Polylactic acid fibre disperse dyeing accelerant

A dyeing accelerator, polylactic acid fiber technology, applied in the direction of dyeing, textiles and papermaking, etc., can solve the problems of difficult to dye deep color, low dyeing rate, low dyeing rate, etc., and achieve dyeing color fastness. High, improve dye uptake, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

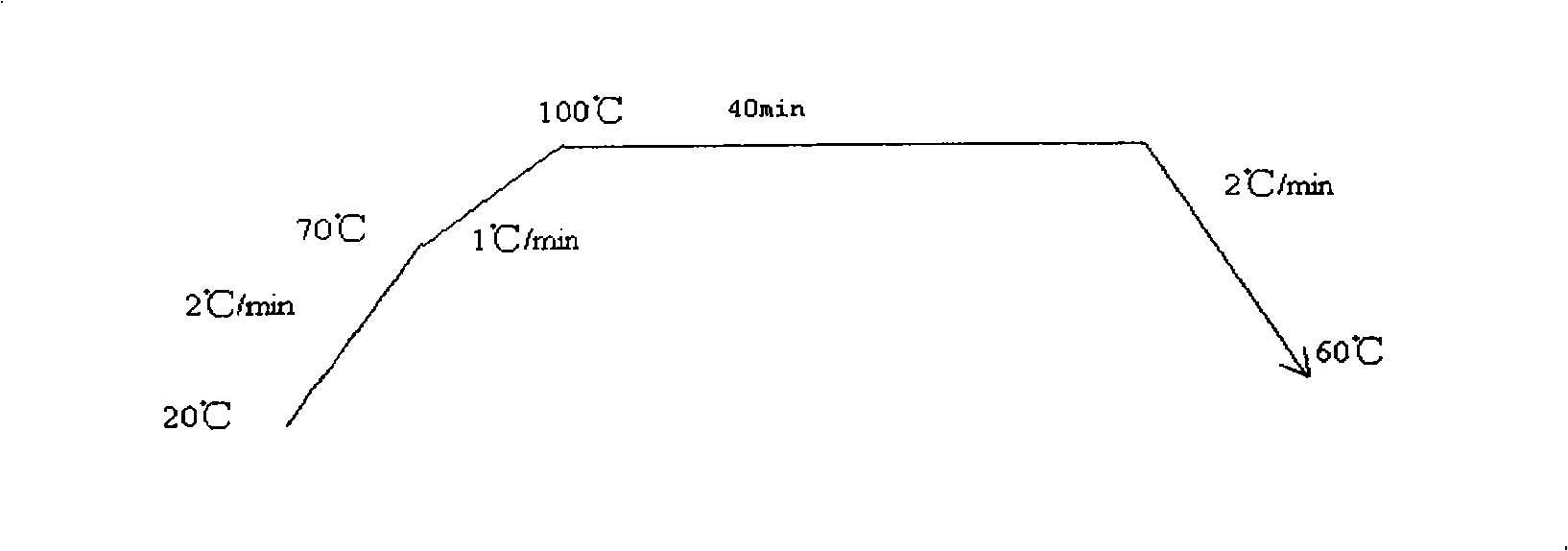

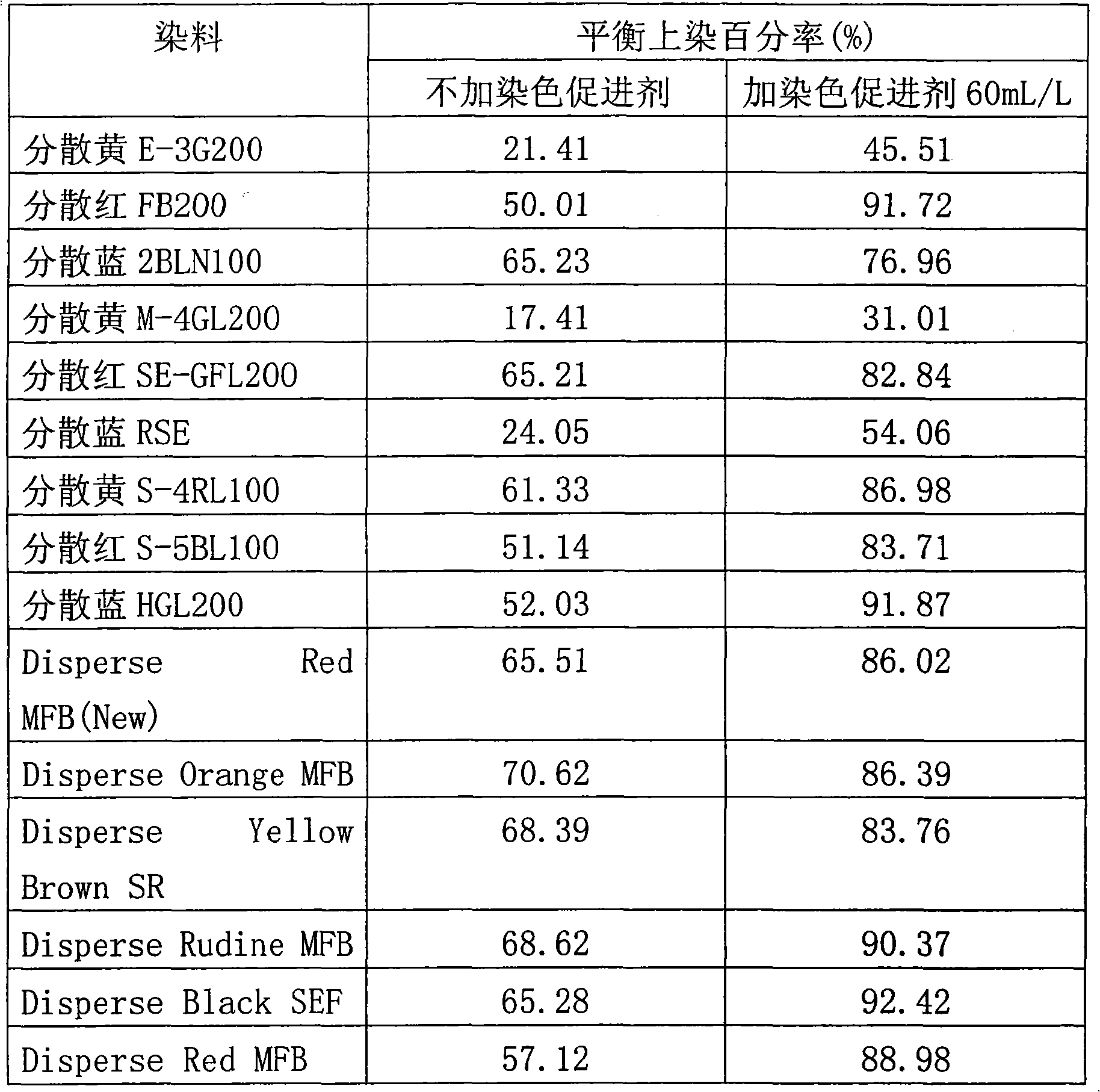

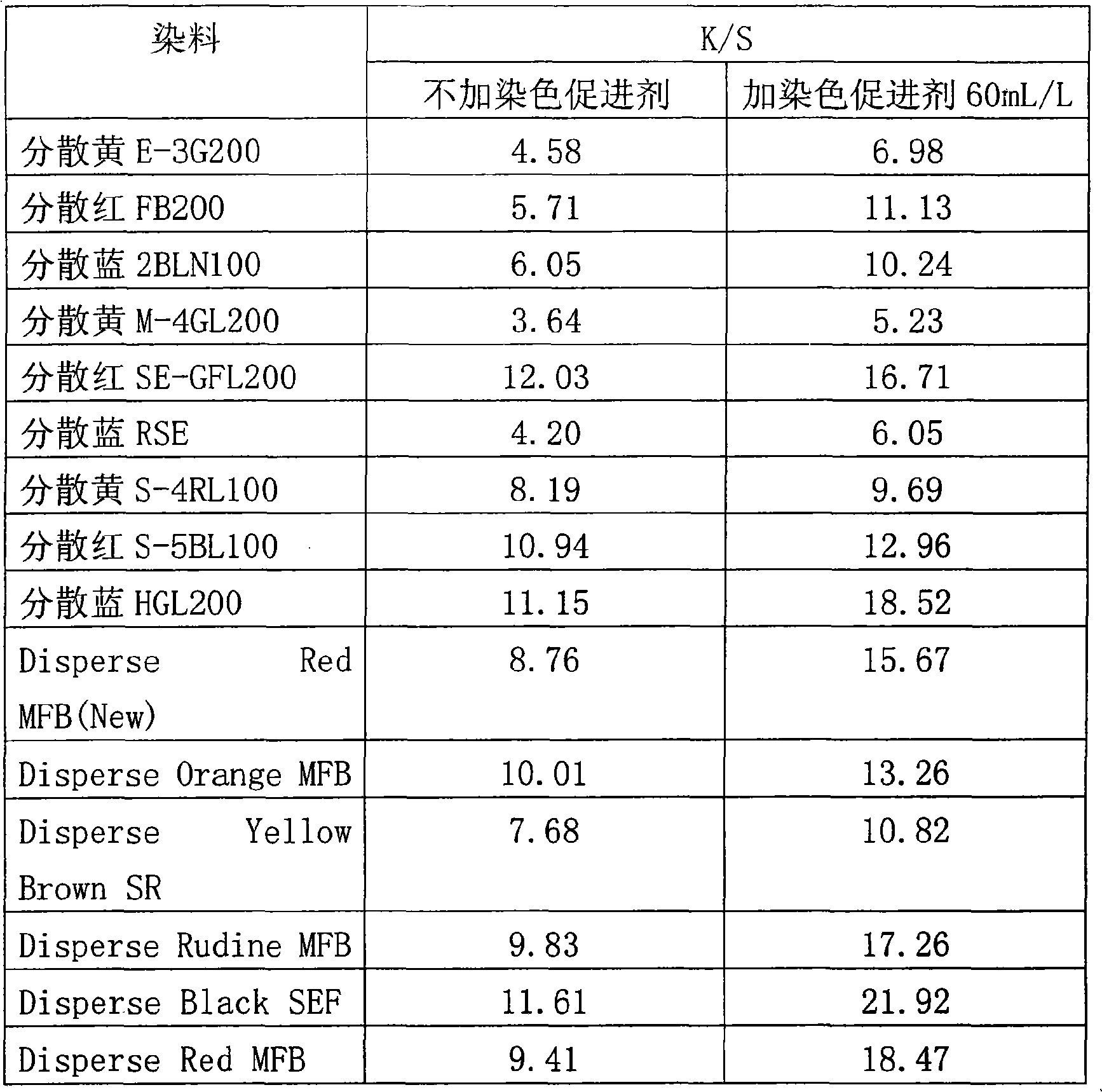

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: A kind of composition of polylactic acid fiber disperse dyeing accelerator

[0036] Expressed by volume percentage: n-pentyl acetate 10, composite emulsifier 0.3, water 89.7; wherein the composition of composite emulsifier is represented by volume percentage: Span-20 emulsifier 3, Tween-20 emulsifier 92, ethanol 5.

Embodiment 2

[0037] Embodiment 2: a kind of composition of polylactic acid fiber disperse dyeing accelerator

[0038] Expressed by volume percentage: n-pentyl acetate 10, composite emulsifier 0.4, water 89.6; wherein the composition of composite emulsifier is represented by volume percentage: Span-40 emulsifier 2, Tween-40 emulsifier 96, butanol 2.

Embodiment 3

[0039] Embodiment 3: A kind of composition of polylactic acid fiber disperse dyeing accelerator

[0040] Expressed as: n-pentyl acetate 10, complex emulsifier 0.5, water 89.5; wherein the composition of the complex emulsifier is expressed as: Span-60 emulsifier 10, Tween-60 emulsifier 90, ethanol 0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com