Method for preparing solid acid catalyst by microwave solid phase method and application thereof

A solid acid catalyst, solid-phase method technology, applied in molecular sieve catalysts, chemical instruments and methods, catalyst activation/preparation and other directions, can solve the problems of increasing the isoamyl acetate treatment process, long reaction time, and many side reactions, etc. Easy to use repeatedly, simplify the post-processing process, and synthesize the effect of the simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

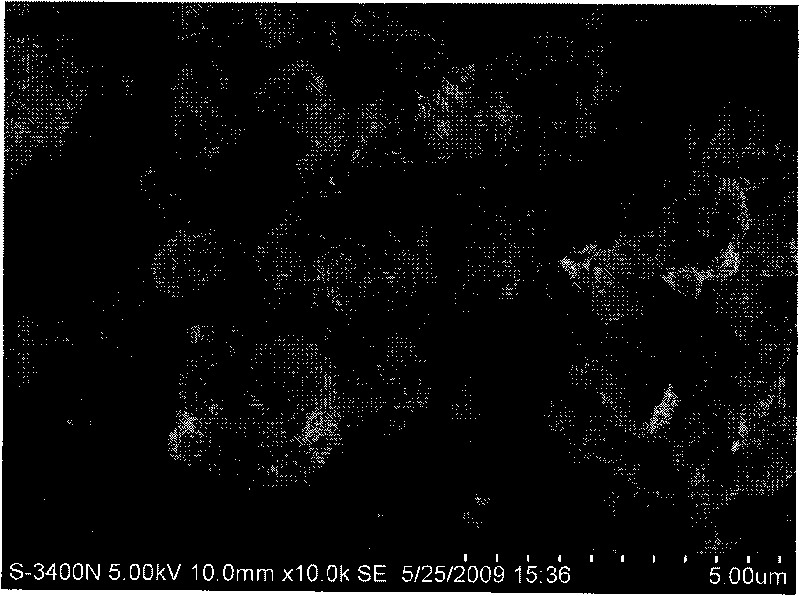

Image

Examples

Embodiment 1

[0014] Example 1: Weigh tin chloride and carrier OMS-2 according to the ratio of 0.001mmol: 1g carrier OMS-2, mix and grind them, then put them into a microwave oven and heat them for 4 minutes under 600w power to obtain OMS-2 loaded chloride Tin solid acid catalyst. The esterification reaction conditions are: the amount of catalyst used is 3.35% of the total mass of acetic acid and isoamyl alcohol, the molar ratio of acetic acid and isoamyl alcohol is 1:1.5, the reaction temperature is controlled at 110-120°C, and after the reaction, the solid-liquid separation and separation The solid catalyst can be used for the reaction again, and the separated liquid is washed with water, distilled and other further processes to obtain isoamyl acetate with an ester yield of 74%.

Embodiment 2

[0015] Embodiment 2: Take by weighing tin chloride and carrier OMS-2 according to the ratio of 0.009mmol: 1g carrier OMS-2, mix and grind, then put into microwave oven and heat under 600w power for 4 minutes to obtain the chlorine loaded on OMS-2 Tin oxide solid acid catalyst. The esterification reaction conditions are: the amount of catalyst used is 3.35% of the total mass of acetic acid and isoamyl alcohol, the molar ratio of acetic acid and isoamyl alcohol is 1:1.5, the reaction temperature is controlled at 110-120°C, and after the reaction, the solid-liquid separation and separation The solid catalyst can be used for the reaction again, and the separated liquid is washed with water, distilled and other further processes to obtain isoamyl acetate, and the ester yield is 76%.

Embodiment 3

[0016] Embodiment 3: Weigh tin chloride and carrier OMS-2 according to the ratio of 0.005mmol: 1g carrier OMS-2, mix and grind, then put into microwave oven and heat under 600w power for 4 minutes, namely obtain the chloride of OMS-2 load. Tin solid acid catalyst. The esterification reaction conditions are: the amount of catalyst used is 3.35% of the total mass of acetic acid and isoamyl alcohol, the molar ratio of acetic acid and isoamyl alcohol is 1:1.5, the reaction temperature is controlled at 110-120°C, and after the reaction, the solid-liquid separation and separation The solid catalyst can be used for the reaction again, and the separated liquid is washed with water, distilled and other further processes to obtain isoamyl acetate with an ester yield of 85%. The catalyst is reused three times, and its ester yield remains above 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com