Processing method of chemical milling template

A technology of chemical milling template and processing method, which is applied in the field of chemical milling template processing, can solve the problems of long production cycle, complex processing procedure and difficulty, and achieve the effect of shortening processing period, simplifying processing procedure and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

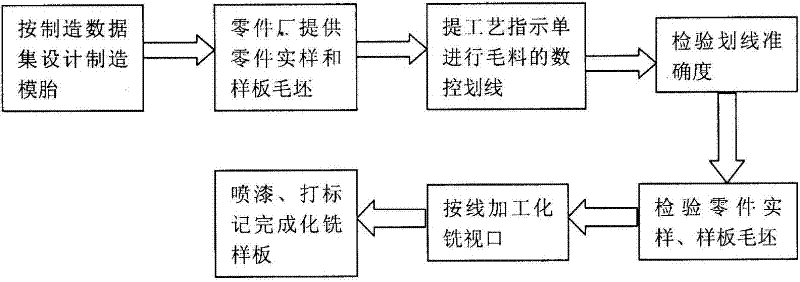

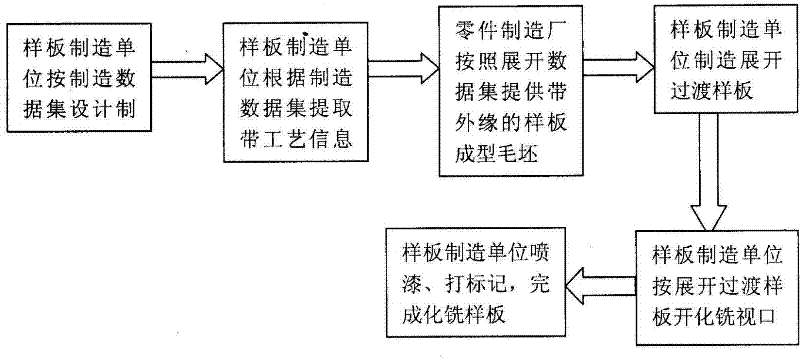

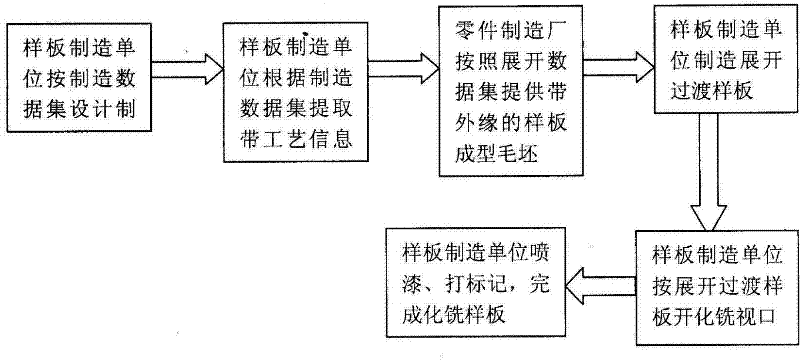

[0014] Such as figure 2 Shown, a kind of chemical milling template processing method is characterized in that comprising the following steps:

[0015] 1) Add process information such as chemical milling allowance line, part edge line, positioning line, pin hole, etc. to the engineering data set, complete the manufacturing data set, and provide the manufacturing data set to the tooling department, parts factory and other units for tire molding manufacturing;

[0016] 2) According to the different milling surfaces, use the curved surface unfolding method to unfold the inner surface, outer surface or middle surface of the part, and at the same time transmit the process information such as the edge line of the part, the milling allowance line, and the positioning hole to the unfolding On the surface after that, an expanded data set is formed;

[0017] 3) Provide the expanded data set of the chemical milling part to the part manufacturing unit, and the part manufacturing unit us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com