Reciprocating motion type sealed ink fountain of printing or coating machine

A reciprocating motion and coating machine technology, which is applied to printing machines, rotary printing machines, screen printing machines, etc., can solve the problems of increased printing costs, scraper consumption, and high frequency of scraper replacement, so as to reduce printing costs and improve printed products The effect of reducing the rate and replacement frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

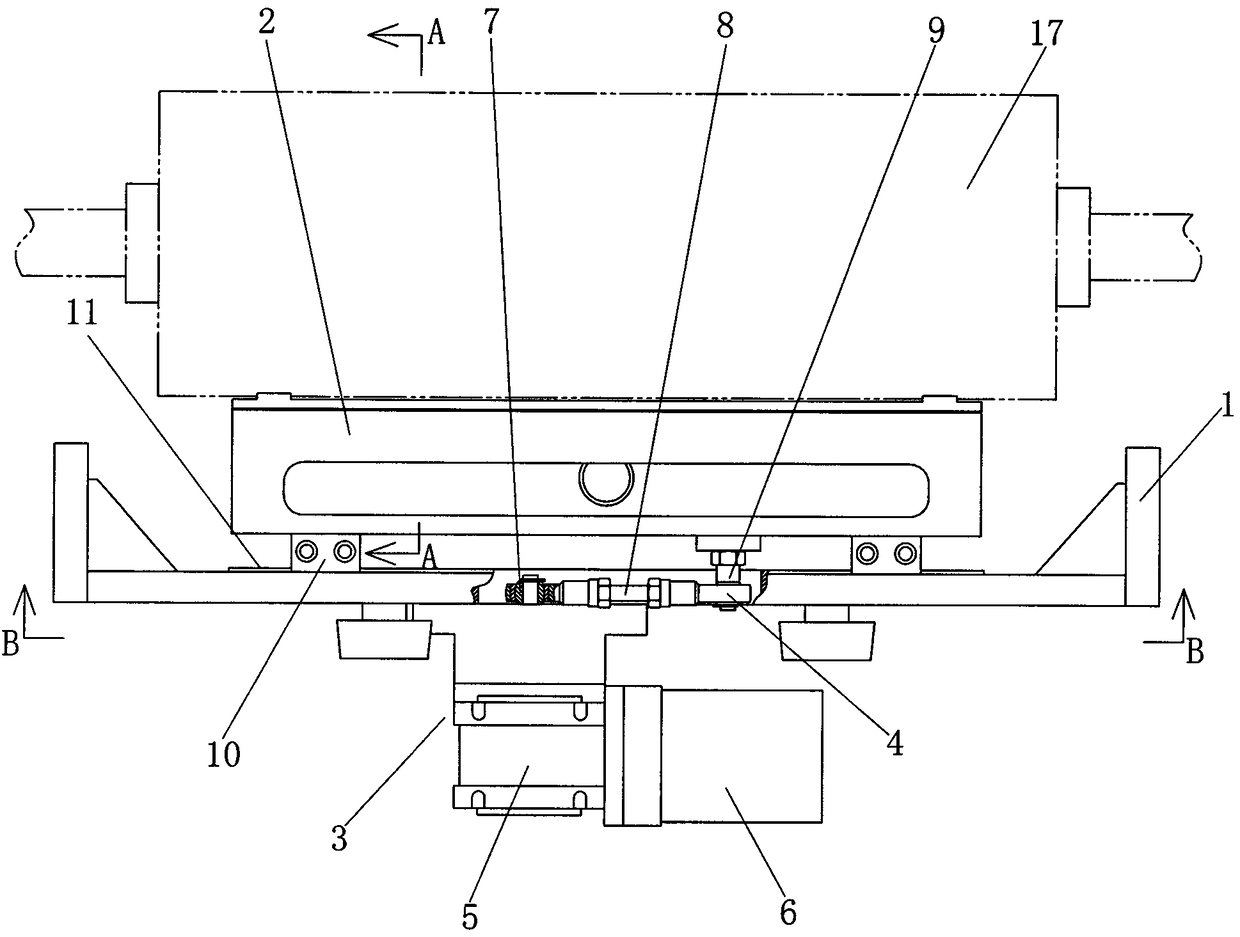

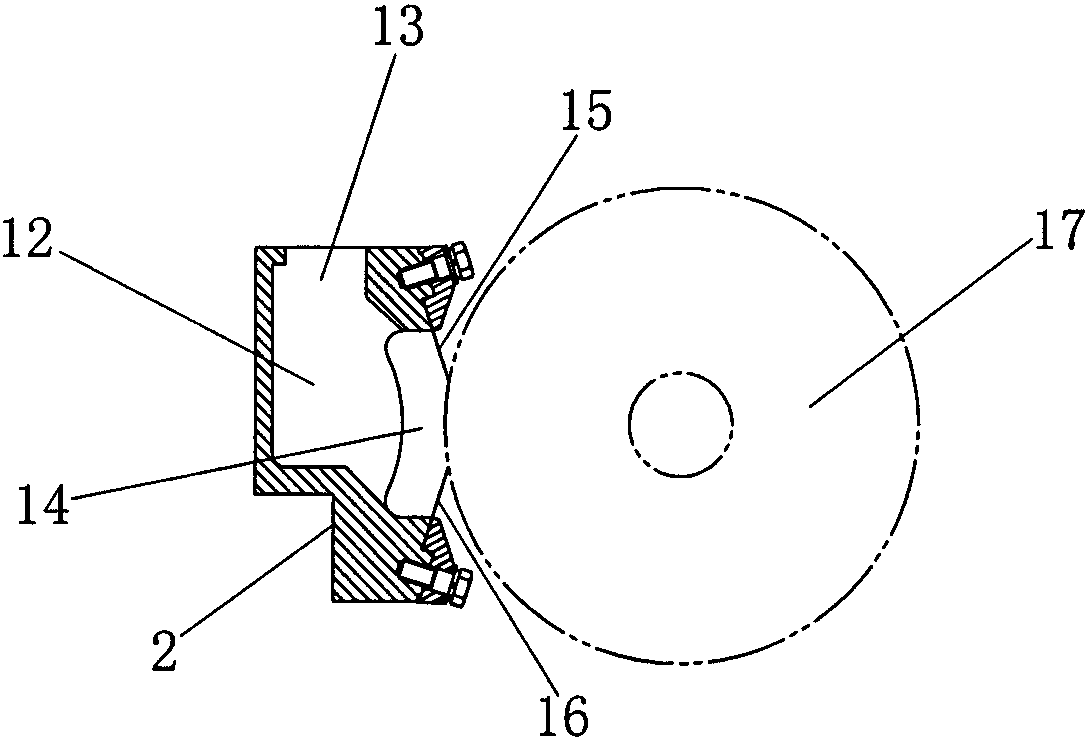

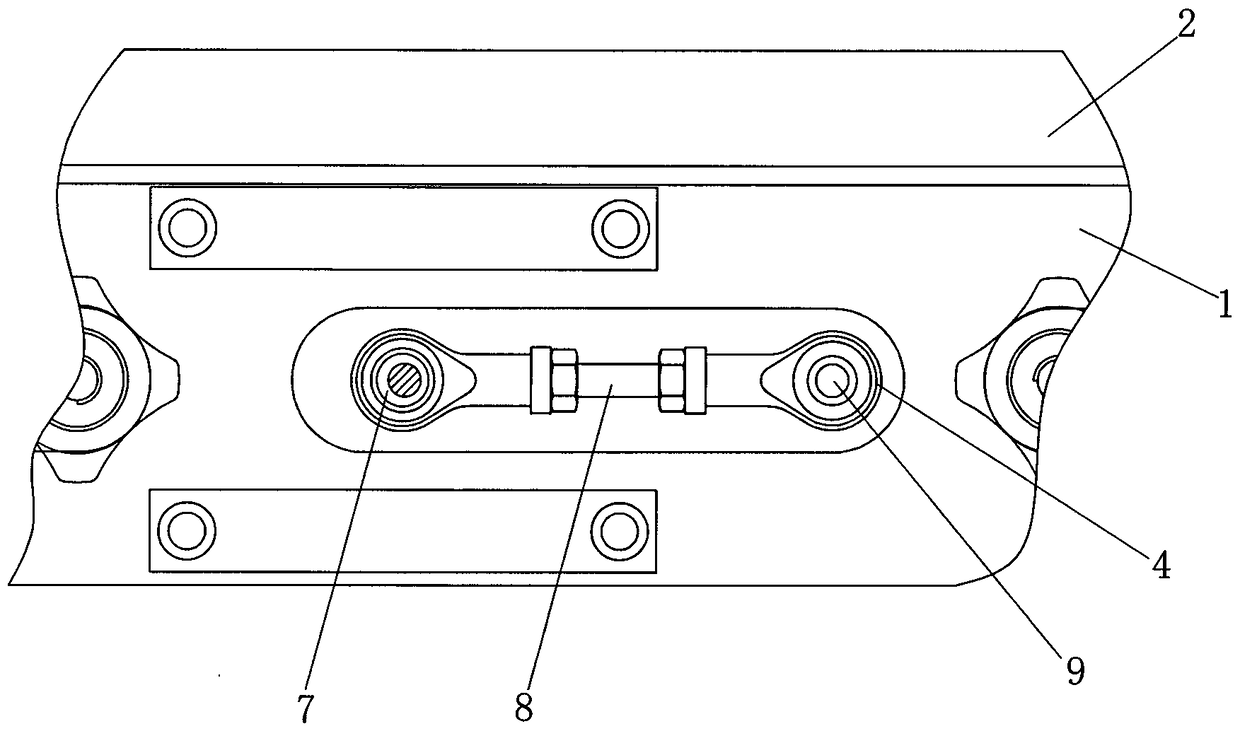

[0019] refer to Figure 1 ~ Figure 3 The reciprocating closed ink fountain on the printing or coating machine includes an ink fountain frame 1 fixed on the frame of the printing or coating machine and a closed ink fountain 2 installed on the ink fountain frame 1, which is characterized in that: The closed ink fountain 2 is horizontally slidably fitted on the ink fountain frame 1 and is located at the front side of the ink fountain frame. A reciprocating drive mechanism 3 is installed on the ink fountain frame 1. The closed ink fountain 2 is connected.

[0020] In addition, the reciprocating drive mechanism 3 is composed of a transmission 5, a motor 6, an eccentric wheel 7 and a connecting rod 8, wherein the transmission 5 is installed and fixed on the ink fountain holder 1, and the motor 6 is connected to the transmission 5 The input end of the eccentric wheel 7 is fixed on the output end of the transmission 5, one end of the connecting rod 8 is slidably sleeved on the outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com