Method for preparing fiber reinforced foam glass

A foam glass and fiber-reinforced technology, which is applied in the field of fiber-reinforced foam glass preparation, can solve problems such as difficulty in guaranteeing the effect, low flexural strength, complicated use procedures, etc., and achieves favorable utilization of waste, wide application range, and improved mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

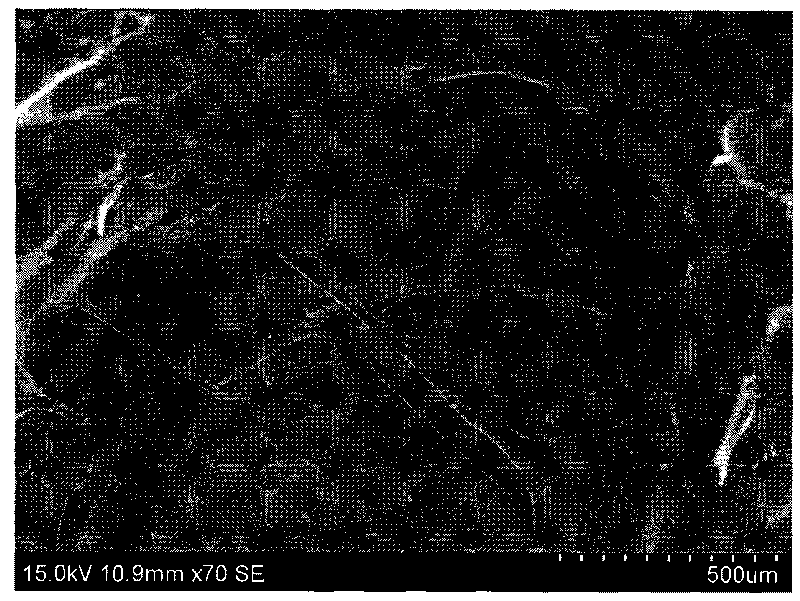

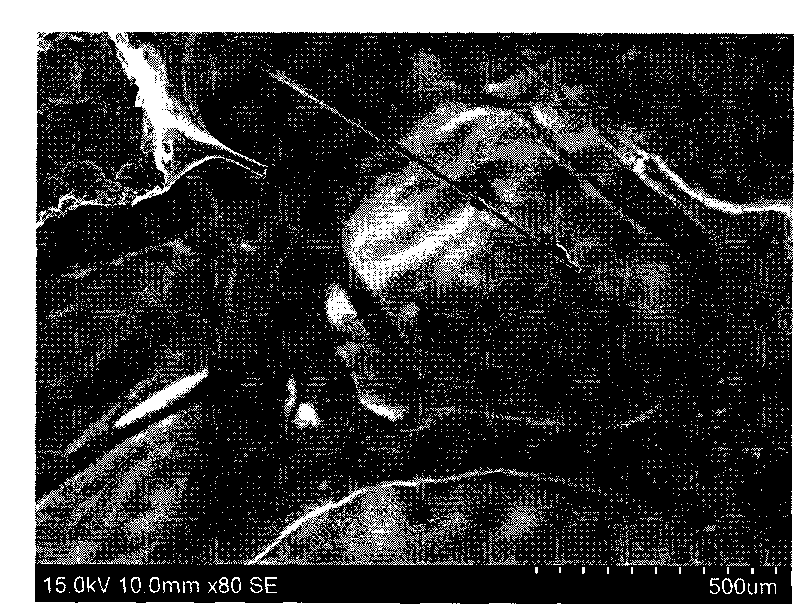

Image

Examples

Embodiment 1

[0016] Embodiment 1, first clean the waste glass, and ball mill it to 300 mesh after drying to obtain glass powder, by mass fraction 90% of glass powder, 2% of calcium carbonate, 1.2% of potassium permanganate, 0.8% of three Ferric oxide, 2.0% boric acid and 1.0% sodium nitrate were put into a paddle mixer, stirred evenly, and then 3% aluminum silicate fibers were added into the mixer to obtain a mixture. The said aluminum silicate fibers The diameter is 0.005 ~ 2 mm, and the length is 0.1 ~ 100 mm. Then, add the mixture mass fraction of 3% polyvinyl alcohol, 3% n-pentyl acetate, 2% alcohol, 2% distilled water and 0.1 Stir and mix after % polyethylene glycol 2000, and after stirring for 8 hours at a stirring speed of 30 rpm at a rotating speed, pour the evenly stirred slurry into the mold; push the mold containing the slurry into the foaming kiln, Firing according to the following firing system: in the drying stage, the heating rate is 3°C / min, the temperature is raised to 110...

Embodiment 2

[0017]Example 2, first clean the waste glass, and ball mill it to 300 mesh after drying to obtain glass powder, and mix 92% glass powder, 2% calcium carbonate, 1.2% potassium permanganate, 0.8% three Ferric oxide, 2.0% boric acid and 1.0% sodium nitrate were put into a paddle mixer, stirred evenly, and then 1% aluminum silicate fiber was added into the mixer to obtain a mixture. The said aluminum silicate fiber The diameter is 0.005 ~ 2 mm, and the length is 0.1 ~ 100 mm. Then, add the mixture mass fraction of 4% polyvinyl alcohol, 4% n-pentyl acetate, 3% alcohol, 7% distilled water and 0.2 Stir and mix after % polyethylene glycol 2000, and after stirring for 12 hours at a stirring speed of 30 rpm at a rotating speed, pour the evenly stirred slurry into the mold; push the mold containing the slurry into the foaming kiln, Firing according to the following firing system: in the drying stage, the heating rate is 3°C / min, the temperature is raised to 110°C, and the temperature is ...

Embodiment 3

[0018] Example 3, first clean the waste glass, and ball mill it to 300 mesh after drying to obtain glass powder, and mix 88% glass powder, 2% calcium carbonate, 1.2% potassium permanganate, 0.8% three Ferric oxide, 2.0% boric acid and 1.0% sodium nitrate are put into a paddle mixer, stirred evenly, and then 5% aluminum silicate fiber is added into the mixer to obtain a mixture, said aluminum silicate fiber The diameter is 0.005 ~ 2 mm, and the length is 0.1 ~ 100 mm. Then, add the mixture mass fraction of 4% polyvinyl alcohol, 4% n-pentyl acetate, 3% alcohol, 7% distilled water and 0.3 Stir and mix after % polyethylene glycol 2000, and after stirring for 15 hours at a stirring speed of 30 rpm at a rotating speed, pour the evenly stirred slurry into the mold; push the mold containing the slurry into the foaming kiln, Firing according to the following firing system: in the drying stage, the heating rate is 3°C / min, the temperature is raised to 110°C, and the temperature is kept ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com