LED printing method

A printing method and LED substrate technology, which is applied in printing, printing machines, rotary printing machines, etc., can solve the problems of glue or solder paste not easy to release the mold, low yield, and LED can not be installed normally, so as to avoid glue and solder paste The effect of no demoulding, increasing the success rate, and improving the yield rate of LED printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

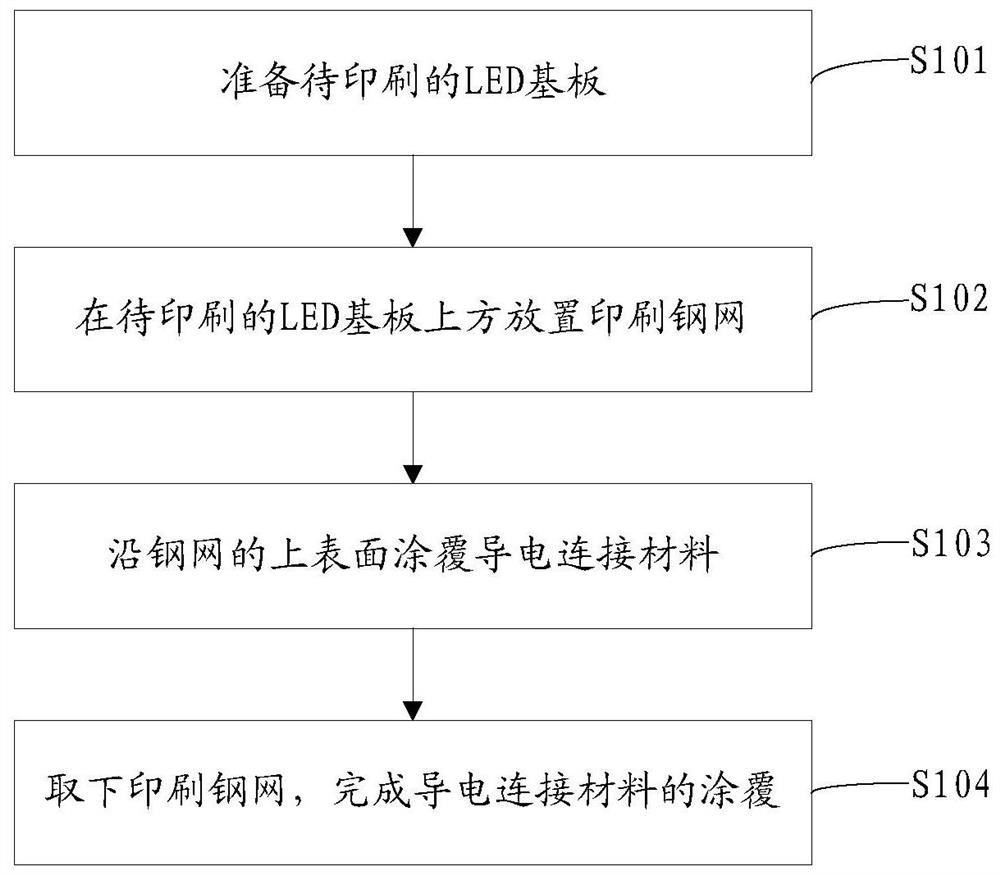

[0029] This embodiment provides a LED printing method, please refer to figure 1 , the method includes:

[0030] S101. Prepare the LED substrate to be printed;

[0031] S102. Place a printing screen above the LED substrate to be printed. The printing screen is a block-shaped flat plate, and there are several via holes penetrating the upper surface and the lower surface of the flat plate, and the aperture of the via hole is along the upper surface of the flat plate to the bottom The direction of the surface gradually increases; the setting position of the via hole corresponds to the pad area on the LED substrate;

[0032] S103, coating the conductive connection material along the upper surface of the printing screen, injecting the conductive connection material into the via hole, and coating it on the corresponding pad area;

[0033] S104. The printing screen is removed, and the coating of the conductive connecting material is completed.

[0034] The characteristic of Mini LE...

no. 2 example

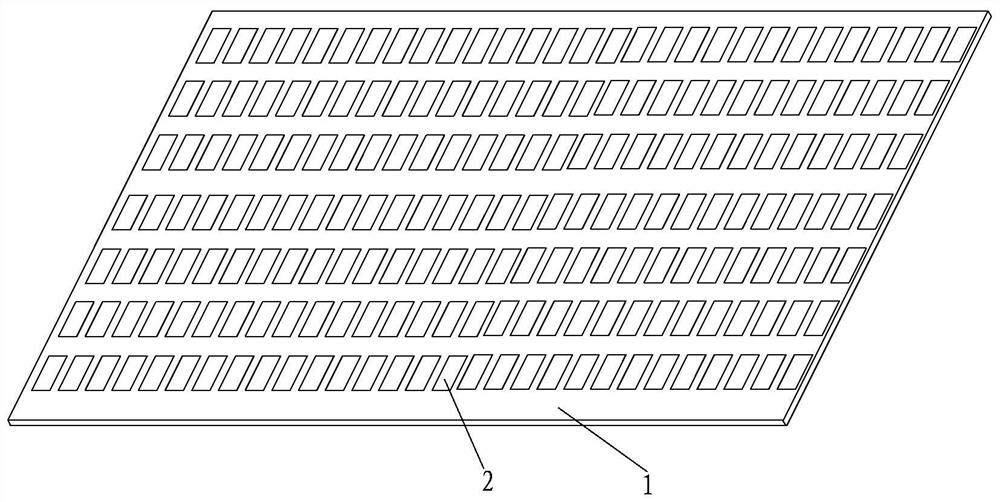

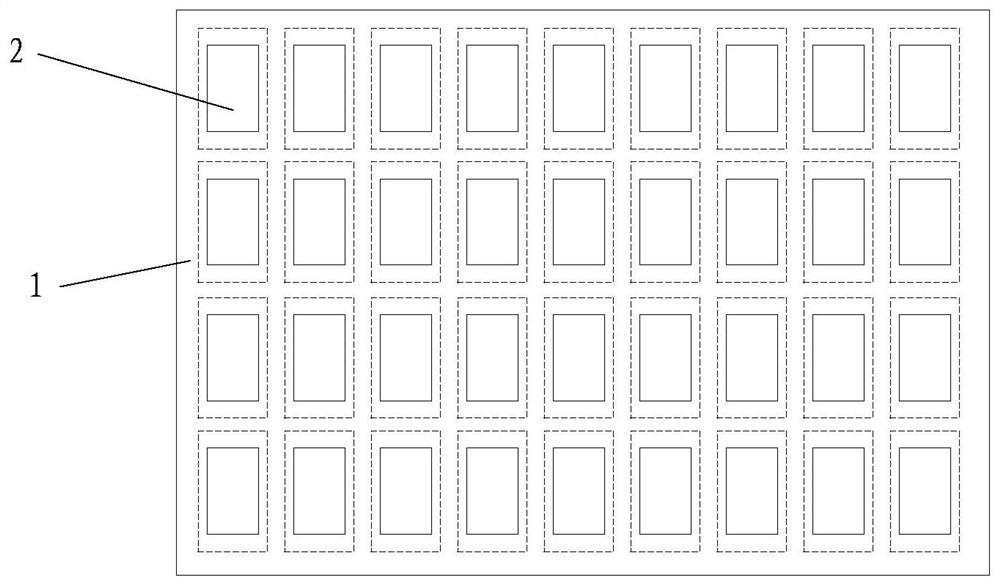

[0049] Please refer to Figure 2-5 , the present embodiment provides a printing screen, which is a block flat plate 1, and the flat plate 1 is provided with several via holes 2 penetrating through the upper surface and the lower surface of the flat plate 1, and the aperture of the via hole 2 is along the upper surface of the flat plate 1. The direction from the surface to the lower surface gradually increases. For the main structure plate 1 of the printing screen, its upper surface is the part where glue or solder paste is injected during the printing process, while the lower surface is the part where glue or solder paste is released. Compared with the upper surface, the lower surface is more close to the substrate. The via hole 2 on the plate 1 is used as a glue injection hole or a solder paste hole, and the size of the hole can be determined according to the bonding point or welding point on the substrate, that is, the pad; due to the characteristics of the via hole 2 in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com