Alkaline molecular sieve catalyst for preparation of styrene, and preparation method thereof

A molecular sieve and catalyst technology, applied in the field of basic molecular sieve catalyst for preparing styrene and its preparation, can solve the problems of poor catalytic activity and low styrene yield, achieve the effect of improving catalytic activity and solving low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Catalyst preparation

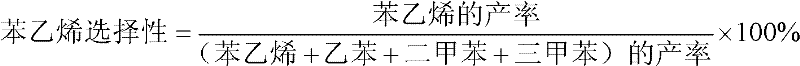

[0029] Take 100g silicon aluminum than SiO 2 / Al 2 o 3 The raw powder of IM-5 zeolite molecular sieve with a ratio of 20 is ion-exchanged with 0.03mol / L potassium nitrate solution at 80°C, and the solid-liquid ratio is 1:80 for 4 exchanges, each exchange time is 4h, After that, wash, filter with suction, and dry the filter cake at 120°C for 6 hours. Calcined at 700°C for 2 hours, then cooled in a desiccator to obtain KIM-5 molecular sieve. Shaping and crushing into 40-60 mesh particles to obtain basic molecular sieve catalyst.

[0030] 2) Reactivity test experiment

[0031] Put 0.5g of the basic molecular sieve catalyst prepared above into the reactor, the raw material ratio of toluene and methanol is 5:1 (molar ratio), and the liquid space velocity is 1h -1 , 450°C, and a nitrogen flow rate of 20ml / min, the reaction performance test was carried out, and the reaction time was 2 hours. The reaction results are listed in Table 1.

Embodiment 2

[0033] 1) Catalyst preparation

[0034] Get phosphoric acid 4.47g (6%), calcium nitrate 0.034g (0.04%), dissolve with appropriate amount of water, add the KIM-5 type molecular sieve 20g that embodiment 1 makes, stir at room temperature, place overnight, then bake at 100 DEG C Dry for 4 hours. Molecular sieves were calcined at 900°C for 4h, and then cooled in a desiccator. Shaping and crushing into 40-60 mesh particles to obtain basic molecular sieve catalyst.

[0035] 2) Reactivity test experiment

[0036] Put 8g of the basic molecular sieve catalyst prepared above into the reactor, the raw material ratio of toluene and methanol is 1:1 (molar ratio), and the liquid space velocity is 3h -1 , 370°C, and a nitrogen flow rate of 20ml / min, the reaction performance test was carried out, and the reaction time was 10 hours. The reaction results are listed in Table 1.

Embodiment 3

[0038] 1) Catalyst preparation

[0039] Take 200g silicon aluminum than SiO 2 / Al 2 o 3 The original powder of IM-5 zeolite molecular sieve with a ratio of 40 is exchanged with 0.1mol / L cesium carbonate solution for IM-5 zeolite molecular sieve at 80°C, and the solid-liquid ratio is 1:80. After 10 hours, wash, filter with suction, and dry the filter cake at 120°C for 6 hours. The molecular sieve was calcined at 400°C for 2 hours, and then cooled in a desiccator to obtain CsIM-5 molecular sieve. Shaping and crushing into 40-60 mesh particles to obtain basic molecular sieve catalyst.

[0040] 2) Reactivity test experiment

[0041] Put 10g of the basic molecular sieve catalyst prepared above into the reactor, the raw material ratio of toluene and methanol is 1:1 (molar ratio), and the liquid space velocity is 6h -1 , 400°C, and a nitrogen flow rate of 20ml / min, the reaction performance test was carried out, and the reaction time was 50h. The reaction results are listed in T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com