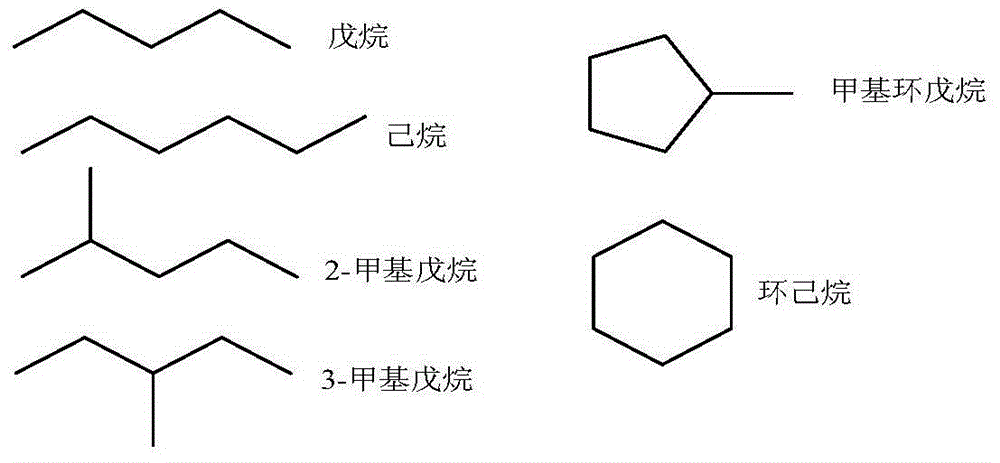

Catalyst for preparing C5 or C6 alkane from sugar or sugar alcohol via water-phase hydrogenolysis

A catalyst and sugar alcohol technology, applied in the field of catalysis, can solve the problems of poor catalyst stability and high C5/C6 alkane yield, and achieve the effects of good stability, high hydrogenolysis activity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

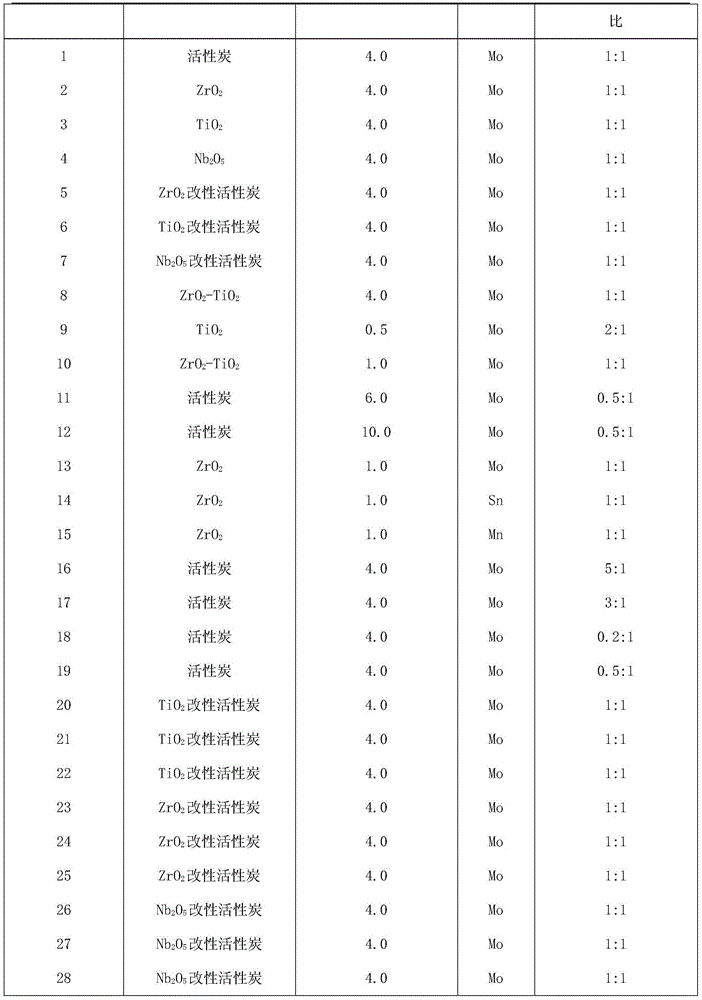

Examples

preparation Embodiment 1

[0019] Carrier Preparation Example 1: ZrO 2 Vector preparation

[0020] ZrO 2 The carrier preparation method is as follows: Weigh 20g of zirconium oxychloride solid and add 100mL of deionized water to stir until it is completely dissolved, then add dropwise an ammonia solution with a mass fraction of 17% while stirring to gradually form a white precipitate until the pH of the solution is about 10. Add ammonia water dropwise, then leave it to age for 12 hours, then filter, wash the filter cake with deionized water for 3 times, put it in a drying oven at 120°C to dry overnight, and finally roast it in a horse-boiling furnace at 500°C for 6 hours to obtain ZrO 2 carrier.

preparation Embodiment 2

[0021] Carrier Preparation Example 2: TiO 2 Preparation of vector

[0022] TiO 2 The carrier preparation method is as follows: adopt TiCl 4 Liquid-phase hydrolysis method, first 5g glacial acetic acid is dissolved in 200mL deionized water, then 20g titanium tetrachloride is added and stirred until completely dissolved, and the ammonia solution with a mass fraction of 17% is added dropwise while stirring to gradually generate a white precipitate until The pH value of the solution is about 10, and then it is left to age for 12 hours and then filtered. The filter cake is washed with deionized water for 3 times and then dried in a drying oven at 120°C overnight. Finally, TiO can be obtained after roasting at 500°C for 6 hours in a horse-boiling furnace. 2 carrier.

preparation Embodiment 3

[0023] Carrier Preparation Example 3: Nb 2 o 5 Preparation of vector

[0024] Nb 2 o 5 The carrier preparation method is as follows: Dissolve 20.4g ammonium niobium oxalate in 200mL deionized water to form a solution, then add dropwise an ammonia solution with a mass fraction of 17% while stirring to produce a white precipitate until the pH value of the solution is about 10, and then let it stand After aging for 12 hours, dry at 120°C for 12 hours in an oven, and finally bake at 500°C for 6 hours in a horse-boiling furnace to obtain Nb 2 O carrier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com