Method for formlng pattern of semiconductor device

A semiconductor and pattern technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems of second photoresist pattern degradation profile, inability to properly perform follow-up procedures, etc., to ensure process margin, Effect of improving adhesion characteristics, reliable semiconductor devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

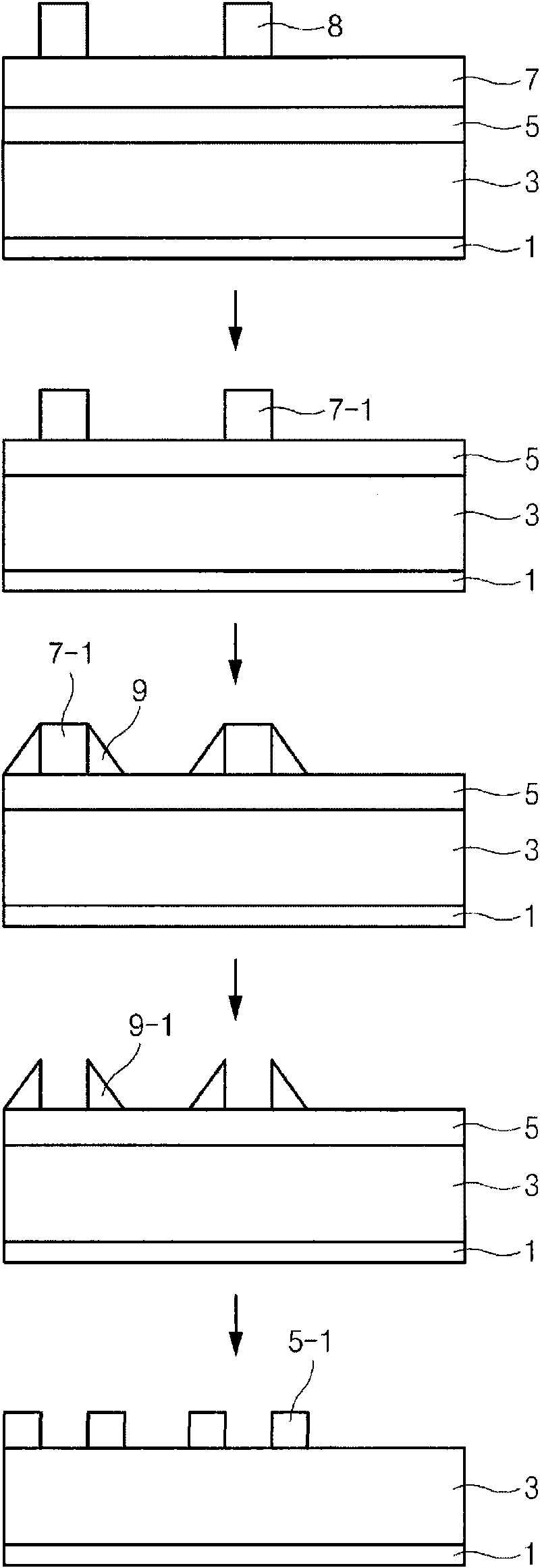

[0051] Figure 4a to Figure 4j is a view illustrating a method for forming a pattern of a semiconductor according to an embodiment of the present invention.

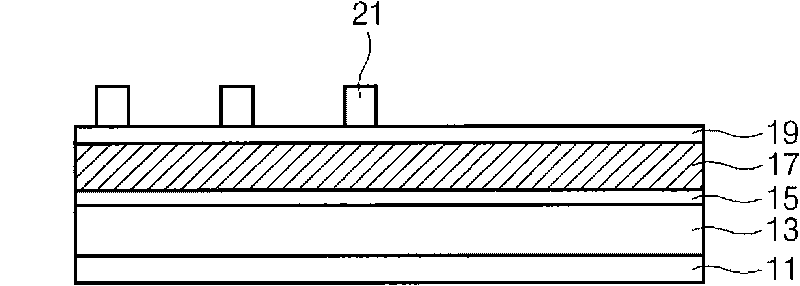

[0052] refer to Figure 4a , forming the base layer 111 on the substrate. The substrate may include an isolation film (ISO) (not shown), and the base layer 111 may include a dielectric film (not shown) [for example, an oxide film-nitride film-oxide film (ONO)], a gate polysilicon layer (not shown), a tungsten conductive layer (not shown), a capping oxide film (not shown), and a gate mask film (not shown).

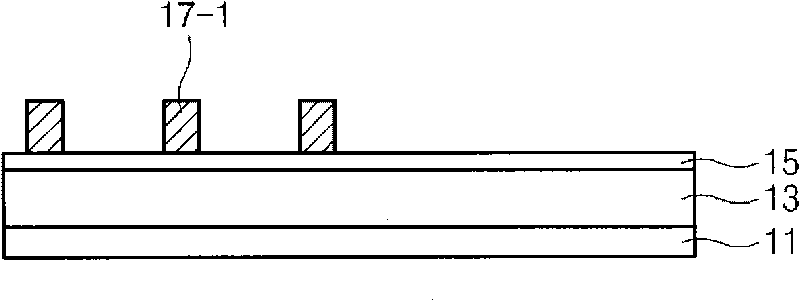

[0053] A polysilicon layer 113, a first nitride film 115 (ie, a first mask film), an oxide film 117 (ie, a second mask film), and a third mask film 119 are sequentially deposited on the base layer.

[0054] The oxide film 117 is formed using tetraethyl silicate (TEOS). Since the oxide film 117 determines the spacer height in the spacer patterning process, it is required that the oxide film has a given height of ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical dimension | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com