Starting voltage testing method for all-digital follow-up system

A technology of servo system and starting voltage, which is applied in the direction of measurement using digital measurement technology, can solve the problems of cumbersome workload and can only be used in the initial debugging state, system or human injury, program runaway, etc., to avoid manual Test and ram program online test effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Because the multi-axis optical cabin system includes multiple axes such as azimuth, pitch, and roll, the principle of testing the starting voltage is the same, but the adjustment of specific parameters is different.

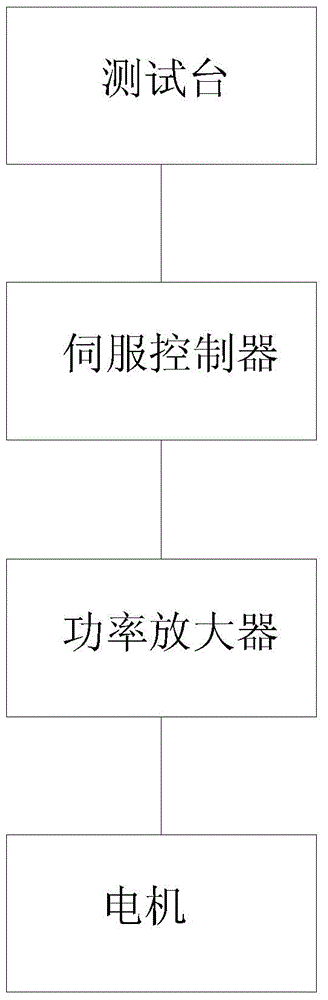

[0012] Such as figure 1 As shown, the present invention includes:

[0013] Test bench: The test bench includes a single-chip microcomputer with a display screen and a start button. The single-chip microcomputer is electrically connected to the start button. A voltage adjustment value text box and a voltage display box are displayed on the display screen. In the adjustment value text box Enter a number in the lower voltage display box, and the current status will be displayed in millivolts immediately. Each time the start button is clicked, the voltage displayed in the voltage display box will increase cumulatively with the number in the voltage adjustment value text box as the increment. Note that the number setting should not be too large, otherwise it w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com