Compound material of anode fit for producing secondary battery and its produced battery

A technology for composite materials and secondary batteries, applied in secondary batteries, nanotechnology for materials and surface science, battery electrodes, etc., can solve the problems of large particle size, uneven distribution, and slowness of compound powders, and achieve simplification The effect of process steps and material cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

[0057] Add 0.2 moles of ferric nitrate to 200 milliliters (ml) of deionized water to dissolve, add 0.2 moles of phosphoric acid after it is completely dissolved, then add 100 ml of lithium hydroxide aqueous solution containing 0.2 moles in advance and mix to make the solution Medium lithium ion: iron ion: phosphate ion depends on LiFePO 4 The metering ratio (1:1:1) is mixed, and after the complete mixing reaction, a metal ion containing Fe, Li + and (PO4) 3- The solution, and in the solution, add 100ml aqueous solution containing oxalic acid 0.252g again, after fully stirring, then this solution is dried, obtains a powdery starting material after drying.

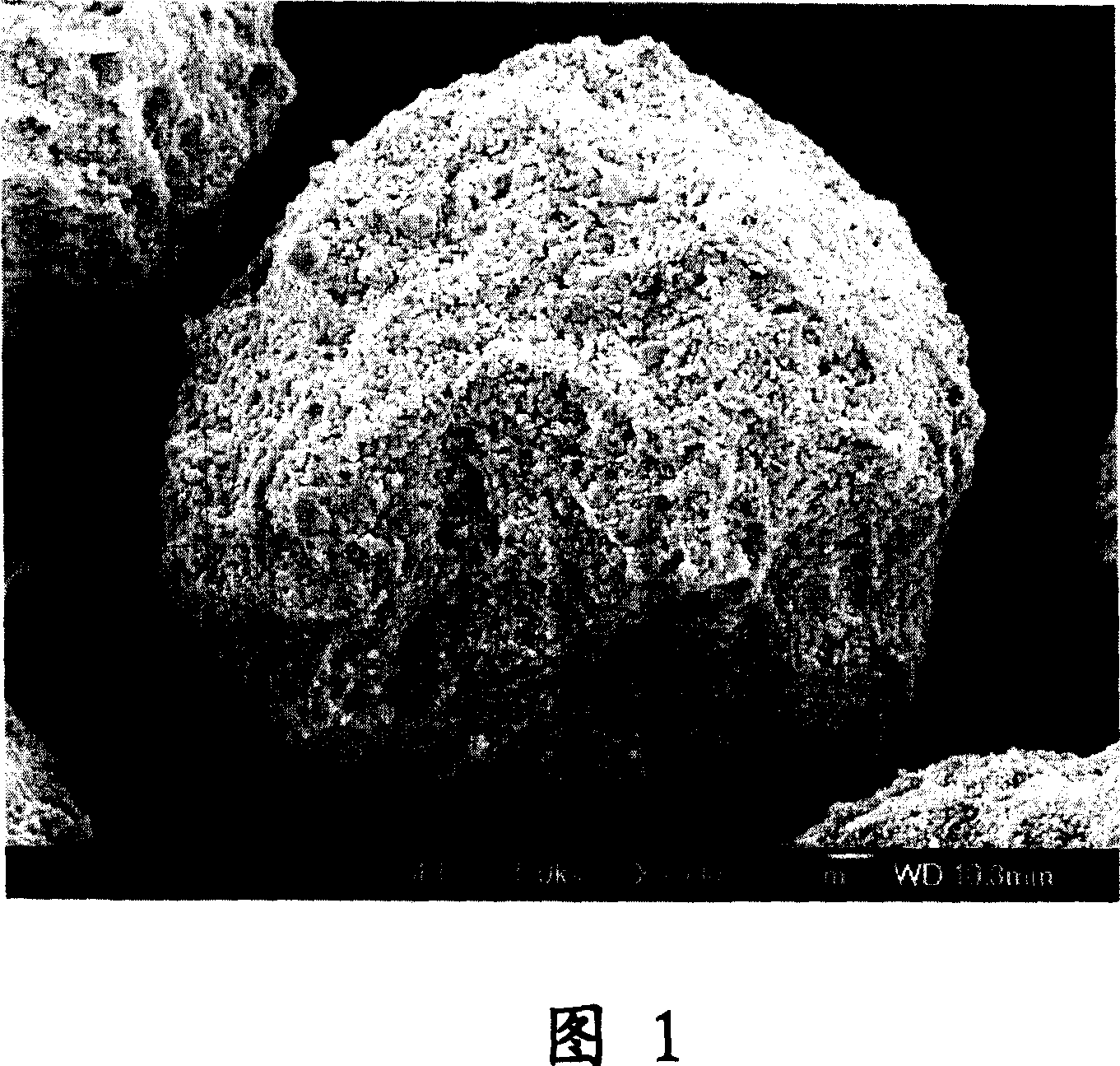

[0058] The starting material is placed in an alumina crucible, and then the crucible is placed in a tubular furnace with charcoal, and it is heat-treated at 700°C for 12 hours under a nitrogen atmosphere. During the heat treatment, charcoal is produced at a high temperature The suspension of carbon particles is carried by ...

Embodiment B

[0060] The preparation method of Example B is roughly the same as that of Example A, the difference is that ferric nitrate is replaced by 0.2 mole of ferric chloride and dissolved in deionized water, and the rest of the steps are the same as in Example A to obtain a Composite powder of lithium iron phosphate as matrix and mixed with carbon.

Embodiment C

[0062] Example C is roughly the same as Example A. The difference is that ferric nitrate is replaced by 0.2 mole iron powder and dissolved in deionized water. The rest of the steps are the same as in Example A to prepare a phosphoric acid Composite powder of lithium-iron matrix mixed with carbon.

PUM

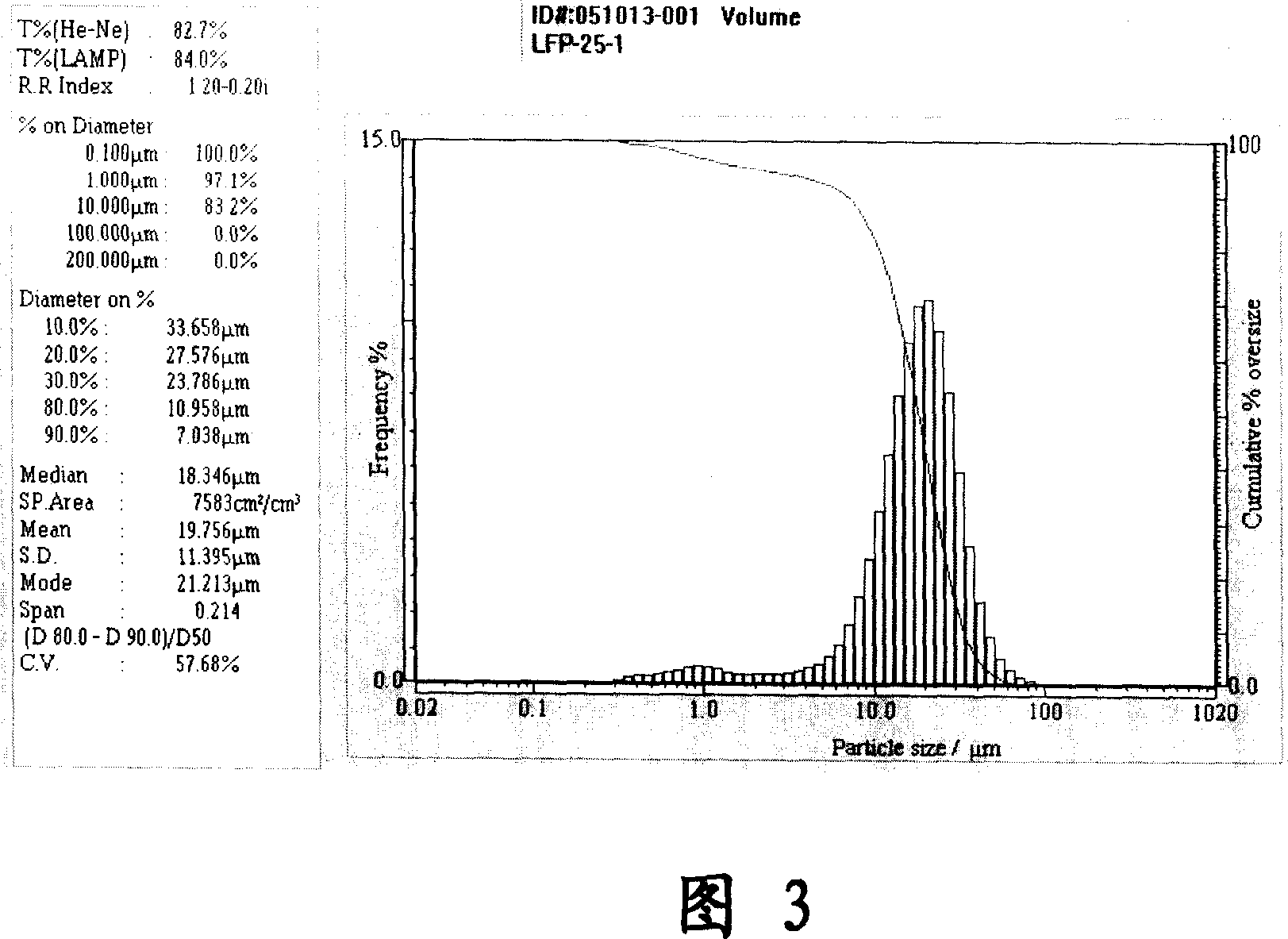

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com