A method for processing and preparing a hemispherical metal storage tank for spacecraft fuel

A hemispherical, spacecraft technology, applied in the field of spacecraft, can solve the problems that key technologies have not made breakthrough progress, restrict the development of aerospace industry, and comprehensive performance gaps, and achieve high product yield, easy quality control, and simple processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

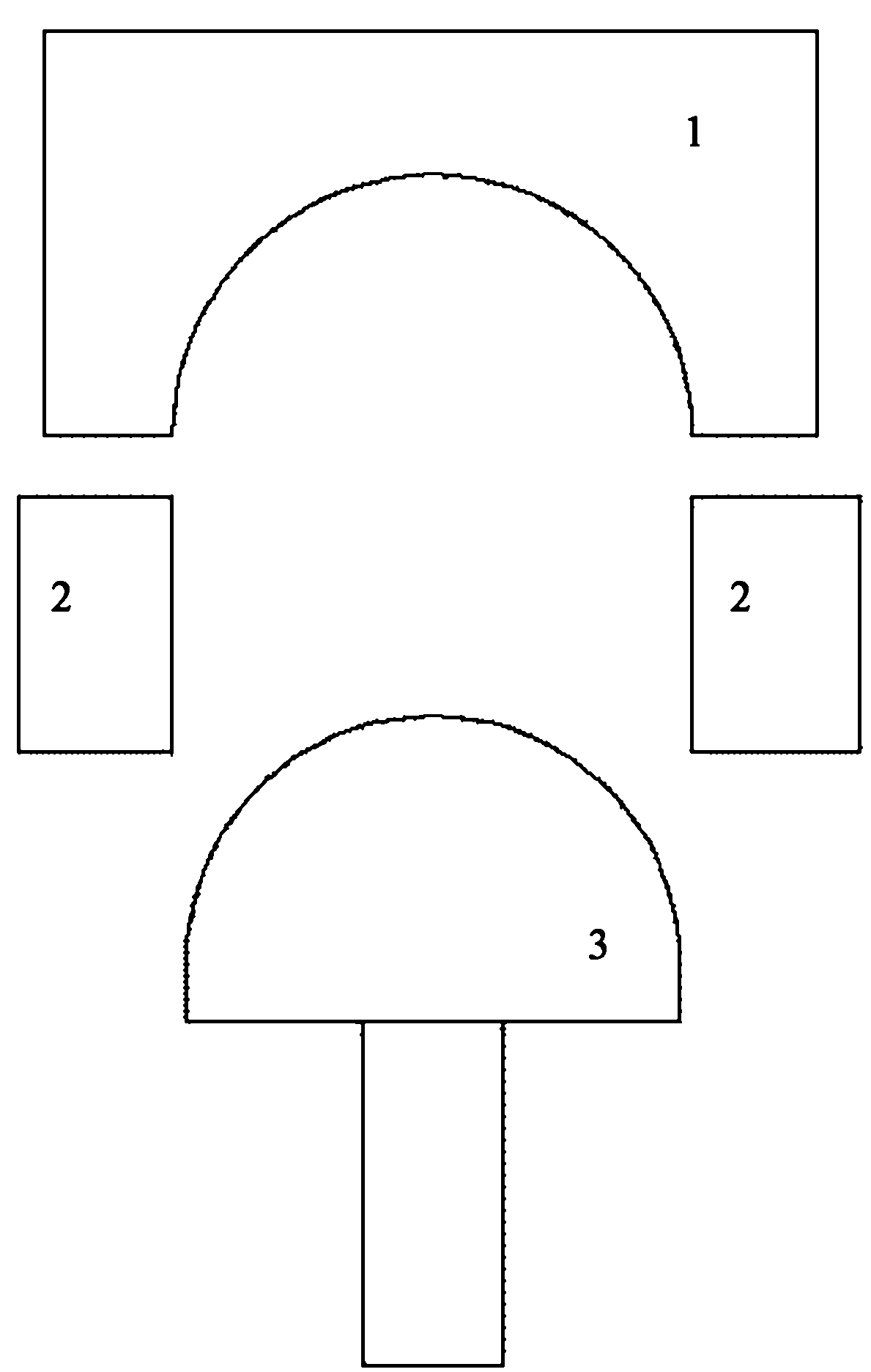

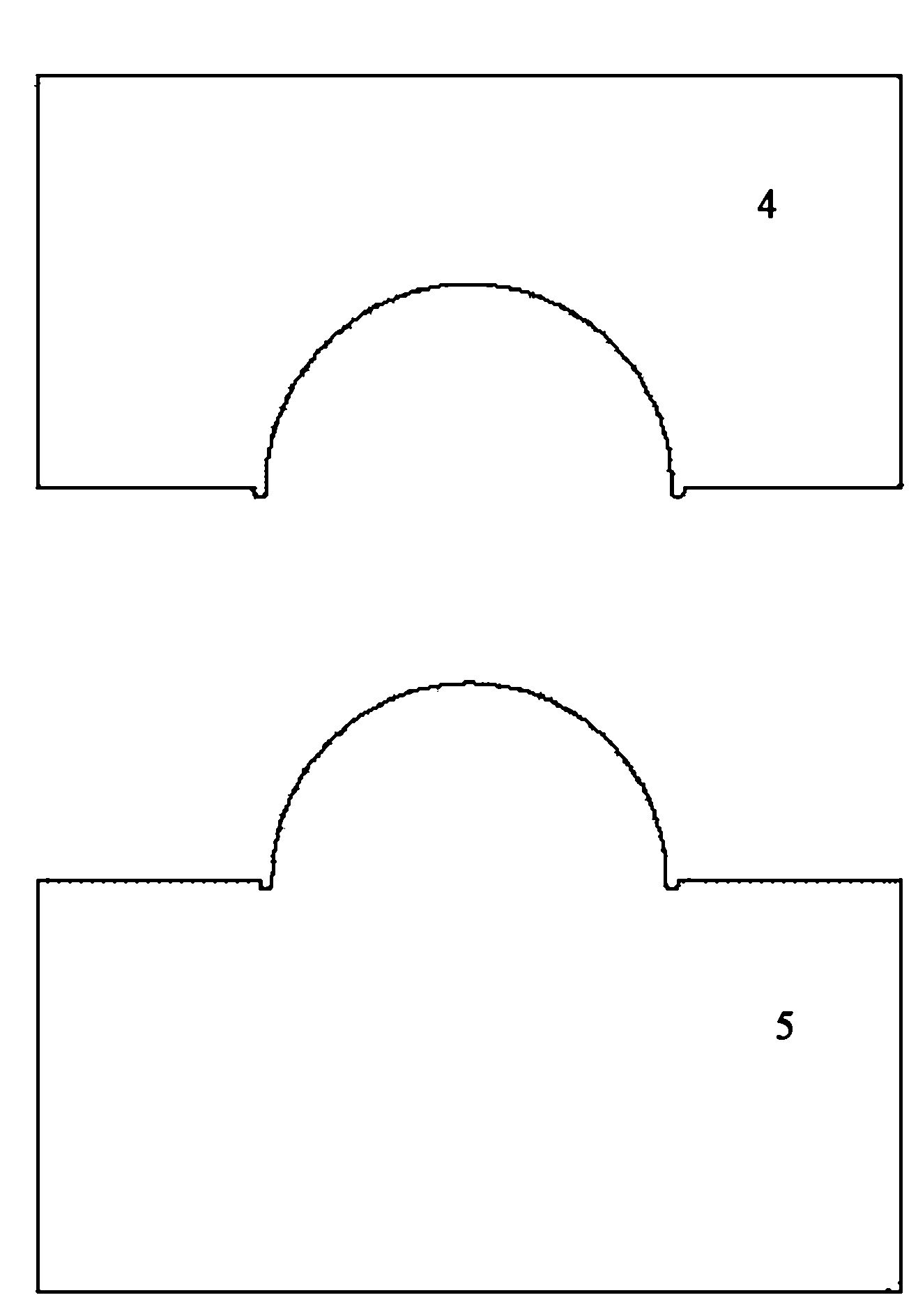

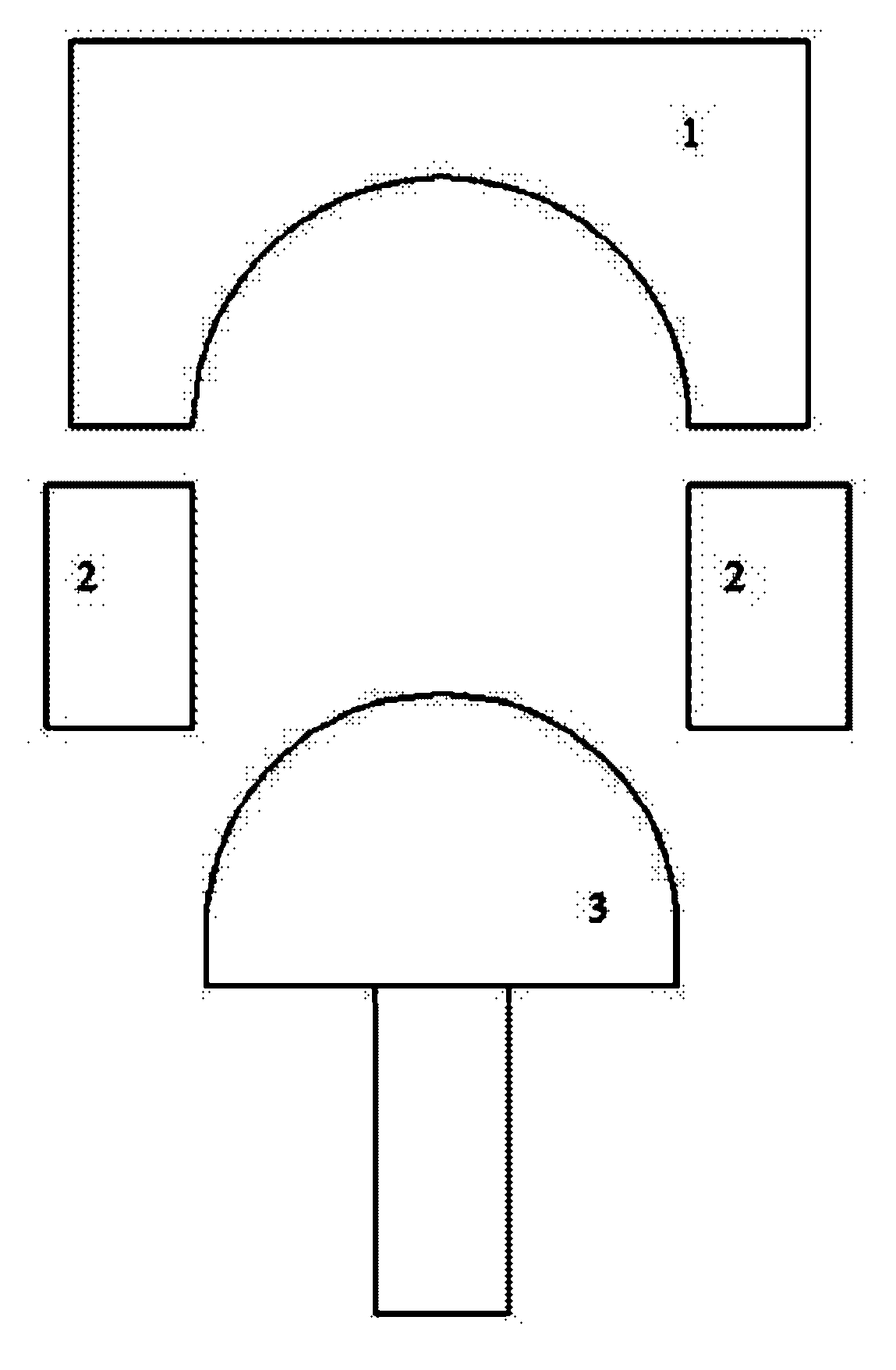

Image

Examples

Embodiment 1

[0024] The present embodiment is carried out according to the following specific steps:

[0025] 1) Mould: Process the hemispherical drawing die and flanging die according to the dimensions of the hemispherical metal storage tank to be processed;

[0026] 2) Cutting: Use a cutting machine to cut the industrial pure titanium plate into a circular shape according to the calculated size; the diameter of the cut circular shape=the diameter of the storage tank+the size of the blank holder, and the size of the blank holder is tank diameter.

[0027] 3) Trimming: Use a grinder to grind off the burrs on the edge of the cut circular plate to ensure that the edge is flat and parallel to the center plane as much as possible;

[0028] 4) Lubrication: Evenly apply a compound lubricant of butter and engine oil on both sides of the plate trimmed in the previous step, wherein butter: engine oil = 3:1, and then cover with a 0.5mm thick plastic film to make the plastic film fully contact with...

Embodiment 2

[0033] The present embodiment is carried out according to the following specific steps:

[0034] 1) Mould: Process the hemispherical drawing die and flanging die according to the dimensions of the hemispherical metal storage tank to be processed;

[0035] 2) Cutting: Use a cutting machine to cut the industrial pure titanium plate into a circular shape according to the calculated size; the diameter of the cut circular shape=the diameter of the storage tank+the size of the blank holder, and the size of the blank holder is tank diameter.

[0036] 3) Trimming: Use a grinder to grind off the burrs on the edge of the cut circular plate to ensure that the edge is flat and parallel to the center plane as much as possible;

[0037] 4) Lubrication: Evenly apply a composite lubricant of butter and machine oil on both sides of the board trimmed in the previous step, wherein butter: machine oil = 3:1, and then cover with a 1.5mm thick plastic film so that the plastic film is in full cont...

Embodiment 3

[0042] The present embodiment is carried out according to the following specific steps:

[0043] 1) Mould: Process the hemispherical drawing die and flanging die according to the dimensions of the hemispherical metal storage tank to be processed;

[0044] 2) Cutting: Use a cutting machine to cut the industrial pure titanium plate into a circular shape according to the calculated size; the diameter of the cut circular shape=the diameter of the storage tank+the size of the blank holder, and the size of the blank holder is tank diameter.

[0045] 3) Trimming: Use a grinder to grind off the burrs on the edge of the cut circular plate to ensure that the edge is flat and parallel to the center plane as much as possible;

[0046] 4) Lubrication: Evenly apply a compound lubricant of butter and machine oil on both sides of the board trimmed in the previous step, wherein butter: machine oil = 3:1, and then cover with a 1mm thick plastic film so that the plastic film is fully in contac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com