A cell testing device for intelligent electric vehicle production

A technology for smart electric vehicles and testing devices, which is applied to measuring devices, measuring electricity, and measuring electrical variables. It can solve problems such as battery offset, influence on insulation effect, and potential safety hazards, and achieve neat and orderly battery cells and improve convenience. performance, improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

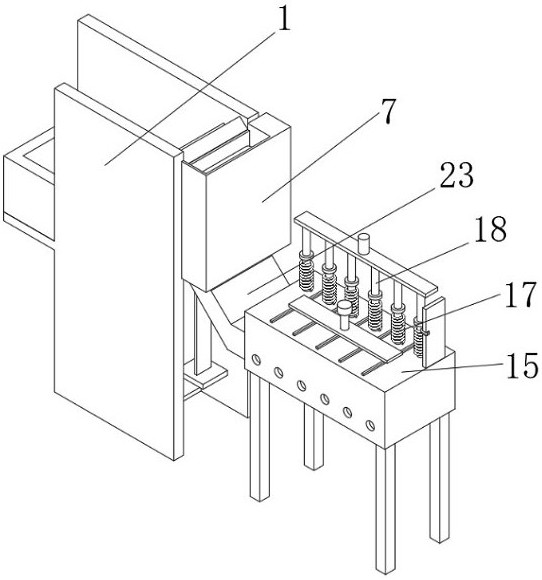

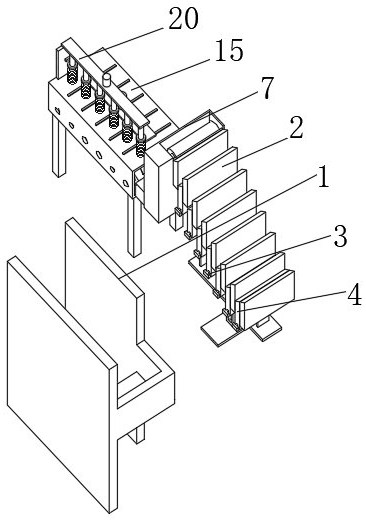

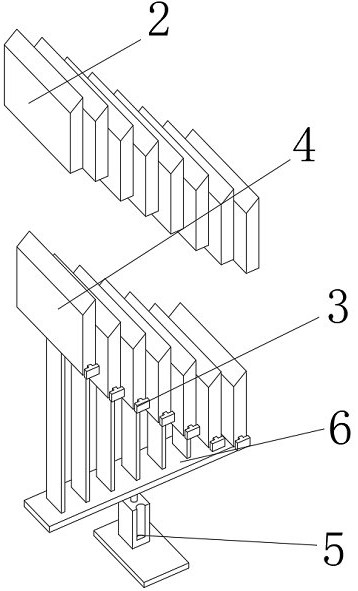

[0026] see figure 1 , figure 2 , image 3 and Figure 8 , the present invention provides a technical solution: a battery cell testing device for intelligent electric vehicle production, comprising an installation base 1, the inner side of the installation base 1 is fixedly installed with a progressive block 2, and the inner side of the installation base 1 is provided with a chute, the installation Slider 3 is movably sleeved in the chute opened on the inner side of the base body 1. The shape of the slider 3 is a T-shaped bump. The contact area between the sliding block 3 and the mounting base 1 makes the connection between the driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com