Printing head, printing method and device using same

A technology of print head and equipment, applied in the field of print head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

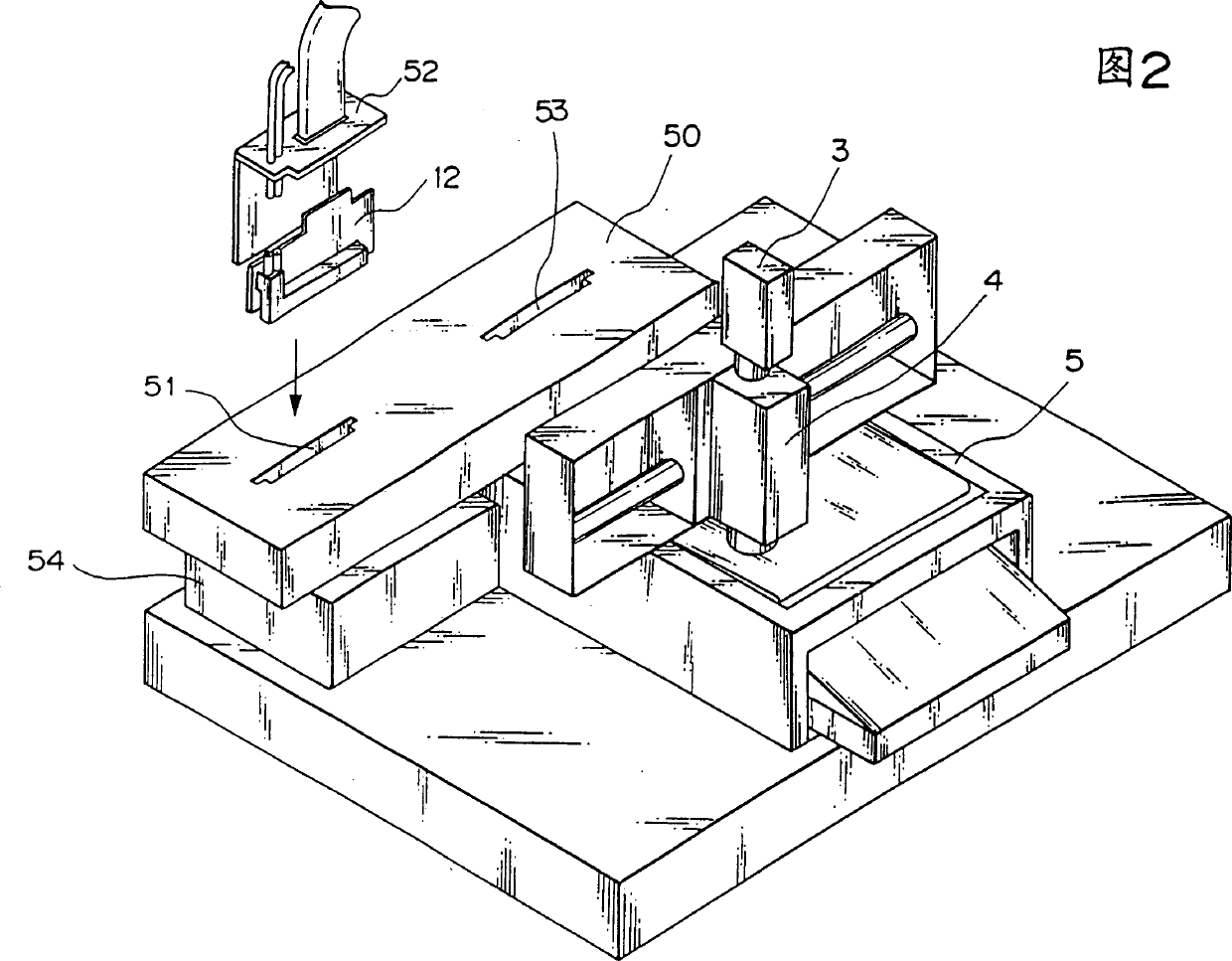

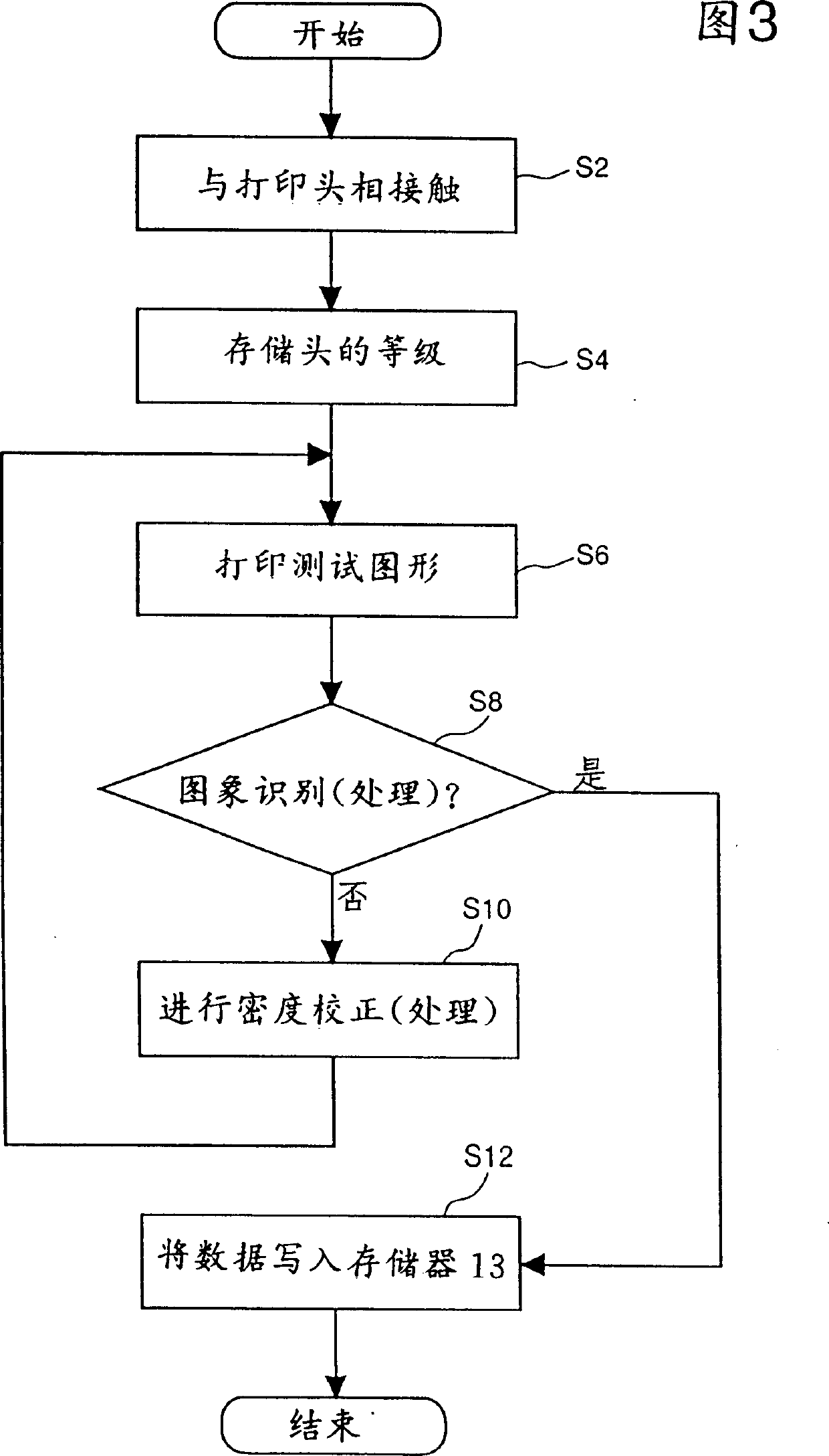

[0063] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

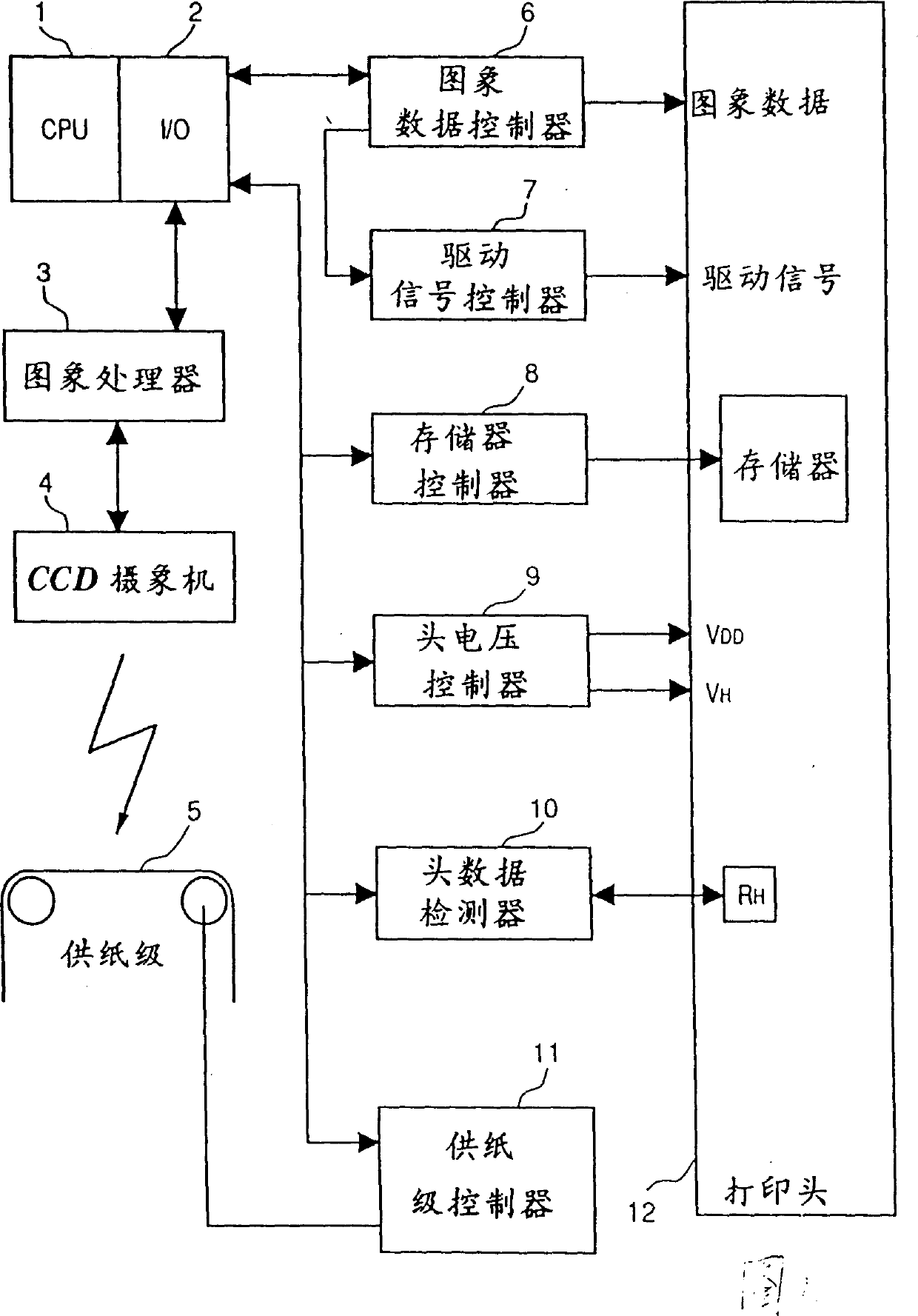

[0064] FIG. 1 is a block diagram showing the configuration of a head correction apparatus for determining correction data of a print head 12 according to a first embodiment of the present invention.

[0065] In FIG. 1, a CPU 1 which controls the entire correction apparatus manages various controllers which will be described later. The I / O interface 2 interfaces the CPU 1 with the respective parts of the device. The image processor 3 reads the printed dot pattern on the recording medium placed on the paper supply stage 5 with the CCD camera 4 and obtains pixels corresponding to the diameter and density of the printed dots. When the dot data corresponding to all the printing elements (nozzles) of the print head 12 are sent from the image processor 3 to the CPU 1, the CPU 1 operates on the dot data in accordance with the driving signal for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com