An anti-mud bag PDC drill bit with pits on the surface of the runner groove

A technology of runner grooves and pits, which is used in drill bits, earth-moving drilling, drilling equipment, etc., to reduce drilling costs, prevent adhesion, and reduce adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

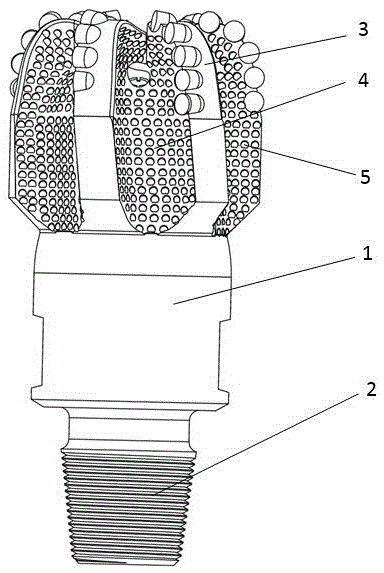

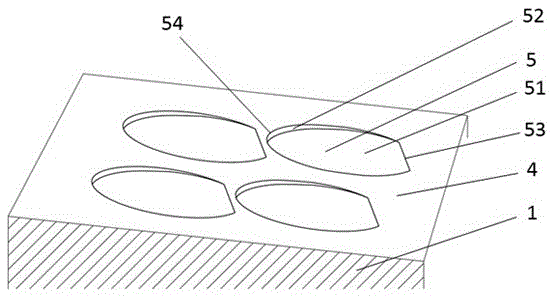

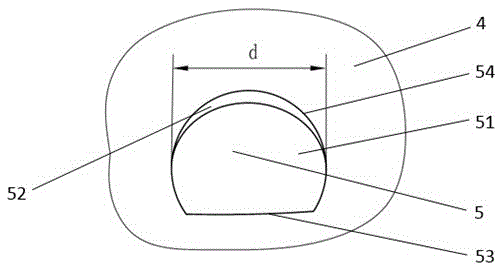

[0040] see Figure 1 to Figure 4As shown, a kind of anti-mud bag PDC drill bit with dimples on the surface of the flow channel includes a drill body 1. The lower part of the drill body 1 is provided with a threaded joint 2 for connecting the drill pipe, and the upper part is provided with several blades 3. Between the blades 3 The groove between them forms the runner groove 4 of the drill bit. The surface of the runner groove 4 is provided with at least two pits 5. The pit 5 is composed of a pit bottom 51 and a pit side 52. The pit bottom 51 It extends directly from the bottom of the pit to the surface of the runner groove 4 . The slope angle α of the bottom surface 51 of the pit ≤ 40°; the ratio of the projected area S1 of the side surface 52 of the pit to the original surface of the runner groove 4 and the projected area S2 of the bottom surface 51 of the pit to the original surface of the runner groove 4 is equal to The range is S1:S2≤1:3. The angle between the bottom sur...

Embodiment 2

[0045] see image 3 with Figure 4 , The difference between this embodiment and Embodiment 1 is that the depth c of the pit 5 is 0.3-5 mm, and the length d≥2 mm.

[0046] This range of depth and length of the pit 5 is the easiest to process. If the length and depth of the pit 5 are too small, the processing difficulty will be very great.

[0047] It should be explained that the so-called length of the pit 5 refers to the largest profile dimension in the transverse or longitudinal direction of the pit.

Embodiment 3

[0049] see Figure 5 The difference between this embodiment and the first embodiment is that the adjacent dimples 5 on the runner groove 4 intersect. Small cuttings adhesion and anti-mudbag effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com