Method for producing reclaimed thermoplastic resin and thermosetting resin multi-layer composite coated controlled-release fertilizer

A technology of controlled-release fertilizers and plastic resins, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of high production cost and sales price of coated fertilizers, high cost of controlled-release fertilizers, difficulty in popularization and application, etc., to save resin The effect of dosage, precise and controlled release of nutrients, and broad promotion and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

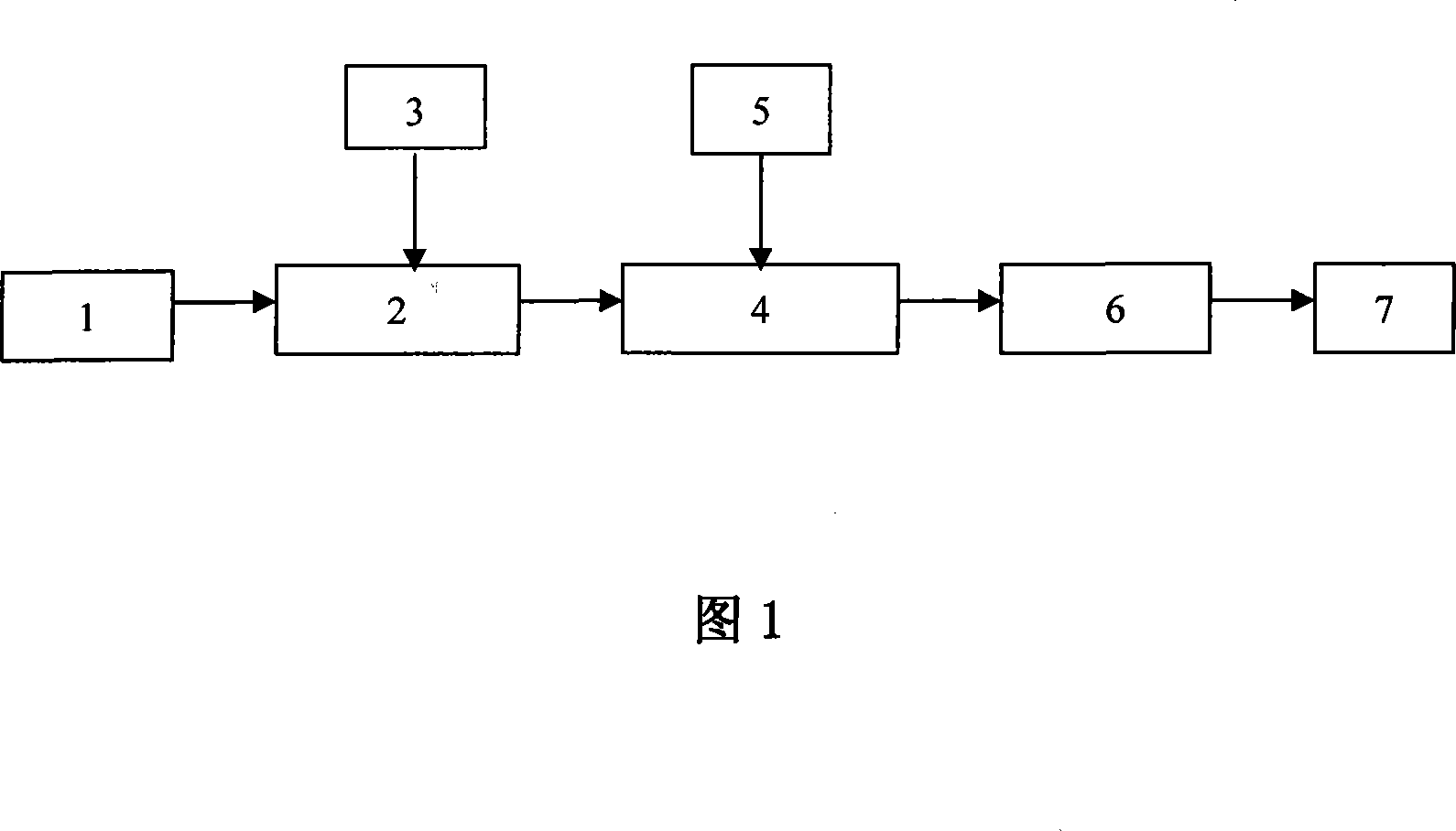

[0012] Put 200kg of large-grained urea with a diameter of 2-4.5mm into a heated fluidized bed (1), heat to 60-70°C (2), dissolve 6kg of recycled polyethylene resin in 100kg of n-butyl acetate and amyl acetate Add 1.5kg of diatomite, wheat flour and rubber powder to the mixed solvent with an ester ratio of 2:1, heat it to 90-100°C, and spray it on the large Granular urea on (3). Transfer the coated granular fertilizer to a heated drum fluidized bed, preheat the fertilizer particles to 75-95°C (4), add 0.6 kg of polyurethane (polyurethane), curing agent TDI (toluene diisocyanate) ) 0.2kg, diluent (butyl acetate) 0.2kg mixed solution is sprayed on the fertilizer granule that rotates, quick reaction solidifies and becomes dense and bright thermosetting resin outer coating film (5), gained fertilizer thermoplastic resin film and thermosetting resin film The total amount accounts for about 4% of the total weight of all controlled-release fertilizers, and the multi-layer compound-co...

Embodiment 2

[0016]Put 200kg of compound fertilizer with a diameter of 2-4.5mm into a heated fluidized bed (1), heat to 50-60°C (2), dissolve 7kg of recycled polyethylene resin in 100kg of n-butyl acetate and amyl acetate Add a total of 1.5kg of light calcium carbonate, corn flour and rubber powder to a mixed solvent with a ratio of 3:1, heat to 100-105°C, spray on the Compound fertilizer granules (3). Transfer the coated granular fertilizer to the heated drum fluidized bed, preheat the fertilizer particles to 70-90°C (4), mix epoxy resin (E44 / PUR=95 / 5) 0.9kg, curing agent ( The mixed solution of T31) 0.3kg, diluent (tributyl phosphate) 0.3kg is sprayed on the fertilizer granule that rotates, and fast reaction solidifies becomes compact and bright thermosetting resin outer coating film (5), gained fertilizer thermoplastic resin film and thermosetting The total amount of the resin film accounts for about 5% of the total weight of all the controlled-release compound fertilizers, and the mul...

Embodiment 3

[0020] Put 200kg of compound fertilizer particles with a diameter of 2-4.5mm into a heated fluidized bed (1), heat to 60-70°C (2), dissolve 9.0kg of recycled polyethylene resin in 100kg of n-butyl acetate and acetic acid Add 1.0kg of 400 mesh talc powder, sweet potato powder and rubber powder to the mixed solvent with a pentyl ester ratio of 4:1, heat to 100-110°C, use a two-fluid nozzle at an atomization pressure of 4kpa at a speed of 2kg per minute Spray on compound fertilizer granules (3). Transfer the coated granular fertilizer to a heated drum fluidized bed, preheat the fertilizer particles to 75-85°C (4), mix 1.3kg of polyurethane (polyurethane), curing agent TDI (toluene diisocyanate) ) 0.3kg, diluent (butyl acetate) 0.4kg mixed solution is sprayed on the fertilizer granule that rotates, quick reaction solidifies and becomes dense and bright thermosetting resin outer coating film (5), gained fertilizer thermoplastic resin film and thermosetting resin film The total amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com