Preparation method of low-carbon chain symmetric anhydride

A low-carbon chain, carbon-chain carboxylic acid technology, applied in the preparation of carboxylic acid anhydrides, etc., can solve the problems of less side reactions, low yield, complicated operation, etc., and achieve the effects of less by-products, high yield and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

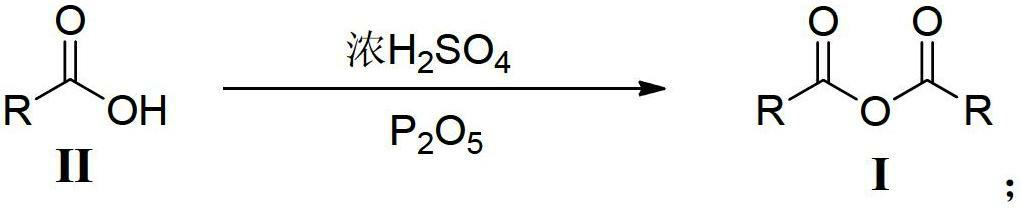

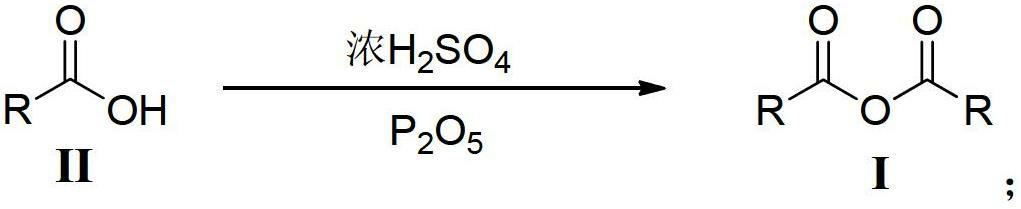

Method used

Image

Examples

Embodiment 1

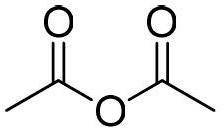

[0017] Embodiment 1: the preparation of acetic anhydride.

[0018]

[0019] Keep the temperature at 20°C, in 98% concentrated sulfuric acid (98kg, 1000mol), add acetic acid (30kg, 500mol) and phosphorus pentoxide (17.8kg, 125mol) in turn while stirring, and continue stirring for 0.5h to make it fully mixed , reacted at 80°C for 3h, and collected fractions at 140°C by atmospheric distillation to obtain 22.8kg of acetic anhydride with a yield of 89.4% and a purity (GC) of 98.6%.

Embodiment 2

[0020] Example 2: Preparation of fluoroacetic anhydride (2-fluoroacetic anhydride).

[0021]

Embodiment 3

[0022] Keeping the temperature at 20°C, in 98% concentrated sulfuric acid (196g, 2.0mol), add 2-fluoroacetic acid (78g, 1.0mol) and phosphorus pentoxide (35.5g, 0.25mmol) successively while stirring, and continue stirring for 0.5 After h, make it fully mixed, react at 100°C for 3 hours, and collect fractions by distillation under reduced pressure to obtain 59.2 g of 2-fluoroacetic anhydride, yield 85.8%, purity Example 3: Difluoroacetic anhydride (2,2- Preparation of difluoroacetic anhydride)

[0023]

[0024] Referring to the method in Example 2, the reaction time was 5 hours, and the fraction at 124-127°C was collected, with a yield of 90.5% and a purity (GC) of 97.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com