A kind of acetic acid chlorination reactor and reaction process method

A chlorination reaction and reactor technology, applied in the field of an acetic acid chlorination reaction process method and its supporting reactor, can solve the problems of high energy consumption, large investment, low yield of chloroacetic acid, etc., and reduce investment and energy consumption , the effect of speeding up the response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

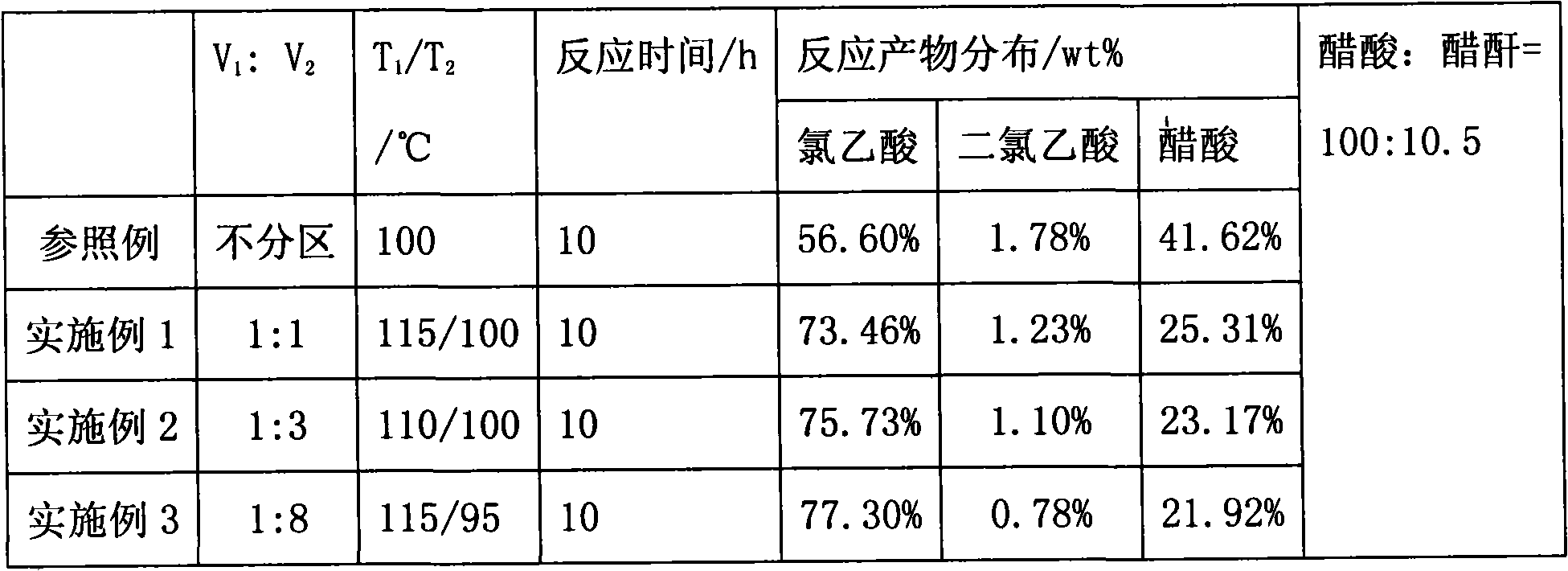

Embodiment 1~3

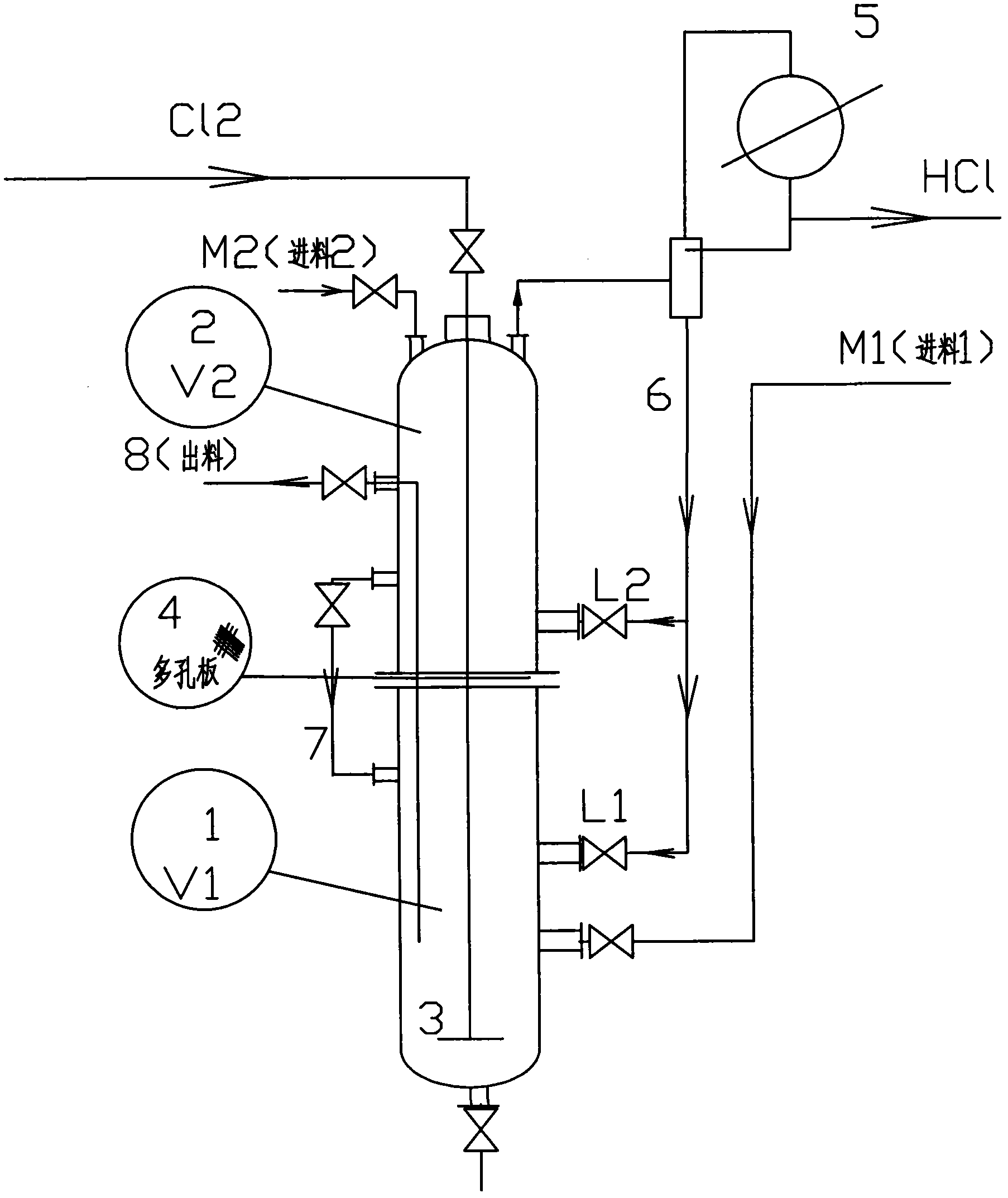

[0025] use figure 1 The shown reactor adopts continuous operation, and the reactor volume V (V 1 +V 2 )=140 liters, adjust the volume of the two reaction zones by changing the position of the perforated plate, namely V 1 with V 2 At the beginning, 90 kg of acetic acid (M2) was added from the feed port of the second reaction zone on the upper part, and 9.5 kg of acetic anhydride (M1) was added from the feed port of the first reaction zone on the lower part, and both the first and second reaction zones were controlled at 100 °C , chlorine gas is introduced from the chlorine gas distribution device 3, and the rate of chlorine gas introduction is 1.4-1.6m 3 / h, adjust according to whether the condenser is yellow, react for 10h, then change to continuous feeding, during the continuous feeding operation, the amount of acetic acid added M2 = 14.0kg / h, enter the second reaction from the upper feeding port zone, the addition of acetic anhydride M1 = 1.48kg / h, enters the first reacti...

Embodiment 4~5

[0029] use figure 1 The reactor structure and process shown in the comparative experiment. Adopt batch-type operation, adjust the reaction temperature of two reaction zones and compare, 110kg of acetic acid addition amount, 12kg of acetic anhydride addition amount at the beginning. The temperatures of the first reaction zone and the second reaction zone are respectively T 1 and T 2 , the chlorine gas flow rate is adjusted according to whether the condenser is yellow. The condensed reflux enters the first zone and the second zone respectively according to L1:L2=7:3 (weight ratio). The results are shown in Table 2.

[0030] Table 2 Reaction result table

[0031]

Embodiment 6

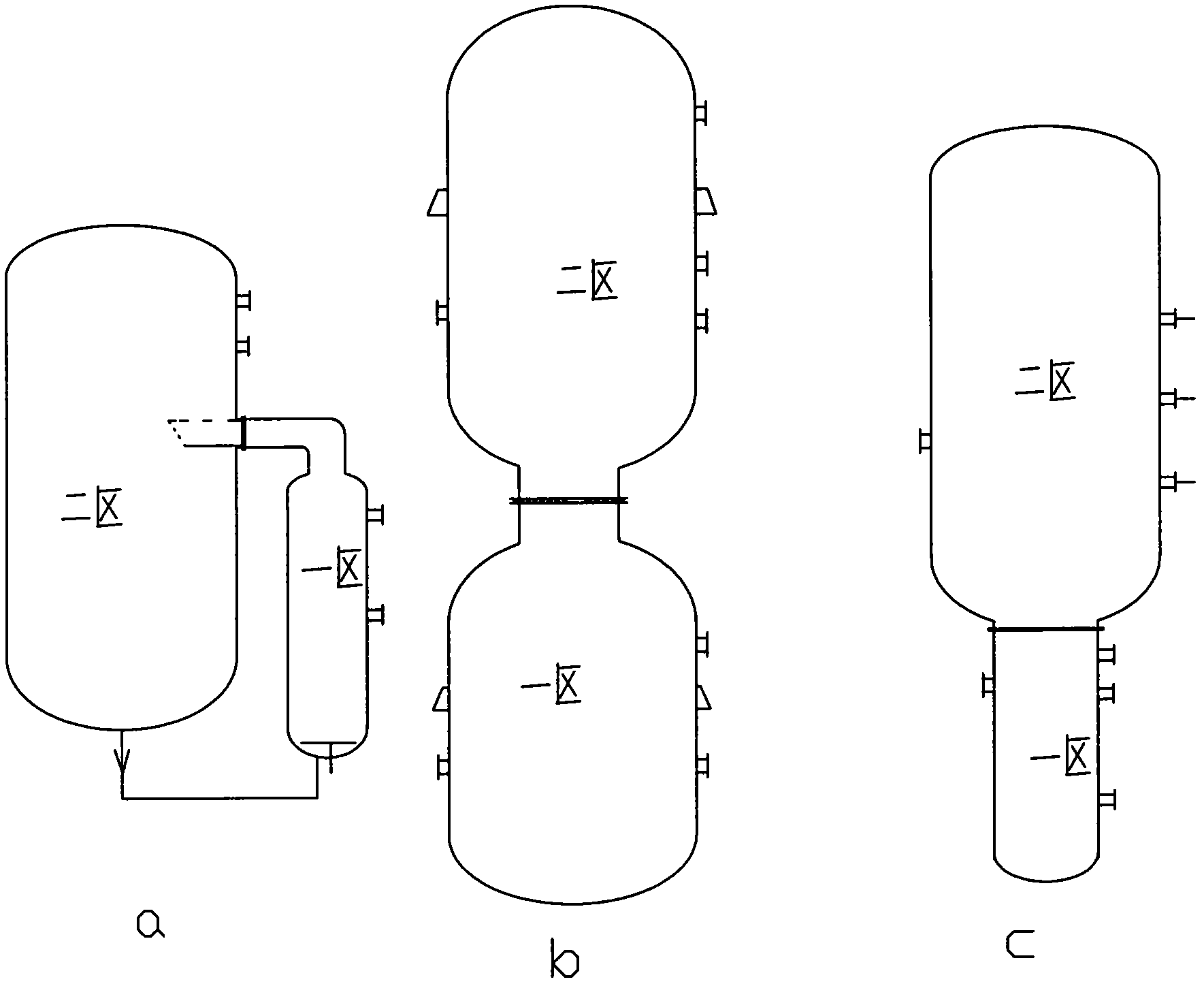

[0033] The reactor can be designed as two or more sections in series, and the diameter and shape of each section can be consistent or inconsistent. The reactor can also be designed as two or more sections, each section is a reaction area, and the reaction area is used The perforated plates are separated, and the temperature of each reaction zone can be independently controlled and adjusted, and the feeding or discharging of each zone can also be independently controlled. The ideal reaction zone is two, and the volume ratio of the two reaction zones is that the ratio of the first reaction zone volume (lower part) V1 to the second reaction zone (upper part) volume V2 ratio is 1:0.6 to 1:25, and the ideal range is 1:3 to 1:8.

[0034] Such as figure 2 Among them, a reactor is composed of two parts, b is a two-stage shrinkage series connection, and c is a unequal diameter series connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com