Refining purifying device and method used for continuously producing battery grade dimethyl carbonate

A technology of dimethyl carbonate and a purification method, which is applied in the field of refining and purification devices for continuous production of battery-grade dimethyl carbonate, can solve the problems of high energy consumption, low yield, generation of solid waste, etc., so as to improve economic benefits and sales. The effect of increasing the price and solving the cumbersome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

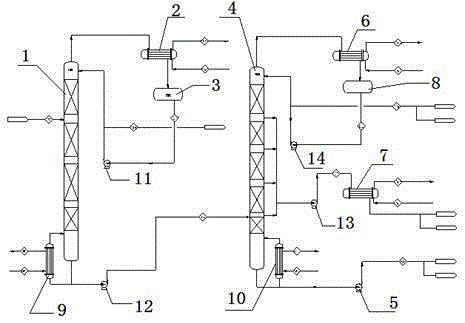

[0034] The device uses industrial-grade dimethyl carbonate as a raw material, and adopts a continuous method to refine and purify battery-grade dimethyl carbonate products, including the following steps:

[0035] A) Raw material feed: The raw material feed dimethyl carbonate extracted from the DMC refining tower tank of the industrial-grade dimethyl carbonate unit is pumped to the light removal tower 1 through the conveying pump, and the material is fed from the middle and upper part of the light removal tower 1 Material, control feed rate 1500Kg / h;

[0036]B) Light removal tower operation: control the top operating temperature of light removal tower 1 to 50°C, the operating temperature of the tower bottom of the light removal tower to 60°C, the top operating pressure of the light removal tower: 60KPa, the reflux ratio control: 20, and light removal The dimethyl carbonate material containing light component impurities obtained at the top of the tower, when the analytical purit...

Embodiment 2

[0039] The device uses industrial-grade dimethyl carbonate as a raw material, and adopts a continuous method to refine and purify battery-grade dimethyl carbonate products, including the following steps:

[0040] A) Raw material feed: The raw material feed dimethyl carbonate extracted from the DMC refining tower tank of the industrial-grade dimethyl carbonate unit is pumped to the light removal tower 1 through the conveying pump, and the material is fed from the middle and upper part of the light removal tower 1 Material, control feed rate 1500Kg / h;

[0041] B) Light removal tower operation: control the top operating temperature of light removal tower 1 to 75°C, the operating temperature of the light removal tower bottom to 85°C, the top operating pressure of the light removal tower: 105KPa, the reflux ratio control: 30, and light removal The dimethyl carbonate material containing light component impurities obtained at the top of the tower, when the analytical purity is greate...

Embodiment 3

[0044] The device uses industrial-grade dimethyl carbonate as a raw material, and adopts a continuous method to refine and purify battery-grade dimethyl carbonate products, including the following steps:

[0045] A) Raw material feed: The raw material feed dimethyl carbonate extracted from the DMC refining tower tank of the industrial-grade dimethyl carbonate unit is pumped to the light removal tower 1 through the conveying pump, and the material is fed from the middle and upper part of the light removal tower 1 Material, control feed rate 1500Kg / h;

[0046] B) Light removal tower operation: control the operating temperature of the top of the light removal tower 1 to 100°C, the operating temperature of the bottom of the light removal tower to 110°C, the operating pressure of the top of the light removal tower: 150KPa, the reflux ratio control: 40, and light removal The dimethyl carbonate material containing light component impurities obtained at the top of the tower, when the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com