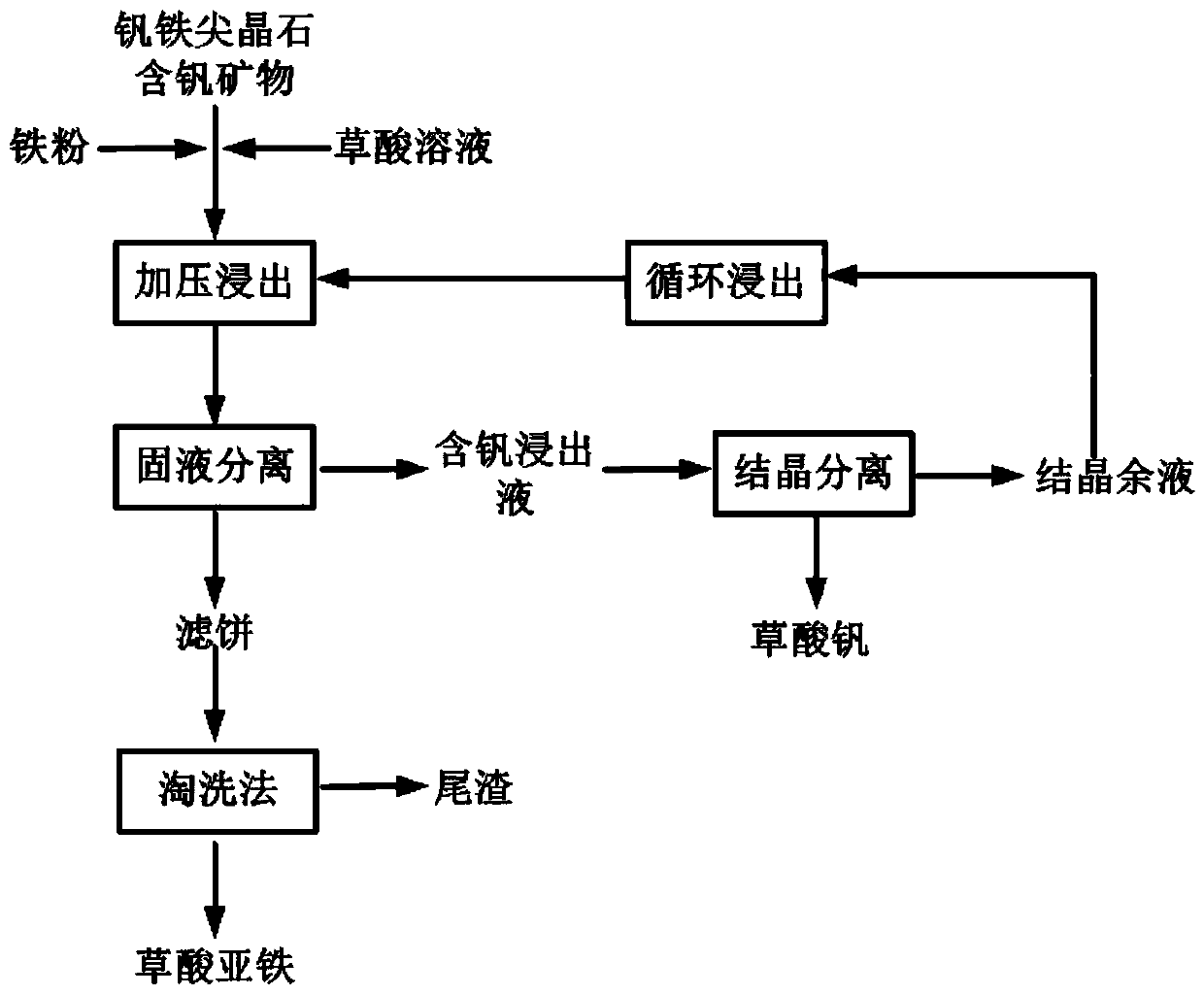

Method for leaching vanadium in ferrovanadium spinel vanadium-containing minerals through complexing of hydrothermal oxalic acid

A spinel and ferrovanadium technology is applied in the field of hydrothermal leaching of vanadium in ferrovanadium spinel-type vanadium-containing minerals, which can solve the problems of difficulty in processing leaching tailings, pollution of the environment by fluoride, and inability to discharge at will, and the like. The effect of accelerating the leaching reaction rate, simplifying the process steps, and cleaning the leaching solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

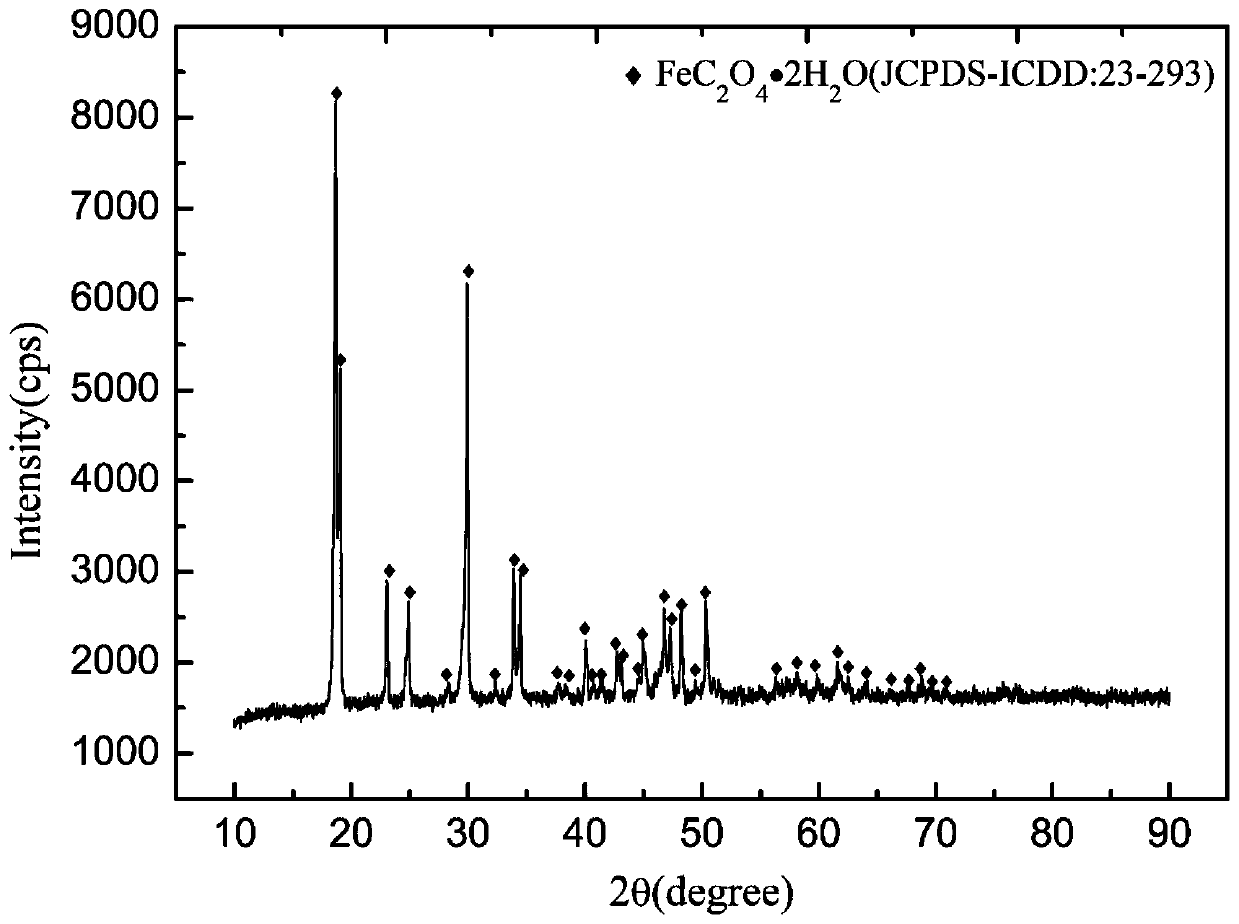

Embodiment 1

[0026] Using vanadium trioxide and ferric oxide as initial raw materials, they were calcined at 1200°C for 48 hours in a reducing atmosphere to obtain pure Fe 2 VO 4 . will obtain pure Fe 2 VO 4 Grind the particle size to less than 0.074mm, weigh 0.2g of ball-milled vanadium iron spinel and 0.6g of reduced iron powder, mix them together and put them into the reactor, add 20ml of 30% oxalic acid solution in the reactor Inside, a mixed slurry is formed, and the leaching reaction is carried out under the conditions of a reaction temperature of 135° C., a time of 120 minutes, and a stirring speed of 500 rpm. After the reaction is completed, solid-liquid separation is carried out to obtain a vanadium-containing leachate and a filter cake, and the filter cake is washed. Obtain ferrous oxalate by-product and leaching residue according to elutriation method. Finally, the concentration of vanadium in the leaching solution was measured by ICP-AES to be 2.2g / L, and the concentration ...

Embodiment 2

[0028] According to the methods of Chinese patents CN106011456A and CN107641723A, stone coal is used as the initial raw material, ferric oxide is used as an additive, and the temperature is 1200 ° C under a reducing atmosphere. Roasting, after magnetic separation, a vanadium-iron-spinel-type vanadium-containing concentrate is obtained . Ball mill the obtained vanadium-iron-spinel-type vanadium-containing concentrate to a particle size below 0.074mm, weigh 0.2g of ball-milled vanadium concentrate, and 0.6g of reduced iron powder, mix them together, put them into the reaction kettle, add Put 20ml of oxalic acid solution with a mass fraction of 30% in a reaction kettle to form a mixed slurry. Under the conditions of a reaction temperature of 135°C, a time of 120min, and a stirring speed of 500rpm, a leaching reaction is carried out. After the reaction is completed, solid-liquid separation is carried out to obtain vanadium-containing Leachate and filter cake, the filter cake is wa...

Embodiment 3

[0030]Using vanadium slag as the initial raw material, the vanadium slag is ball-milled to a particle size below 0.074mm. Weigh 0.2g of ball-milled vanadium slag and 0.6g of reduced iron powder, mix them together and put them into the reactor, add 20ml of oxalic acid solution with a mass fraction of 30% in the reactor to form a mixed slurry. Under the conditions of 135°C, 120min, and stirring speed of 500rpm, the leaching reaction was carried out. After the reaction, solid-liquid separation was carried out to obtain the vanadium-containing leachate and filter cake. The filter cake was washed, and the by-products of ferrous oxalate and Leach residue. Finally, the concentration of vanadium in the leach solution was measured to be 497mg / L by ICP-AES, and the leaching rate was 89%, and the concentration of iron in the leach solution was measured to be 75mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com