Patents

Literature

31results about How to "Avoid Manual Testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

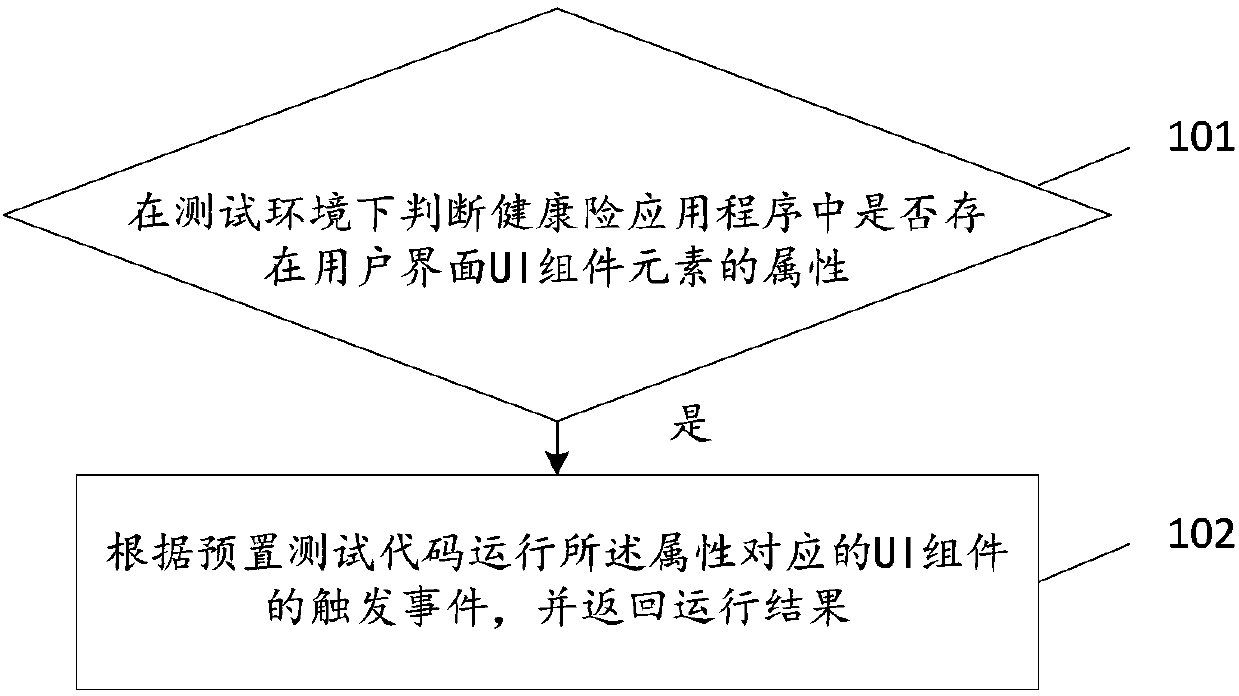

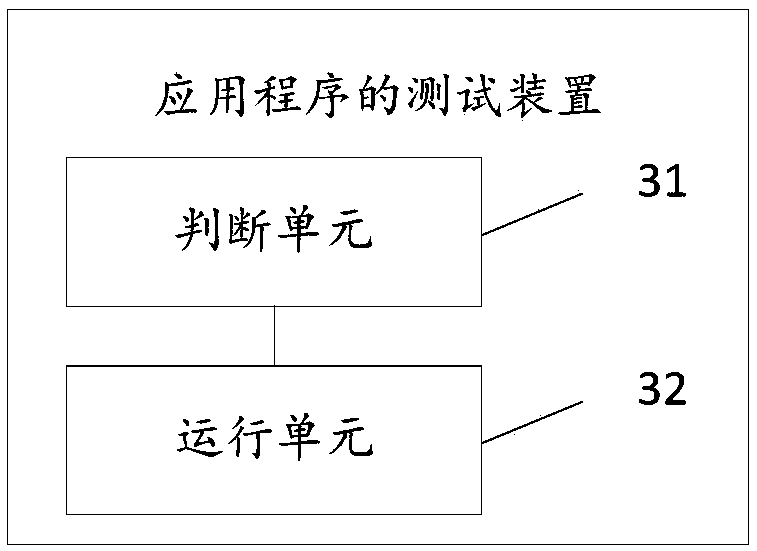

Application test method and apparatus

InactiveCN107704396AImplement automated testingReduce test effectSoftware testing/debuggingSoftware engineeringApplication software

The invention discloses an application test method and apparatus, relates to the technical field of software testing, and mainly aims to solve the problems that during manual testing of an application, developed in a wechat applet, of an existing insurance type electronic commercial product, due to input of a large amount of data such as identity numbers, ages, insurance fees, insurance products and the like, manual testing of pure manpower cannot meet the iterative speed of the electronic commercial product, a large amount of manpower resources are wasted, and the test effect is reduced. According to the main technical scheme, whether attributes of a user interface (UI) component elements exist in a health insurance application or not is judged in a test environment, wherein the UI component elements are objects for executing different UI component programs in the health insurance application according to a business process; and if the attributes exist, a triggering event of the UI components corresponding to the attributes runs according to preset test codes, and a running result is returned. The application test method and apparatus are mainly used for application testing.

Owner:PING AN TECH (SHENZHEN) CO LTD

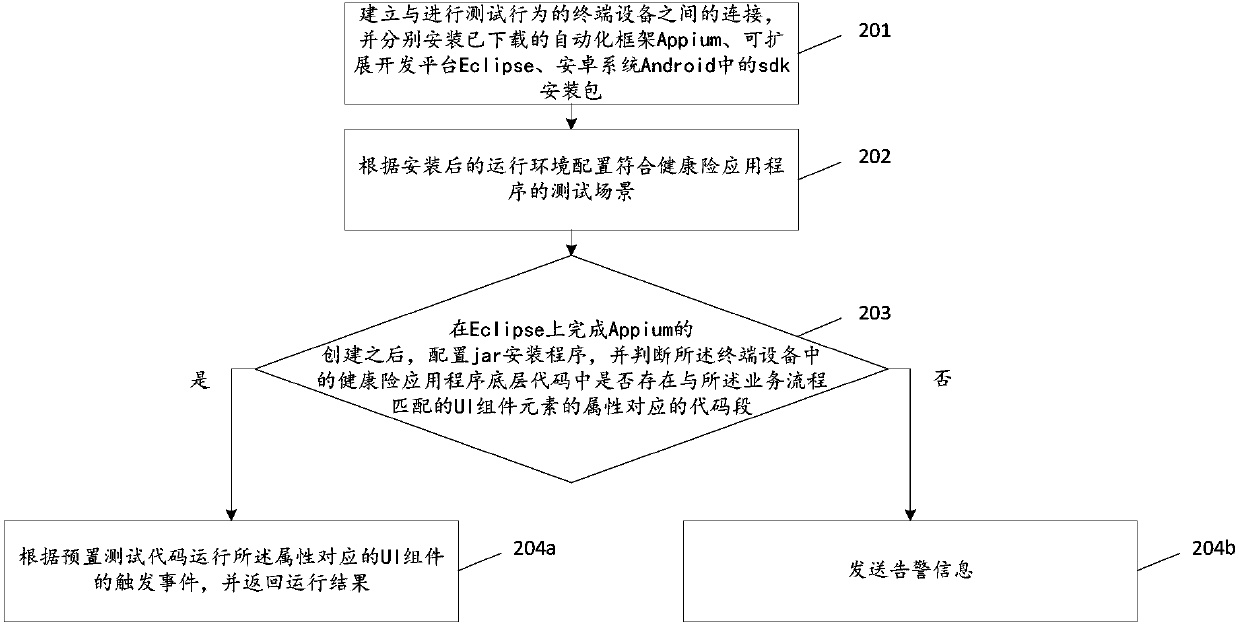

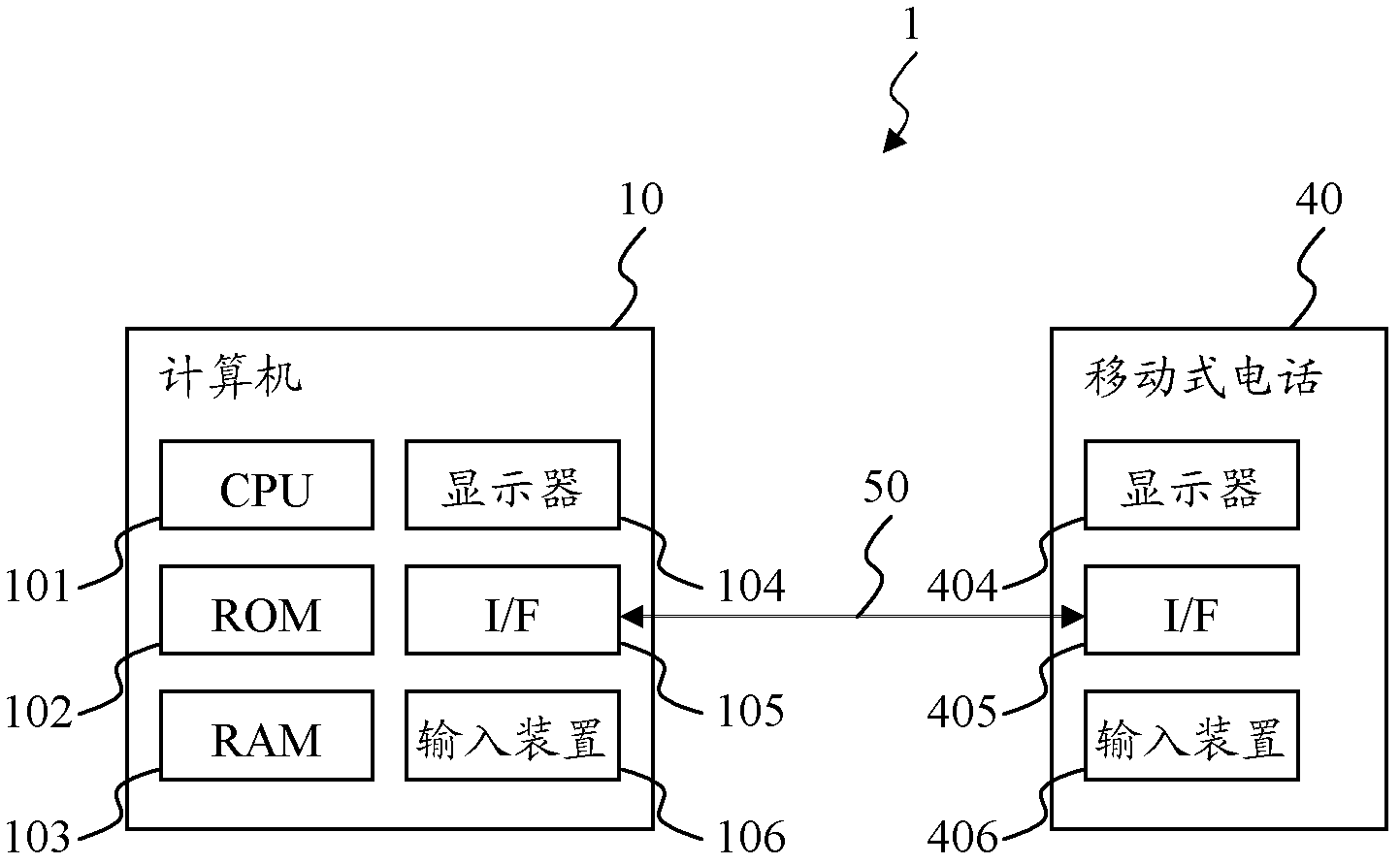

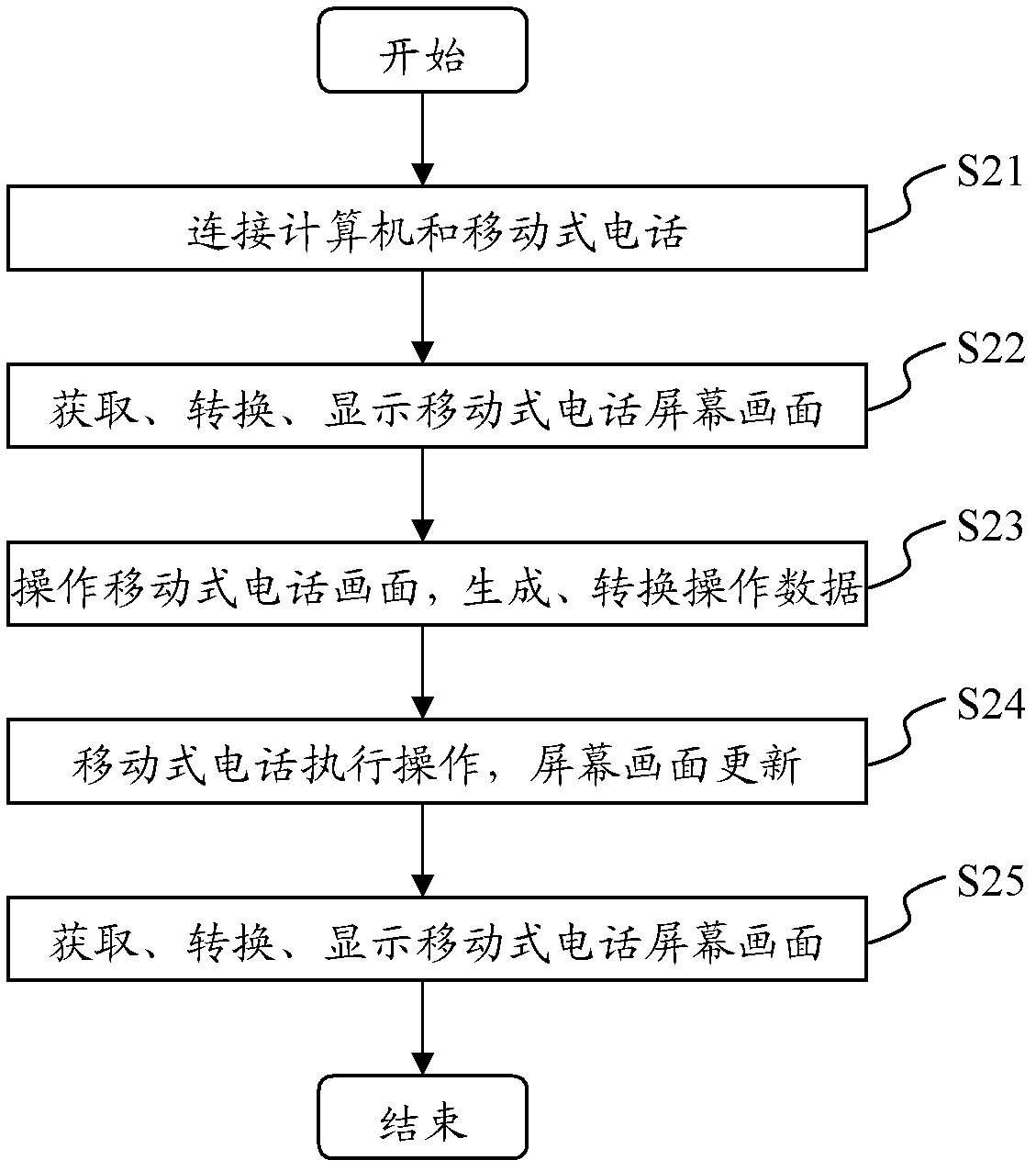

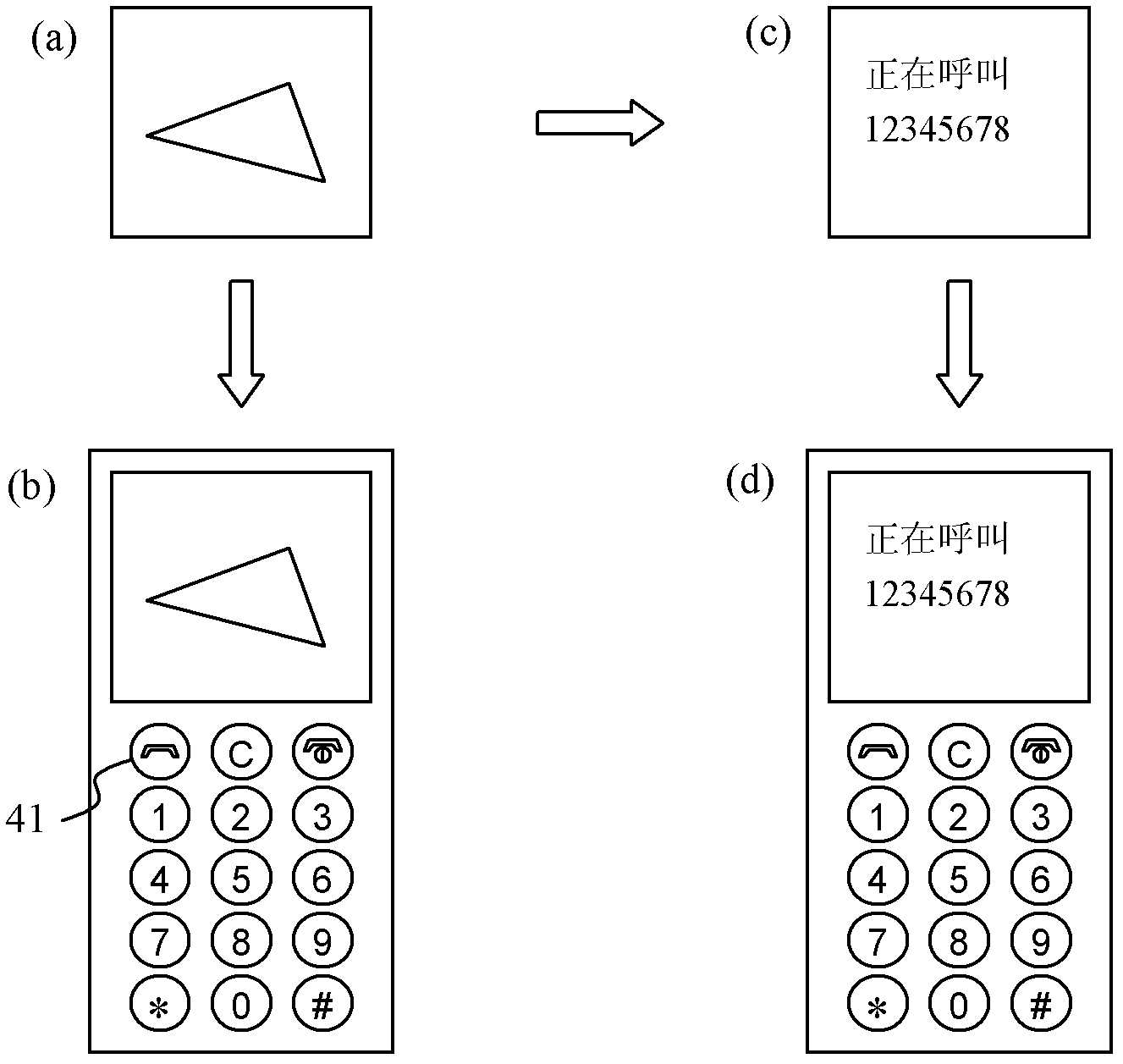

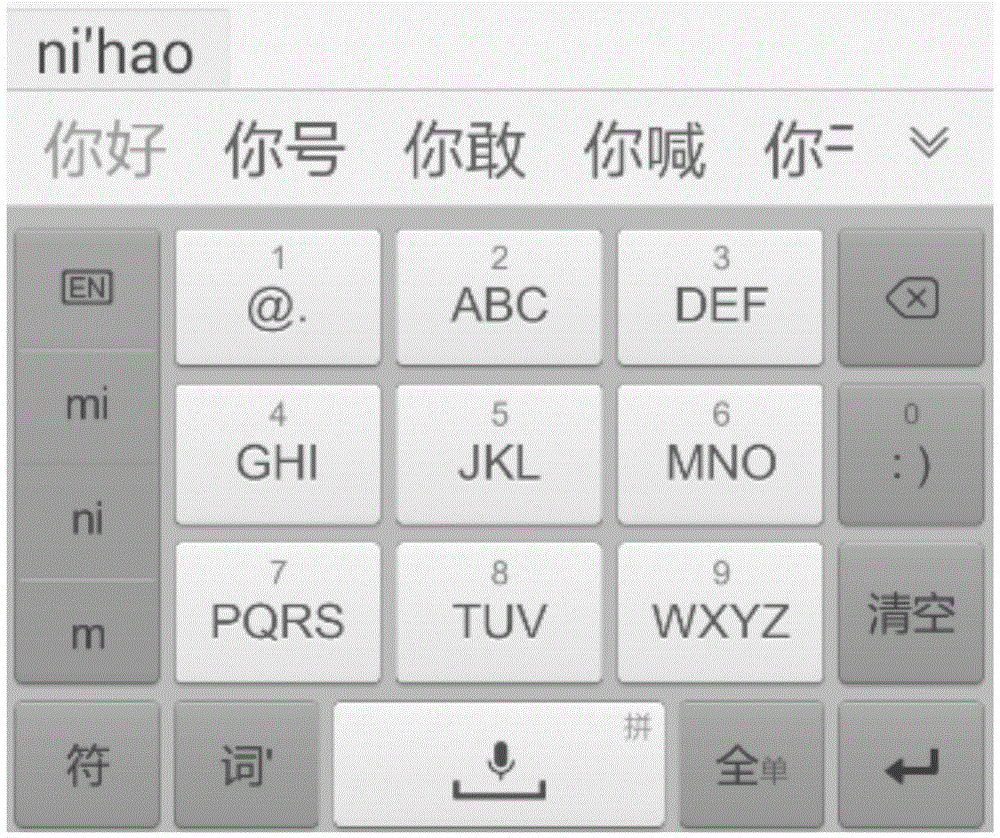

Testing system and method for mobile equipment

InactiveCN102436416AAvoid buyingAvoid Manual TestingSoftware testing/debuggingApplication softwareManual testing

The invention provides a testing system and a method for mobile equipment. The testing system for the mobile equipment comprises a server used for storing an application program to be tested and testing a script file concerned with the application program; a computer connected to the server through a network and used for testing the mobile equipment; and the mobile equipment connected to the computer, wherein the application program and the script file are sent to the computer by the server, the application program is installed to the mobile equipment by the computer, and the script file is executed to operate the mobile equipment to run the application program, result data is returned to the computer by the mobile equipment, and the result data is returned to the server by the computer. Therefore, any computer can automatically carry out testing for the mobile equipment connected with the computer, manual testing is avoided, moreover, purchase for all kinds of mobile equipment for adaptive testing can be avoided.

Owner:BEIJING YUNCE INFORMATION TECH CO LTD

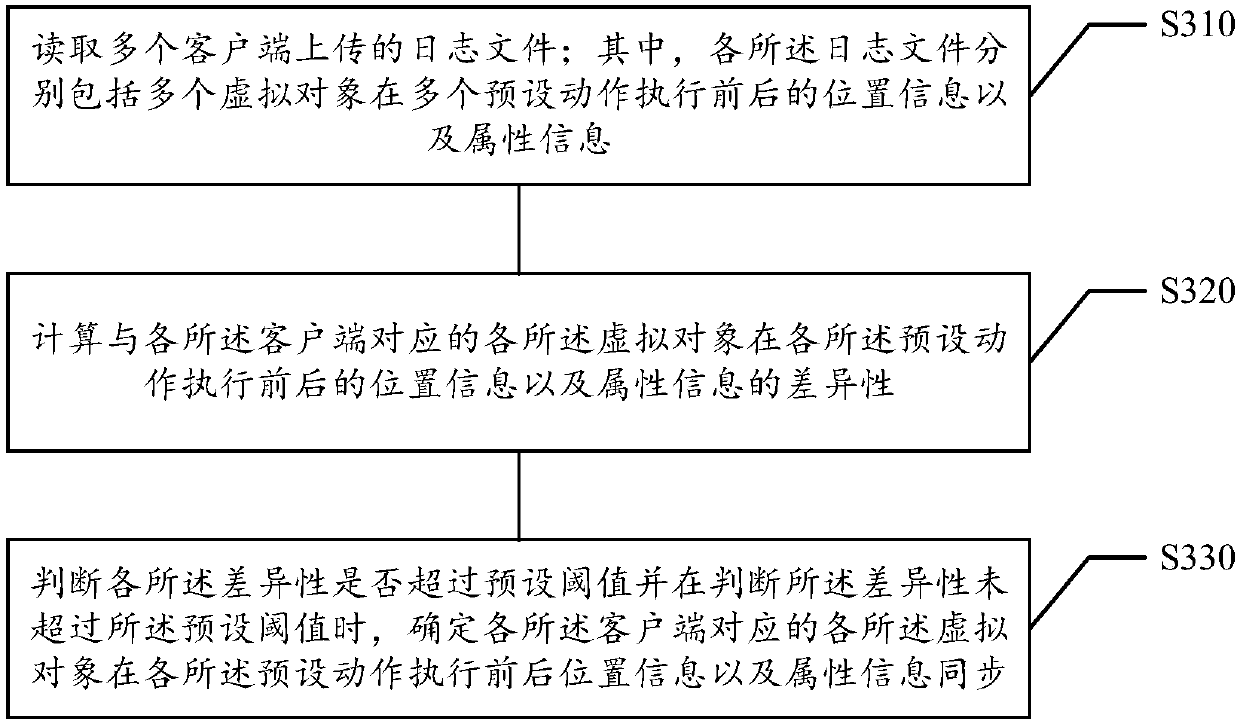

Automatic test method and apparatus, storage medium and electronic device

InactiveCN107678970AImprove test efficiencyHigh precisionSoftware testing/debuggingManual testingSoftware testing

The invention relates to an automatic test method and apparatus, and belongs to the technical field of software testing. The method comprises the steps of reading log files uploaded by multiple clients, wherein the log files comprise position information and attribute information of multiple virtual objects before and after execution of multiple preset actions; calculating difference of the position information and the attribute information of the virtual objects corresponding to the clients before and after execution of the preset actions; and judging whether the difference exceeds a preset threshold or not, and when it is judged that the difference does not exceed the preset threshold, determining that the position information and the attribute information of the virtual objects corresponding to the clients before and after execution of the preset actions are synchronous. According to the method, the problem that test personnel are required to perform manual testing for judging whether synchronization is realized or not is solved, so that the situation that a large amount of manpower and time are required to perform the manual testing is avoided, and the test efficiency is improved.

Owner:NETEASE HANGZHOU NETWORK

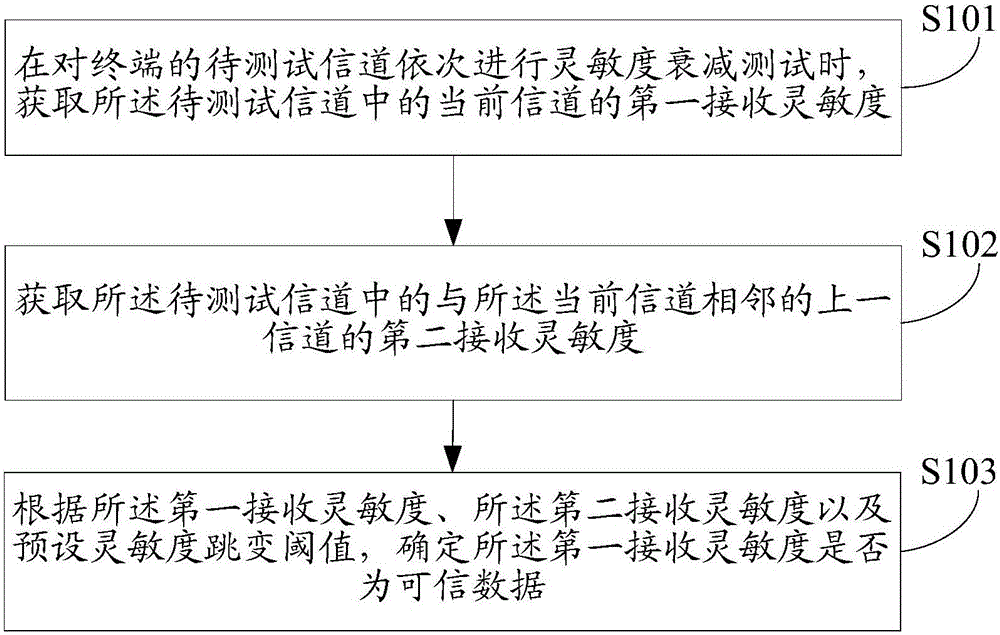

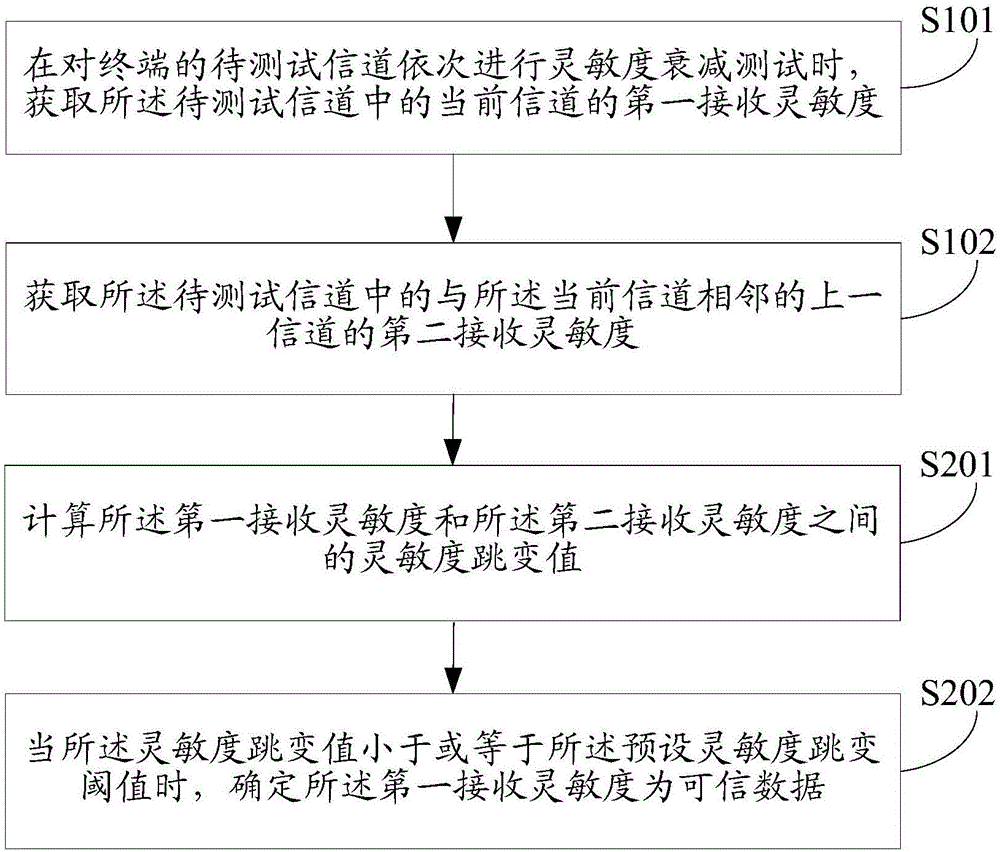

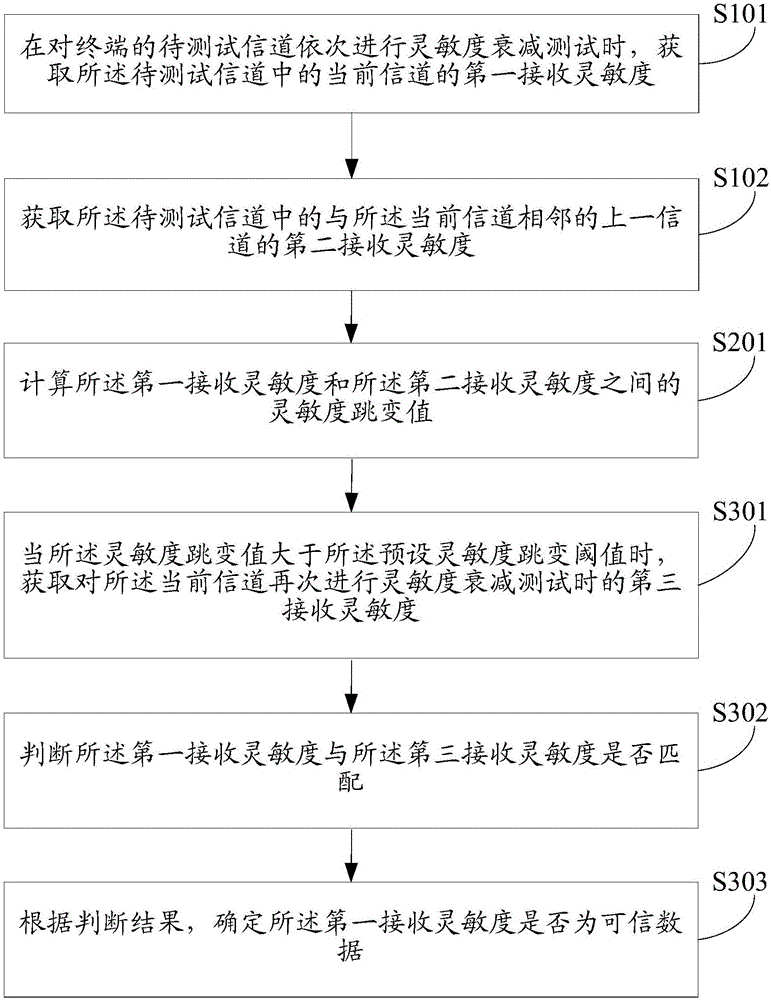

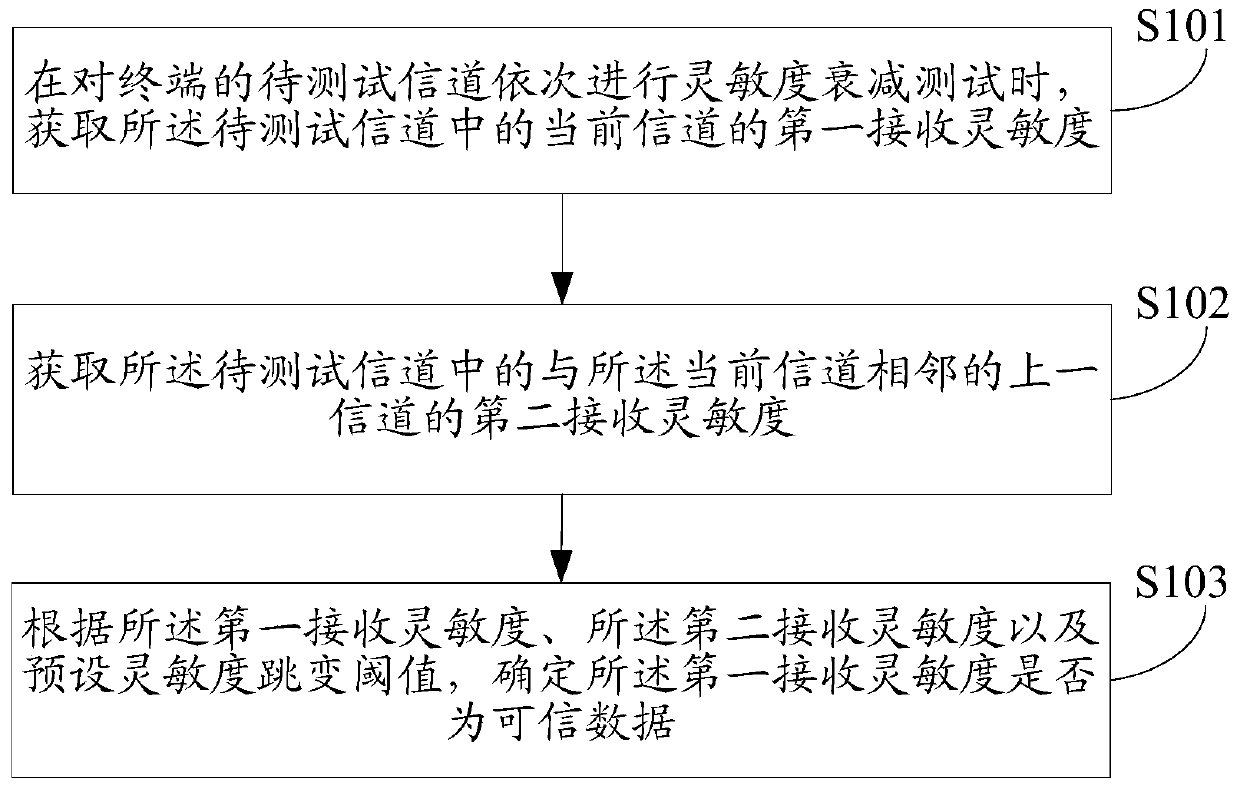

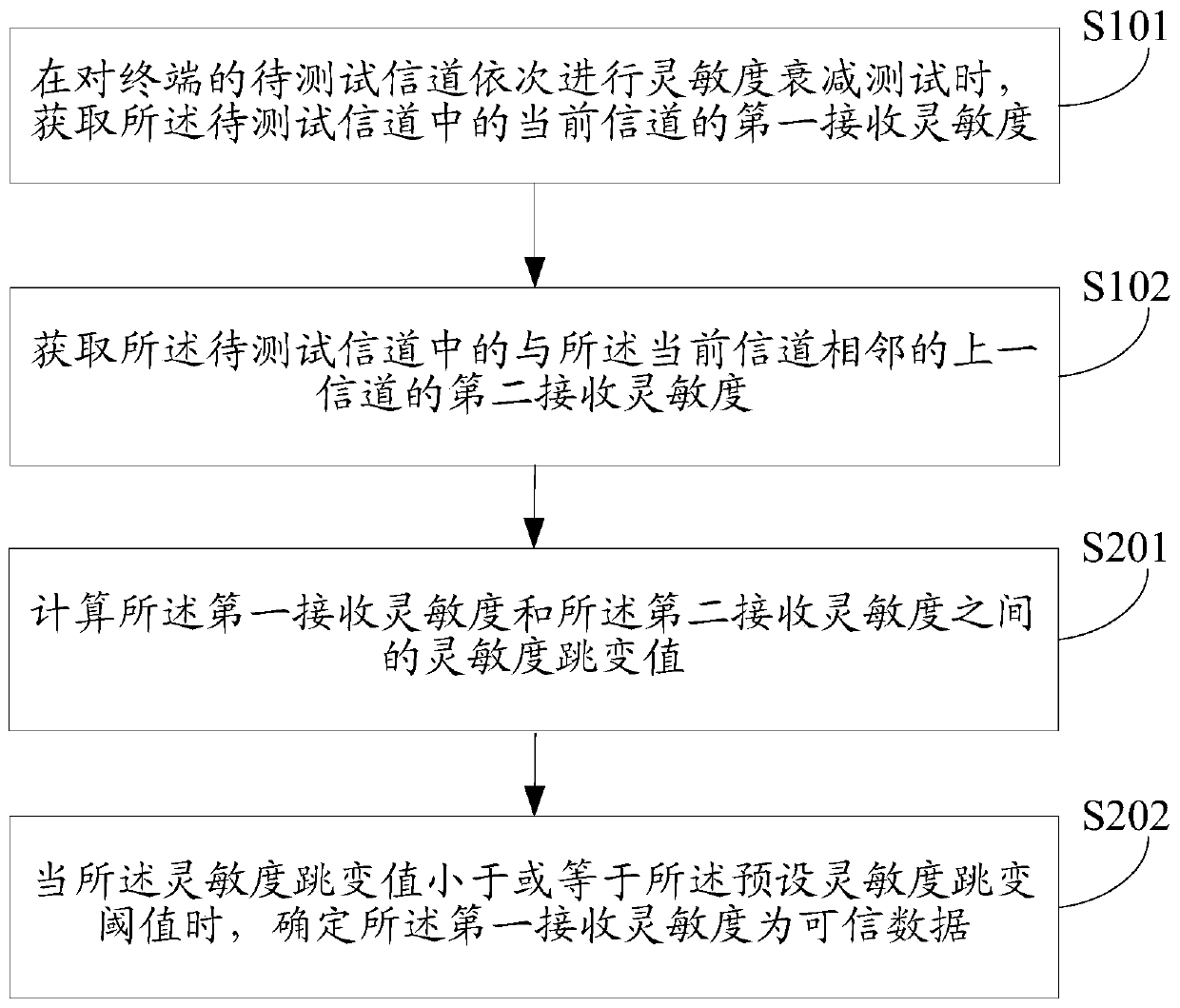

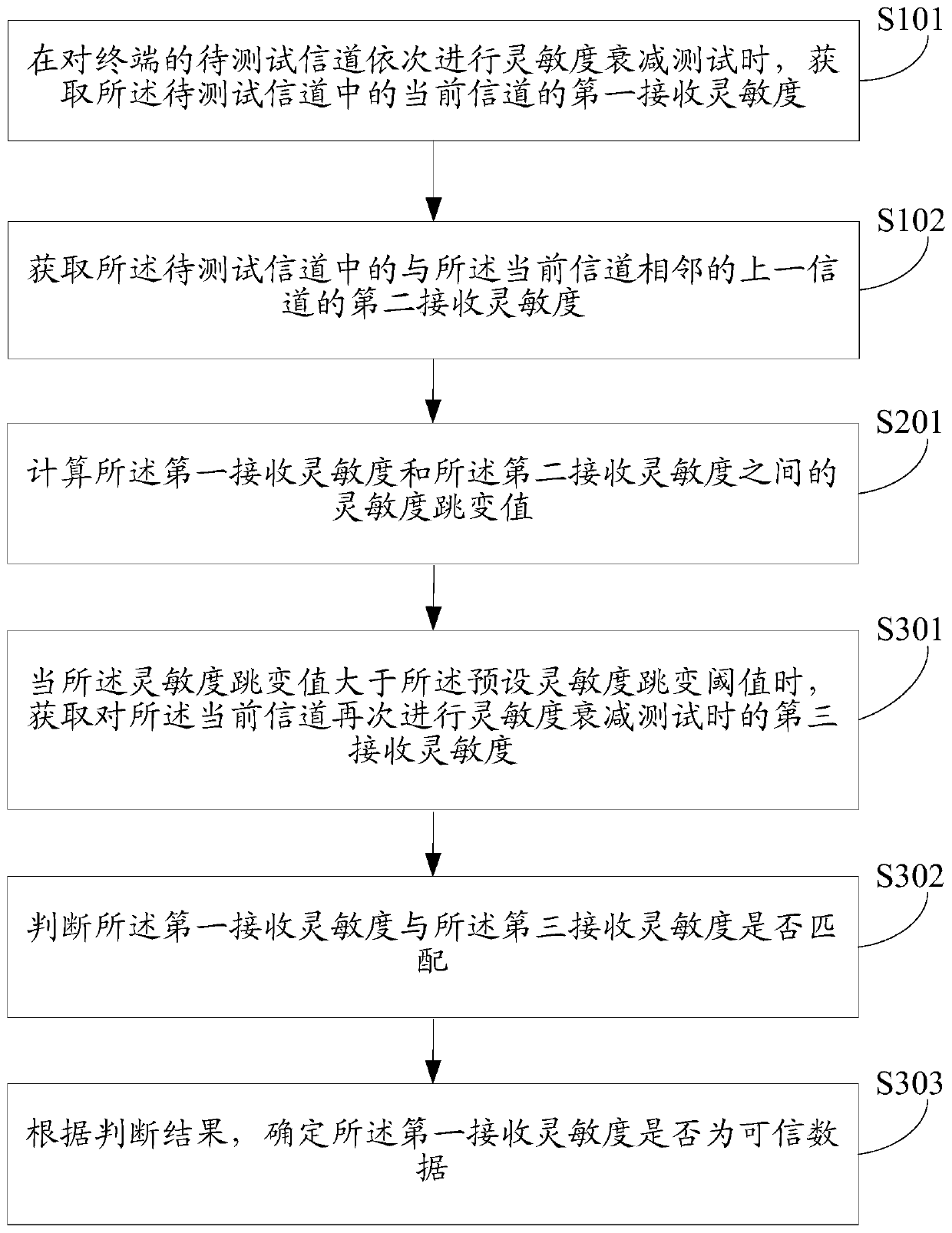

Sensitivity attenuation test method and apparatus

ActiveCN106253996AGuaranteed accuracyImprove Sensitivity Test EfficiencyReceivers monitoringUltrasound attenuationEngineering

The invention relates a sensitivity attenuation test method and apparatus. The method comprises a step of obtaining the first reception sensitivity of a present channel in channels to be tested when the sensitivity attenuation tests of the channels to be tested of a terminal is carried out in order, a step of obtaining the second reception sensitivity of a former adjacent channel of the present channel in channels to be tested, and a step of determining whether the first reception sensitivity is trusted data according to the first reception sensitivity, the second reception sensitivity and a preset sensitivity jump threshold. According to the technical scheme, whether the first reception sensitivity is the trusted data can be accurately determined according to the first reception sensitivity, the second reception sensitivity and a preset sensitivity jump threshold, thus the accurate of the sensitivity test result of the present channel is ensured, and the sensitivity test efficiency can be substantially improved according to the method of automatically testing whether the first reception sensitivity is the trusted data.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

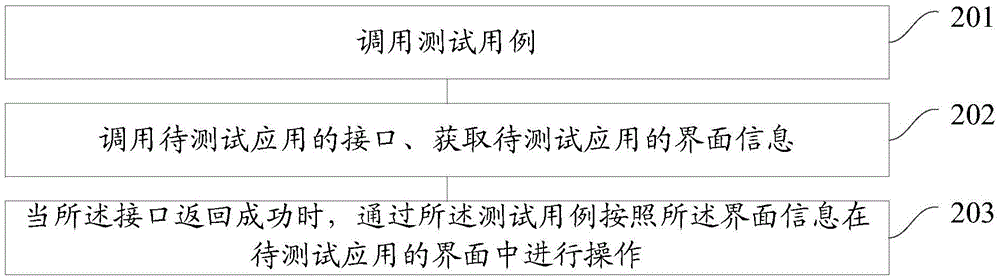

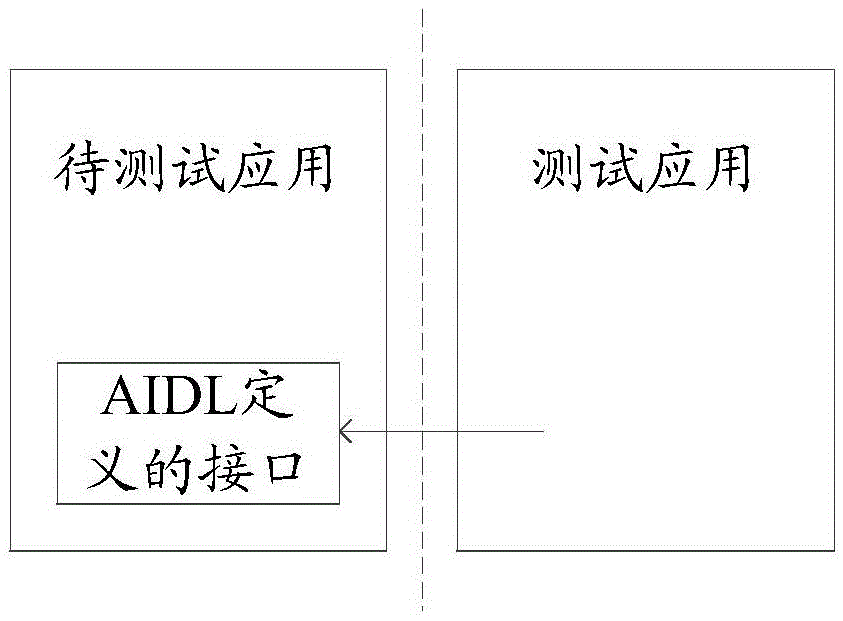

Test method and device capable of aiming at interface

InactiveCN105630674AGet value in real timeAvoid resolution issuesSoftware testing/debuggingTest efficiencyManual testing

The embodiment of the invention provides a test method and device capable of aiming at an interface. The method comprises the following steps: calling a test case; calling the interface of an application to be tested, and obtaining the interface information of the application to be tested; and when the interface succeeds in returning, operating through the test case in the interface of the application to be tested according to the interface information. The embodiment of the invention lowers test complexity, in addition, an automatic test is realized through the interface information fed back from the application to be tested, a manual test is avoided, an error probability is lowered, and test efficiency is improved.

Owner:BEIJING QIHOO TECH CO LTD +1

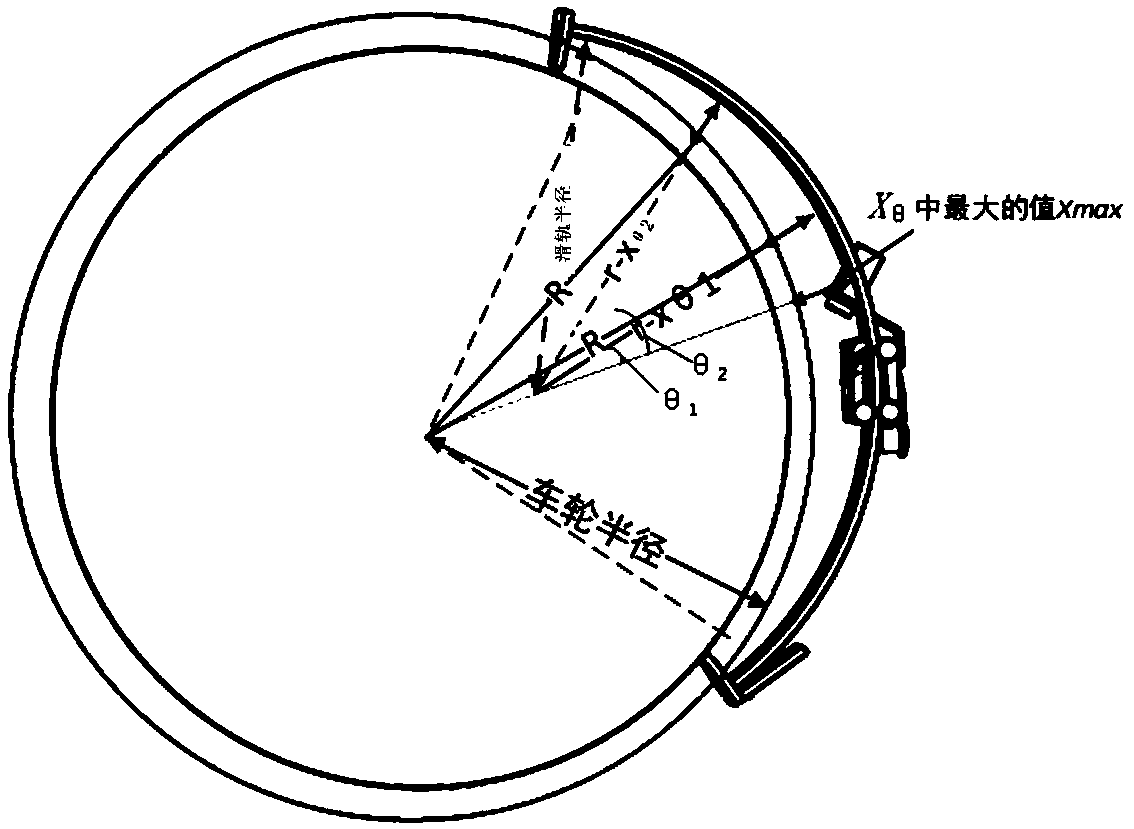

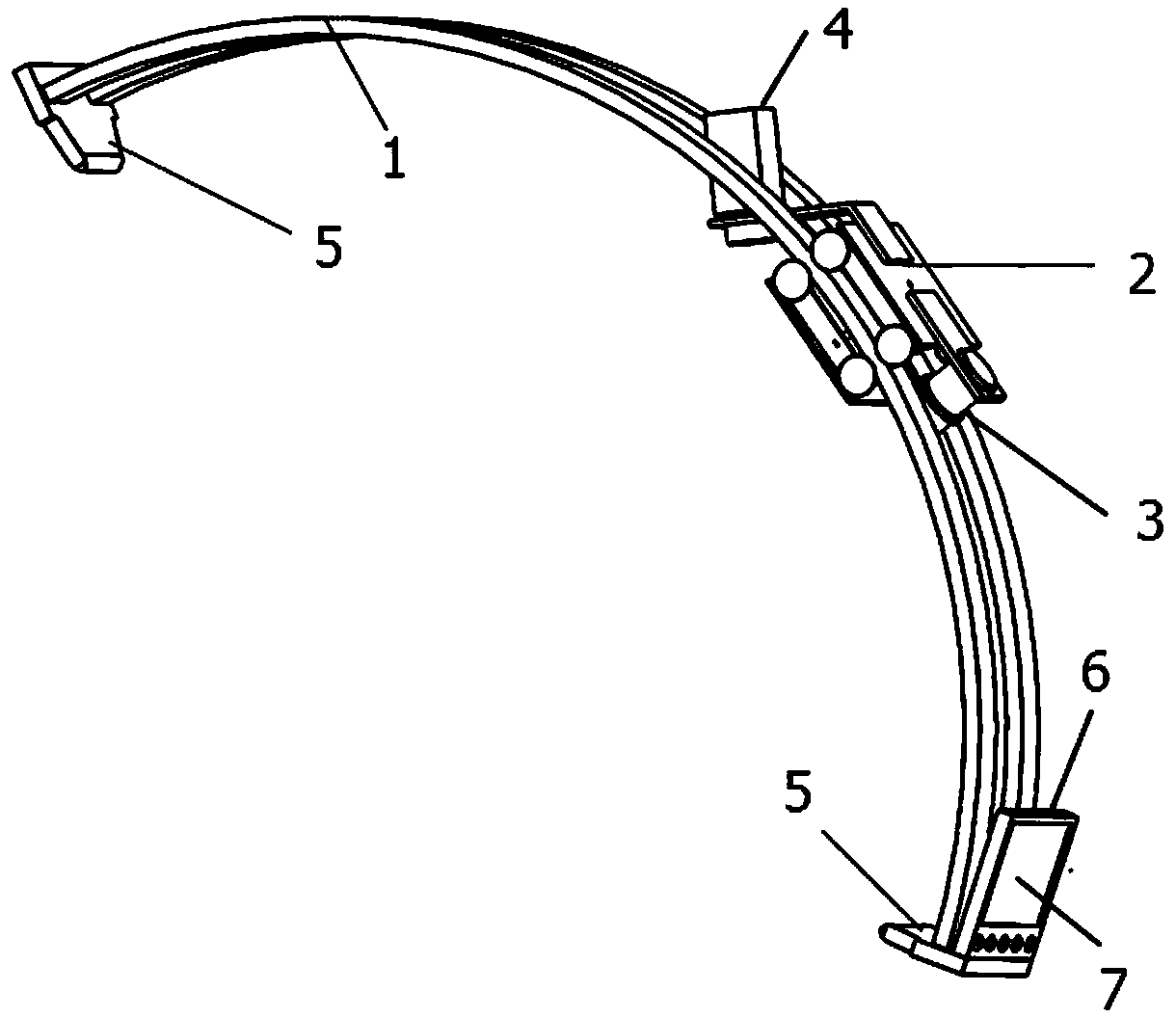

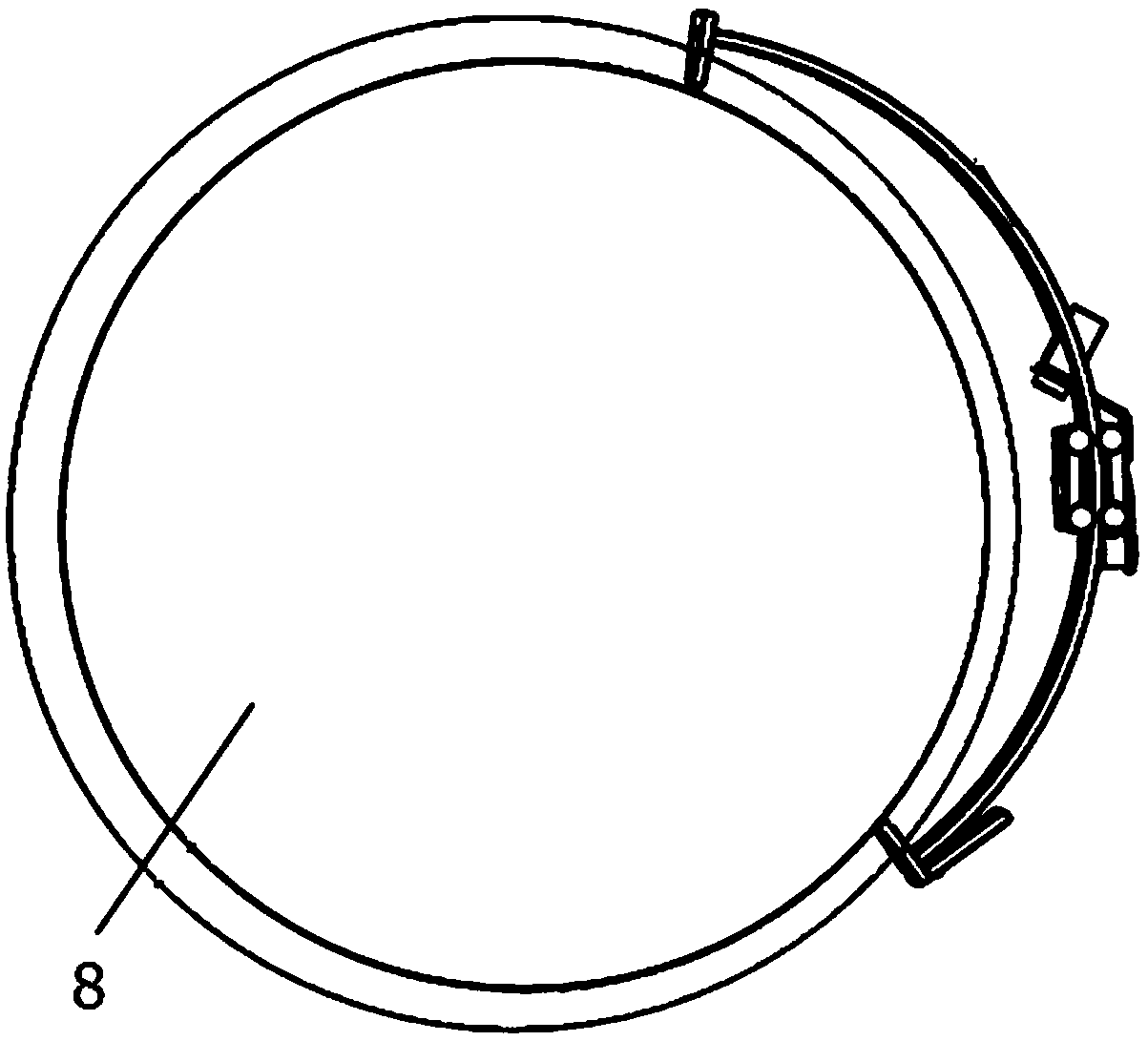

Parameter detection device and system for portable subway wheel pairs

InactiveCN109141253AAvoid Manual TestingNo fixed installation requiredUsing optical meansMechanical measuring arrangementsImaging processingComputer module

The invention relates to the technical field of rail engineering and discloses a parameter detection device for portable subway wheel pairs. The device includes an arc-shaped track arranged at a distance from wheel treads and a sliding block arranged on the arc-shaped track, wherein the sliding block can reciprocate along the arc-shaped track and is provided with a line laser light source and a photographing device, a laser plane of the line laser light source is projected on the wheel treads along a specified angle to form light bars, a camera of the photographing device collects a light barimage of the wheel treads along another specified angle, the line laser light source and the photographing device are connected with a processor, the processor is further connected with a touch screen, an image processing module and a data transmission module, the image processing module is used for processing the light bar image collected by the photographing device, parameters of the multiple wheel treads are obtained through calculation, the touch screen is used for displaying the light bar image collected by the photographing device and the multiple parameters obtained through calculationby the image processing module, and the data transmission module is used for performing data transmission between the processor and a server.

Owner:SHANGHAI UNIV OF ENG SCI

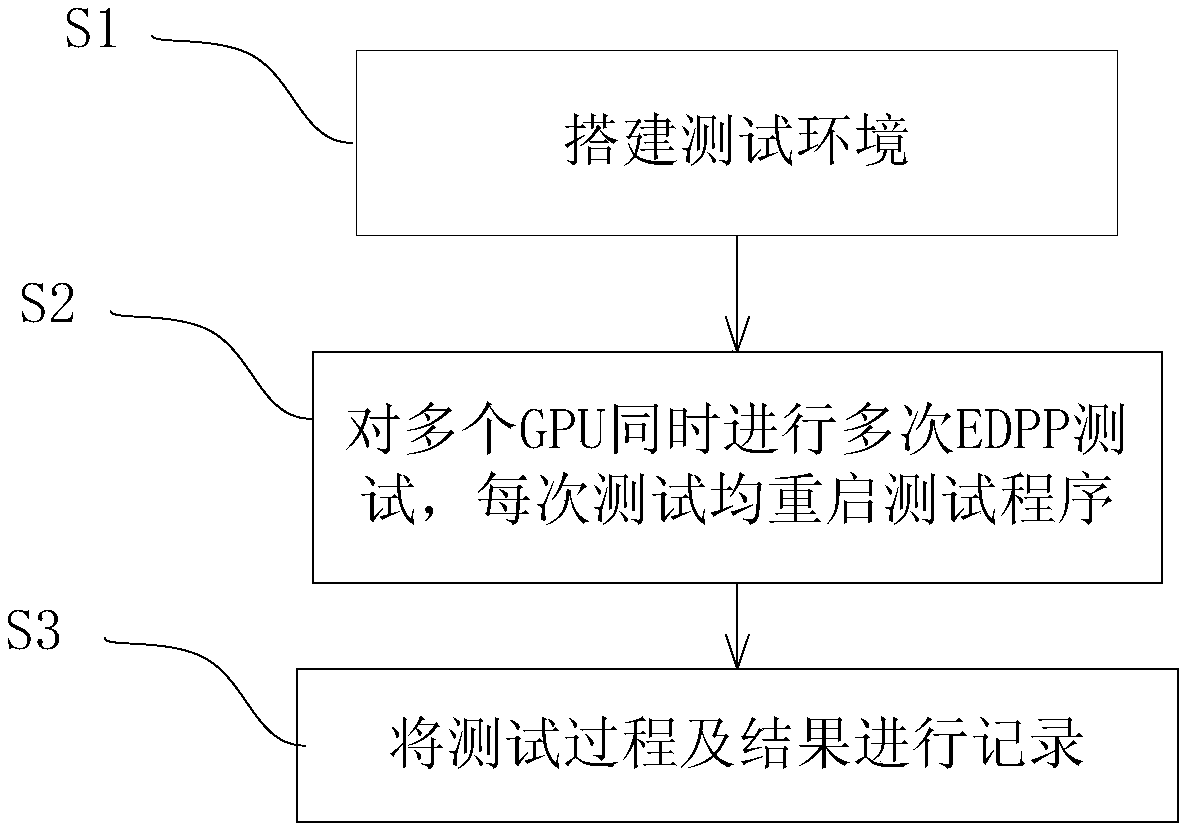

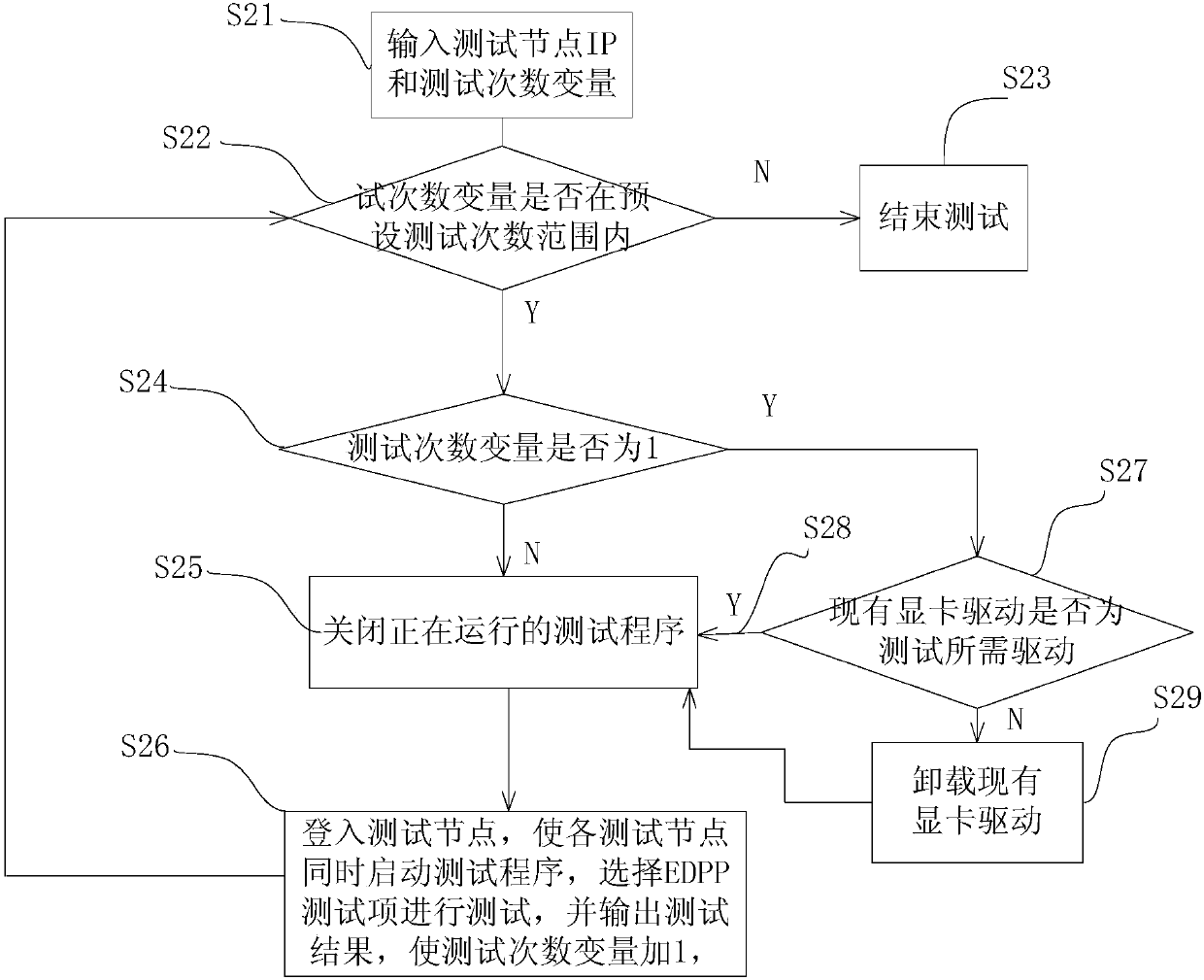

Electrical data peak processing (EDPP) test method for server graphics processing unit (GPU)

InactiveCN107590037AShorten test timeImprove work efficiencyDetecting faulty computer hardwareComputer hardwareGraphics processing unit

The invention discloses an electrical data peak processing (EDPP) test method for a server graphics processing unit (GPU). The method comprises the steps of creating a test environment; performing multiple EDPP tests on multiple GPUs simultaneously, wherein a test program is restarted in each test; and recording a test process and a test result. Compared with the prior art, the test process involves no manual labor, thereby making the test result more reliable; and EDPP tests are performed on multiple GPUs simultaneously, so that test time is shortened greatly, and the working efficiency is improved.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

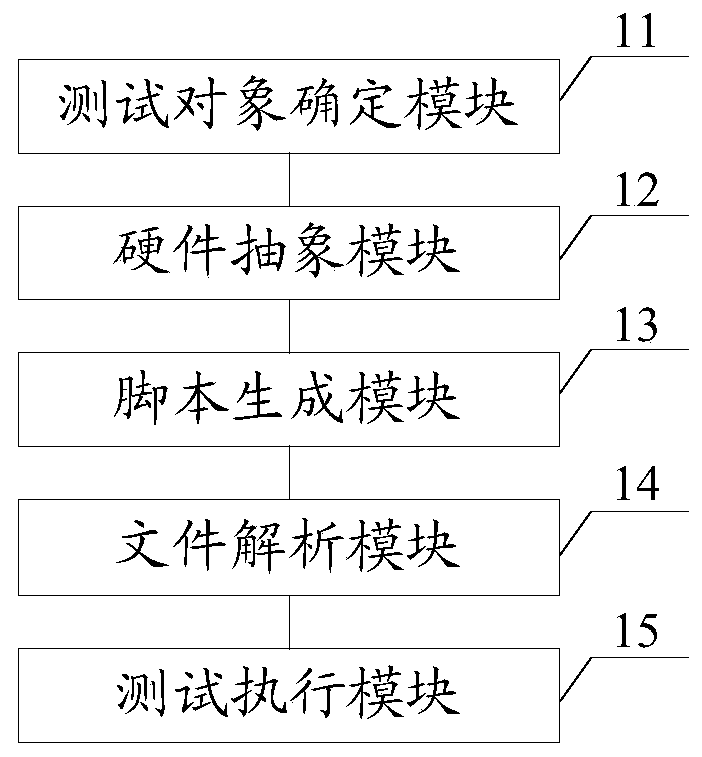

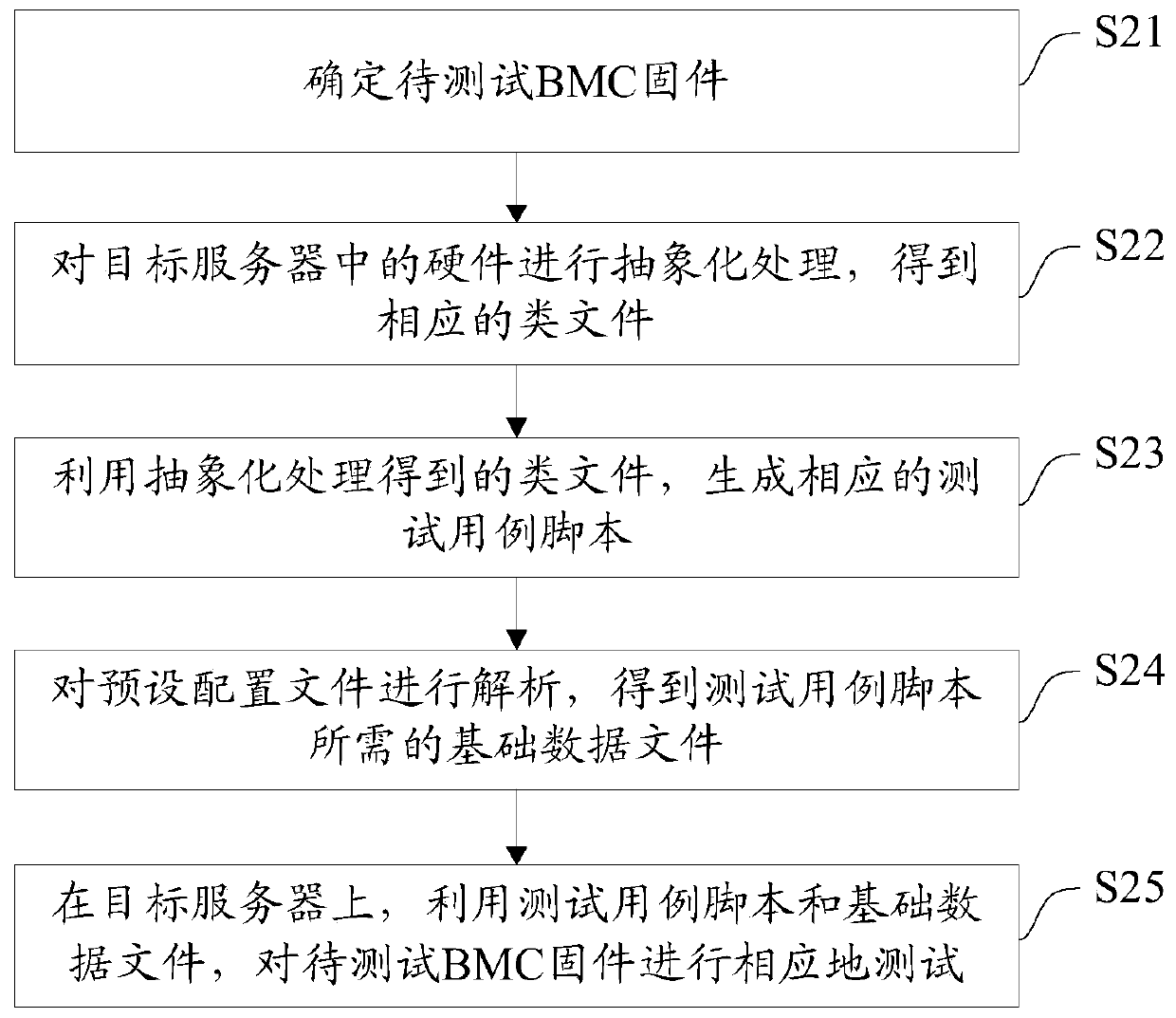

BMC automatic testing system and method

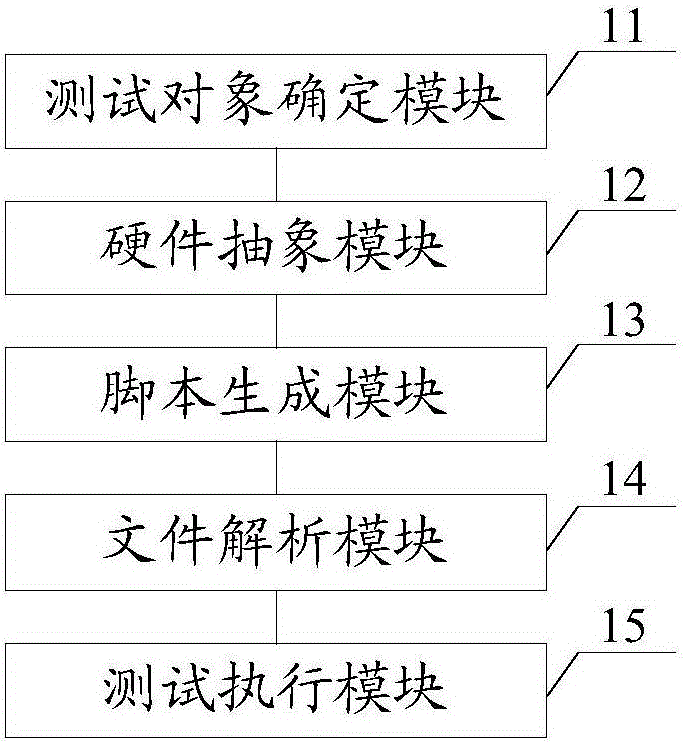

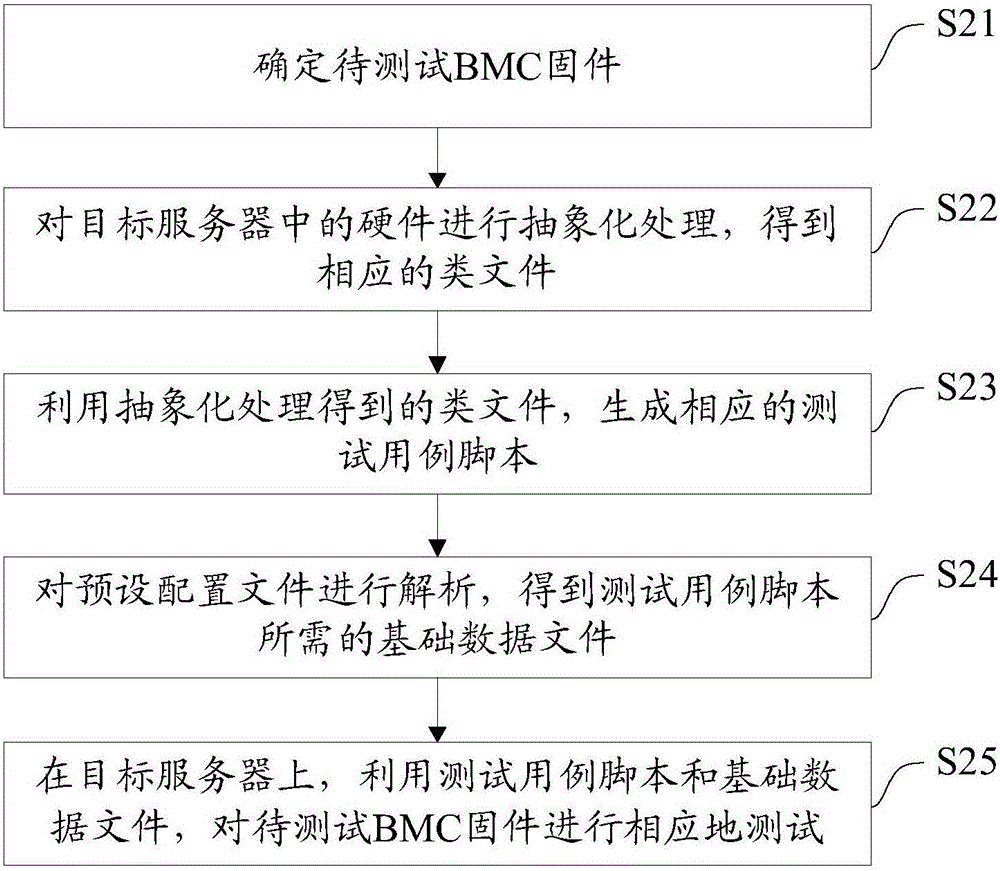

ActiveCN106407054AReduce labor costsAvoid Manual TestingFaulty hardware testing methodsTest efficiencyData file

The invention discloses a BMC automatic testing system. The BMC automatic testing system comprises a test object determination module, a hardware abstraction module, a script generation module, a file analysis module and a test execution module, wherein the test object determination module is used for determining to-be-tested BMC firmware; the hardware abstraction module is used for performing abstraction processing on hardware in a target server to obtain corresponding class files; the script generation module is used for generating corresponding test case scripts through the class files obtained by hardware abstraction module; the file analysis module is used for analyzing preset configured files to obtain basic data files required by the test case scripts; and the test execution module is applied to the target server for performing corresponding test on the to-be-tested BMC firmware through the test case scripts and the basic data files. By adoption of the BMC automatic testing system, the manpower cost in the BMC firmware testing is lowered while the test efficiency is improved. In addition, the invention also correspondingly discloses a BMC automatic testing method.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

Particle swarm optimization (PSO) algorithm based Android automatic testing method

ActiveCN105512046AAvoid redundancyAvoid Manual TestingBiological modelsSoftware testing/debuggingNODALTheoretical computer science

The invention discloses a particle swarm optimization algorithm (PSO) based Android automatic testing method. Triggering of an application control can be carried out in a modularized manner; relatively efficient input test data can be generated; and software exception can be relatively efficiently triggered when convenience is achieved. The method comprises the following steps: (1) mounting an app on a simulator, starting view server service by a viewer module, and obtaining control hierarchy tree information of the app through a hierarchy viewer; (2) with the obtained control hierarchy tree information as input, organizing a tree structure convenient to traverse by a build tree method of a PSO module; (3) traversing a control hierarchy tree constructed by the build tree, and searching whether a historical test case exists or not in a test case module after traversing a node every time; and (4) calling a test case set stored in the test case module, thereby implementing automatic testing.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

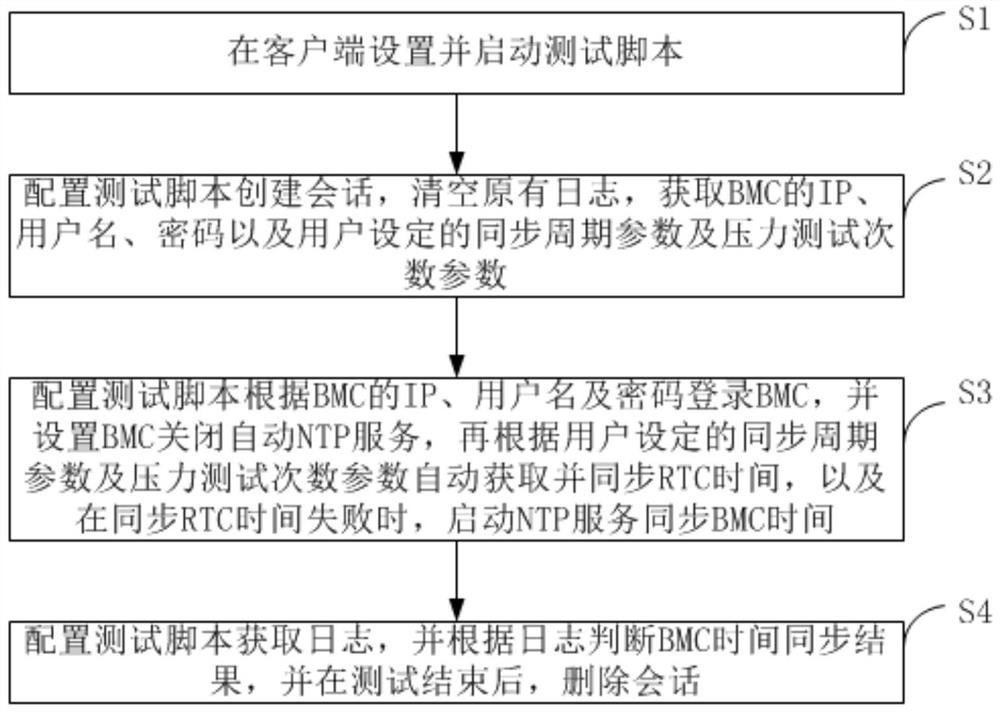

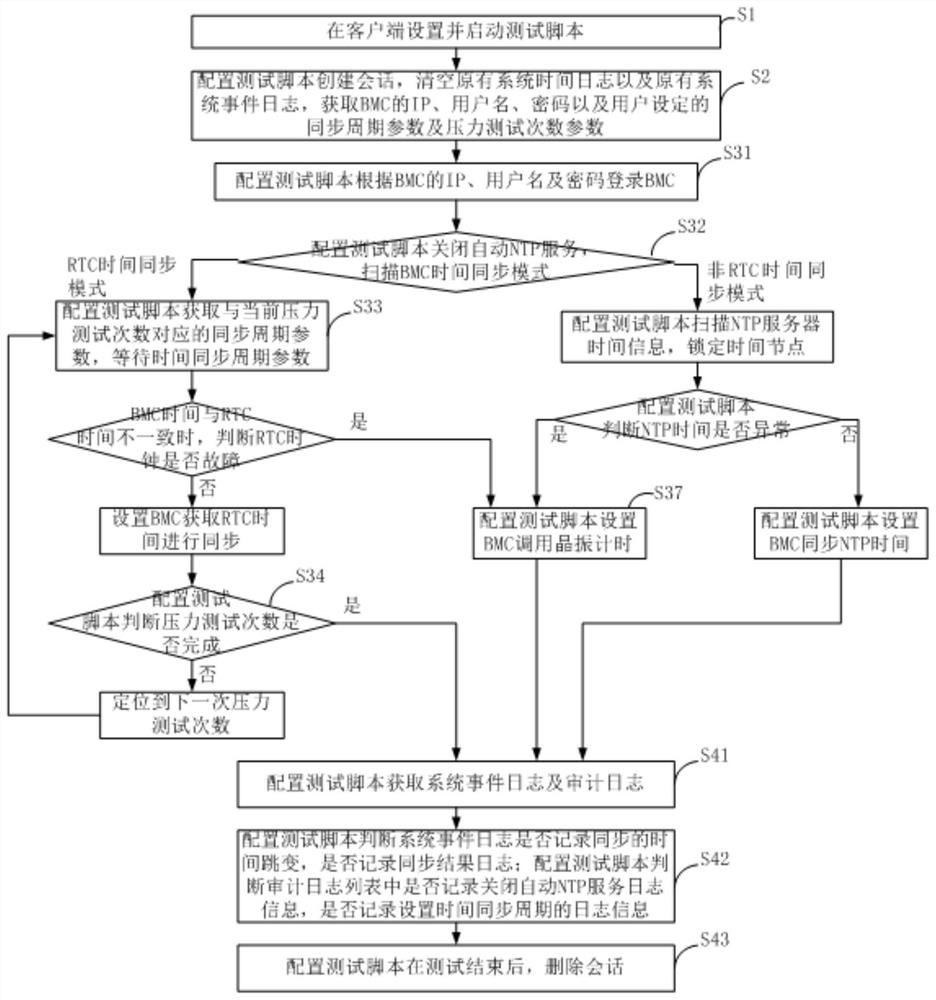

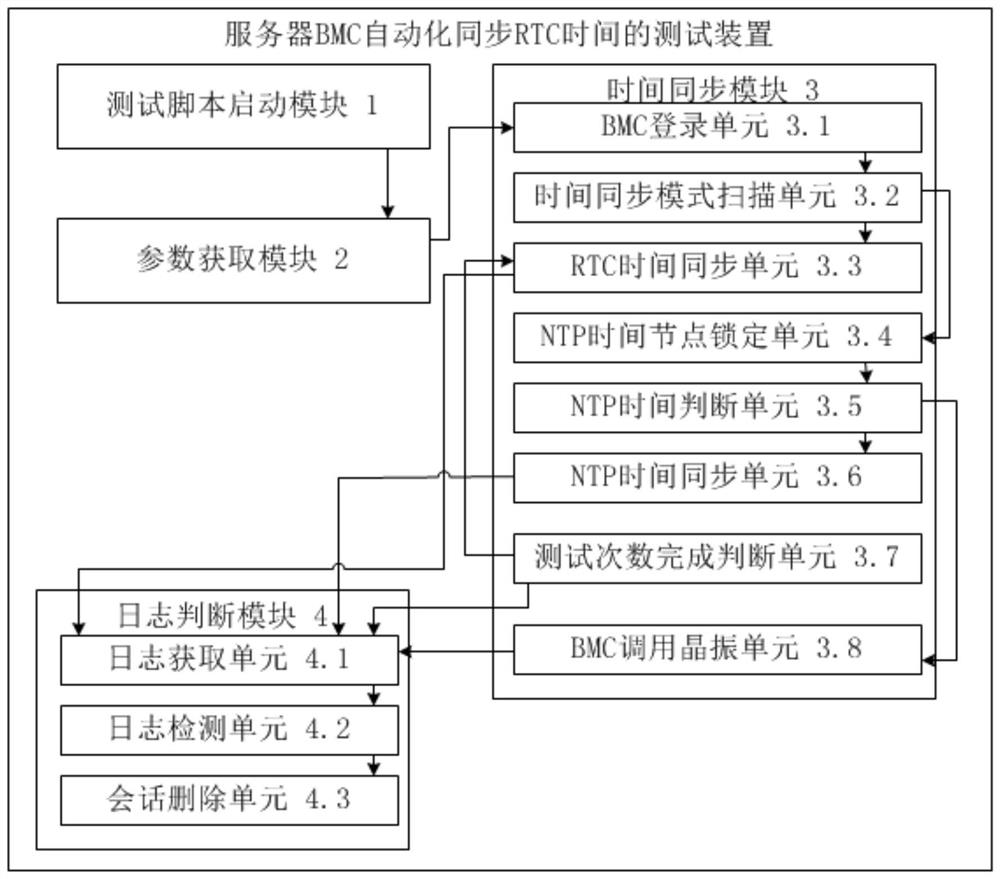

Test method and device for server BMC automatic synchronization RTC time

ActiveCN111694699AImprove reliabilityImprove normativeFaulty hardware testing methodsTest scriptPassword

The invention provides a test method and system for server BMC automatic synchronization RTC time. The method comprises the following steps: S1, setting and starting a test script at a client; s2, configuring a test script to create a session, emptying an original log, and obtaining an IP, a user name and a password of the BMC and a synchronization period parameter and a pressure test frequency parameter set by a user; s3, configuring a test script to log in the BMC according to the IP, the user name and the password of the BMC, setting a BMC to close the automatic NTP service, automatically acquiring and synchronizing RTC time according to a synchronization period parameter and a pressure test frequency parameter set by a user, and starting the NTP service to synchronize the BMC time whenthe RTC time synchronization fails; and S4, configuring a test script to obtain a log, judging a BMC time synchronization result according to the log, and deleting the session after the test is finished.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

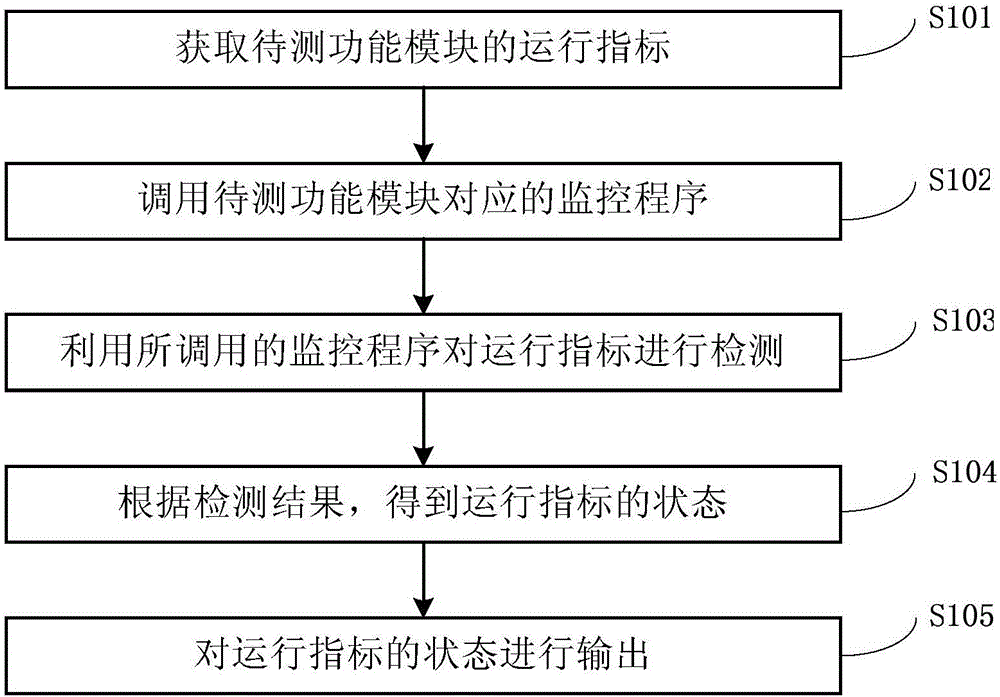

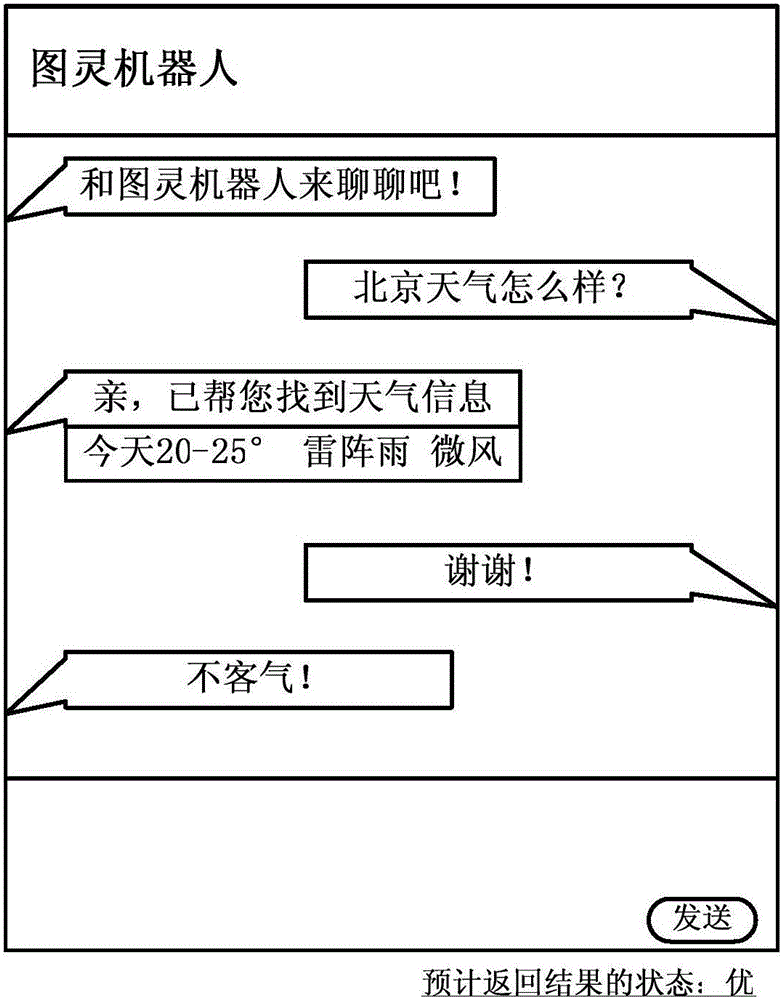

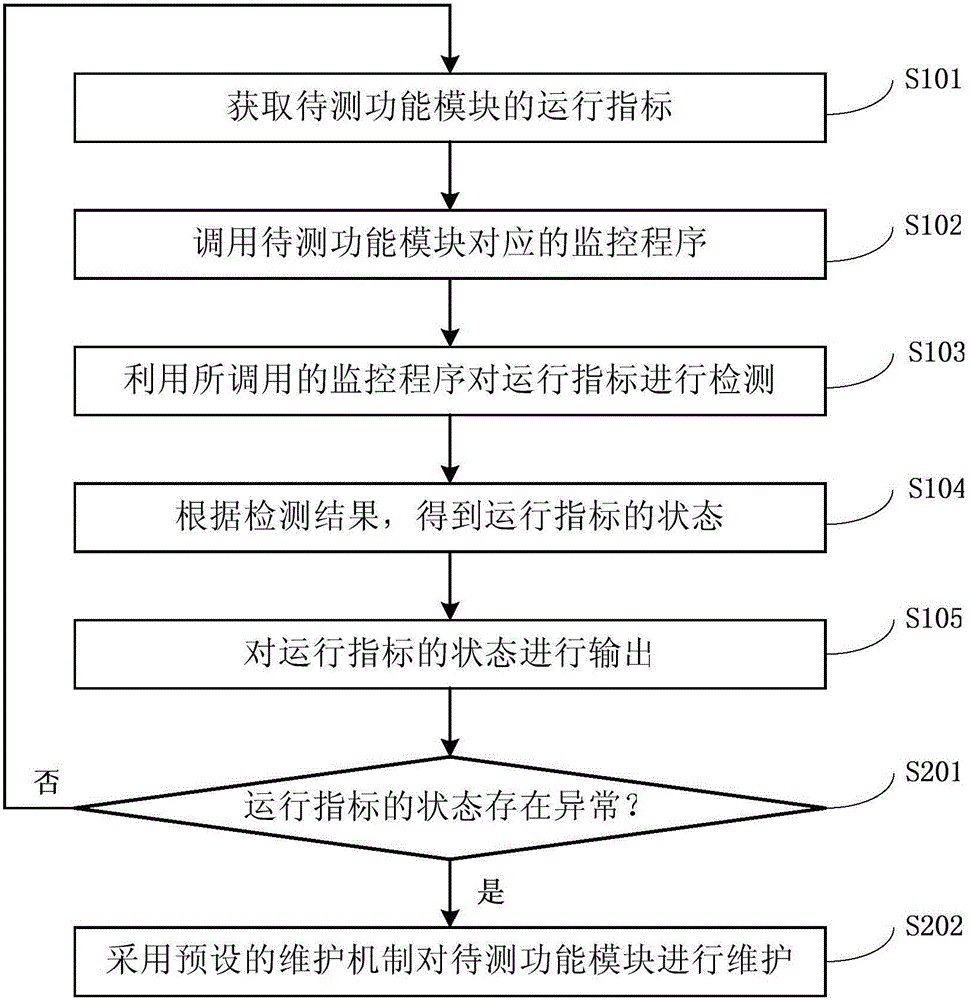

Functional module detection method and system for question and answer robot

InactiveCN106168970AGuaranteed uptimeImprove stabilitySoftware testing/debuggingSpecial data processing applicationsComputer moduleQuestions and answers

The invention discloses a functional module detection method and system for a question and answer robot. The method comprises the steps of acquiring the operating index of a functional module to be detected, calling a monitoring program corresponding to the functional module to be detected to detect the operating index, and obtaining and outputting the state of the operating index according to a detection result. By the adoption of the method and system, the state of the operating index of the functional module can be automatically detected and fed back to a user in time, so that the user or a maintenance module can take measures in time. On the basis that normal operation of the question and answer robot is guaranteed, the situation that detection requires lots of labor is avoided, normal operation of each functional module of the question and answer robot is effectively guaranteed, performance stability of the question and answer robot can be improved, and good user experience is provided for the user from the technical view.

Owner:BEIJING GUANGNIAN WUXIAN SCI & TECH

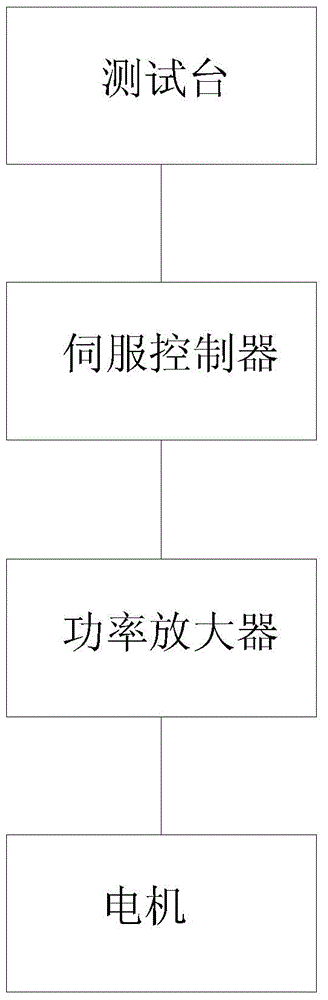

Starting voltage testing method for all-digital follow-up system

InactiveCN104483535AAvoid Manual TestingAvoid the problem of ram program online testMeasurement using digital techniquesMicrocontrollerElectricity

The invention relates to a starting voltage testing method for an all-digital follow-up system. A test bench, a servo controller and a power amplifier are adopted, wherein the test bench comprises a singlechip microcomputer with a display screen and a starting button; the singlechip microcomputer is electrically connected with the starting button; a voltage regulating value text frame and a voltage display frame are displayed on the display screen; when a number is input into the voltage regulating value text frame, a voltage value in a current state can be immediately displayed in the voltage display frame below the voltage regulating value text frame; every time the starting button is clicked, the voltage displayed by the voltage display frame is cumulatively increased by taking the number of the voltage regulating value text frame as an increment; the servo controller is electrically connected with the singlechip microcomputer, receives voltage digital quantity displayed by the voltage display frame of the test bench and sends the voltage digital quantity to the power amplifier; the input end of the power amplifier is electrically connected with the servo controller, and the output end of the power amplifier is electrically connected with a motor; the power amplifier can be a digital power amplifier or an analog power amplifier and drives the motor.

Owner:HEBEI HANGUANG HEAVY IND

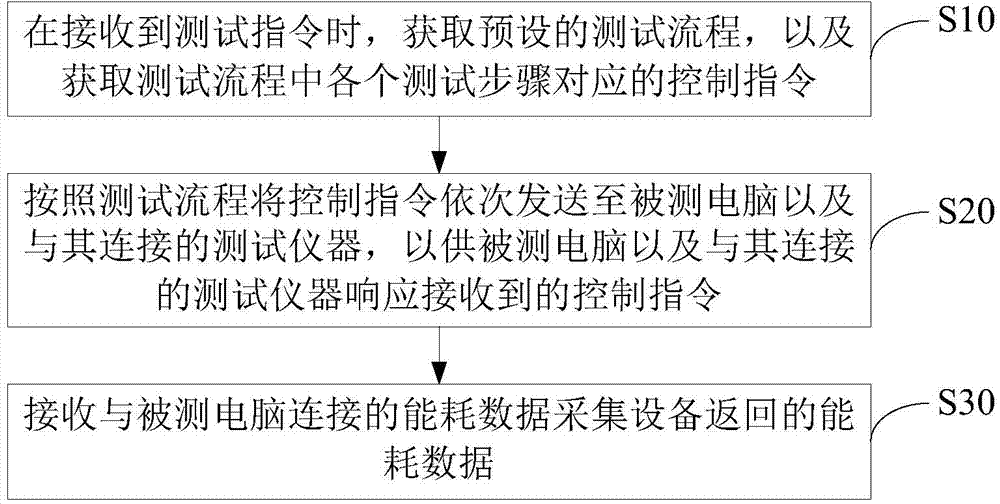

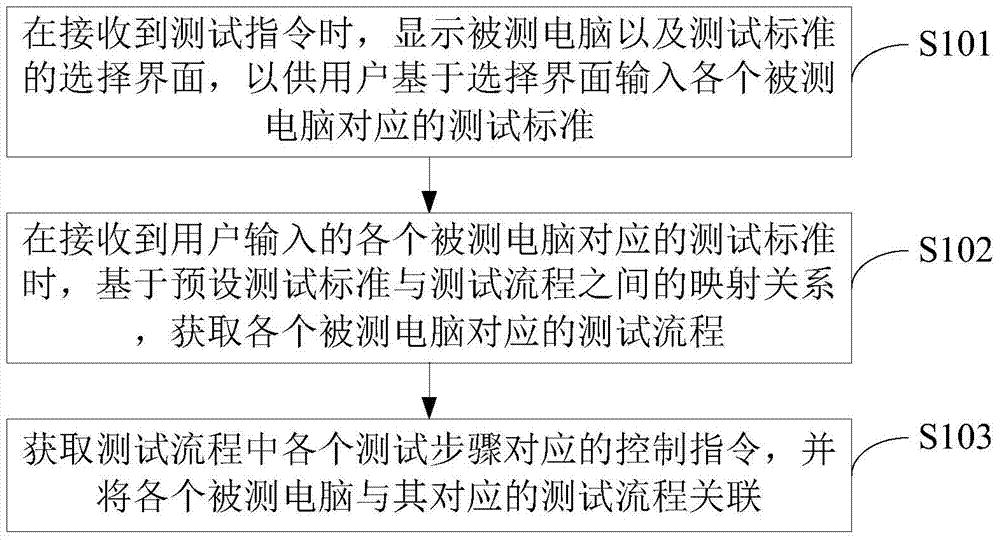

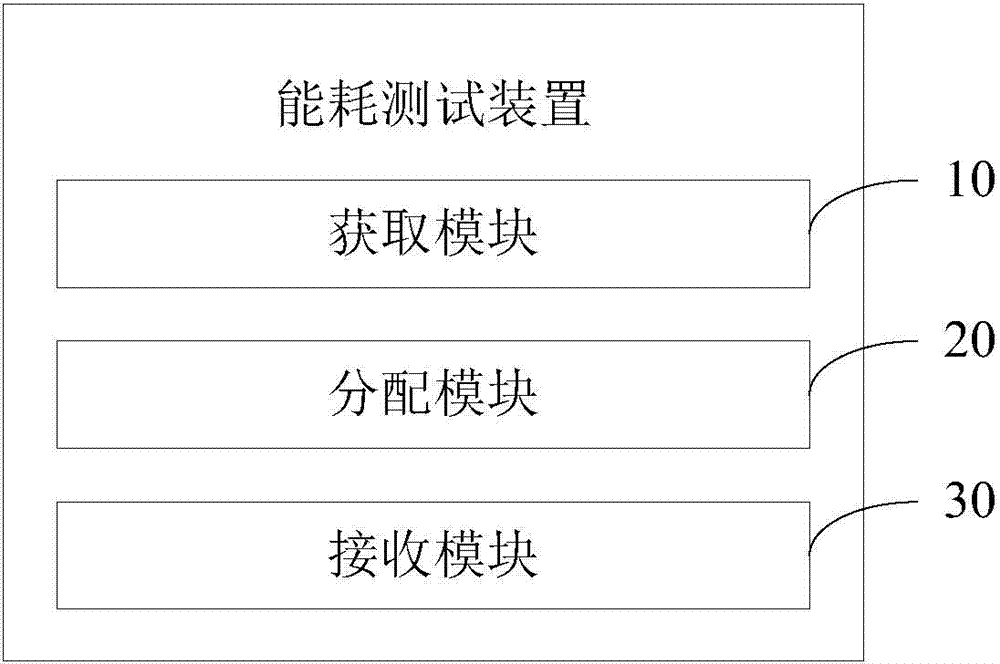

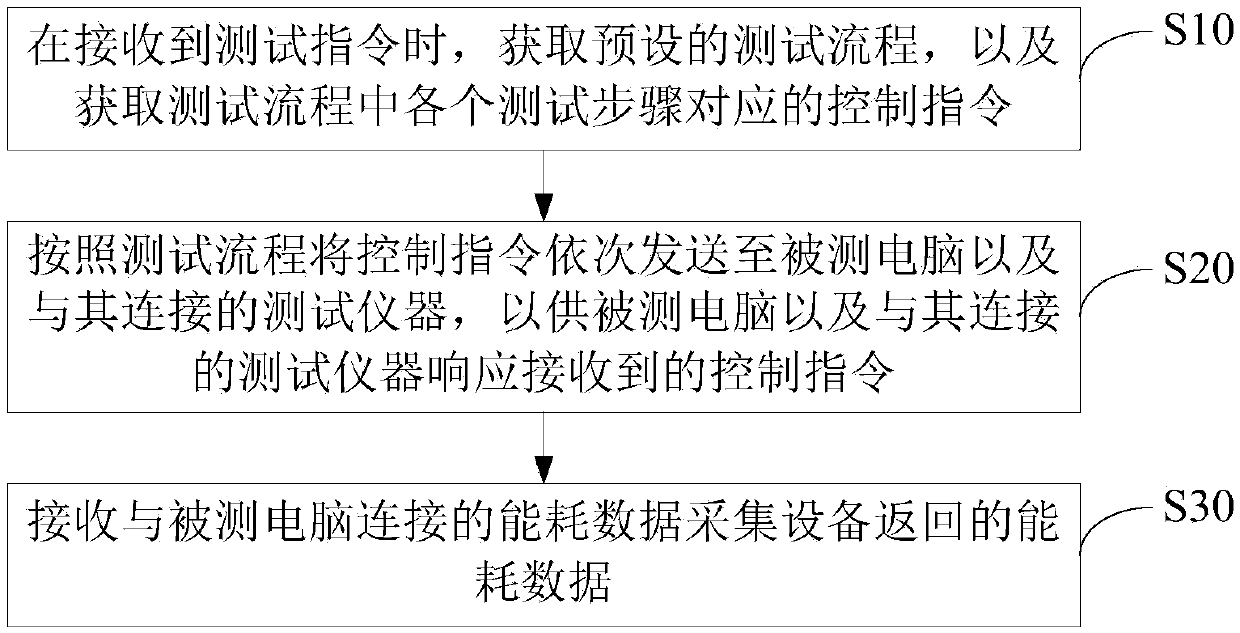

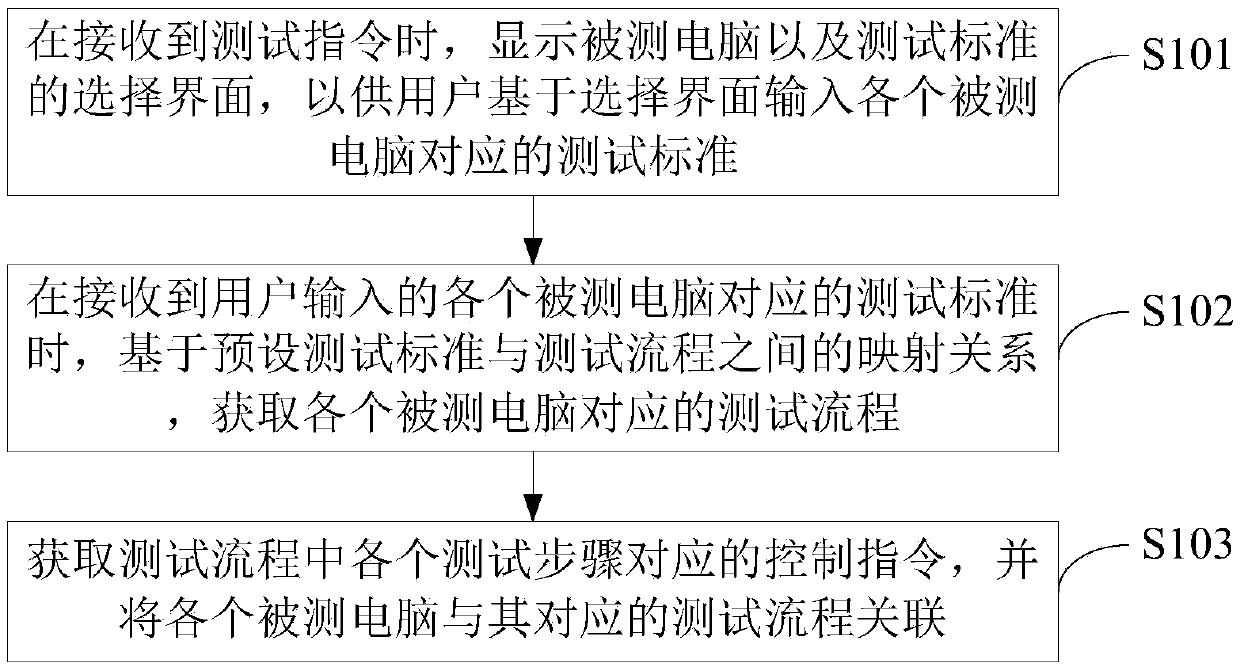

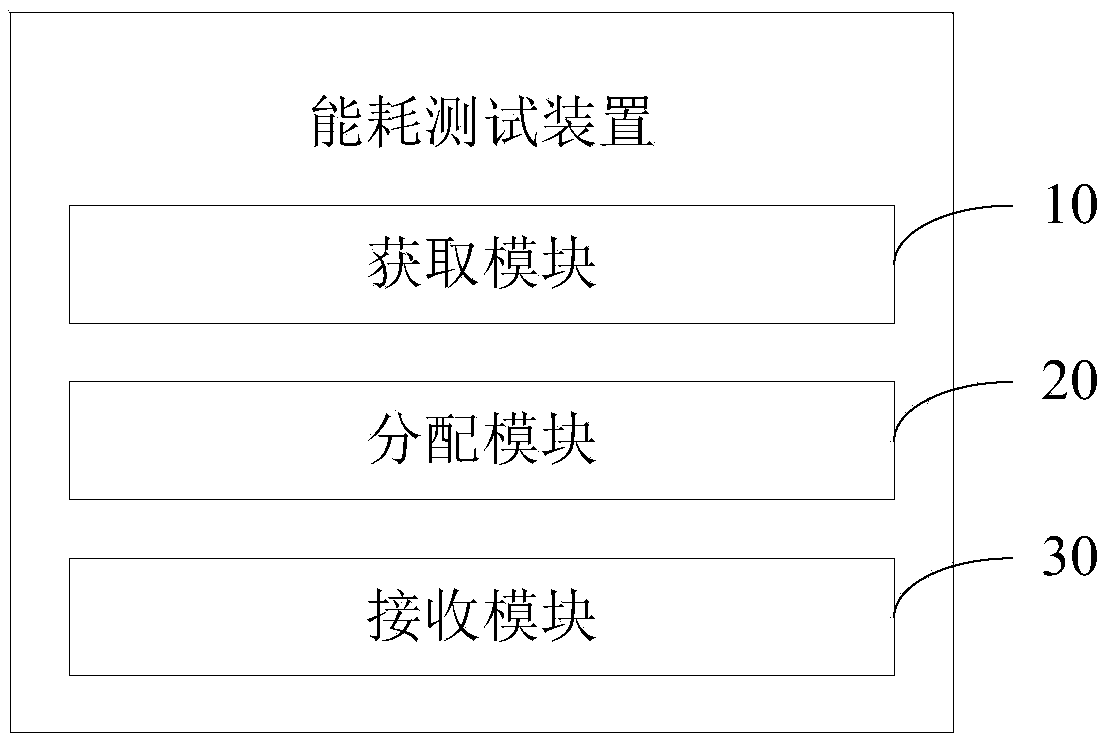

Energy consumption testing method and device

ActiveCN104731693AFully automatedAvoid Manual TestingElectric devicesHardware monitoringData acquisitionTest fixture

The invention discloses an energy consumption testing method. The energy consumption testing method includes the following steps that when a testing instruction is received, a preset testing process is acquired, and control instructions corresponding to testing steps in the testing process are acquired; the control instructions are sequentially sent to a tested computer and a testing instrument connected with the tested computer according to the testing process so that the tested computer and the testing instrument connected with the tested computer can respond to the received control instructions; energy consumption data fed back by energy consumption data acquisition equipment connected with the tested computer are received. The invention further discloses an energy consumption testing device. The energy consumption testing method and the energy consumption testing device can improve the energy consumption testing efficiency.

Owner:RHEINLAND SHENZHEN

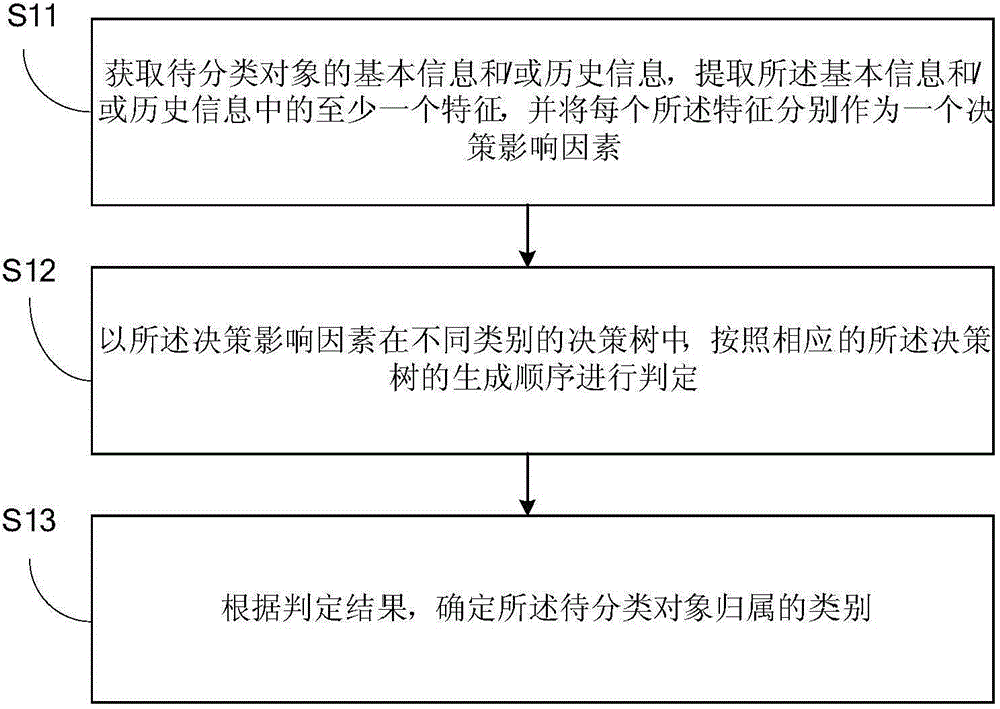

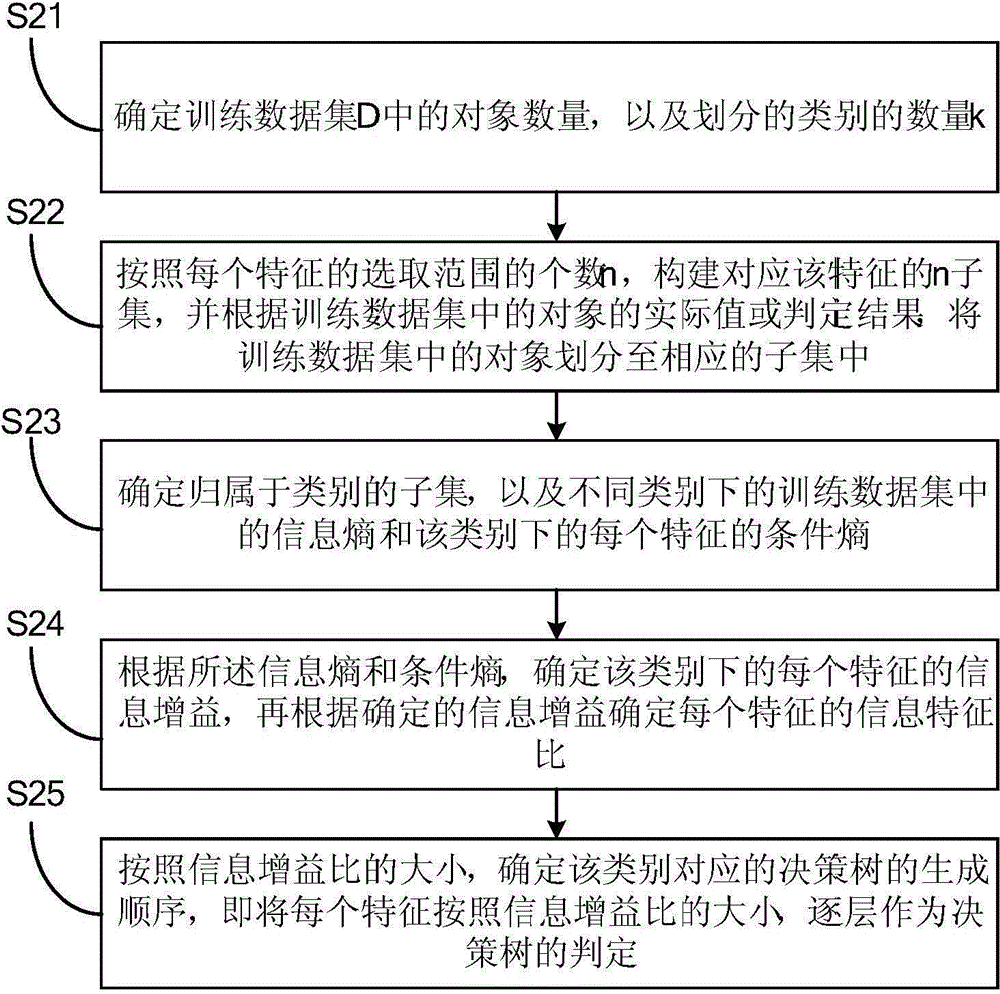

Decision-tree-based translator classification method

InactiveCN104572854AAvoid Manual TestingImprove reliabilityRelational databasesSpecial data processing applicationsClassification methodsDependability

The invention discloses a decision-tree-based translator classification method, which comprises the following steps of acquiring the basic information and / or the historical information of an object to be classified, extracting at least one characteristic in the basic information and / or the historical information, and taking each characteristic as a decision influence factor; performing judgment according to a generation sequence of a corresponding decision tree in the decision trees of different classes with the decision influence factors; determining the class to which the object to be classified belongs according to a judgment result. According to the method, objective data and information are extracted from the basic information and the historical information, and the decision trees are used for judging the data and the information, so that the reliability is greatly improved, a translator is prevented from being manually tested, human and material cost is lowered, and the translation efficiency can be remarkably improved.

Owner:IOL WUHAN INFORMATION TECH CO LTD

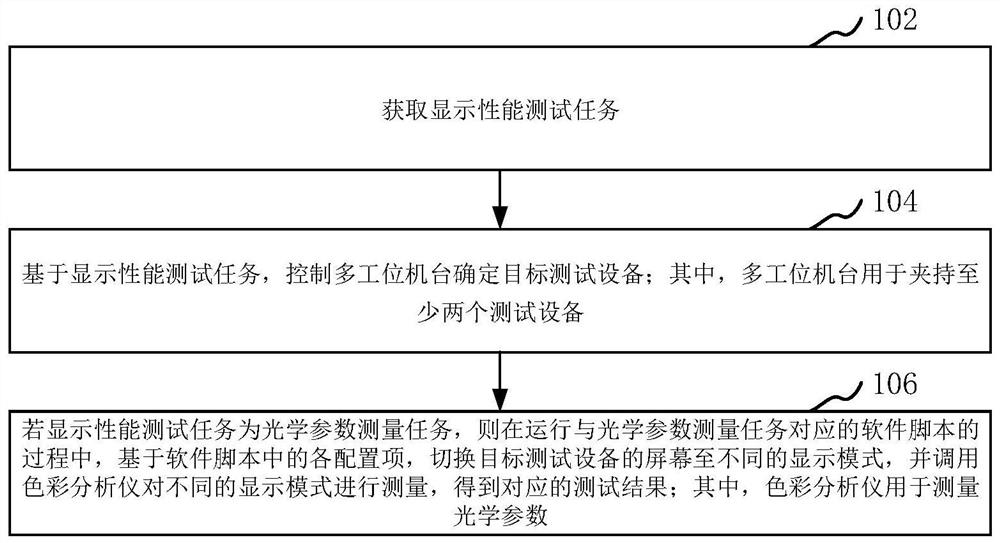

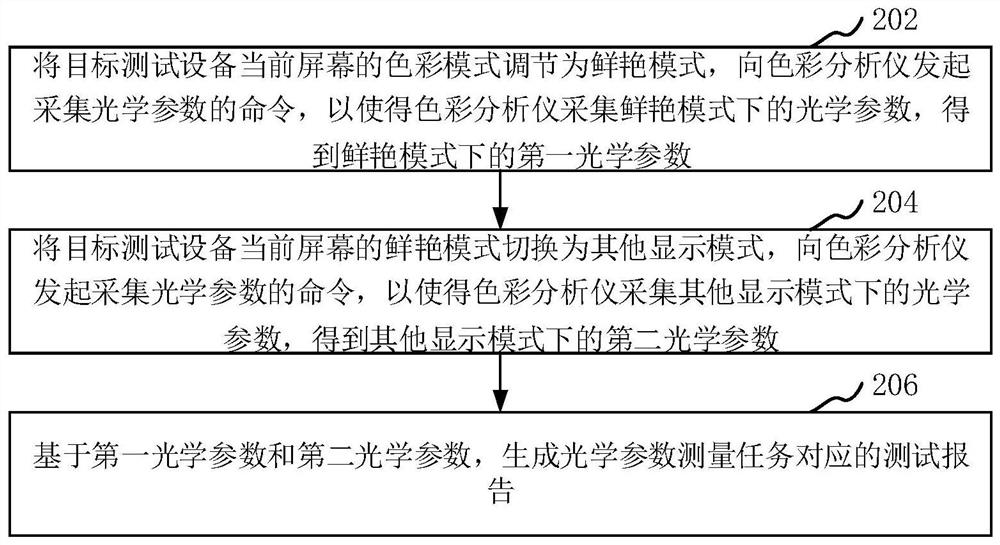

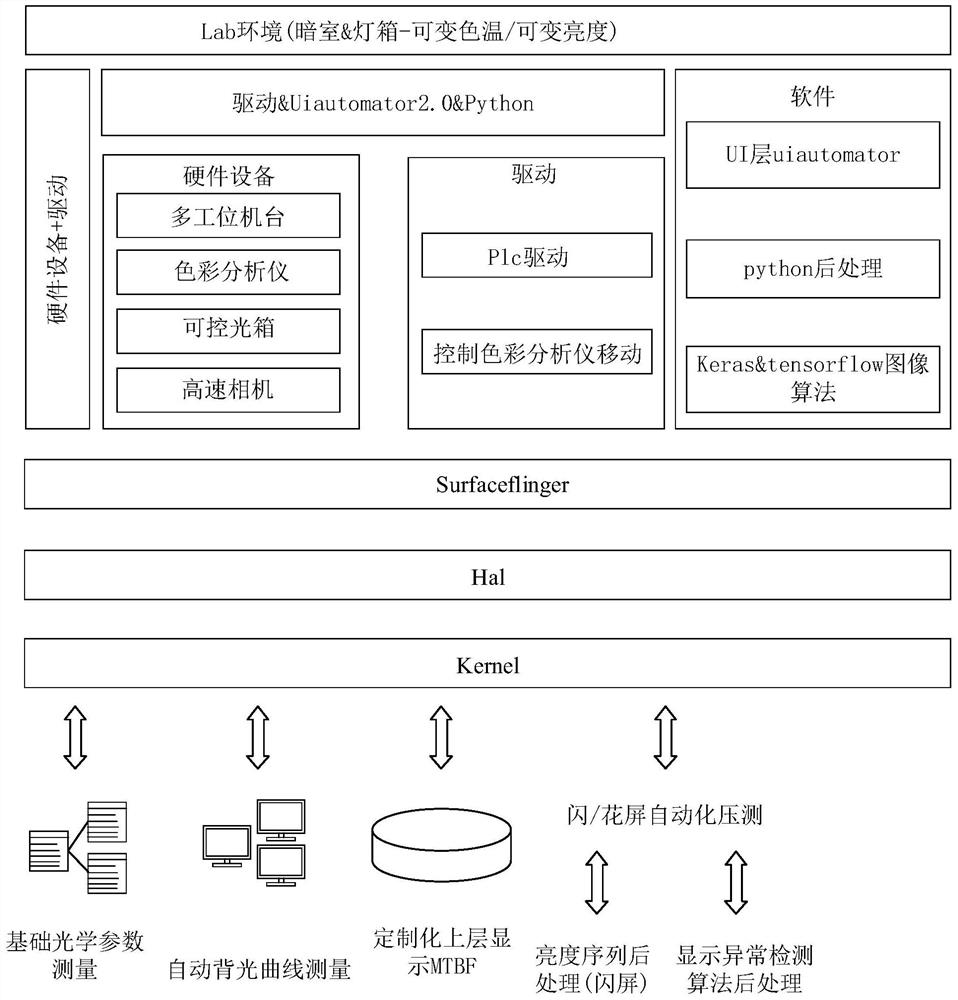

Display performance test method and device and electronic equipment

PendingCN114858417AImprove test efficiencyImplement automated testingColor measuring devicesTesting optical propertiesComputer hardwareTest efficiency

The invention relates to a display performance testing method and device, computer equipment, a storage medium and a computer program product. The method comprises the following steps: acquiring a display performance test task; based on the display performance test task, controlling a multi-station machine table to determine target test equipment; wherein the multi-station machine table is used for clamping at least two pieces of test equipment; and if the display performance test task is an optical parameter measurement task, switching a screen of the target test equipment to different display modes based on each configuration item in a software script in a process of running the software script corresponding to the optical parameter measurement task, calling a color analyzer to measure different display modes to obtain corresponding test results; wherein the color analyzer is used for measuring optical parameters. By adopting the method, the test efficiency of the display performance test can be effectively improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

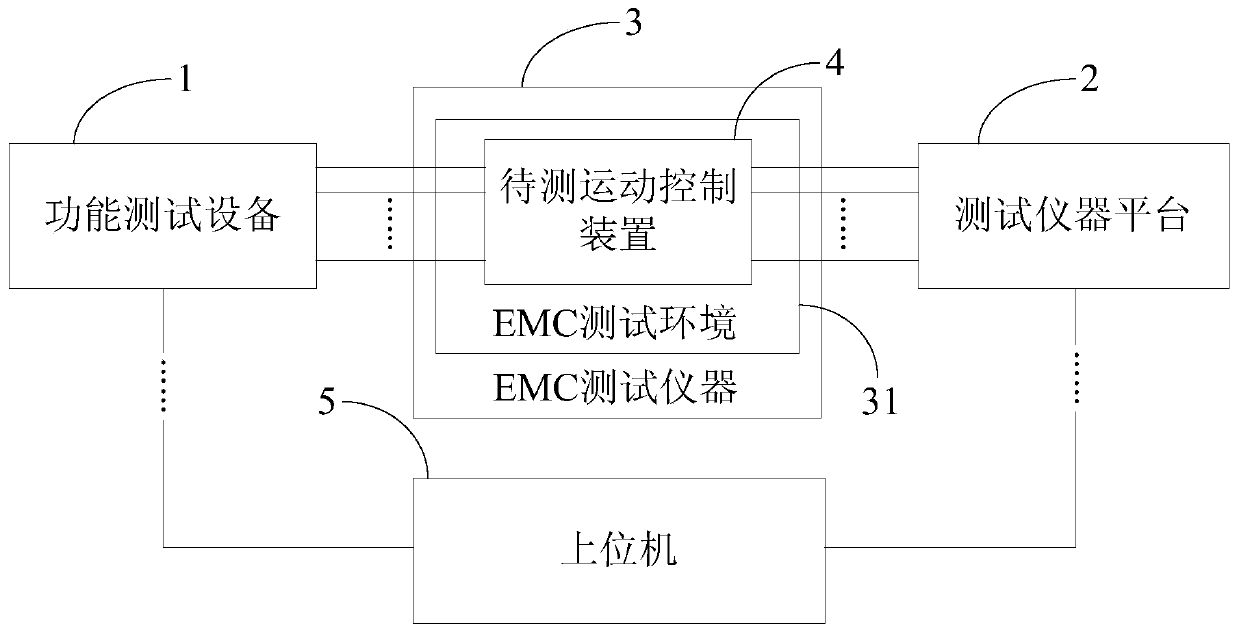

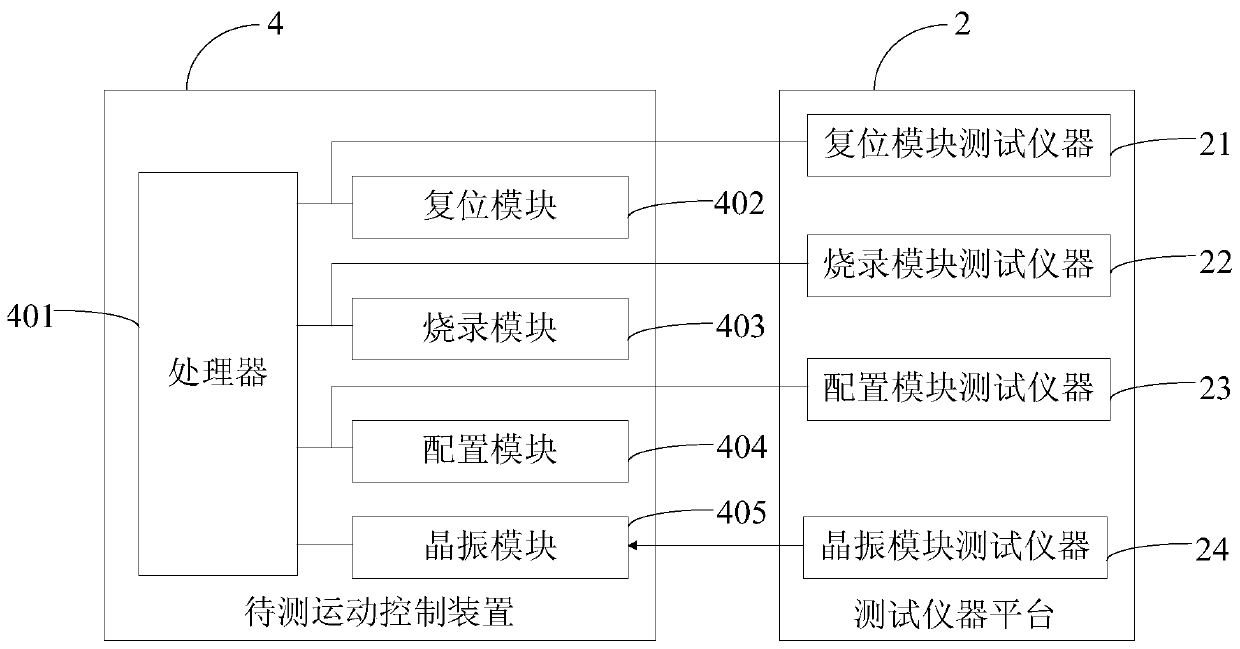

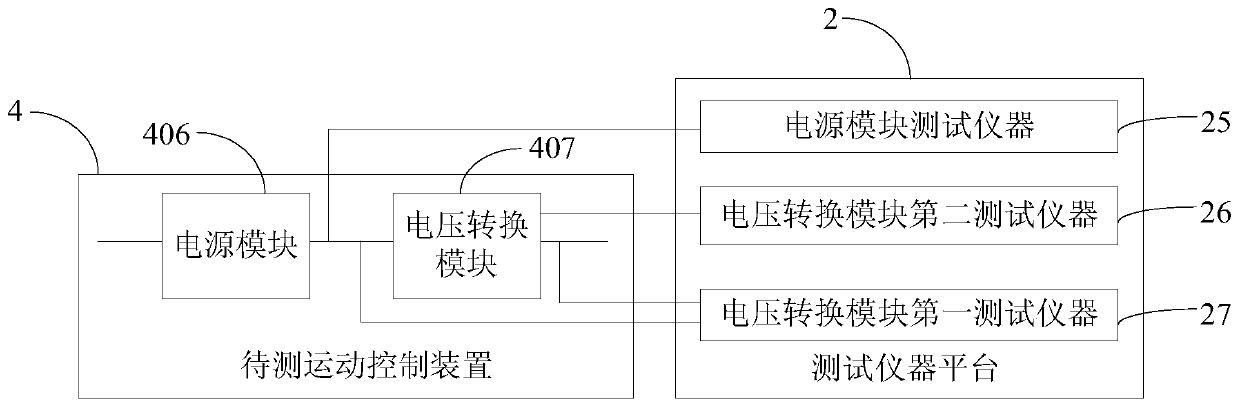

Test system of motion control device

PendingCN111290375ATest automationAvoid Manual TestingProgramme controlElectric testing/monitoringPhysical medicine and rehabilitationFunctional testing

The invention provides a test system of a motion control device. The test system comprises an EMC test instrument, a function test device, an upper computer and a test instrument platform, wherein thefunction test device is connected with an interactive interface of a to-be-tested motion control device; the function test device is used for monitoring an interaction signal of the interaction interface; the test instrument platform comprises at least two test instruments, and different test instruments are connected to different circuit modules of the to-be-tested motion control device so as toacquire operation information of the corresponding circuit module; the upper computer is used for determining whether the function of the to-be-tested motion control device corresponding to the interaction signal is abnormal or not according to the interaction signal or the state information of the interaction signal, and obtaining a function test result for the to-be-tested motion control device; and according to the received operation information, whether the corresponding circuit module is abnormal or not is determined, and a circuit test result for the to-be-tested motion control device is obtained.

Owner:上海柏楚数控科技有限公司

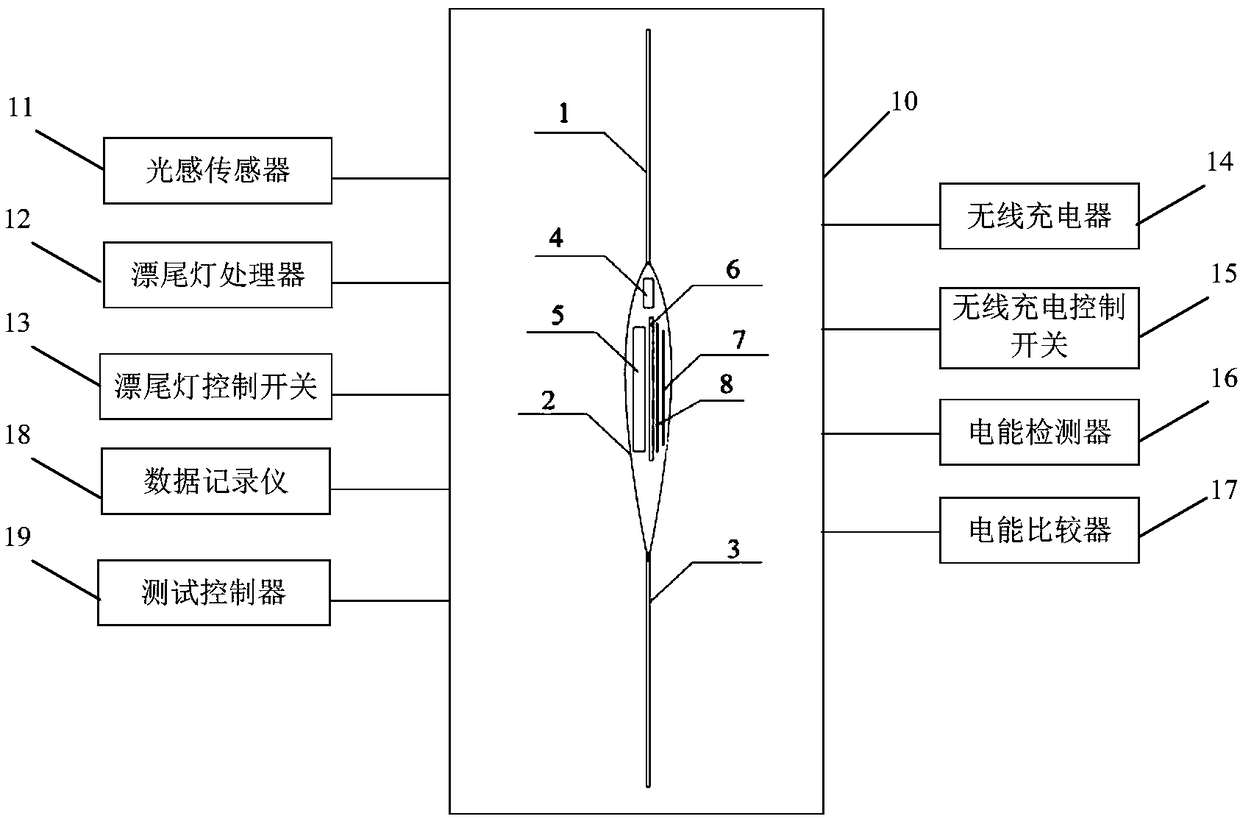

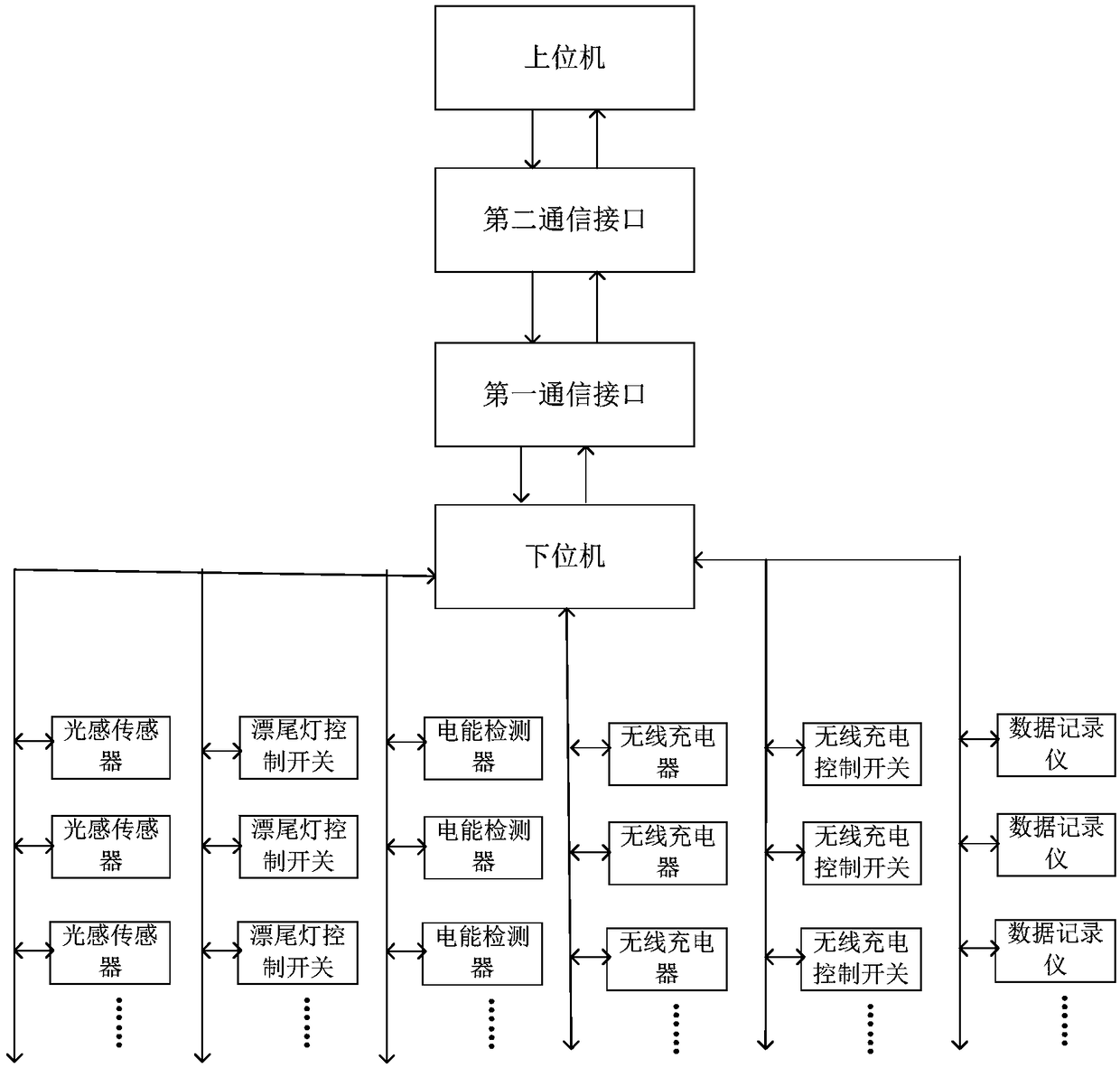

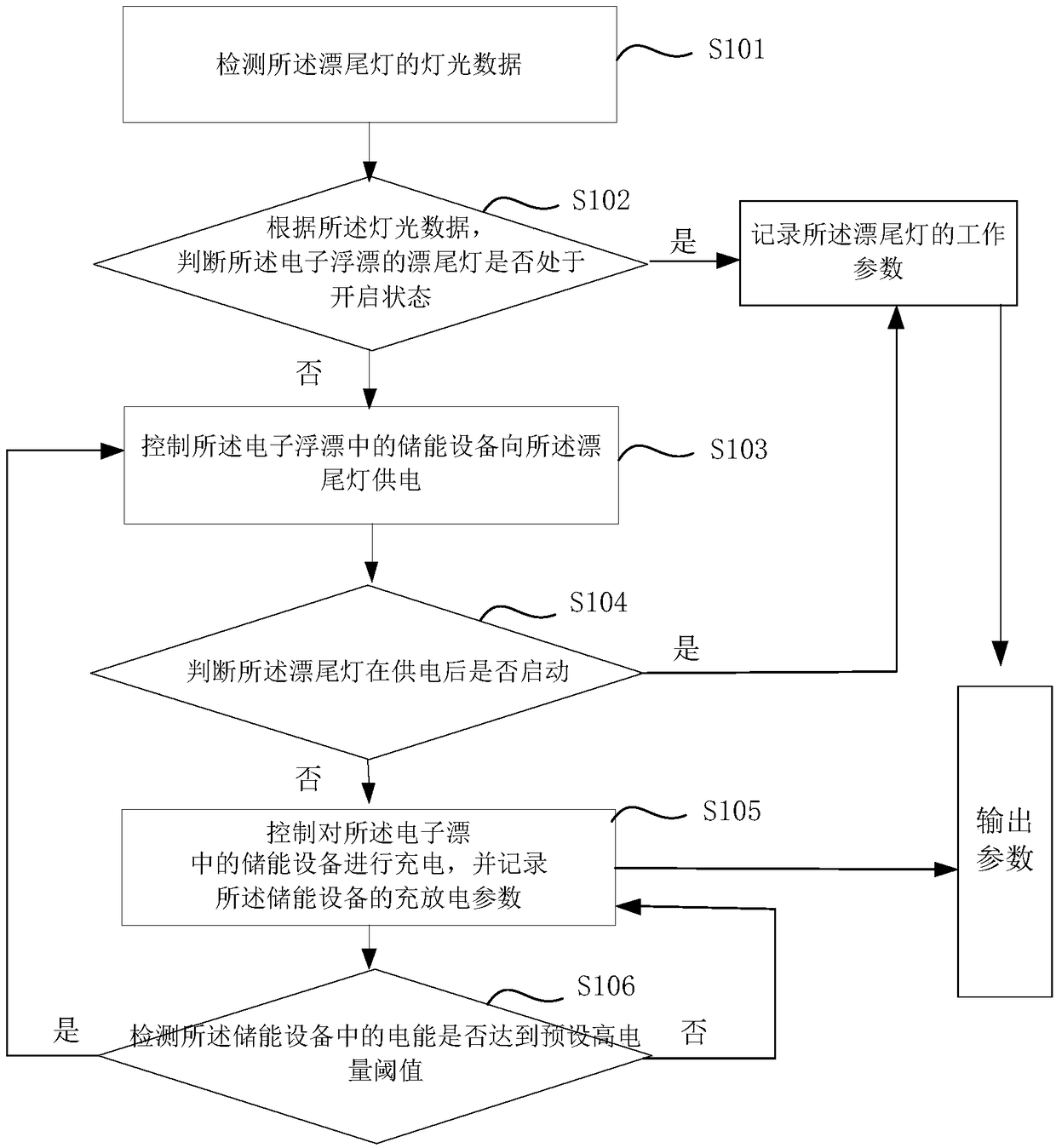

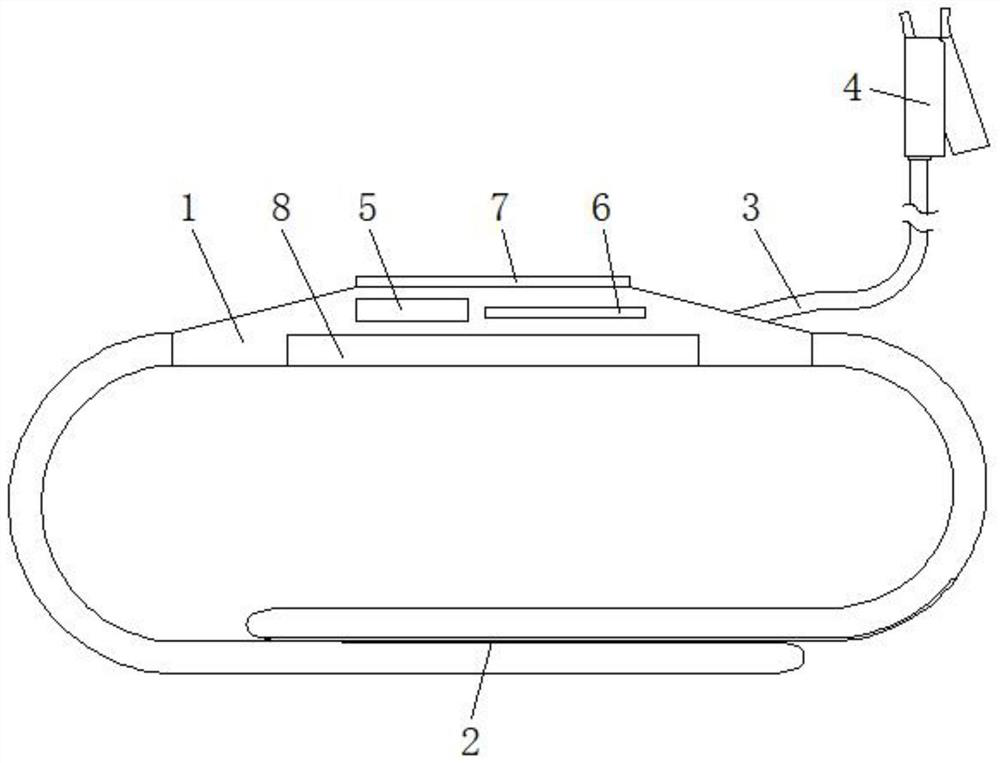

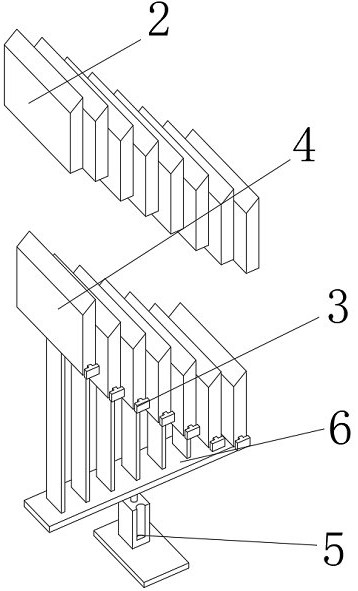

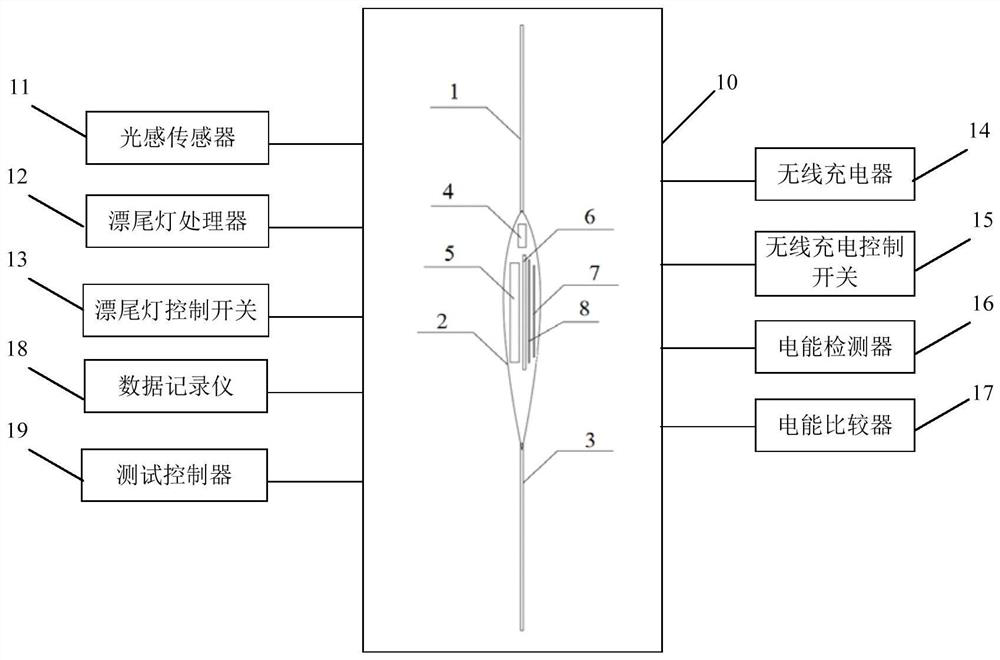

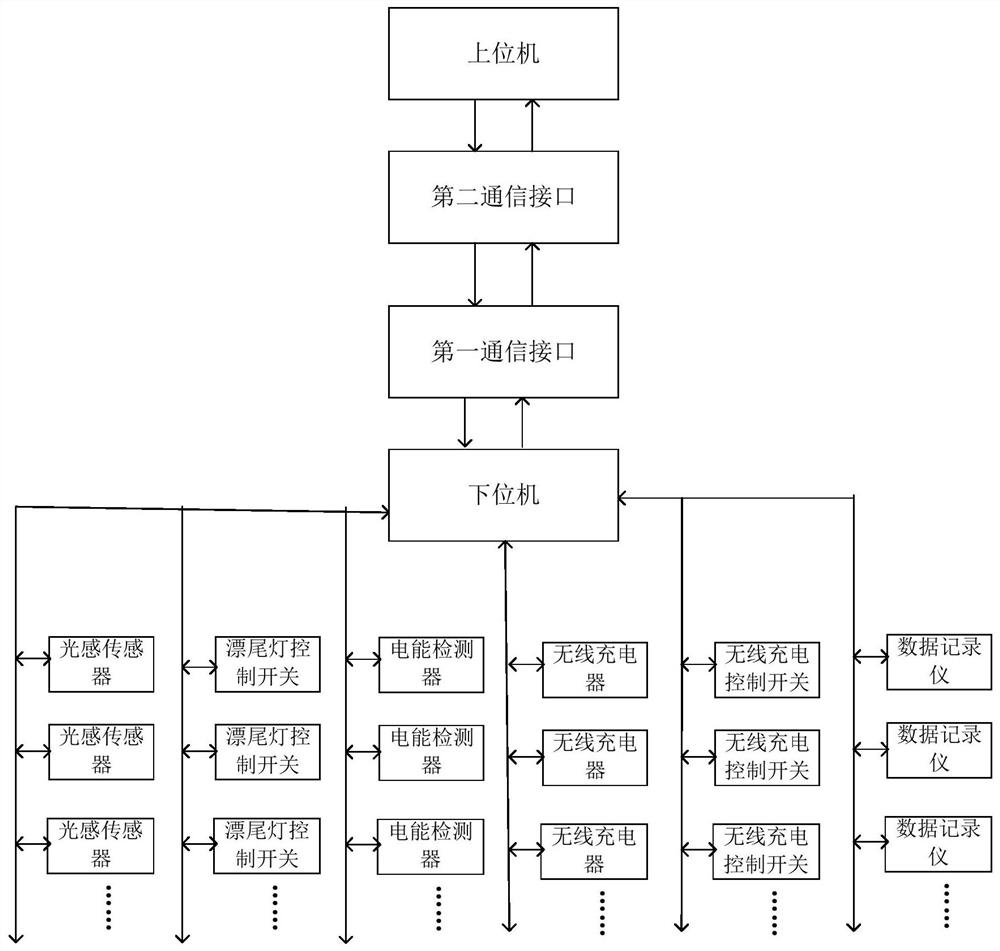

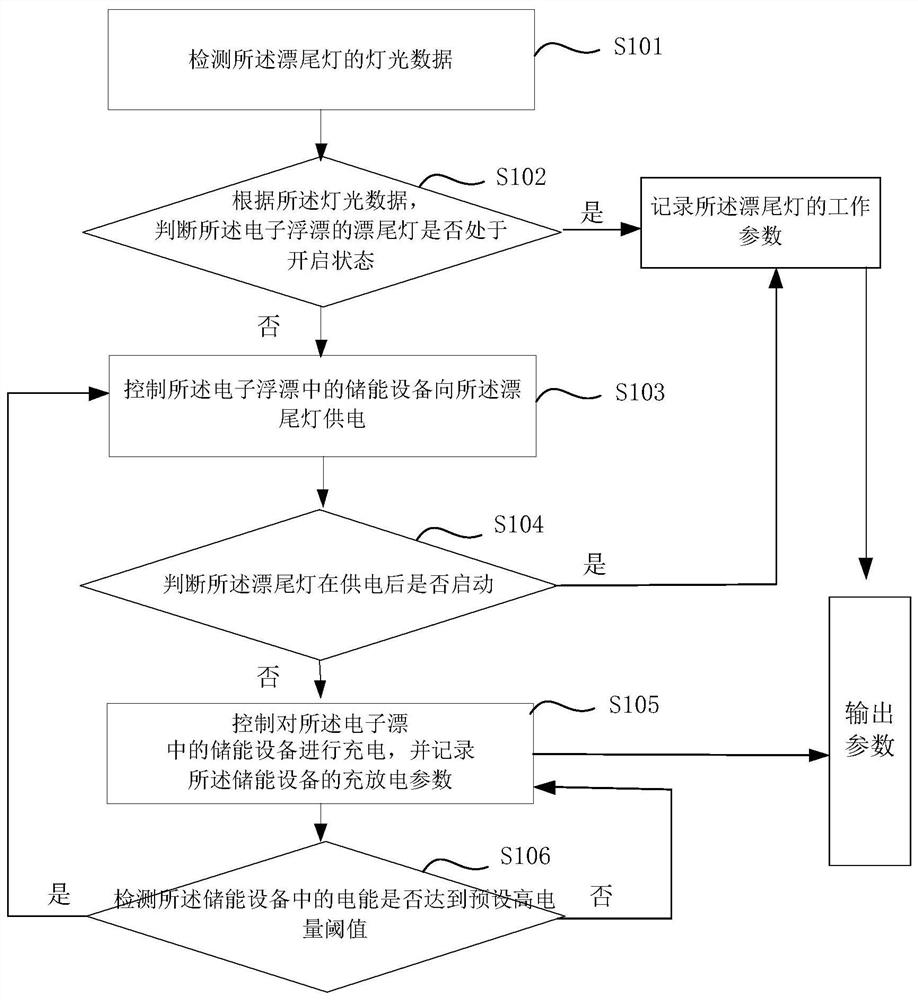

Wireless charging electronic float automatic test device, system and method

The invention relates to a wireless charging electronic float automatic test device, system and method. A wireless charging electronic float is provided with floating taillight and energy storage equipment. A device module comprises an installation position, a light sensing sensor, a floating taillight processor, a floating taillight control switch, a wireless charger, a wireless charging controlswitch, an electric energy detector, an electric energy comparator, a data recorder and a test controller. When the wireless charging electronic float automatic test device tests a wireless charging electronic float, performance parameters when the wireless charging electronic float works or charges can be detected by the sensor or other devices, such as the floating taillight and the energy storage equipment and the like. The starting of the floating taillight and the charging process of the energy storage equipment can be automatically controlled, and then, the automatic test system can completely avoid manual testing, each performance testing of the wireless charging electronic float can be completed, a test speed is fast and efficiency is high.

Owner:深圳市众凌汇科技有限公司

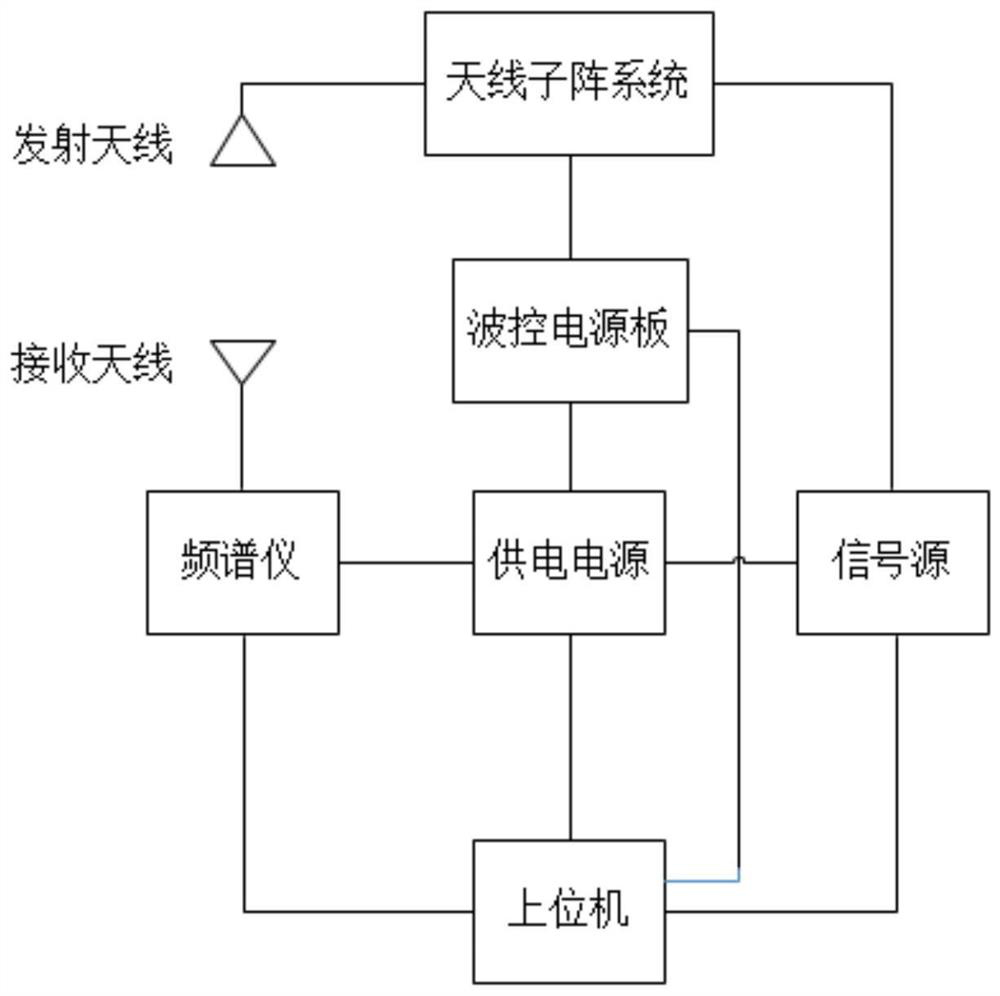

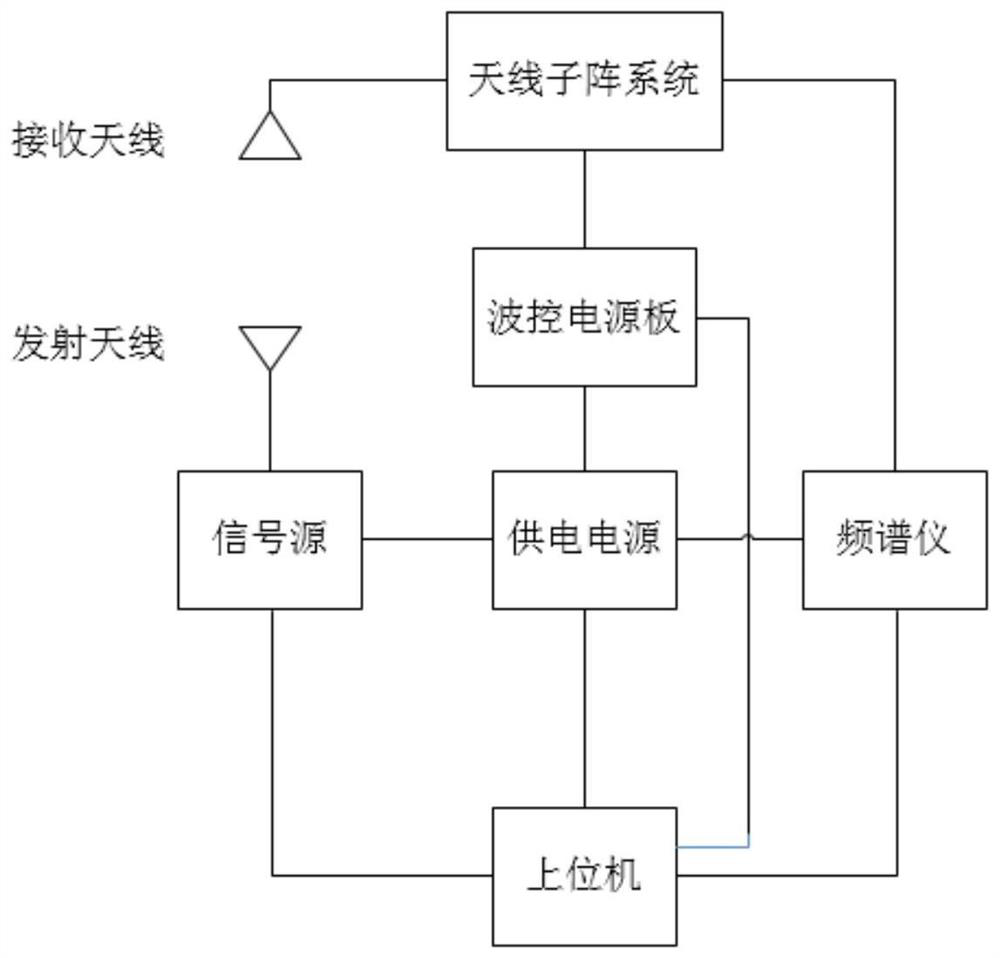

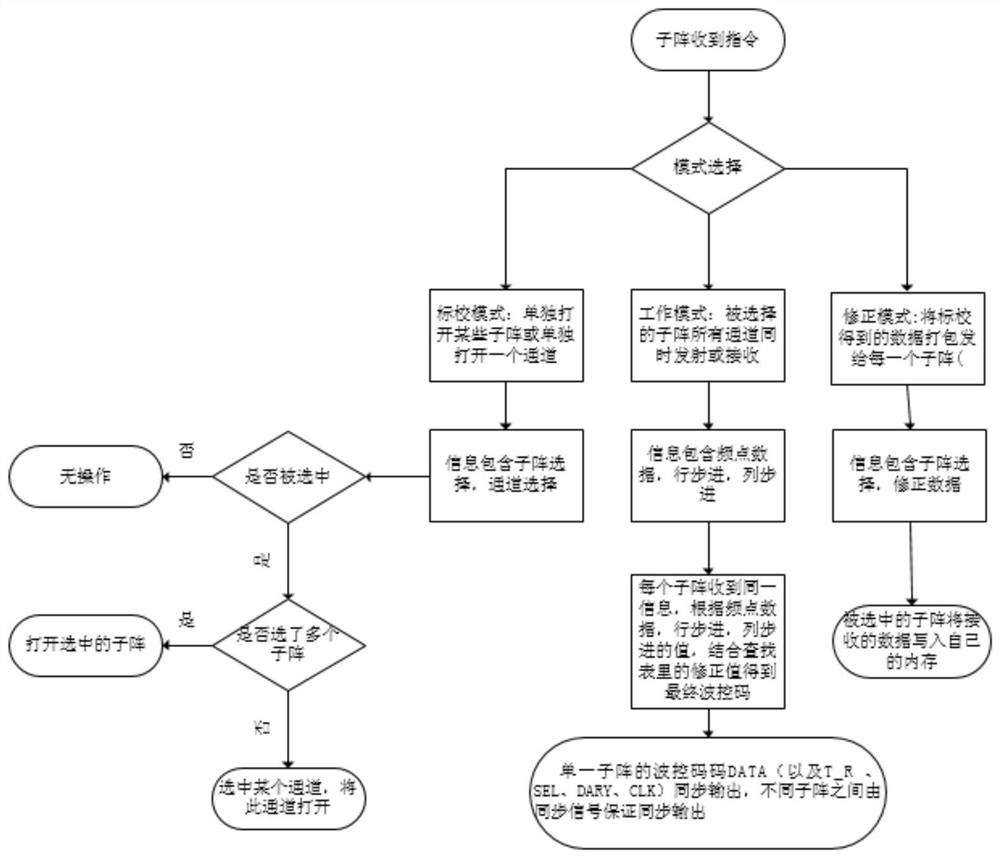

Static detection device and method of phased array radar system

PendingCN114063026AImplement automatic detectionAvoid Manual TestingWave based measurement systemsTelecommunicationsRadar systems

The invention relates to static detection device and method for a phased array radar system. The device comprises an upper computer, a power supply, a signal source, a frequency spectrograph, a wave control power panel, an antenna sub-array system, a transmitting antenna and a receiving antenna; wherein the upper computer is respectively connected with the power supply, the frequency spectrograph and the signal source, and the upper computer is also connected with the wave control power panel through a low-voltage differential signal; the power supply is also respectively connected with the frequency spectrograph, the signal source and the wave control power supply board; the antenna sub-array system is connected with the transmitting antenna wave control power panel and the signal source respectively; and the frequency spectrograph is also connected with the receiving antenna. By arranging the wave control power supply board, the power supply and the upper computer, automatic detection of the antenna sub-array system is realized, manual testing is avoided, the labor cost is saved, the testing precision is improved, and the testing accuracy is ensured.

Owner:ZHEJIANG UNIV

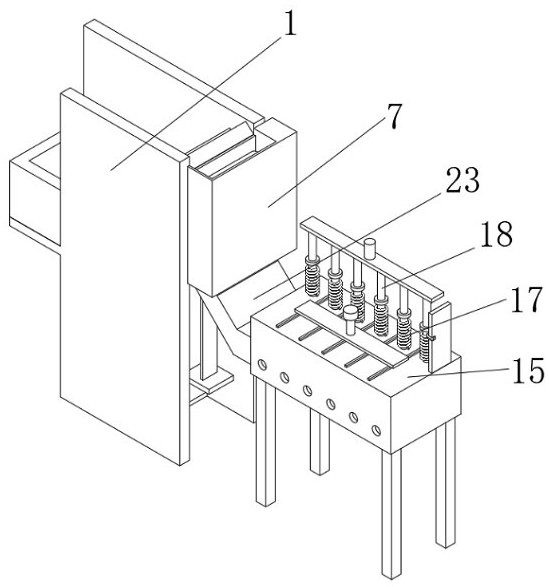

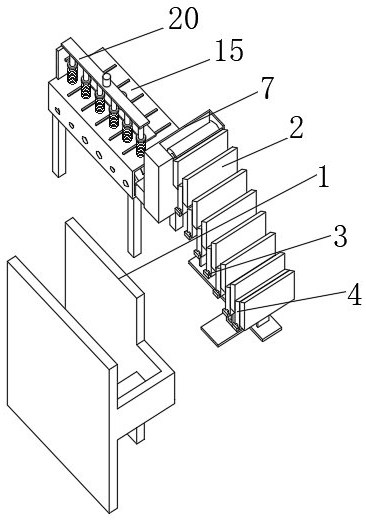

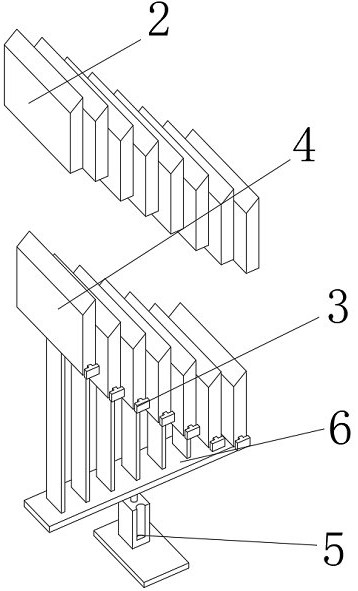

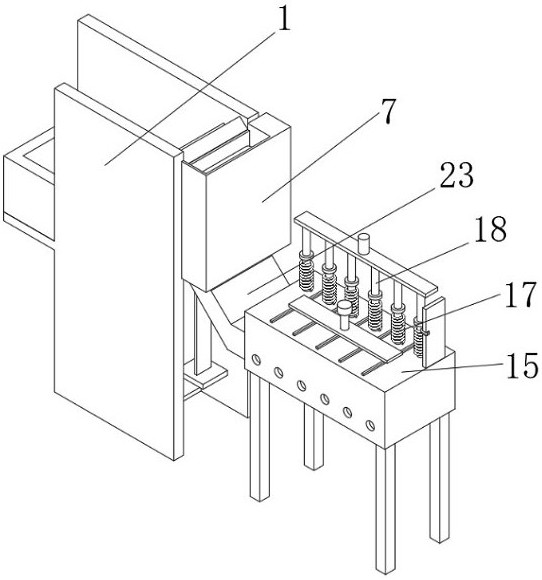

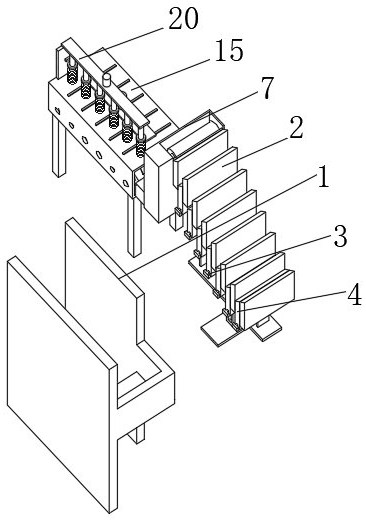

Battery cell testing device for intelligent electric vehicle production

ActiveCN114325408AHigh precisionEasy to testElectrical testingElectric vehicleMechanical engineering

The invention discloses a battery cell testing device for intelligent electric vehicle production, and relates to the technical field of battery cell testing devices, in particular to a battery cell testing device for intelligent electric vehicle production, which comprises a mounting base body, a progressive block is fixedly mounted on the inner side of the mounting base body, and a sliding groove is formed in the inner side of the mounting base body. A sliding block is movably connected in a sliding groove formed in the inner side of the installation base body in a sleeved mode, a driving block is fixedly installed on the inner side of the sliding block, and the top of the driving block and the top of the sliding block are both inclined planes. According to the battery cell testing device for intelligent electric vehicle production, a battery cell is placed in the inner cavity of the mounting base body, then a hydraulic rod is started, so that a connecting plate drives a driving block to ascend, the battery cell is jacked, the battery cell enters the top of a progressive block, and in the jacking process, the battery cell enters the progressive block; the battery cells can be arranged through the cooperation of the driving block and the progressive block, so that the battery cells are neat and ordered, the later test is facilitated, and the accuracy of the test result is improved.

Owner:CHANGCHUN VOCATIONAL INST OF TECH

Energy consumption test method and device

ActiveCN104731693BFully automatedAvoid Manual TestingElectric devicesHardware monitoringData acquisitionTest fixture

The invention discloses an energy consumption testing method. The energy consumption testing method includes the following steps that when a testing instruction is received, a preset testing process is acquired, and control instructions corresponding to testing steps in the testing process are acquired; the control instructions are sequentially sent to a tested computer and a testing instrument connected with the tested computer according to the testing process so that the tested computer and the testing instrument connected with the tested computer can respond to the received control instructions; energy consumption data fed back by energy consumption data acquisition equipment connected with the tested computer are received. The invention further discloses an energy consumption testing device. The energy consumption testing method and the energy consumption testing device can improve the energy consumption testing efficiency.

Owner:RHEINLAND SHENZHEN

A kind of bmc automatic testing system and method

ActiveCN106407054BReduce labor costsAvoid Manual TestingFaulty hardware testing methodsTest efficiencyData file

The invention discloses a BMC automatic testing system. The BMC automatic testing system comprises a test object determination module, a hardware abstraction module, a script generation module, a file analysis module and a test execution module, wherein the test object determination module is used for determining to-be-tested BMC firmware; the hardware abstraction module is used for performing abstraction processing on hardware in a target server to obtain corresponding class files; the script generation module is used for generating corresponding test case scripts through the class files obtained by hardware abstraction module; the file analysis module is used for analyzing preset configured files to obtain basic data files required by the test case scripts; and the test execution module is applied to the target server for performing corresponding test on the to-be-tested BMC firmware through the test case scripts and the basic data files. By adoption of the BMC automatic testing system, the manpower cost in the BMC firmware testing is lowered while the test efficiency is improved. In addition, the invention also correspondingly discloses a BMC automatic testing method.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

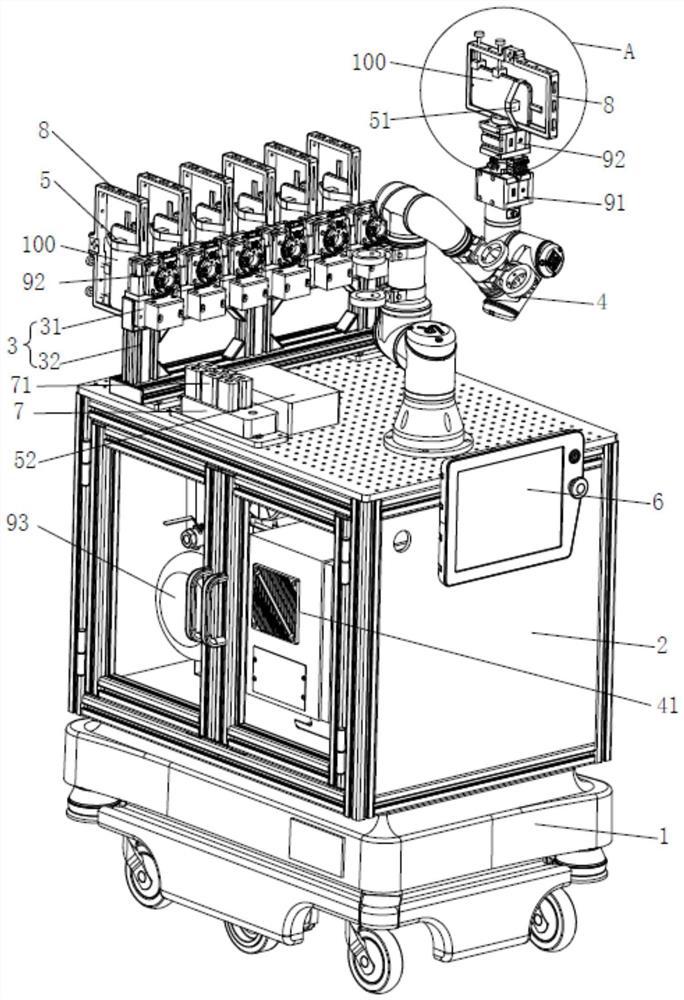

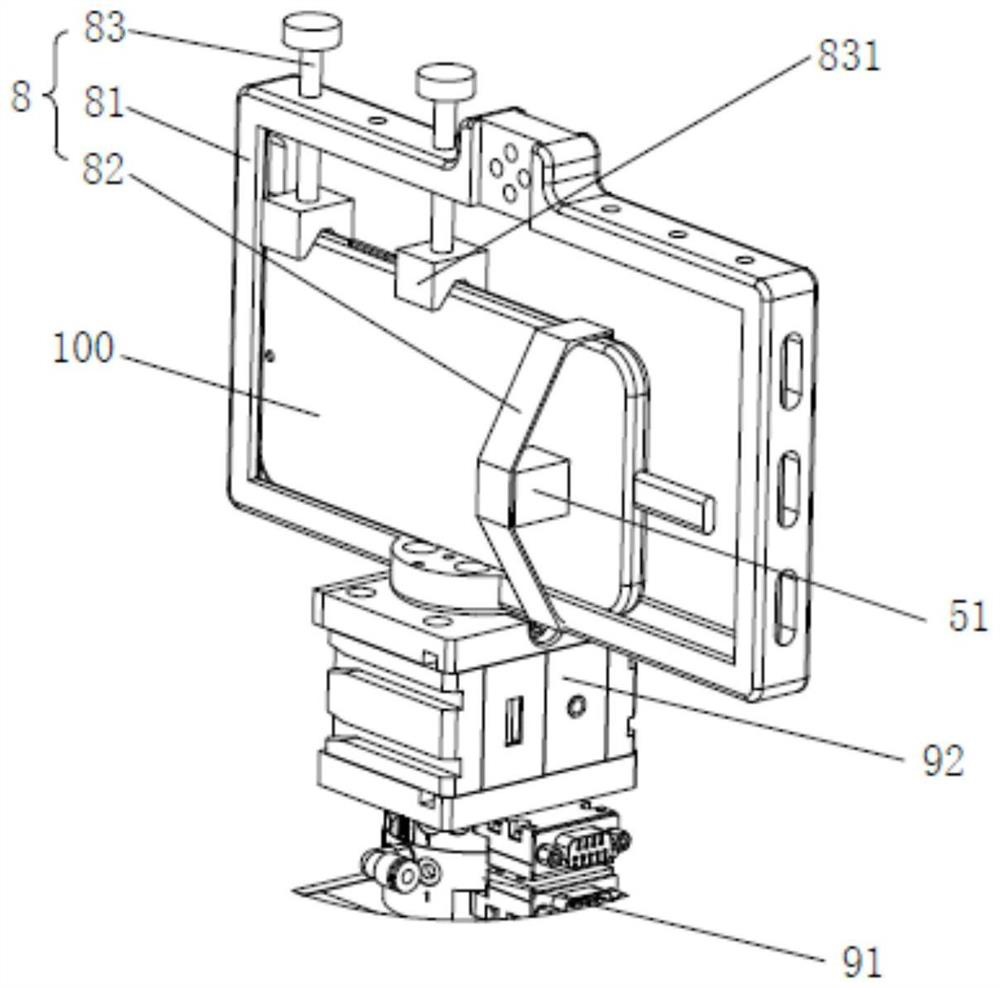

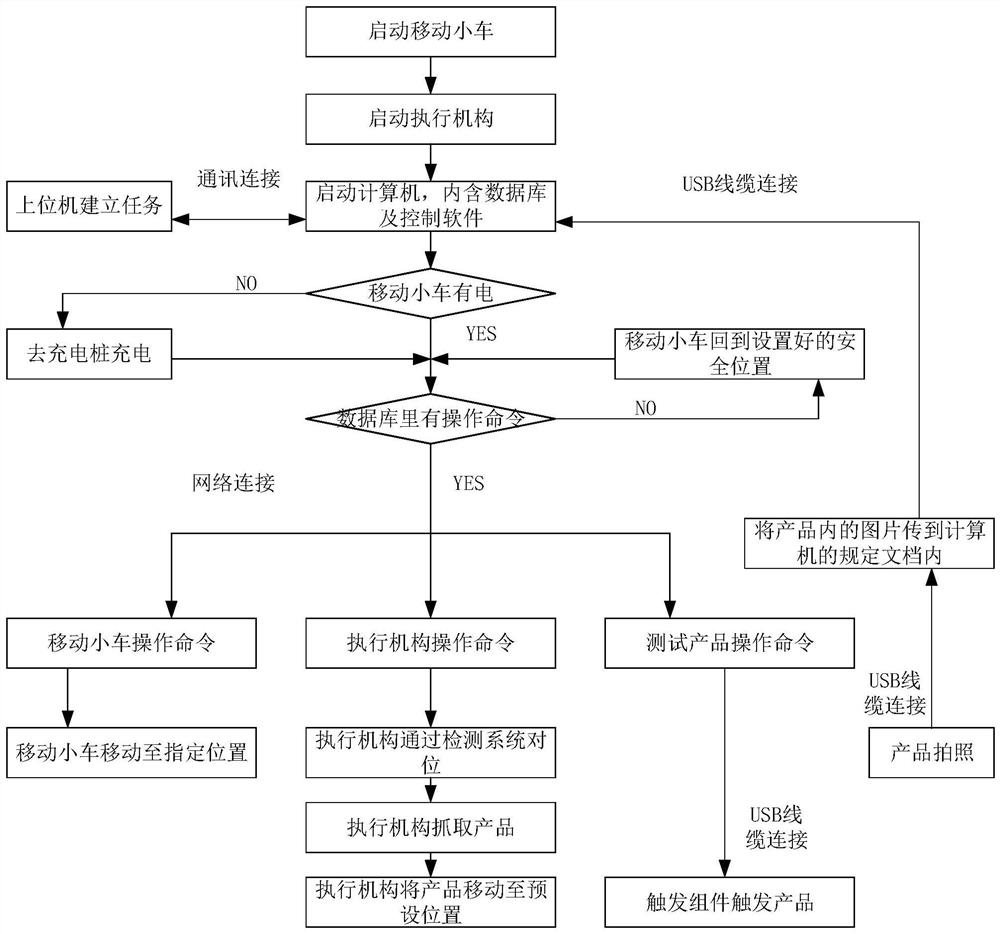

Automatic testing equipment for products

PendingCN114217161AAvoid Manual TestingEasy to operateElectrical testingProcess engineeringE testing

The invention belongs to the technical field of automatic equipment, and discloses automatic testing equipment for products, which comprises a frame body, and a containing bin, an execution mechanism, a trigger assembly and a computer which are arranged on the frame body, and is characterized in that the containing bin can contain a plurality of products, and when the products are contained in the containing bin, the products can be charged; the executing mechanism can move the products in the containing bin to a preset position and can place the products into the containing bin. The triggering assembly can trigger the product; the computer is in communication connection with the execution mechanism, the trigger assembly and the product located on the execution mechanism, and the computer is in communication connection with the upper computer. The upper computer enables the execution mechanism to move according to a preset track through the computer, enables the product located at the preset position to enter a shooting mode, and enables the triggering assembly to trigger a shooting key of the product. According to the automatic test equipment of the product, automatic shooting is realized, the shooting efficiency is improved, the consistency of shooting positions is improved, and the test data precision and the test reliability are improved.

Owner:上海研鼎信息技术有限公司

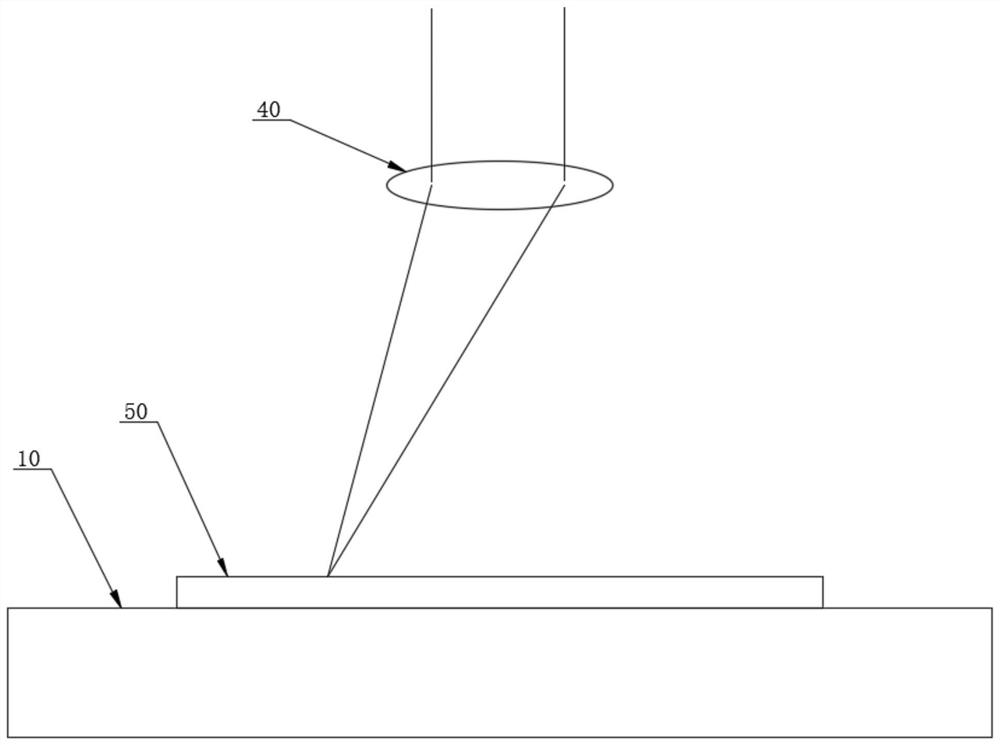

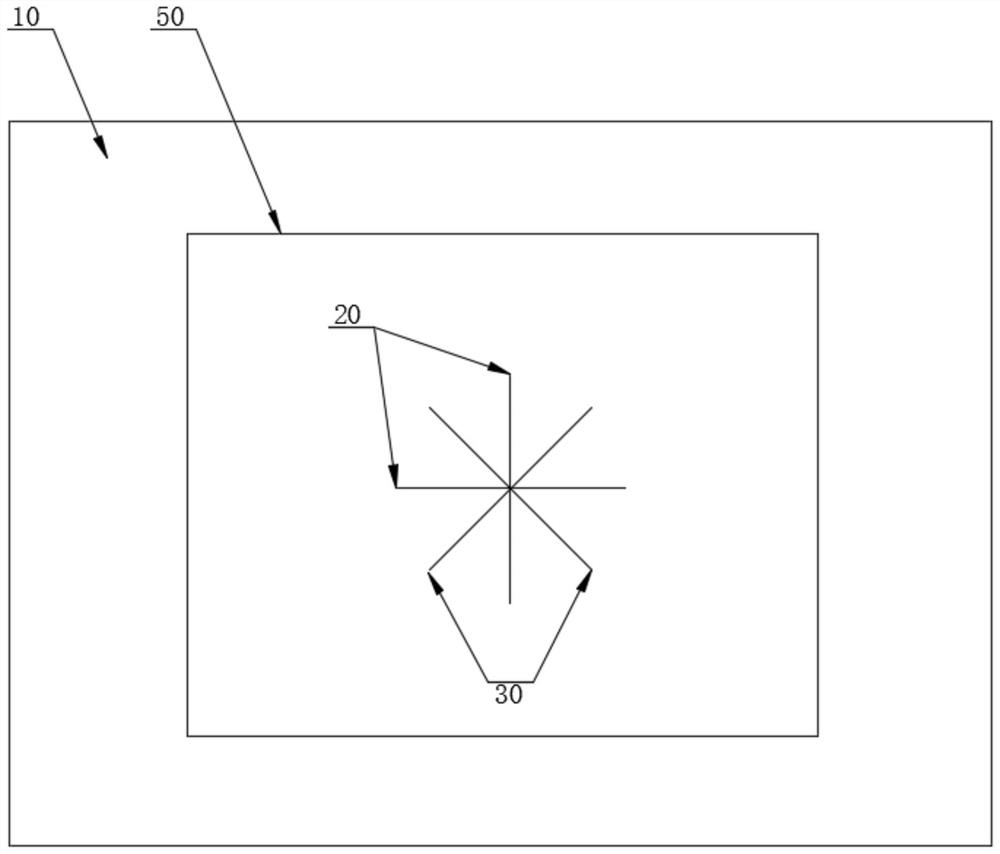

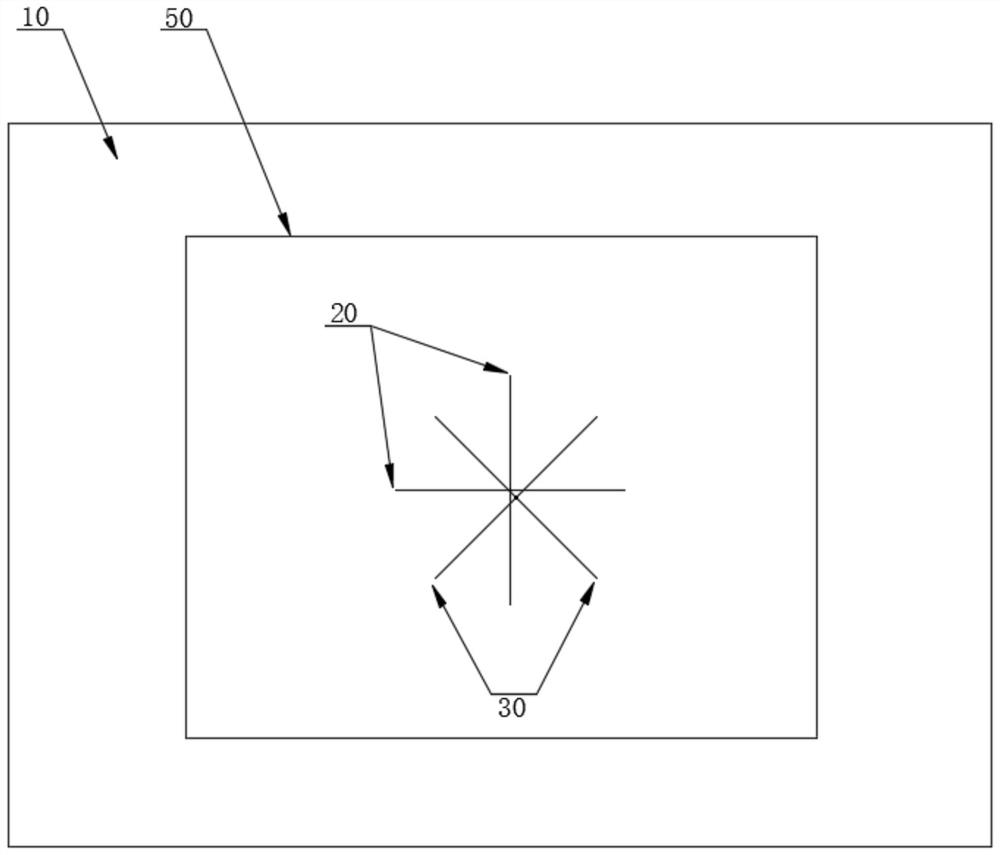

A 3D printing laser galvanometer level detection method

The invention relates to a method for detecting the level of a 3D printing laser vibrating mirror. After confirming that the printing platform is in a horizontal state, establish a cross coordinate, control the laser to print the first cross-shaped track on the printing platform, and then control the rotation of the cross coordinate to 0‑90° to control The laser continues to print the second cross-shaped track on the printing platform, and finally observe whether the intersection of the first cross-shaped track and the second cross-shaped track coincides to judge whether the vibrating mirror is installed horizontally. When the intersection of the first cross-shaped track and the second cross-shaped track coincides, the vibrating mirror is installed horizontally; when the intersection of the first cross-shaped track and the second cross-shaped track does not coincide, the vibrating mirror is not installed horizontally, This can achieve the purpose of quickly and automatically detecting whether the galvanometer is installed horizontally, thereby avoiding manual testing, greatly reducing labor costs and testing time, and improving printing yield and work efficiency.

Owner:HANS LASER TECH IND GRP CO LTD +1

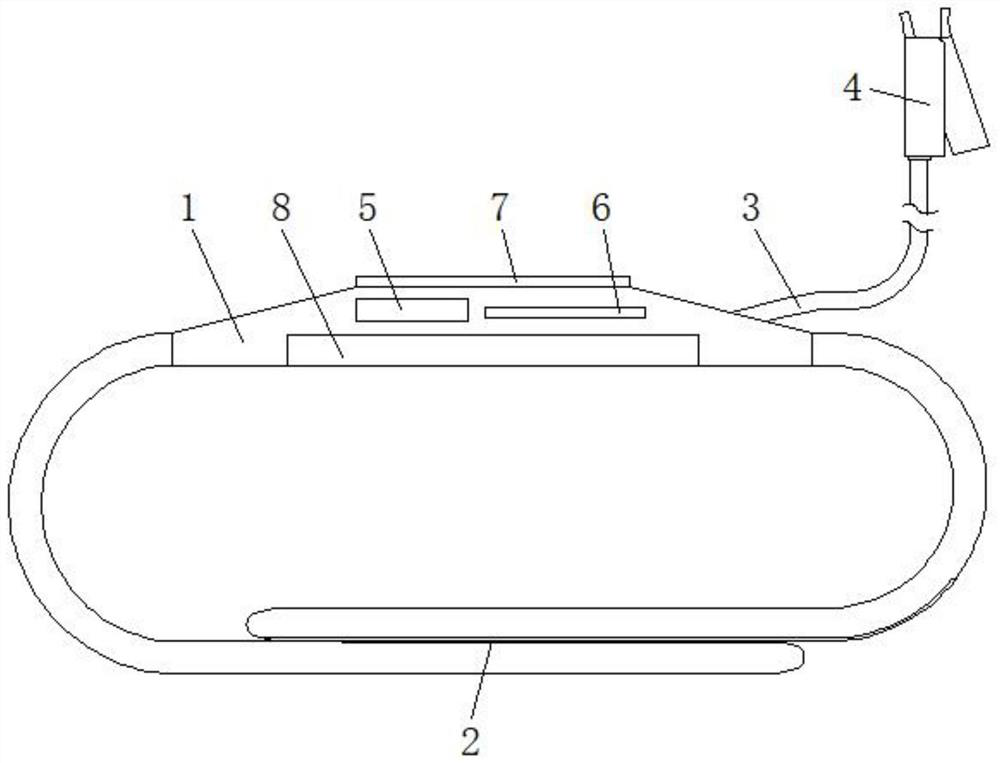

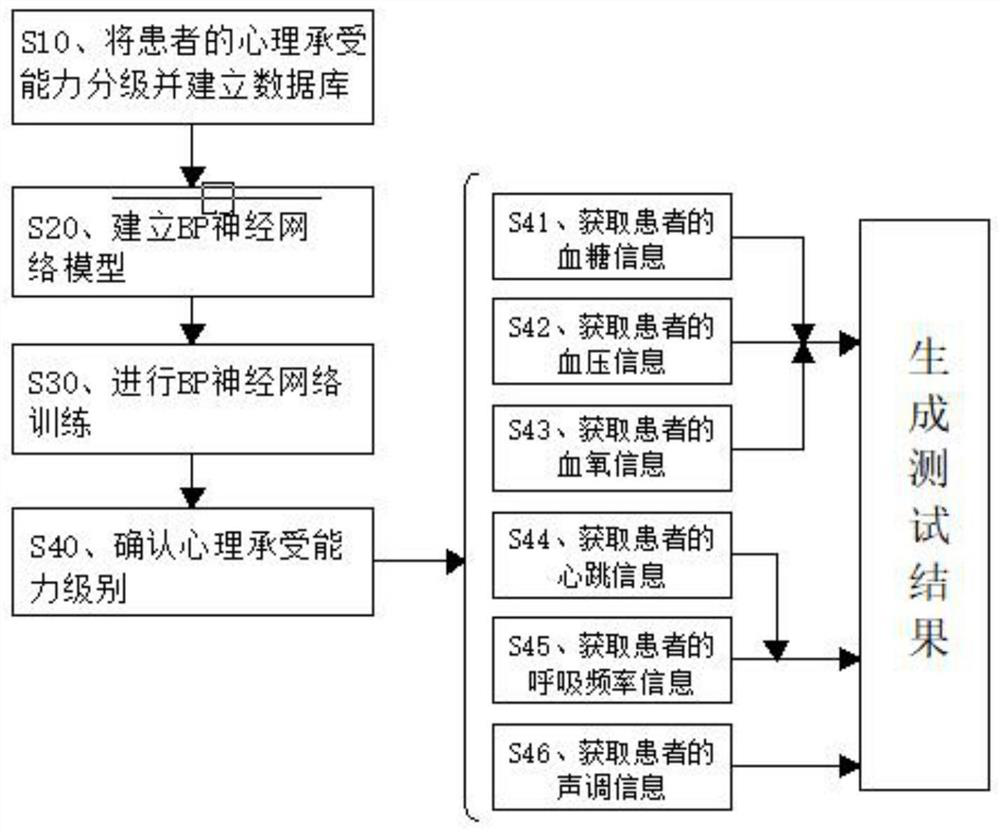

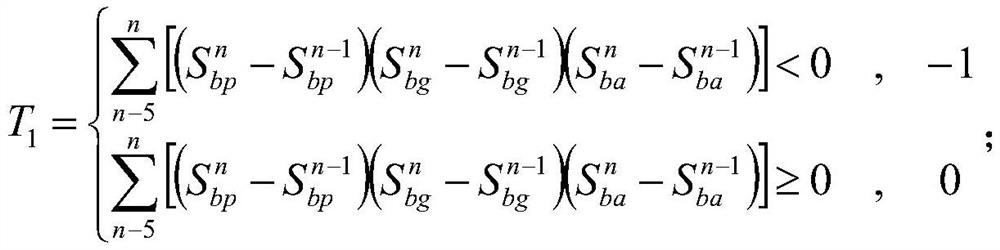

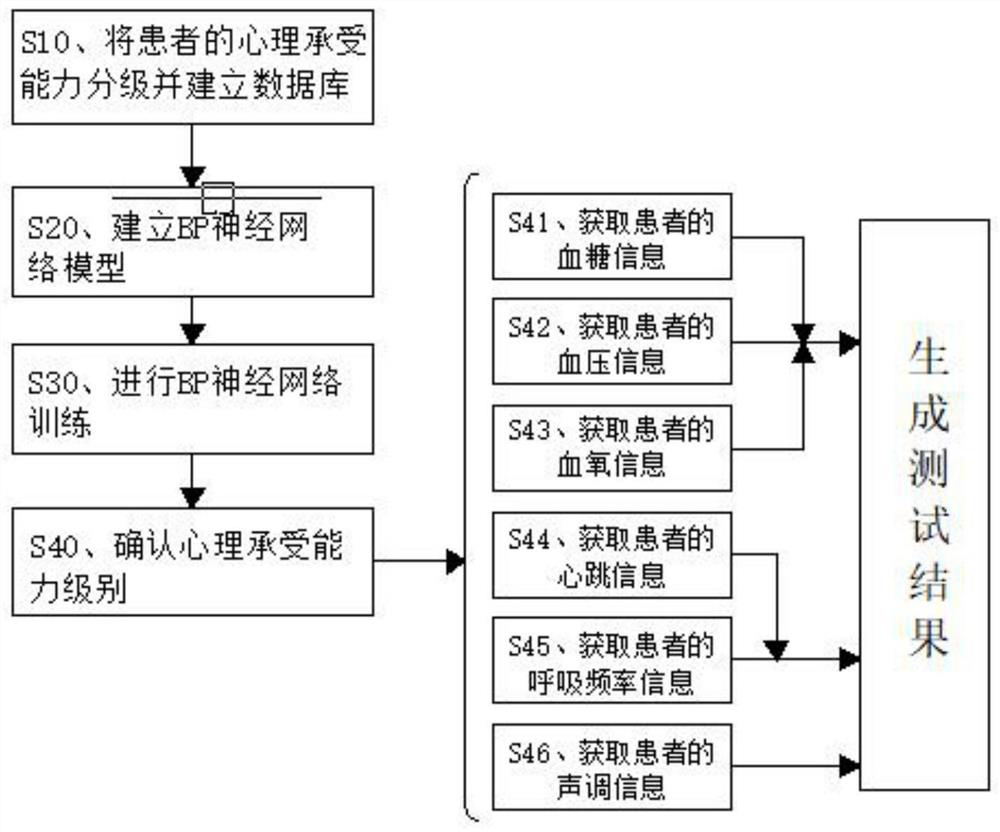

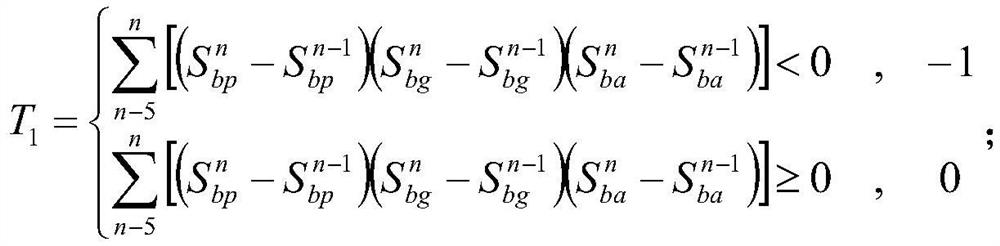

Automatic psychological tester for tumor patient and test method thereof

ActiveCN113303796AEasy to operateEasy to useEvaluation of blood vesselsSensorsPhysical medicine and rehabilitationBlood pressure

The invention discloses an automatic psychological tester for tumor patients. The automatic psychological tester comprises a shell, a wrist strap fixedly arranged outside the shell and used for wearing the shell on a wrist; a connecting wire, wherein one end of the connecting wire is fixedly connected with the shell and extends into the shell; an oxyhemoglobin saturation clip electrically connected with the other end of the connecting line and used for detecting the blood oxygen and blood sugar information of the patient; a charging power supply fixedly arranged in the shell and used for supplying power; a display screen fixedly mounted on one side of the shell; and a sensing detection unit which is fixedly installed in the shell, extends to the other side of the shell and is used for detecting information such as blood pressure, blood sugar, heartbeat and breathing frequency and tone of a patient. According to the method for automatically testing the psychology of the tumor patient, the situation of manual testing is avoided through systematic calculation, and the testing result is more accurate by considering multi-aspect information of the patient.

Owner:XIEHE HOSPITAL ATTACHED TO TONGJI MEDICAL COLLEGE HUAZHONG SCI & TECH UNIV

Android automated testing method based on particle swarm optimization algorithm

ActiveCN105512046BAvoid redundancyAvoid Manual TestingBiological modelsSoftware testing/debuggingTheoretical computer scienceModularity

The invention discloses a particle swarm optimization algorithm (PSO) based Android automatic testing method. Triggering of an application control can be carried out in a modularized manner; relatively efficient input test data can be generated; and software exception can be relatively efficiently triggered when convenience is achieved. The method comprises the following steps: (1) mounting an app on a simulator, starting view server service by a viewer module, and obtaining control hierarchy tree information of the app through a hierarchy viewer; (2) with the obtained control hierarchy tree information as input, organizing a tree structure convenient to traverse by a build tree method of a PSO module; (3) traversing a control hierarchy tree constructed by the build tree, and searching whether a historical test case exists or not in a test case module after traversing a node every time; and (4) calling a test case set stored in the test case module, thereby implementing automatic testing.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Sensitivity attenuation test method and device

ActiveCN106253996BGuaranteed accuracyImprove Sensitivity Test EfficiencyReceivers monitoringTelecommunicationsSensitivity testing

The invention relates a sensitivity attenuation test method and apparatus. The method comprises a step of obtaining the first reception sensitivity of a present channel in channels to be tested when the sensitivity attenuation tests of the channels to be tested of a terminal is carried out in order, a step of obtaining the second reception sensitivity of a former adjacent channel of the present channel in channels to be tested, and a step of determining whether the first reception sensitivity is trusted data according to the first reception sensitivity, the second reception sensitivity and a preset sensitivity jump threshold. According to the technical scheme, whether the first reception sensitivity is the trusted data can be accurately determined according to the first reception sensitivity, the second reception sensitivity and a preset sensitivity jump threshold, thus the accurate of the sensitivity test result of the present channel is ensured, and the sensitivity test efficiency can be substantially improved according to the method of automatically testing whether the first reception sensitivity is the trusted data.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

An automatic psychological tester for tumor patients and its test method

ActiveCN113303796BEasy to operateEasy to useEvaluation of blood vesselsSensorsPhysical medicine and rehabilitationPsychological testing

Owner:XIEHE HOSPITAL ATTACHED TO TONGJI MEDICAL COLLEGE HUAZHONG SCI & TECH UNIV

A cell testing device for intelligent electric vehicle production

ActiveCN114325408BHigh precisionEasy to testElectrical testingElectric vehicleMechanical engineering

The invention discloses a battery cell testing device for intelligent electric vehicle production, which relates to the technical field of battery core testing devices, in particular to a battery cell testing device for intelligent electric vehicle production, comprising an installation base, and the inner side of the installation base is fixedly installed There is a progressive block, the inner side of the installation base is provided with a chute, a sliding block is movably sleeved in the chute opened on the inner side of the installation base, and a driving block is fixedly installed on the inner side of the sliding block, and the driving block is connected to the inner side of the sliding block. The tops of the progressive blocks are beveled. The battery cell testing device for the production of smart electric vehicles, by placing the battery cell in the inner cavity of the installation base, and then starting the hydraulic rod, so that the connecting plate drives the drive block to rise, so as to lift the battery cell, so that the battery cell enters the transmission The top of the incoming block, and during the lifting process, the cells can be arranged through the cooperation of the driving block and the progressive block, so that the cells are neat and orderly, which is convenient for later testing and improves the accuracy of the test results.

Owner:CHANGCHUN VOCATIONAL INST OF TECH

A wireless charging electronic float automatic test device, system and method

The invention relates to a wireless charging electronic float automatic test device, system and method. A wireless charging electronic float is provided with floating taillight and energy storage equipment. A device module comprises an installation position, a light sensing sensor, a floating taillight processor, a floating taillight control switch, a wireless charger, a wireless charging controlswitch, an electric energy detector, an electric energy comparator, a data recorder and a test controller. When the wireless charging electronic float automatic test device tests a wireless charging electronic float, performance parameters when the wireless charging electronic float works or charges can be detected by the sensor or other devices, such as the floating taillight and the energy storage equipment and the like. The starting of the floating taillight and the charging process of the energy storage equipment can be automatically controlled, and then, the automatic test system can completely avoid manual testing, each performance testing of the wireless charging electronic float can be completed, a test speed is fast and efficiency is high.

Owner:深圳市众凌汇科技有限公司

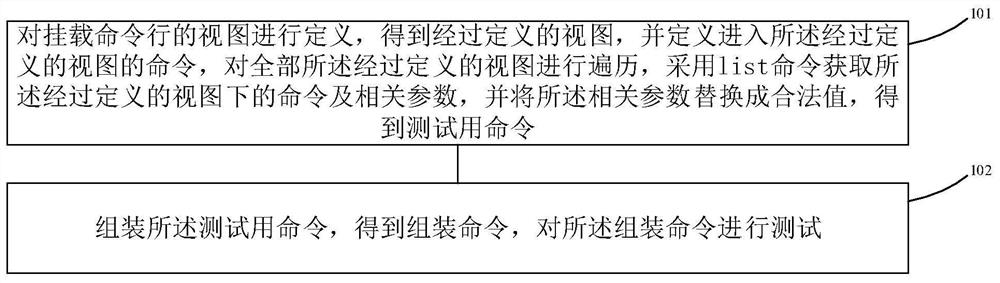

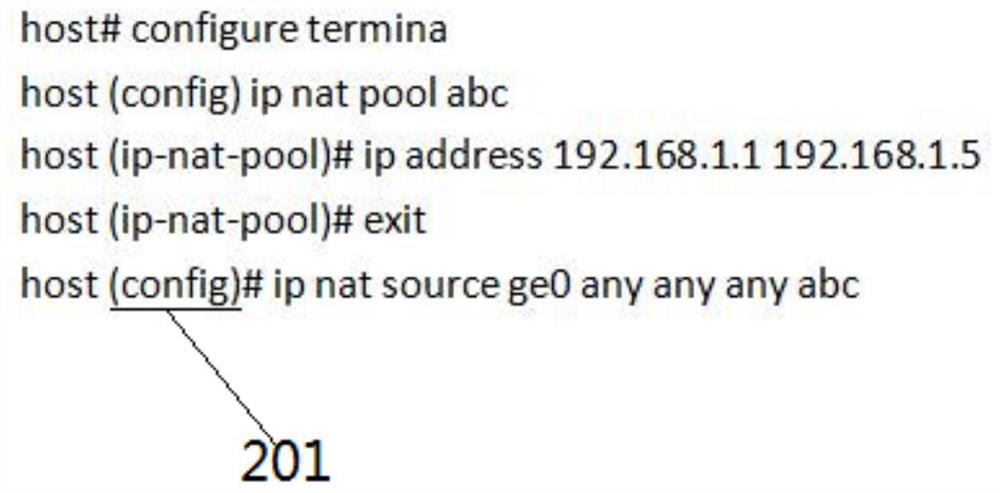

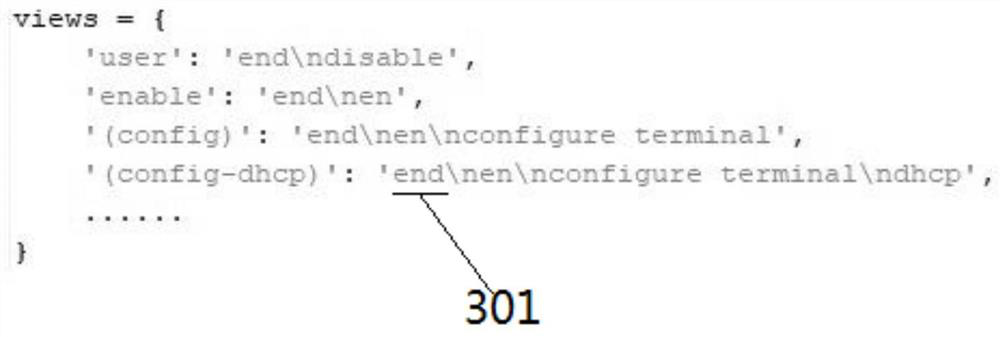

Method, device and storage medium for automated testing of command line commands

ActiveCN110071848BAvoid Manual TestingValid testData switching networksProgramming languageTest efficiency

The embodiment of the invention provides a method and device for automatically testing a command line command. The method comprises the following steps of defining a view of a mounting command line toobtained a defined view, and defining a command entering the defined view, and traversing all the defined views, obtaining the command and the related parameters under the defined views by adoptinga list command, and replacing the related parameters with legal values to obtain a test command; and assembling the test command to obtain an assembly command, and testing the assembly command. According to the method and the device for automatically testing the command line command provided by the embodiment of the invention, not only the test personnel can be liberated from heavy repeated work,but also the test efficiency and the test accuracy are greatly improved.

Owner:武汉思普崚技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com