Connecting rod machining technique

A processing technology and connecting rod technology, applied in the field of mechanical parts processing, can solve the problems of complex connecting rod processing technology, low processing efficiency, weak connecting rod bearing capacity, etc., and achieve reasonable arrangements, improve productivity, and improve connecting rod bearing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

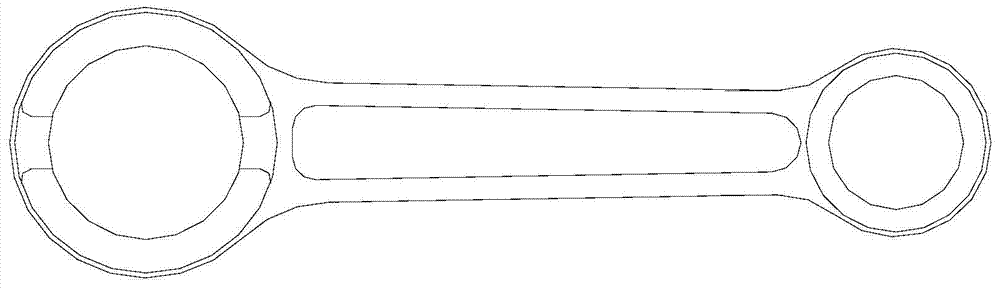

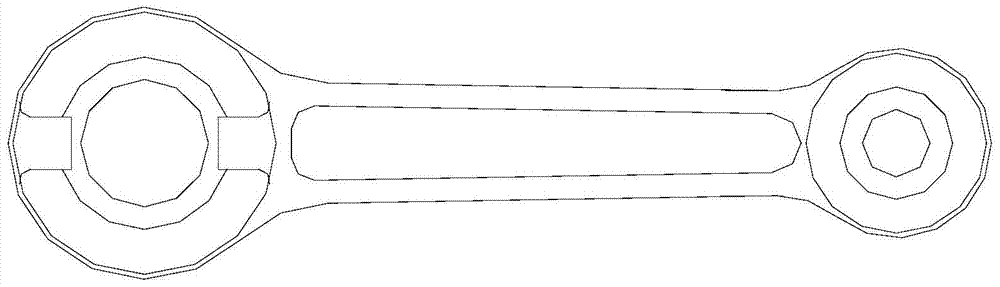

[0018] see figure 1 and figure 2 , a connecting rod machining process, including a rough machining stage, a semi-finishing machining stage and a finishing machining stage,

[0019] (1) Rough machining stage: Forging blanks with smooth surface, no bruises, scratches and cracks. The blanks are 20Cr steel with a hardness HRC value of 20°. The blanks include big end, shaft and small end , the big end and the small end are both round cake shapes, the center distance between the big end and the small end of the connecting rod is 100mm, the radius of the big end is 26mm, and the radius of the small end is 16.5mm. The surface of the forged piece is plated For copper treatment, use a surface grinder to rough grind the surface of the workpiece. Taking the two ends of the connecting rod as the plane reference, use a CNC drilling machine to drill large and small holes on the big end and small end of the connecting rod to obtain a rough machined workpiece ;

[0020] (2) Semi-finishing ...

Embodiment 2

[0023] see figure 1 and figure 2 , a connecting rod machining process, including a rough machining stage, a semi-finishing machining stage and a finishing machining stage,

[0024] (1) Rough machining stage: Forging blanks with smooth surface, no bruises, scratches and cracks. The blanks are made of 20Cr steel with a hardness HRC value of 23°. The blanks include big end, shaft and small end , the big end and the small end are both round cake shapes, the center distance between the big end and the small end of the connecting rod is 100mm, the radius of the big end is 26mm, and the radius of the small end is 16.5mm. The surface of the forged piece is plated For copper treatment, use a surface grinder to rough grind the surface of the workpiece. Taking the two ends of the connecting rod as the plane reference, use a CNC drilling machine to drill large and small holes on the big end and small end of the connecting rod to obtain a rough machined workpiece ;

[0025] (2) Semi-fi...

Embodiment 3

[0028] see figure 1 and figure 2 , a connecting rod machining process, including a rough machining stage, a semi-finishing machining stage and a finishing machining stage,

[0029] (1) Rough machining stage: forging blanks with smooth surface, no bruises, scratches and cracks. The blanks are 20Cr steel with a hardness HRC value of 25°. The blanks include big end, shaft and small end , the big end and the small end are both round cake shapes, the center distance between the big end and the small end of the connecting rod is 100mm, the radius of the big end is 26mm, and the radius of the small end is 16.5mm. The surface of the forged piece is plated For copper treatment, use a surface grinder to rough grind the surface of the workpiece. Taking the two ends of the connecting rod as the plane reference, use a CNC drilling machine to drill large and small holes on the big end and small end of the connecting rod to obtain a rough machined workpiece ;

[0030] (2) Semi-finishing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com