Photoresist stripper compositions

a technology of compositions and strippers, applied in the field of photoresist stripper compositions, can solve the problems of reducing device yield, adversely affecting product reliability, and photoresist material inevitably becoming coated onto the backside of the wafer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

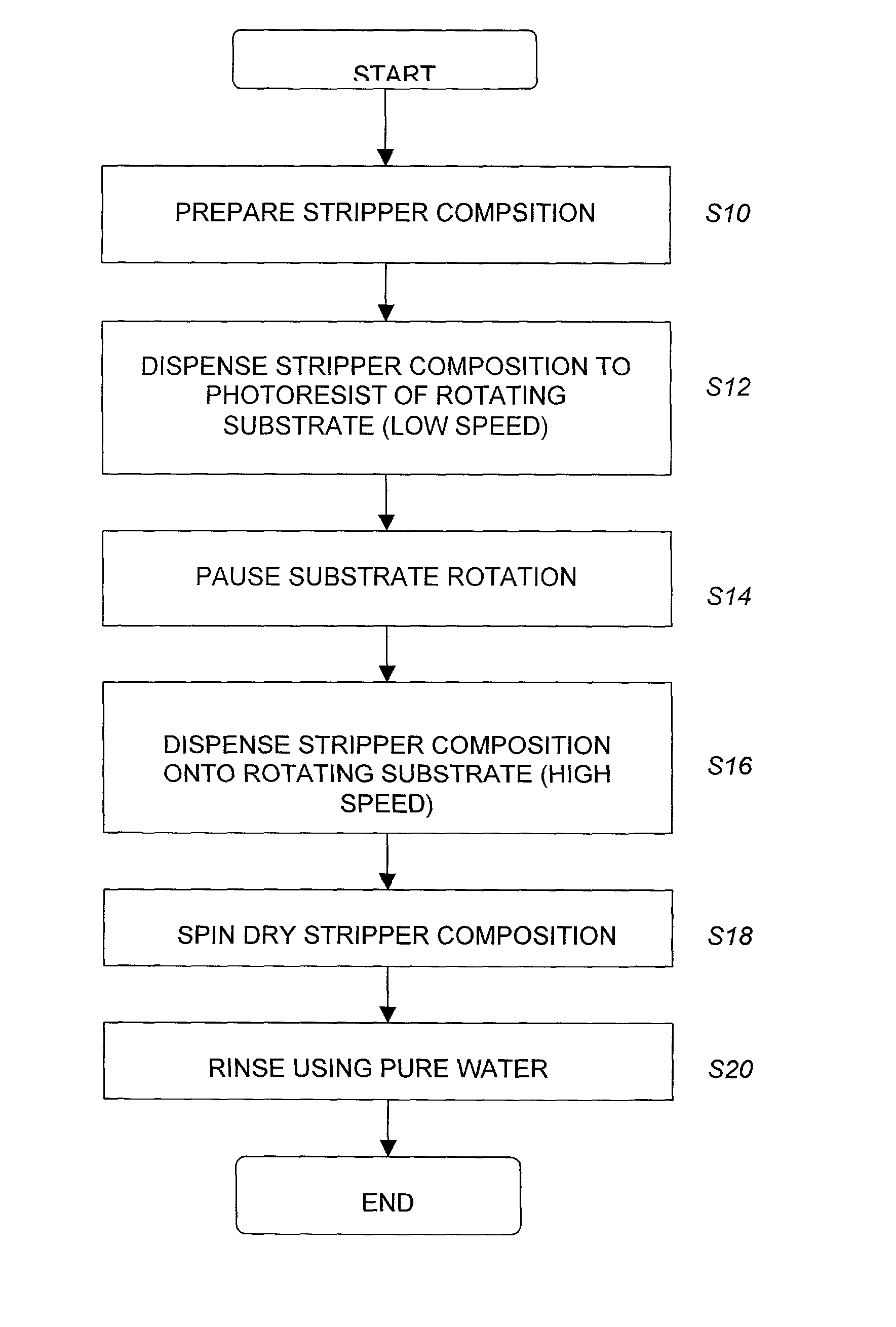

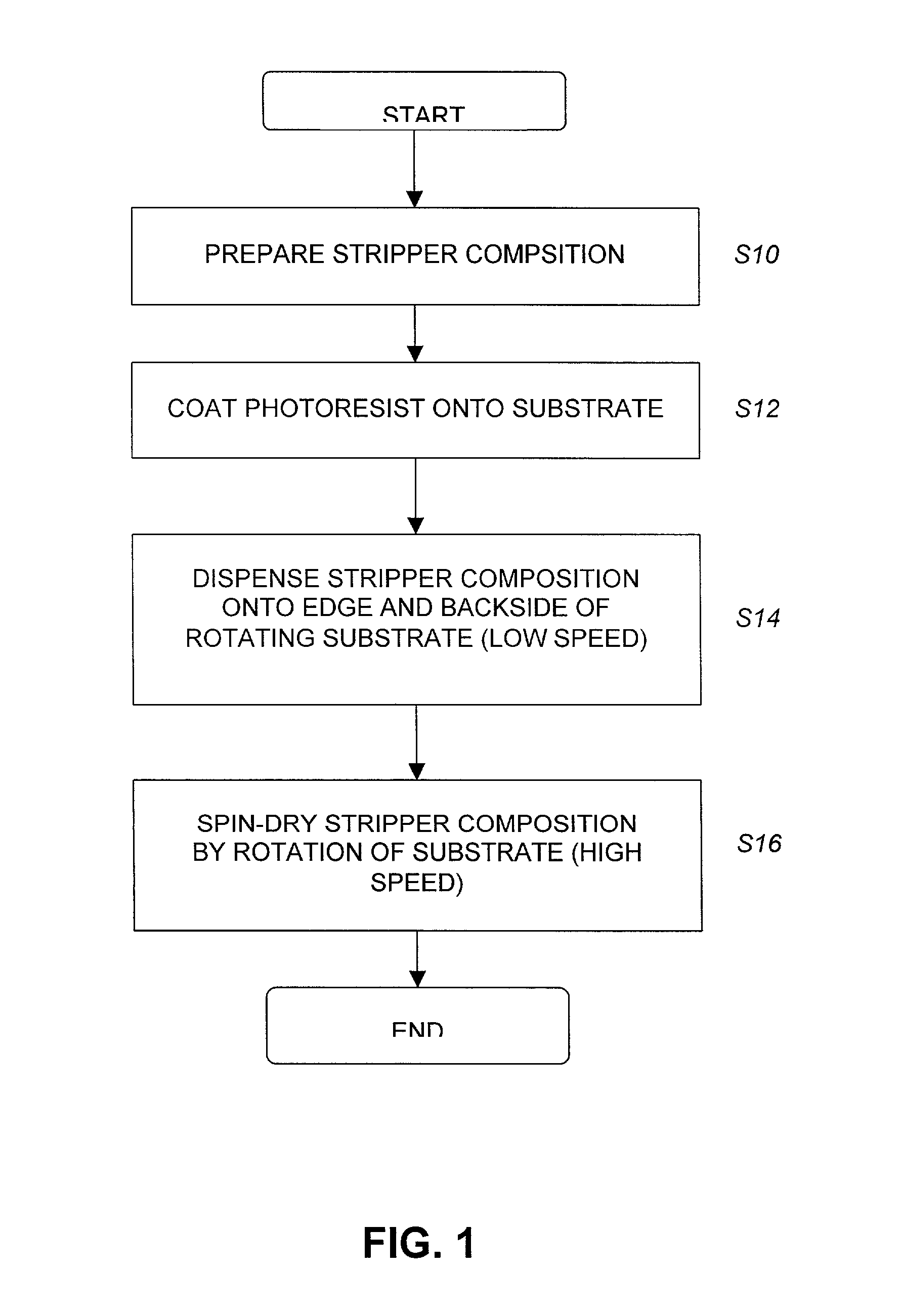

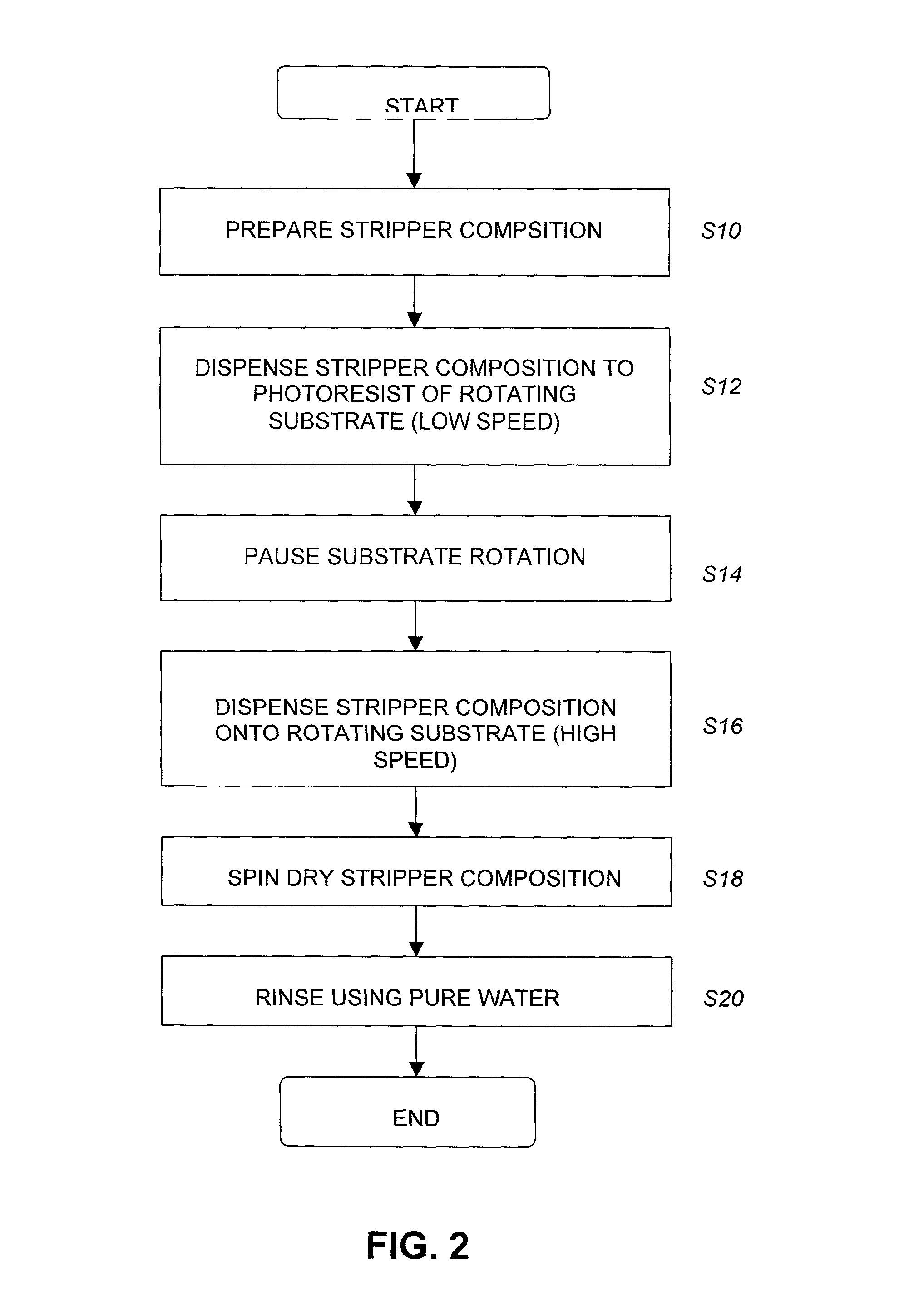

Method used

Image

Examples

example 1

[0046] NBA, GBL and EL were placed into a vessel and mixed to prepare a stripper composition. The amount of each component of the stripper composition was adjusted to 85% by weight of NBA, 5% by weight of GBL, and 10% by weight of EL. The viscosity of the thus prepared stripper composition was 0.79 cp (measured in a thermostat at 25.degree. C.).

example 2

[0047] NBA, GBL and EL were placed in a vessel and mixed to prepare a stripper composition. The amount of each component of the stripper composition was adjusted to 75% by weight of NBA, 5% by weight of GBL and 20% by weight of EL. The viscosity of the thus prepared stripper composition was 0.88 cp (measured in a thermostat at 25.degree. C.).

example 3

[0048] NBA, GBL and EEP placed in a vessel and mixed to prepare a stripper composition. The amount of each component of the stripper composition was adjusted to 85% by weight of NBA, 5% by weight of GBL and 10% by weight of EEP. The viscosity of the thus prepared stripper composition was 0.74 cp (measured in a thermostat at 25.degree. C.).

PUM

| Property | Measurement | Unit |

|---|---|---|

| wt % | aaaaa | aaaaa |

| wt % | aaaaa | aaaaa |

| wt % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com