Anhydrous lithium hydroxide production device and use method thereof

A technology of anhydrous lithium hydroxide and production equipment, applied in the directions of lithium oxide;/hydroxide, dry gas arrangement, lighting and heating equipment, etc., can solve the problem of high dust content processing difficulties, reduced product yield, and production efficiency Low problems, to achieve the effect of low product yield, stable product quality, and large environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the content of the present invention, the present invention will be described in detail below in conjunction with specific examples.

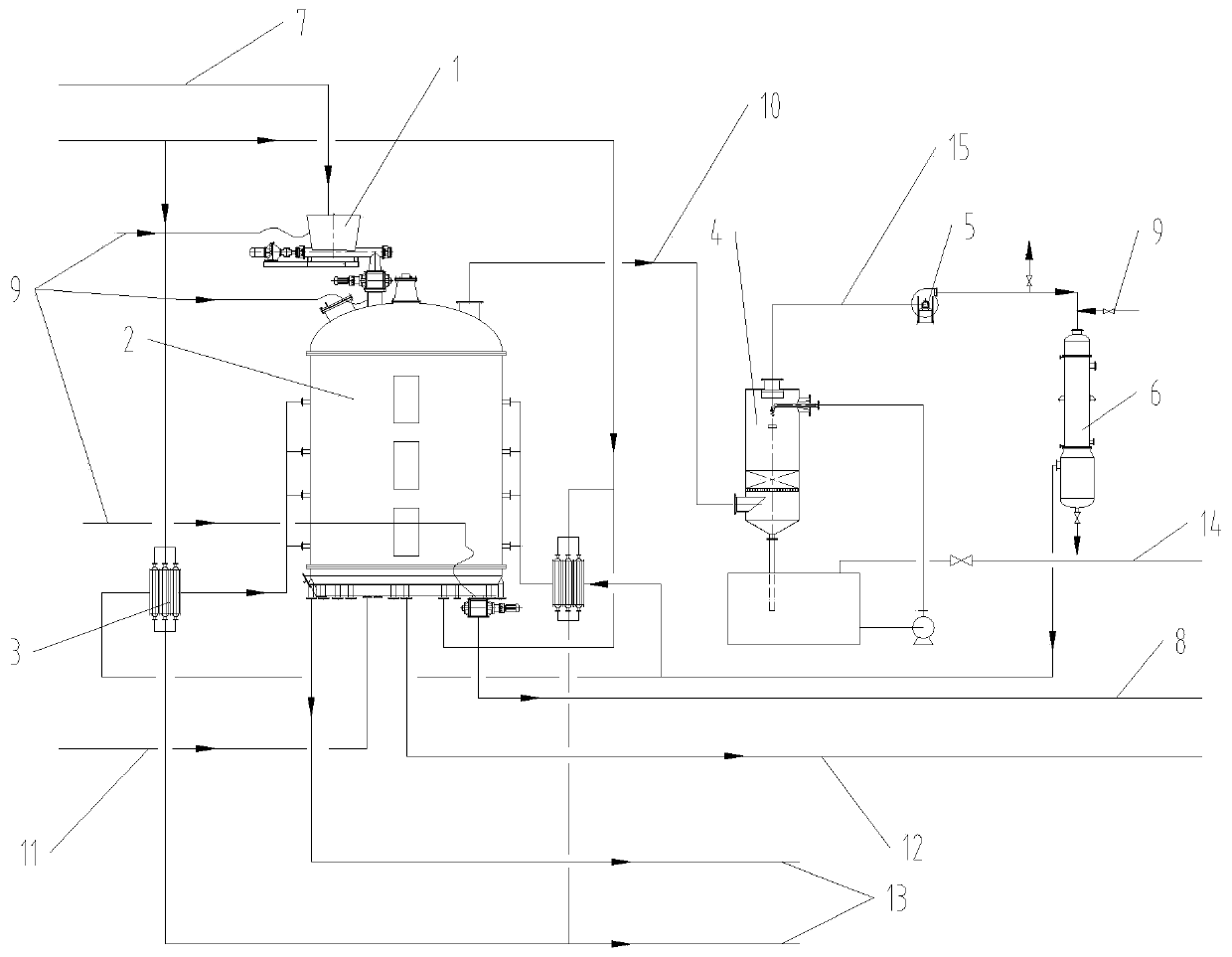

[0022] Such as figure 1 As shown, the present invention provides a kind of anhydrous lithium hydroxide production device, comprises disc type continuous drier 2, deduster 4 and dehumidifier 6, and the upper end of described disc type continuous drier 2 is a head type design, so The upper end of the disc continuous dryer 2 is provided with a feed port and a first exhaust port, and the feed port and the first exhaust port are all arranged on the head structure, which can provide a large amount of moisture space, to facilitate the discharge of moisture, and further reduce the dust entrainment in the tail gas. The lower end of the disc continuous dryer 2 is provided with a discharge port, the feed port is used to add lithium hydroxide wet material, and the first exhaust port It is used to discharge the gas car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com