Powder paint solidifying agent and method of manufacturing used long chain carbon polyanhydride

A technology of powder coating and curing agent, which is applied in the direction of powder coating, preparation of organic compounds, preparation of carboxylic anhydride, etc. It can solve the problems of long reaction time, high distillation temperature, yellow color of polyanhydride finished products, etc., and achieve yellowing resistance Highlighted, light-colored effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

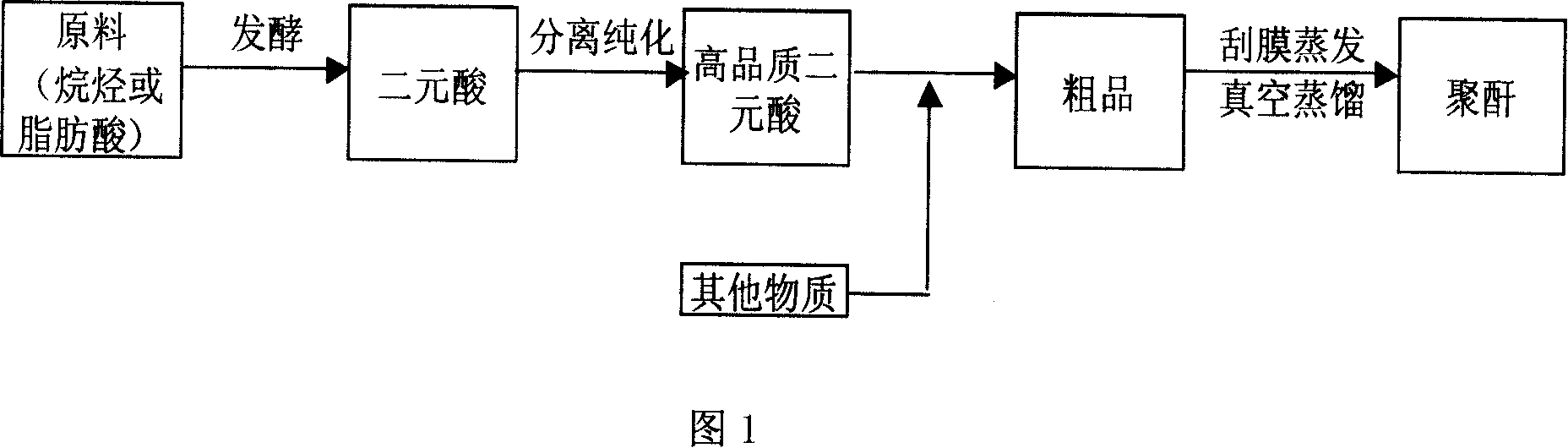

[0046] The preparation method of its long-carbon chain dibasic acid polyanhydride, the method includes a polymerization step and a purification step, wherein the polymerization step is to first produce a long-carbon chain dibasic acid through a biofermentation method of an alkane or fatty acid with a specific carbon chain length. The dibasic acid is purified to meet specific specification requirements, and then a suitable amount of long-carbon chain dibasic acid and other reactive substances are put into it, controlled according to the composition and molecular weight of the polyanhydride of the existing polyanhydride curing agent, The proportion of feeding materials is put into an atmospheric distillation kettle, heated to 100-140°C, and the low-molecular substances are evaporated at atmospheric pressure, and the distillation time is 1-6 hours; The finished product is obtained; or the polyanhydride product is obtained after distillation is carried out in a wiped film evaporati...

preparation example 1

[0068] In a 200M3 fermenter equipped with 100M3 medium, insert the seed solution to start fermentation. The composition of the fermentation medium is: 1.5% glucose, 1.5% KH2PO4, 1.0% yeast extract, 0.5% corn steep liquor, 0.35% urea, 0.1% NaCl, 30.7% KNO, natural pH, sterilized at 121°C. Dissociation of alkanes and feed sugars. Cultivate at 29°C under the conditions of ventilation rate 0.5vvm and tank pressure 1.0Mpa. 20 hours before fermentation, the pH is natural, and the growth is mainly based on bacterial growth. When the optical density (OD600) of bacterial growth is greater than 0.6, start to feed C11 alkane, control the concentration of C11 alkane in the fermentation broth to maintain at about 5%, and adjust the pH to 7.0 at the same time , Within 48 hours, adjust the pH to 7.0 with NaOH solution every 4 hours, 48-72 hours, adjust the pH to 7.5 with NaOH solution every 4 hours, 72-120 hours, adjust the pH to 7.8 with NaOH solution every 4 hours, 120 hours Until the ta...

preparation example 2

[0071]In a 200M3 fermenter equipped with 100M3 medium, insert the seed solution to start fermentation. The composition of the fermentation medium is: 3.0% glucose, 0.5% KH2PO4, 2% yeast extract, 1.5% corn steep liquor, 0.25% urea, 0.2% NaCl, 0.5% KNO3, prepared with tap water, natural pH, and sterilized at 121°C. Dissociation of C12 alkanes and fed sugars. Cultivate at 29°C under the conditions of ventilation rate 0.5vvm and tank pressure 1.0Mpa. 20 hours before fermentation, the pH is natural, and the growth is mainly based on bacterial growth. When the optical density (OD) of bacterial growth is greater than 0.6, start adding 8% of C12 alkanes in batch mode, and then add alkanes every 8 hours to control the concentration of alkanes in the fermentation broth Maintain at about 5%, adjust the pH to 6.5 at the same time, after 48 hours, adjust the pH to 7.0 with NaOH solution every 4 hours, adjust the pH to 7.5 with NaOH solution every 4 hours, 72-120 hours, every 4 hours Adju...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com