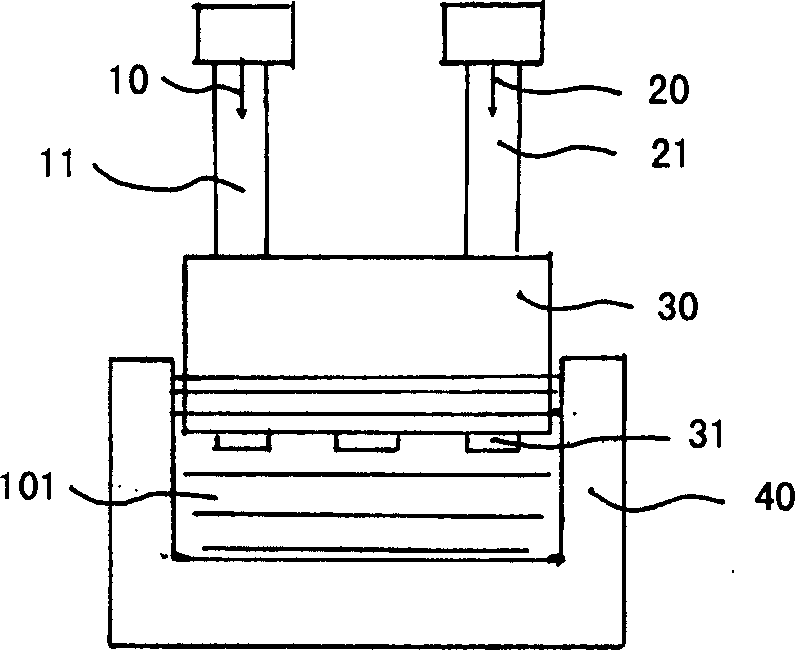

Ink jetting head cleaning device

An inkjet head, cleaning technology, applied in printing and other directions, can solve the problems of light-emitting panel defects, irregularities, and shortening the life of inkjet heads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

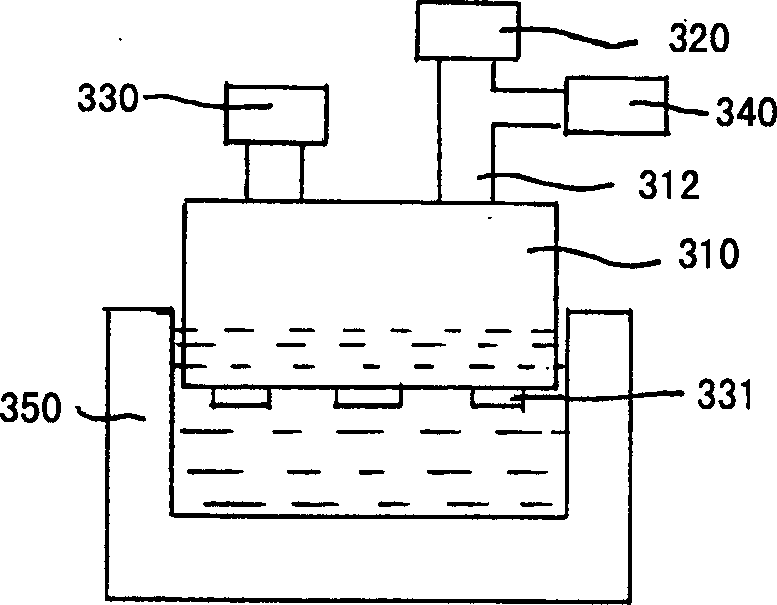

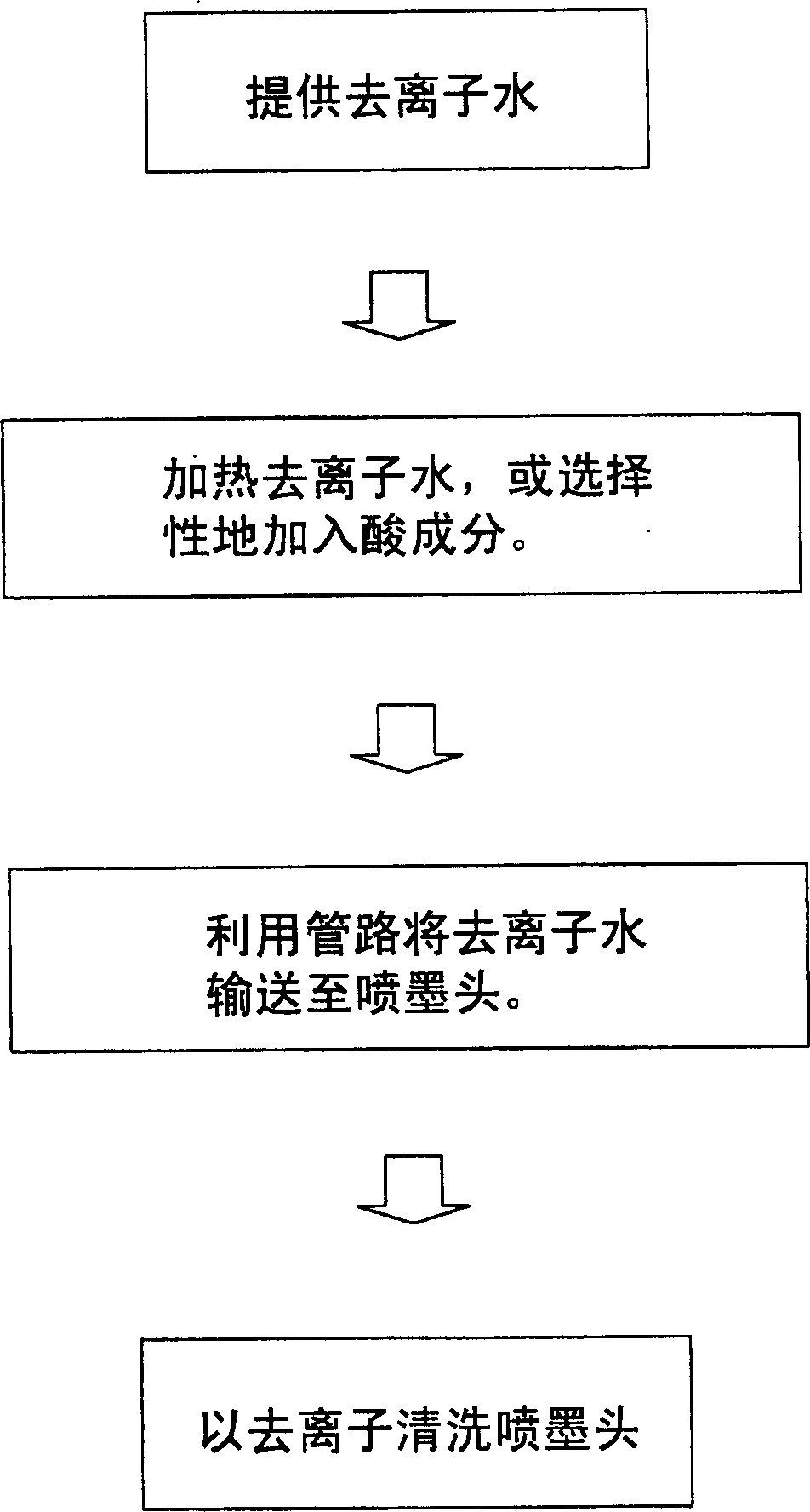

Embodiment Construction

[0032] Cleaning the inkjet head of the present invention preferably further includes providing a container for recovering the used heating solution or weak acid solution; more preferably cleaning the inkjet head further includes providing a storage tank for accommodating the heating solution or weak acid solution. In the device for cleaning the inkjet head of the present invention or in the cleaning inkjet head of the present invention, when the solvent is a weak acid solution or a hot solution with a temperature higher than 20°C, the temperature of the heating solution used is not limited, and can be adjusted at 25 to 65°C as required between ℃. In cleaning the inkjet head of the present invention, the heating solution used is preferably deionized water. In the device for cleaning the inkjet head of the present invention or the weak acid solution used for cleaning the inkjet head of the present invention, the type of acid component is not limited, it can be any component that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com