Method for measuring short chain chlorinated paraffin in high polymer material

A technology of short-chain chlorinated paraffins and polymer materials, which is applied in the direction of analysis materials, material separation, and measuring devices. It can solve the problems of interference with short-chain chlorinated paraffins analysis and incomplete separation, so as to avoid interference and improve extraction rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

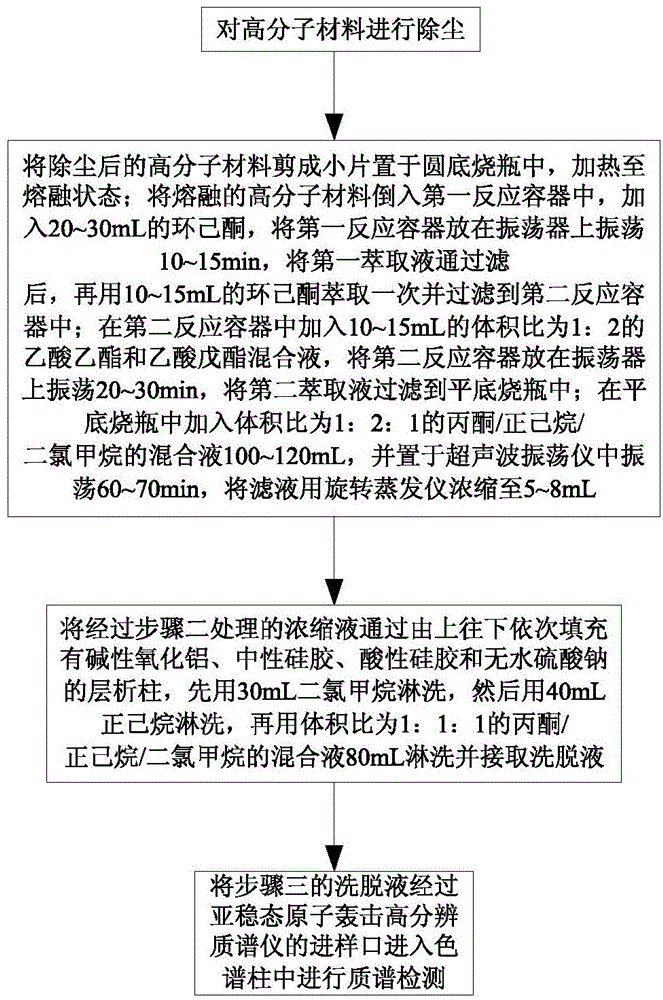

Image

Examples

Embodiment 1

[0022] The invention provides a method for measuring short-chain chlorinated paraffins in polymer materials, comprising:

[0023] Step 1. Dedusting the plastic to be tested, soaking the plastic to be tested in clean water for 20 minutes, and brushing off the dust and dirt on the surface of the plastic to be tested.

[0024] Step 2: Cut the plastic to be tested after dust removal into an area of 0.2cm 2 Weigh 2g of small pieces and place them in a round bottom flask, heat to 150°C to be in a molten state; pour the molten plastic to be tested into the first reaction container, add 20mL of cyclohexanone, and put the first reaction The container was placed on a shaker and vibrated for 10 min, and the first extract was passed through the filter paper equipped with anhydrous sodium sulfate, then extracted once with 10 mL of cyclohexanone and filtered into the second reaction container; in the second reaction container Add 10mL of ethyl acetate and pentyl acetate mixed solution wi...

Embodiment 2

[0030] The invention provides a method for measuring short-chain chlorinated paraffins in polymer materials, comprising:

[0031] Step 1. Dedusting the rubber to be tested, soaking the rubber to be tested in clear water for 40 minutes, and brushing off the dust and dirt on the surface of the rubber to be tested.

[0032] Step 2: Cut the rubber to be tested after dust removal into an area of 0.5cm 2Weigh 3g of small pieces and place them in a round bottom flask, and heat them to 180°C to be in a molten state; pour the molten rubber to be tested into the first reaction container, add 30mL of cyclohexanone, and put the first reaction The container was placed on a shaker to vibrate for 15min, and after the first extract was passed through the filter paper equipped with anhydrous sodium sulfate, it was extracted once with 15mL of cyclohexanone and filtered into the second reaction vessel; in the second reaction vessel Add 15mL of a mixture of ethyl acetate and amyl acetate with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com