Positioning apparatus and print device using the positioning apparatus

A positioning device and printing device technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of reducing product yield, increasing manufacturing cost, and low production efficiency, so as to improve production efficiency, improve printing yield, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

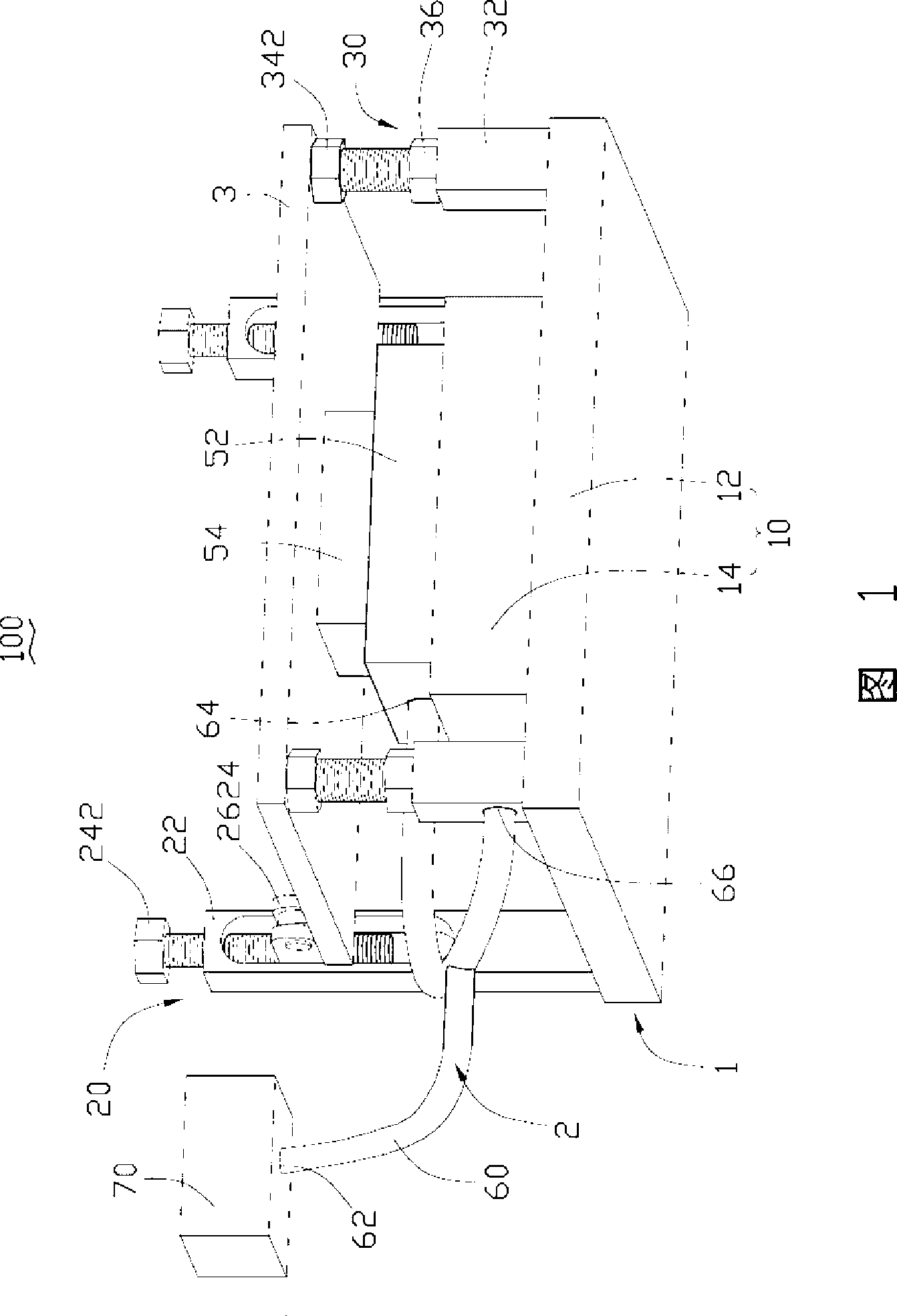

[0014] Please refer to FIG. 1 , which shows a printing device 100 according to a preferred embodiment of the present invention. The printing device 100 includes a worktable 1 , a positioning device 2 and a screen 3 .

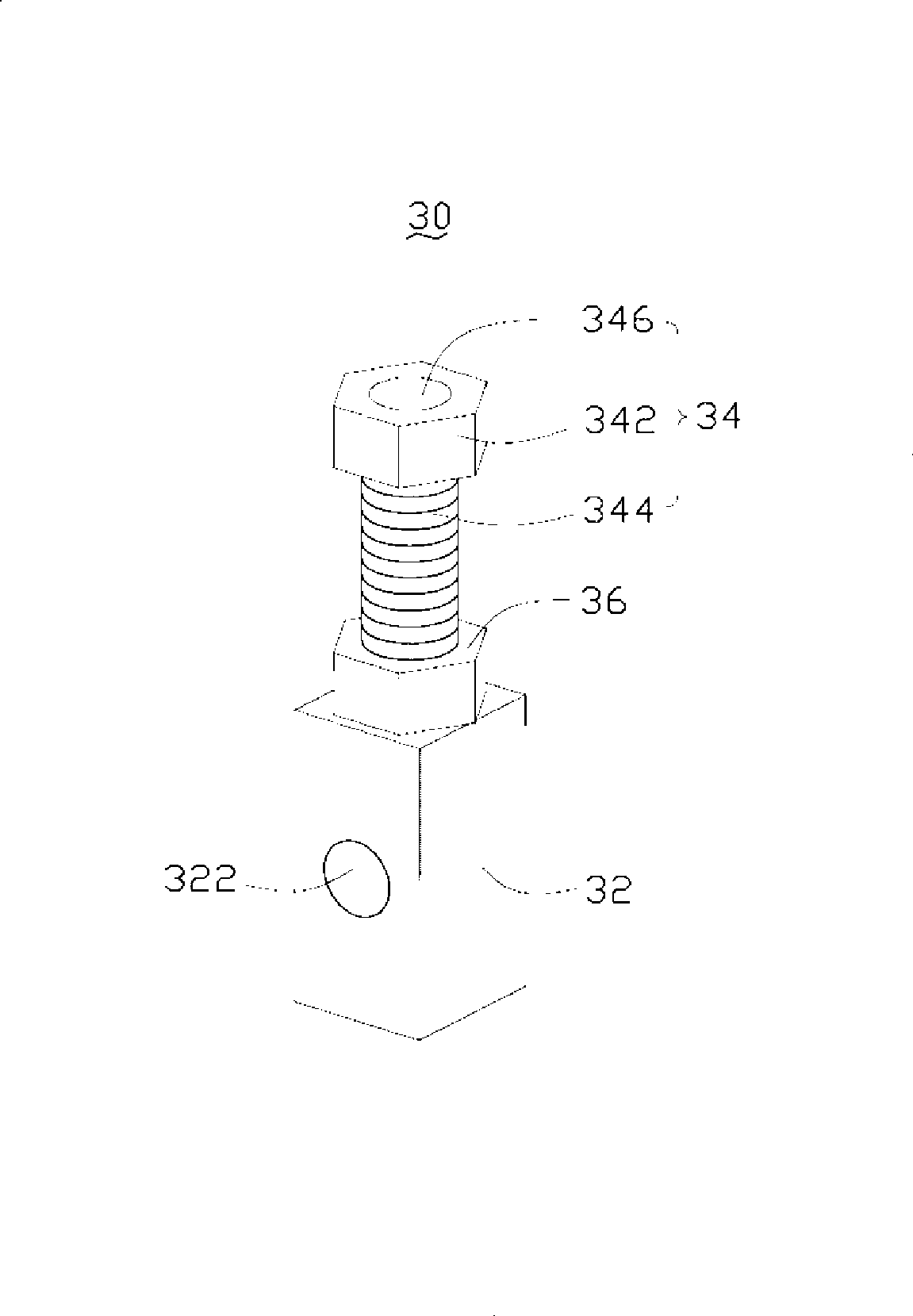

[0015] The workbench 1 includes a base 10 , two supports 20 and two pillars 30 . The base 10 is substantially a boss, which includes a bottom plate 12 and a supporting plate 14 . The base plate 12 is substantially a rectangular plate, and the supporting plate 14 , the two brackets 20 and the two pillars 30 are respectively disposed on a surface of the base plate 12 . The carrying plate 14 is substantially a rectangular plate, which protrudes from the center of the surface of the bottom plate 12 and is smaller in size than the bottom plate 12 . The carrying plate 14 is used for carrying some components of the positioning device 2 .

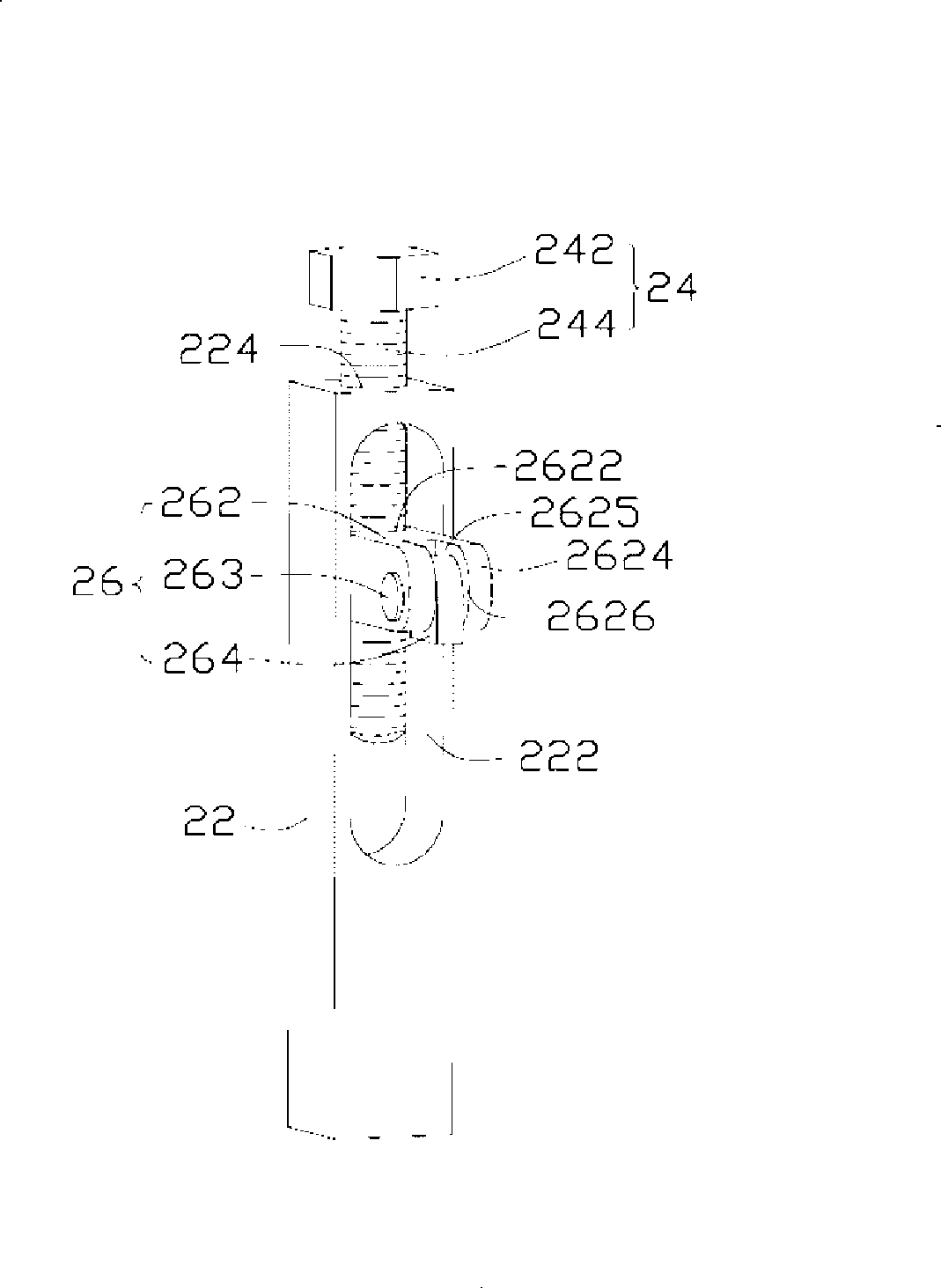

[0016] Please also see figure 2 , each bracket 20 respectively includes a bracket base 22 , a first bolt 24 and a hinge 26 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com