Storage box

A storage box and material storage technology, applied in the field of storage boxes, can solve the problem of inability to take into account the appearance of the grid and the thickness of the grid, so as to reduce the probability of uneven winding, reduce the probability of printing deviation, and improve the yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

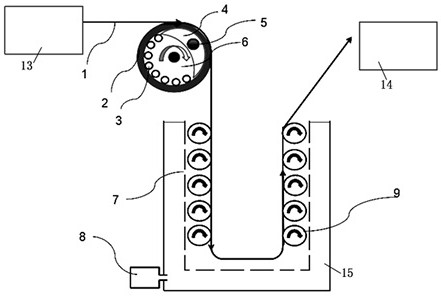

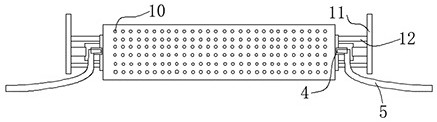

[0020] Example: as Figure 1 to Figure 2 As shown, a storage box can be arranged between the printing process section 13 and the oven curing section 14, mainly to ensure that the substrate 1 at the printing process section 13 is in a "static state" during screen printing of the sheet web. ” state, and at the same time ensure that the substrate 1 at the curing section 14 of the oven is in a moving state, so as to prevent the sheet from causing adverse effects under the high temperature of the oven, that is, the storage box 15 is left in the printing process section 13. After printing the substrate 1 to be entered into the oven curing section 14 , the substrate 1 in the oven curing section 14 is prevented from being pulled and the like in the printing process section 13 , so as to ensure the production quality of the sheet.

[0021] In order to facilitate the entry of the substrate 1, the storage box 15 is provided with an opening. In order to prevent the position of the substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com