Clean production method of diketene

A technology of clean production and diketene, applied in combustion methods, chemical instruments and methods, solid waste removal, etc., can solve problems such as pollution, environmental pollution, and material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

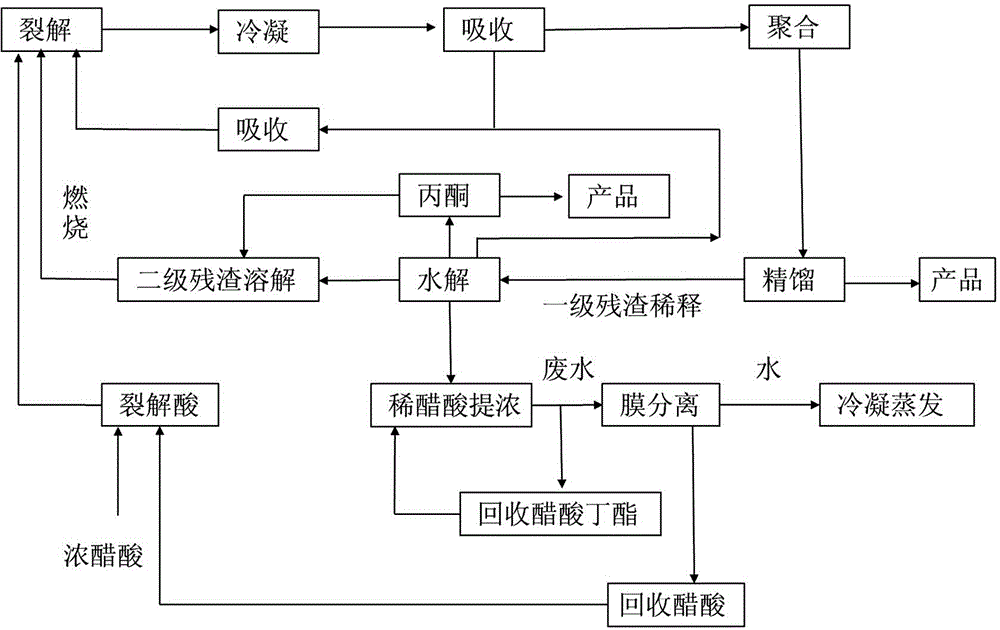

[0032] Such as figure 1 Shown, the invention provides a kind of diketene clean production method, comprises the following steps:

[0033] a. 99.8% concentrated acetic acid and 85% dilute acetic acid recovered by the system are prepared in proportion to cracking acid, and 1.8 T of 96% cracking acid is thrown into the cracking furnace. The outlet control temperature of the cracking furnace is 720 degrees and the pressure is -80 KPa. The condensed ketene gas is sent to the polymerization section to obtain 0.846 T of crude diketene, which is then purified by rectification to obtain 0.765 T of finished diketene, and 0.1 T of the first-grade residue is produced.

[0034] b. Fully dilute the primary residue with the pump liquid (the content of crude diketene is 40%, the content of anhydride is 40-50%, and the rest is acetic acid) 1.2T pump liquid is fully mixed and diluted, and sent to the hydrolysis section. Put 1T of dilute acid into the hydrolysis section, and add the first-grade...

Embodiment 2

[0039] a. 99.8% concentrated acetic acid and 85% dilute acetic acid recovered by the system are prepared in proportion to cracking acid, and 1.5 T of 96% cracking acid is thrown into the cracking furnace. The outlet control temperature of the cracking furnace is 730 degrees and the pressure is -85 KPa. The condensed ketene gas is sent to the polymerization section to obtain 0.72 T of crude diketene, which is then purified by rectification to obtain 0.65 T of diketene finished product, resulting in 800 Kg of primary residue.

[0040] b. Fully dilute the primary residue with the pump liquid (the content of crude diketene is 40%, the content of anhydride is 40-50%, and the rest is acetic acid) 1.2T pump liquid is fully mixed and diluted, and sent to the hydrolysis section. Put 1T of dilute acid into the hydrolysis section, and add the first-grade residue dilution solution dropwise at a pressure of 10KPa and a temperature of 165-170°C. The dropping time is 2-3 hours, and the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com