Method for manufacturing sheet metal part stereo chemical milling sample plate

A technology for milling a template and a manufacturing method, which is applied in the field of aircraft manufacturing, can solve the problems of increasing the scribing error and cumbersomeness, and achieves the effects of eliminating errors, good flexibility and convenient manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

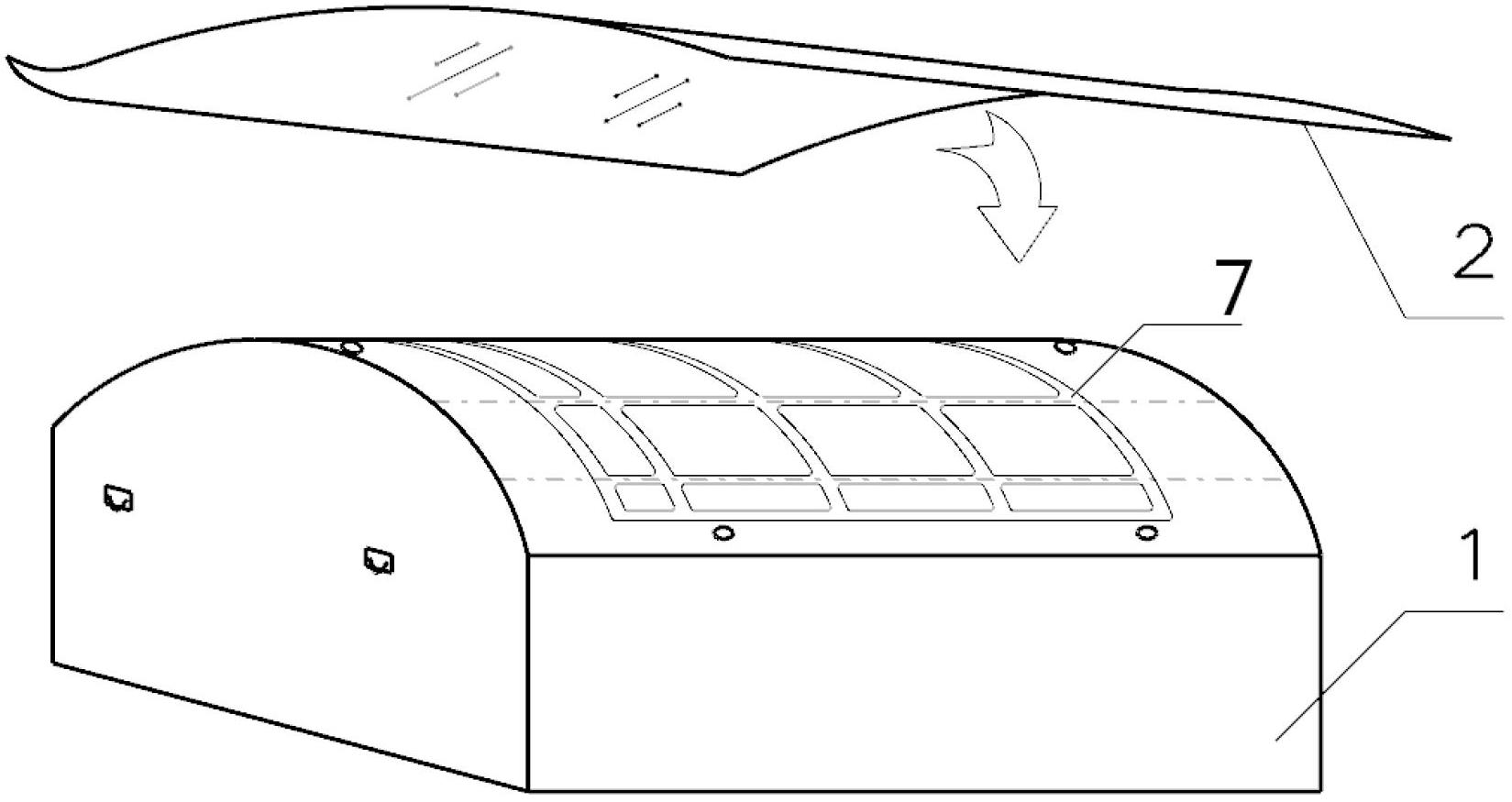

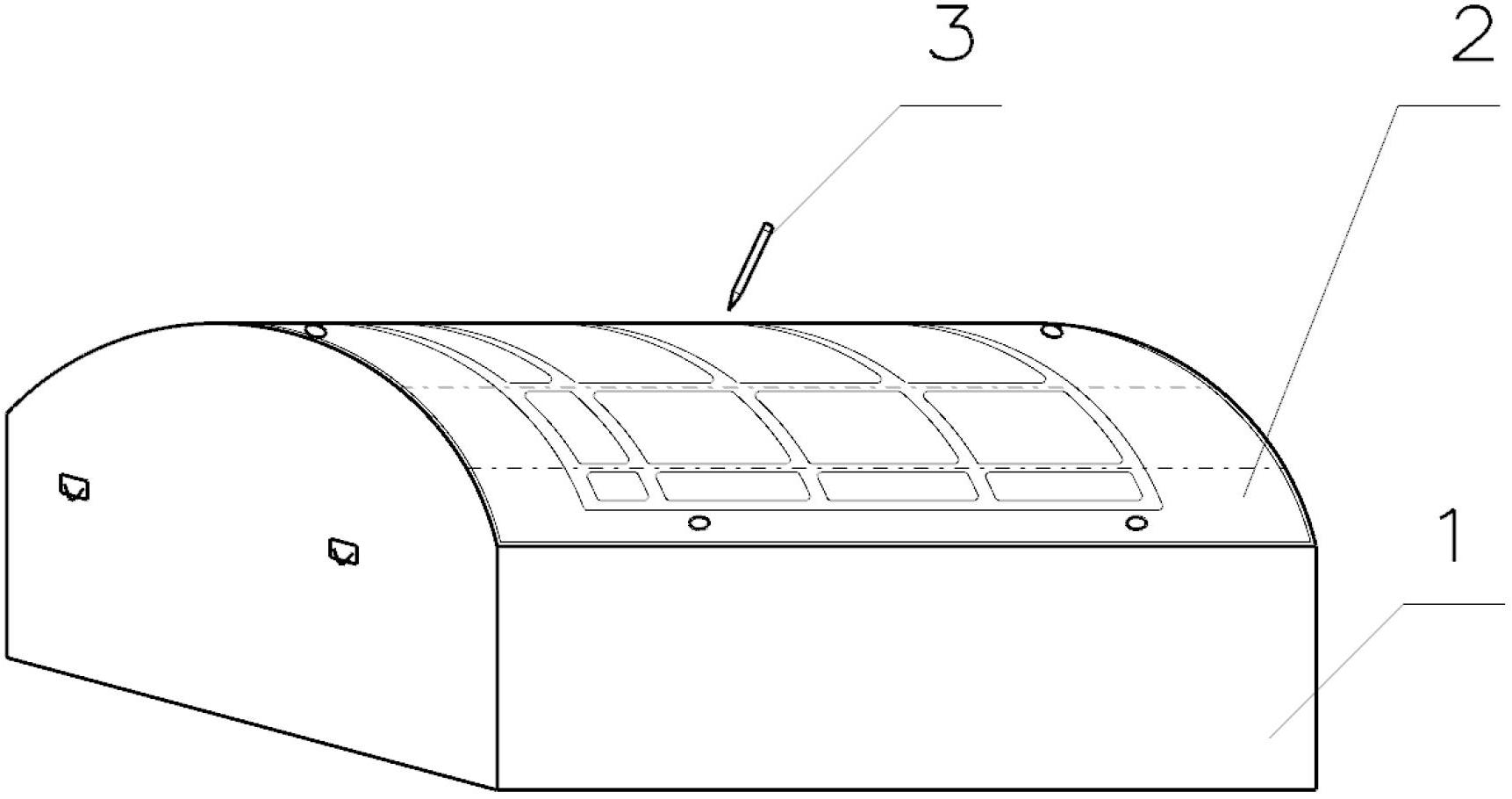

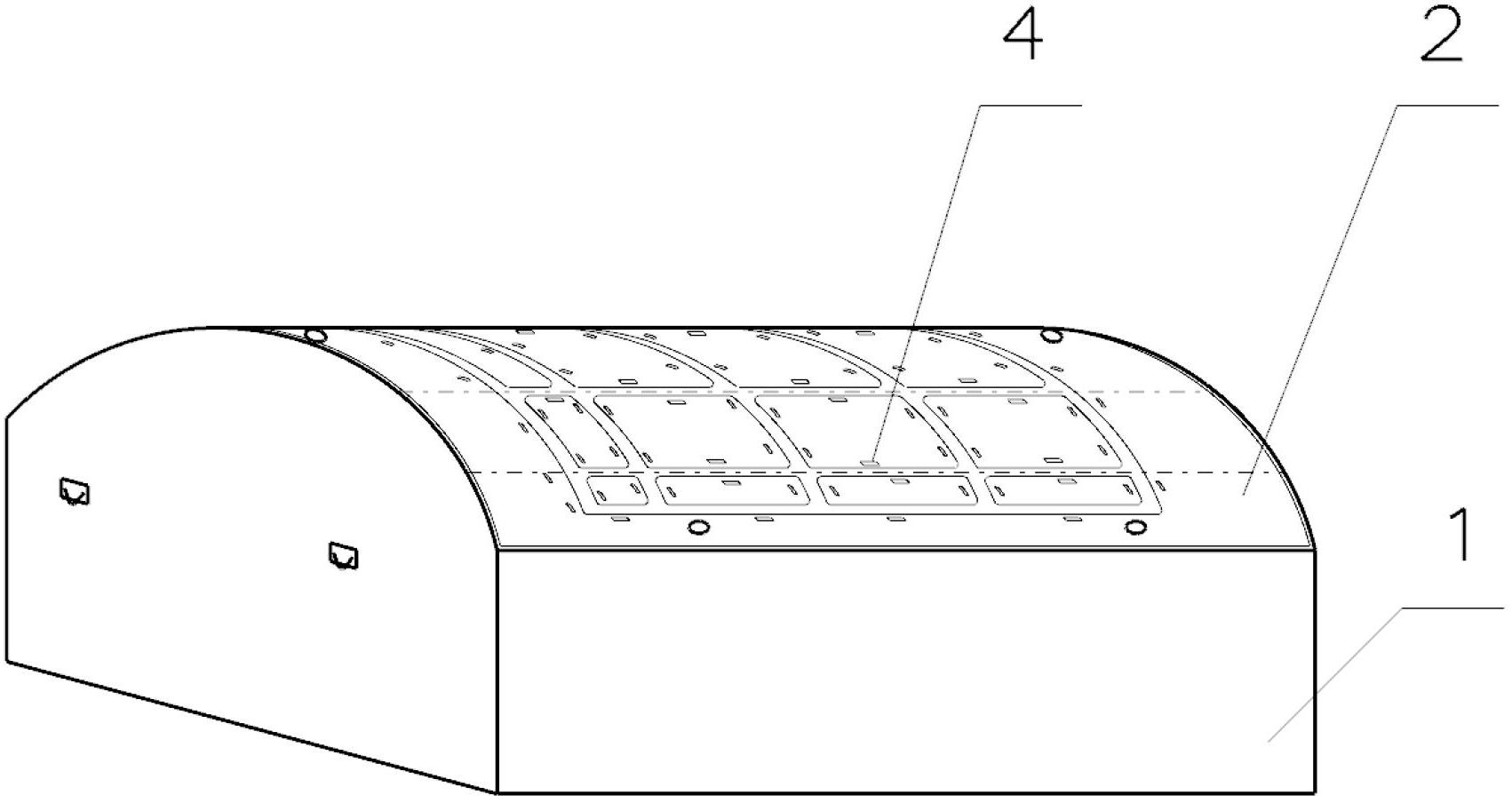

[0016] A method for manufacturing a three-dimensional milling template of a sheet metal part of the present invention mainly includes six steps: 1. Use a transparent gelatin plate 2 to position and cover the surface of the mold tire 1 with the chemical milling pattern 7 . 2. Draw the chemical milling pattern on the gelatin board. 3. Paste double-sided adhesive tape 4 on the surface of the gelatin plate 2. 4. Position and cover the formed chemical milling sample blank 5 on the surface of the mold tire 1, so that the gelatin plate 2 with the chemical milling pattern 7 attached to the chemical milling sample The inner surface of the blank 5, 5, the chemical milling model blank 5 is separated from the mold tire 1. 6. Process and manufacture a chemical milling template according to the chemical milling pattern 7 on the gelatin plate 2 .

[0017] figure 1 Shown is a molded body 1 with a chemically milled pattern 7 and a transparent gelatin plate 2 . Firstly, the mold tire 1 is cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com