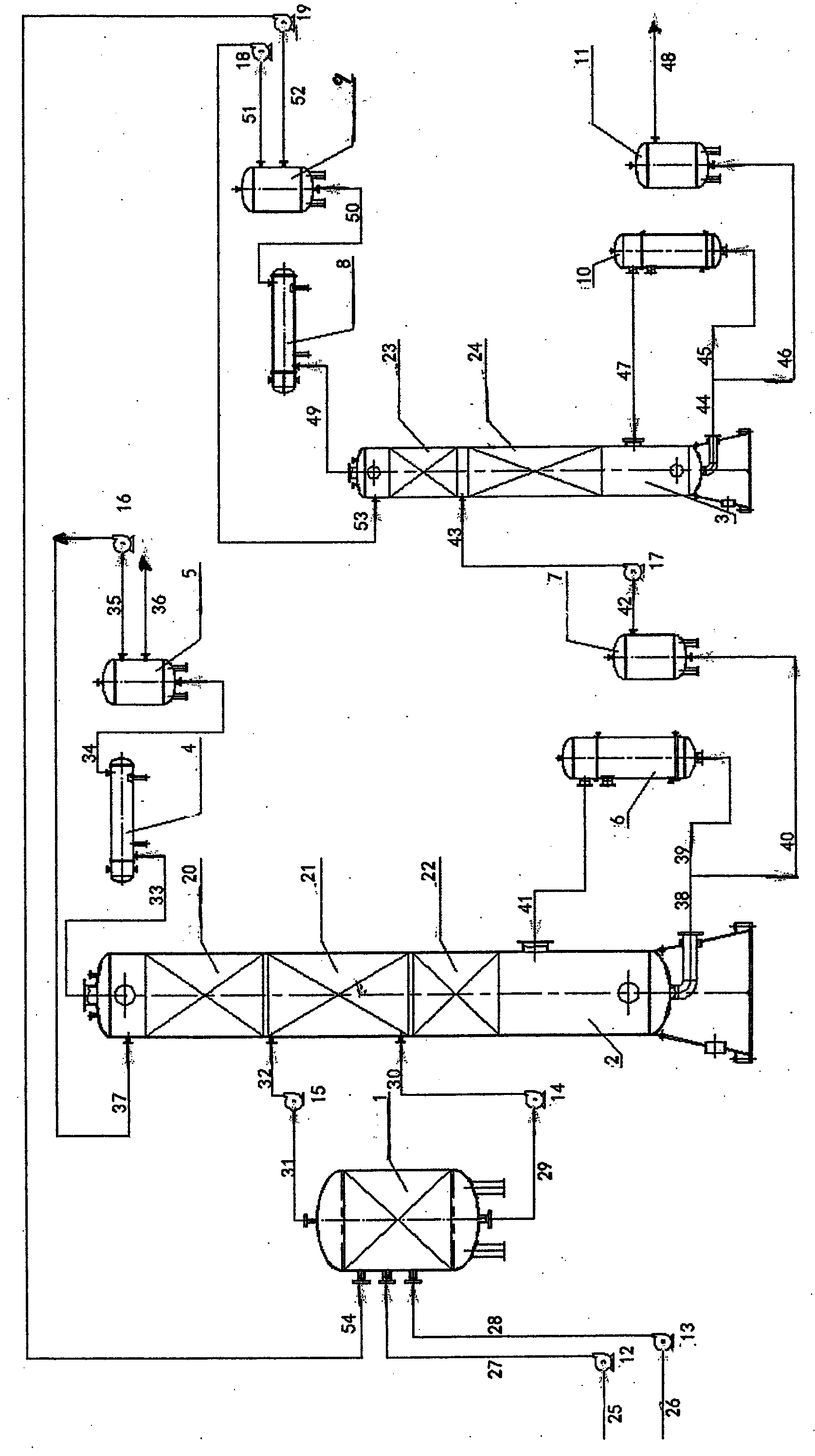

Device and method for preparing propionic anhydride through reactive distillation of acetic anhydride and propionic acid

A technology of reactive distillation and reactive distillation tower, which is applied in the field of devices for producing propionic anhydride by reactive distillation of acetic anhydride and propionic acid, which can solve the problems of environmental pollution, low conversion rate, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 3

[0050] The reactive distillation column consists of 3 parts: 10 trays in the rectification section (reactive distillation trays), 22 trays in the reaction section (reactive distillation trays), and 13 trays in the stripping section (reactive distillation trays). plate), the tower diameter is 1 meter. The acetic anhydride refining tower has 12 trays in the rectification section and 12 trays in the stripping section, with a tower top of 0.8 meters. Acetic anhydride and propionic acid feed molar ratio are 0.5, and reactive distillation tower operating pressure is 35kPa (absolute pressure), 25kPa (absolute pressure), 15kPa (absolute pressure), propionic anhydride refining tower operating pressure is 1atm (absolute pressure), The purity of propionic anhydride in the output of the propionic anhydride refining tower tank is 90.1%, 95.3%, 98.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com