Method for recycling manganese and lead in electrolytic manganese anode mud

A technology of anode slime and electrolytic manganese, which is applied in the field of metallurgy, can solve problems such as stacking pollution of electrolytic manganese anode slime, and achieve the effects of creating economic value, reducing production costs, and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

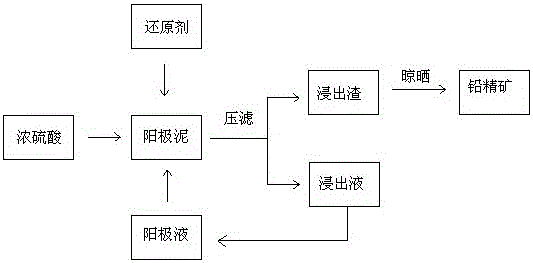

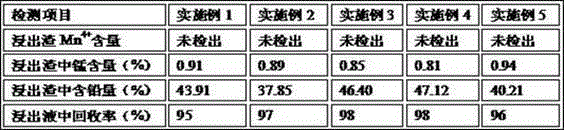

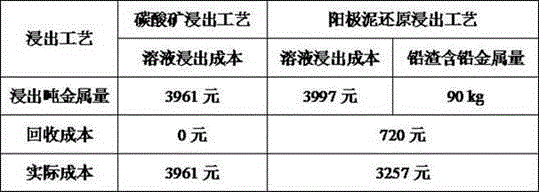

[0026] A method for recovering manganese and lead in electrolytic manganese anode slime, comprising the following steps:

[0027] (1) Reduction leaching of electrolytic manganese anode slime: add anolyte, waste molasses and concentrated sulfuric acid solution to electrolytic manganese anode slime successively for reduction reaction, the mass ratio of electrolytic manganese anode slime to anolyte is 1:2, electrolytic manganese anode slime The solid-to-liquid mass ratio of the reducing agent is 8:1, the mass ratio of the electrolytic manganese anode slime to the concentrated sulfuric acid is 1:1, the reaction time is 6h, and then pressure filtration is carried out to obtain the leaching residue containing PbSO4 and the leaching solution containing MnSO4;

[0028] (2) Treatment of leaching slag: air-dry the leaching slag obtained above at 30°C until the moisture content is 5%, and then obtain the lead concentrate product;

Embodiment 2

[0031] A method for recovering manganese and lead in electrolytic manganese anode slime, comprising the following steps:

[0032] (1) Reduction leaching of electrolytic manganese anode slime: add anolyte, industrial grade glucose and concentrated sulfuric acid solution to electrolytic manganese anode slime successively for reduction reaction, the mass ratio of electrolytic manganese anode slime to anolyte is 1:6, electrolytic manganese anode slime The solid-to-liquid mass ratio to the reducing agent is 20:1, the mass ratio of the electrolytic manganese anode slime to the concentrated sulfuric acid is 8:1, and the reaction time is 10 hours, and then pressure filtration is carried out to obtain the leach residue containing PbSO4 and the leach solution containing MnSO4;

[0033] (2) Treatment of leaching slag: air-dry the leaching slag obtained above at 35°C until the water content reaches 4%, and then obtain the lead concentrate product;

[0034] (3) Treatment of leachate: colle...

Embodiment 3

[0036] A method for recovering manganese and lead in electrolytic manganese anode slime, comprising the following steps:

[0037] (1) Reduction leaching of electrolytic manganese anode slime: add anolyte, waste molasses and concentrated sulfuric acid solution to electrolytic manganese anode slime successively for reduction reaction, the mass ratio of electrolytic manganese anode slime to anolyte is 1:3, electrolytic manganese anode slime and The solid-to-liquid mass ratio of the reducing agent is 10:1, and the mass ratio of the electrolytic manganese anode slime to concentrated sulfuric acid is 2:1. The reaction time is 8 hours, and then pressure filtration is performed to obtain the leaching residue containing PbSO4 and the leaching solution containing MnSO4;

[0038] (2) Treatment of leaching slag: air-dry the leaching slag obtained above at 32°C until the moisture content reaches 3%, and then obtain the lead concentrate product;

[0039] (3) Treatment of leachate: collect t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com