Balling-resistant PDC (polycrystalline diamond compact) drill bit with communicated pits in surfaces of flow channels

A pit and drill bit technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling and mining, etc., to achieve the effects of reducing viscosity and drag, preventing accumulation and preventing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific embodiments and drawings.

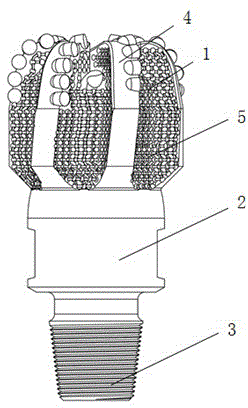

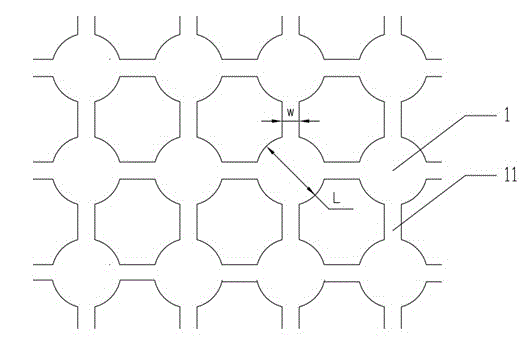

[0026] See figure 1 with figure 2 An anti-mud pack PDC drill bit with penetrating pits on the flow channel surface, comprising a drill bit body 2, the lower part of the drill bit body 2 is provided with a threaded joint 3 for connecting the drill rod, and the upper part is provided with several blades 4, between the blades 4 The grooves formed by forming the runner groove 5 of the drill bit, and the entire surface of the runner groove 5 is provided with pits 1 that penetrate each other.

[0027] The PDC bit can also be provided with interpenetrating pits 1 on only part of the surface of the runner groove 5, that is, only on the surface of the runner groove 5 on the front side of the blade, or only on the runner groove 5. The bottom surface of the blade is provided with mutually penetrating pits 1 or only on the surface of the runner groove 5 on the rear side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com