Method for forming fine pattern of semiconductor device

A fine pattern and semiconductor technology, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of unobtainable pattern, inaccurate alignment and poor pattern overlapping, so as to avoid misalignment and improve efficiency , The effect of simplifying the process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

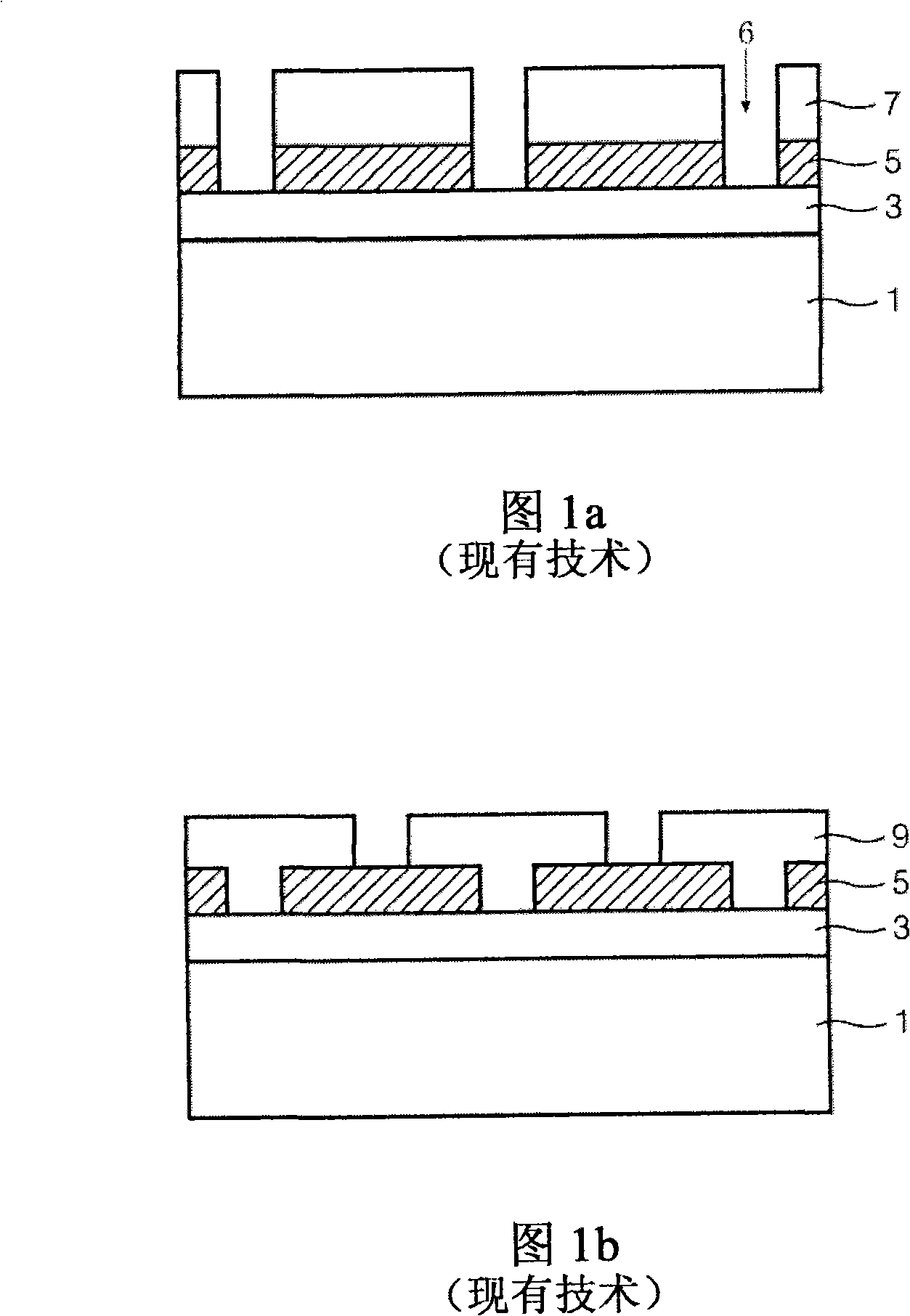

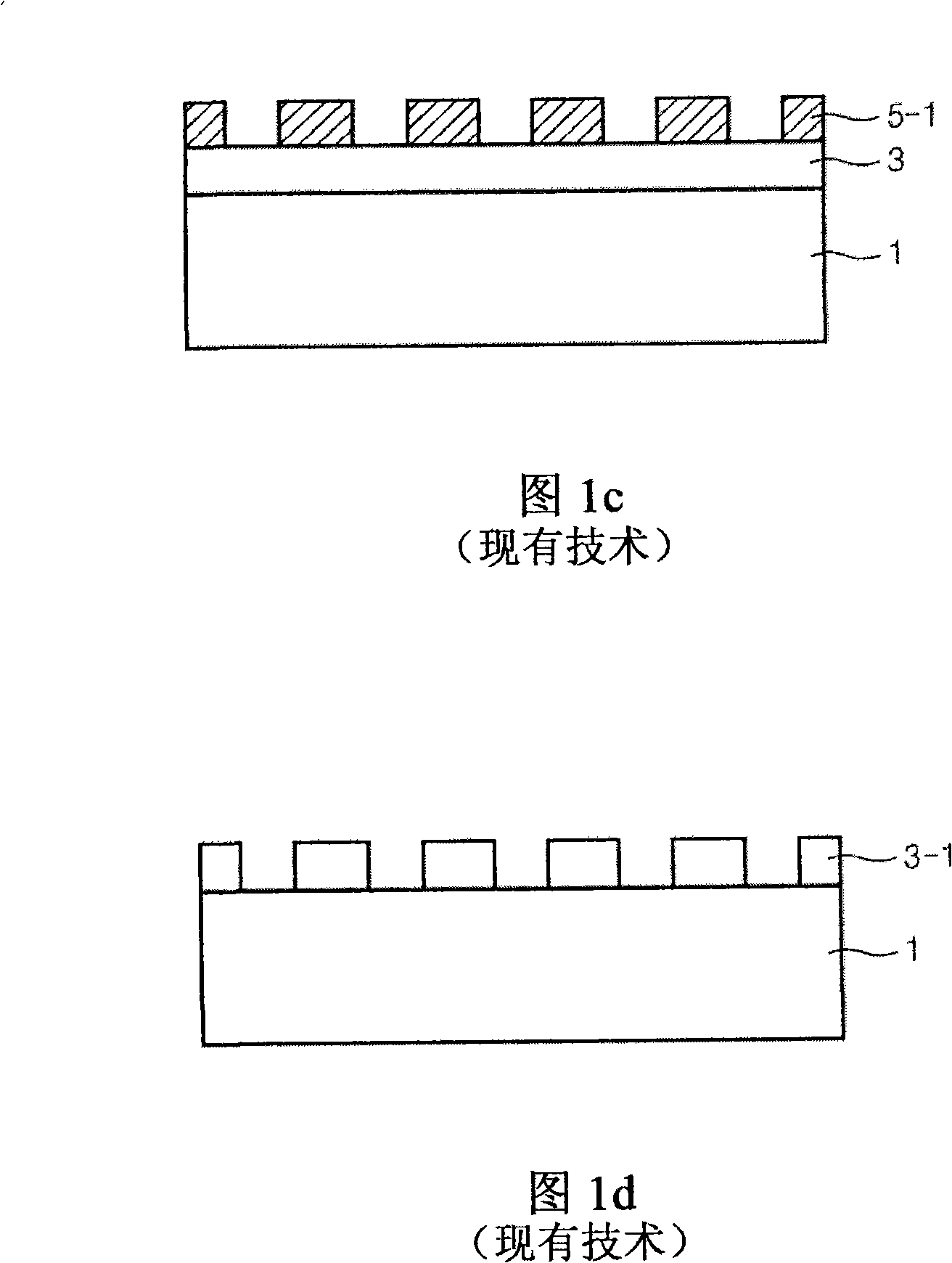

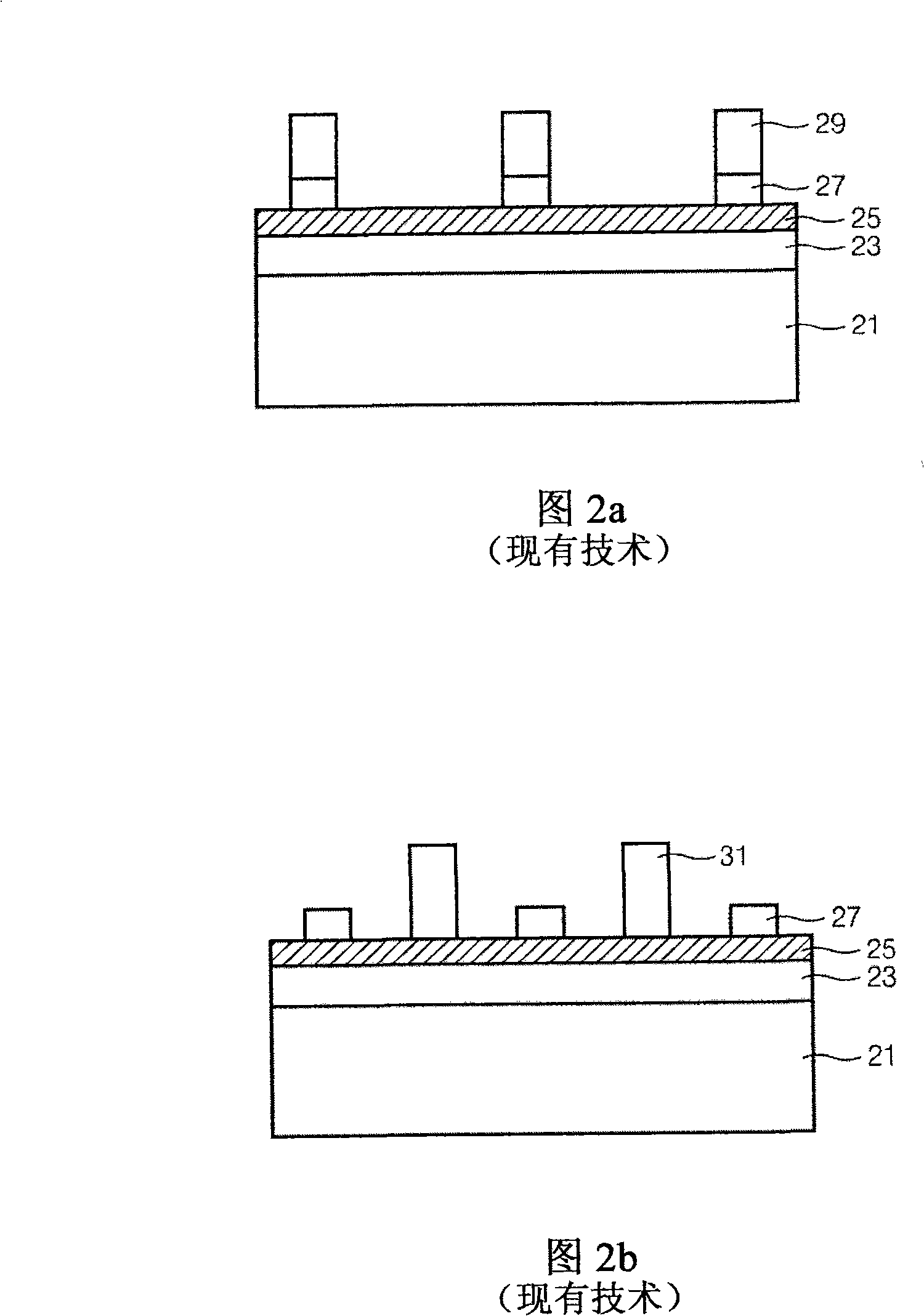

[0018] The double patterning technique for forming fine patterns includes forming grooves to obtain patterns, or forming lines to obtain patterns.

[0019] 1a to 1d are cross-sectional views illustrating a conventional method of forming fine patterns, which includes forming grooves to obtain fine patterns. 2a to 2d are cross-sectional views illustrating a conventional method of forming a fine pattern, which includes forming lines to obtain a fine pattern.

[0020] Referring to FIG. 1 a , a bottom layer 3 , a mask film (not shown) and a first photoresist film (not shown) are deposited on a substrate 1 . A first photolithography process is performed on the first photoresist film to form a first photoresist pattern 7 . Using the first photoresist pattern 7 as an etching mask, a first patterning process is performed on the mask film to form a stack structure including the first mask pattern 5 and the first photoresist pattern 7 and having the trench 6 .

[0021] Referring to FIG...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com