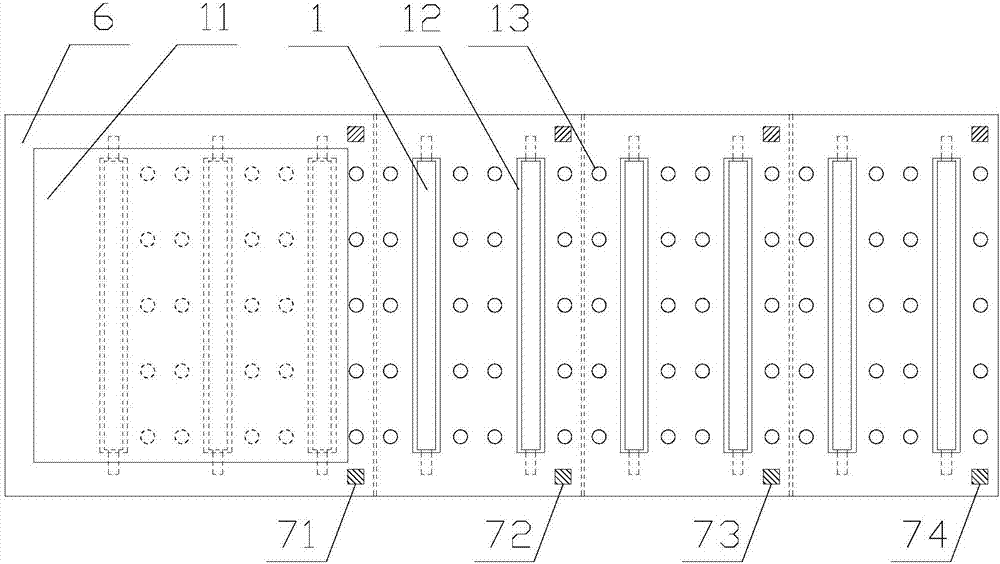

[0024] Such as figure 1 , 2 As shown, the paper feeding mechanism in this example includes a frame 8, a bellows part, a conveying part, an exhaust part and a detection part; On the top of the frame 1, there are a plurality of rectangular grooves 12 and a plurality of air suction ports 13 arranged side by side not only successively but also transversely to the conveying direction of the cardboard 11 on the paper feeding table 6; the air suction ports 13 are circular; The quantity is consistent with the number of rectangular grooves 12 provided on the paper feeding table 6, the scroll wheel 1 is installed under the rectangular groove 12 on the paper feeding table 6, and the outer edge of the rolling wheel 1 passes through the paper feeding table 6 The rectangular groove 12 on the top exposes the upper edge of the paper feeding table 6; the driving mechanism drives the scroll wheel 1 to rotate; the upper edge of the outer circular surface of the scroll wheel 1 is on the same hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com