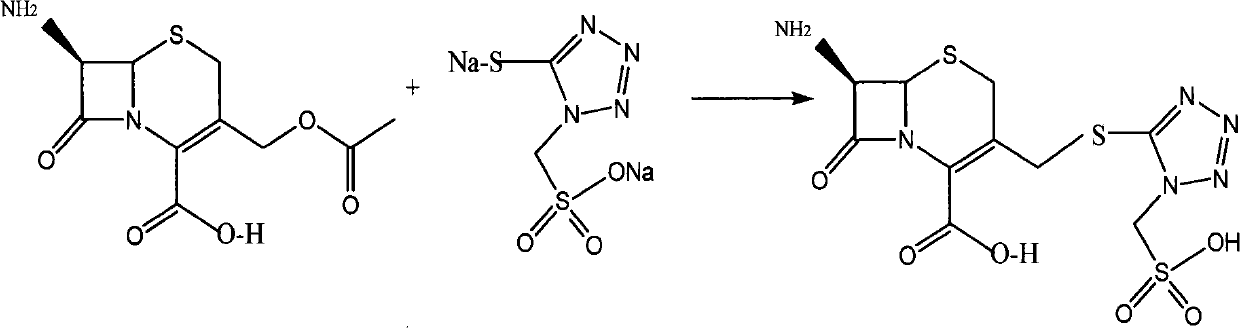

Method for preparing 7-amino-3-sulfotetrazolthiomethylcephalosporanic acid

A technology of sulfotetrazolium thiomethyl cephalosporanic acid and sulfotetrazolium thiomethyl cephalosporan, which is applied to the preparation of 7-amino-3-sulfotetrazolium thiomethyl cephalosporanic acid It can achieve the effect of solving expensive, mild and simple reaction conditions, and reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] a. adding 230kg boron trifluoride concentration in 250kg dimethyl carbonate solvent is 35% dimethyl carbonate solution, after stirring evenly, add 45kg of 7-ACA and 43kg of 5-mercapto-1 sulfonic acid Methyl tetrazolium disodium salt, then reacted at 21°C under stirring;

[0021] b. Stop the reaction when the 7-ACA residue in the above reaction is ≤0.5%, then add 60kg of purified water, and continue the reaction at 25°C;

[0022] c. After the above reaction was carried out for 0.5 to 1 hour, the temperature was lowered to 12°C, and after stirring for 30 minutes, the crude product of 7-amino-3-sulfonic acid tetrazolium thiomethyl cephalosporanic acid crystals was obtained by filtering and washing;

[0023] d. After adding the crude crystalline product above to 200kg of purified water to dissolve, add 15kg of acetone solvent at room temperature 20-25°C, adjust the pH value of the reaction solution to 1.9 with sodium bicarbonate solution or ammonia solution and fully stir i...

Embodiment 2

[0025] Embodiment 2: the difference between this embodiment and embodiment 1 is that

[0026] a. Add 100kg boron trifluoride concentration in 350kg dimethyl carbonate solvent and be 18% dimethyl carbonate solution, after stirring evenly, add 20kg of 7-ACA and 19kg of 5-mercapto-1 sulfonic acid Methyl tetrazolium disodium salt, then reacted at 12°C under stirring;

[0027] b. Stop the reaction when the 7-ACA residue in the above reaction is ≤0.5%, then add 30kg of purified water and continue the reaction at 40°C;

[0028] c. After the above reaction was carried out for 0.5 to 1 hour, the temperature was lowered to 5° C., and after stirring for 30 minutes, filtered and washed to obtain the crude 7-amino-3-sulfonic acid tetrazolium thiomethyl cephalosporanic acid crystal;

[0029] d. After dissolving the crude crystalline product above in 350kg of purified water, add 10kg of tetrahydrofuran solvent at room temperature 20-25°C, adjust the pH value of the reaction solution to 0.9 ...

Embodiment 3

[0031] Embodiment 3: the difference between this embodiment and embodiment 1 is,

[0032] a. in 500kg dimethyl carbonate solvent, add the weight percent concentration of 250kg boron trifluoride to be 50% dimethyl carbonate solution, after stirring, add successively 5-mercapto-1 sulfonic acid of 50kg of 7-ACA and 47kg Methyl tetrazolium disodium salt, then react at 40°C under stirring;

[0033] b. Stop the reaction when the 7-ACA residue in the above reaction is ≤0.5%, then add 60kg of purified water and continue the reaction at 30°C;

[0034] c. After the above reaction was carried out for 0.5 to 1 hour, the temperature was lowered to 15° C., stirred for 30 minutes, filtered and washed to obtain the crude 7-amino-3-sulfonic acid tetrazolium thiomethyl cephalosporanic acid crystal;

[0035] d. After adding the crude crystalline product above to 500kg of purified water for dissolution, add 30kg of isopropanol solvent at room temperature 20-25°C, adjust the pH value of the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com