Patents

Literature

32results about How to "Uniform thinning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Meteorologic balloon and production method thereof

ActiveCN101526630AImprove anti-aging performanceImprove overall machining performanceInstrumentsPotassium hydroxideCasein

The invention relates to a meteorological balloon and a production method thereof. The meteorological balloon has the quality of 700g to 800g, the length of a balloon body is 205 cm to 255 cm, and a balloon handle has a width of 9 cm to 10 cm and a length of 10 cm to 14 cm. The meteorological balloon comprises a solid raw material, an oil raw material and a colloid raw material, wherein the solid raw material comprises the ingredients by weight ratio: 100 parts of centrifugal concentrated natural latex, 0 part to 0.30 part of potassium hydroxide, 0 part to 0.15 part of casein, 0 part to 0.10 part of leveling agent O, 1.00 part to 3 parts of sulfur, 1.00 part to 2 parts of antioxidant D, 1.00 part to 2 parts of 4010NA, 1.50 part to 3 parts of rubber accelerator PX and 0.20 parts to 5 parts of zinc oxide; the oil raw material comprises 7.00 parts to 10.0 parts of mechanical oil by weight ratio; and the colloid raw material comprises neoprene latex which is added by the mixed weight ratio of the mixture of the solid raw material and the oil raw material to the neoprene latex, namely 1 to 10. The neoprene latex is added in a raw material formulation so as to improve the anti-aging performance and the whole processing performance of the meteorological balloon, ensure the streamlined appearance of the meteorological balloon, improve the evenness degree of a balloon surface and enable the balloon surface to swell evenly in the discharge process.

Owner:CHEMCHINA ZHUZHOU RUBBER RES & DESIGN INST

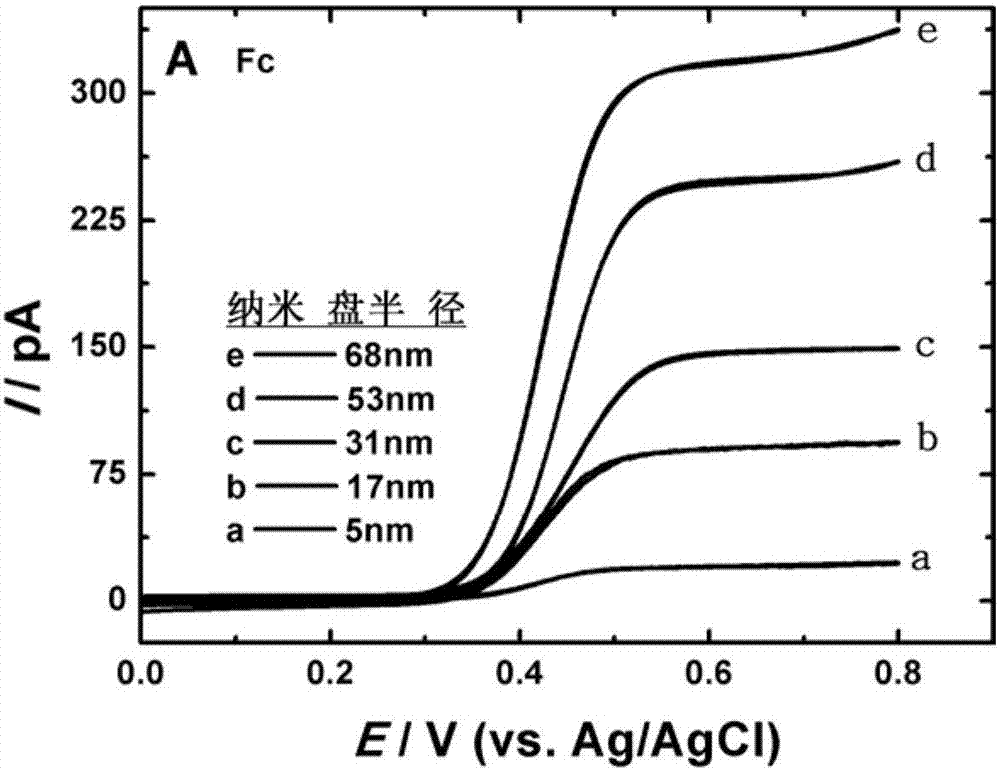

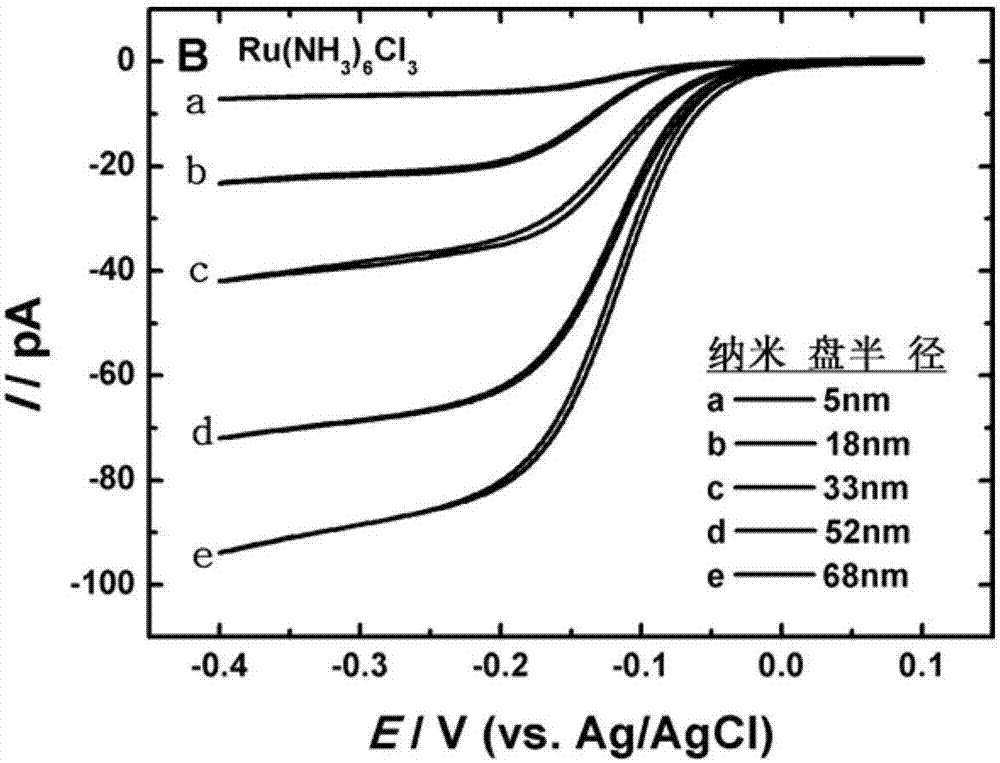

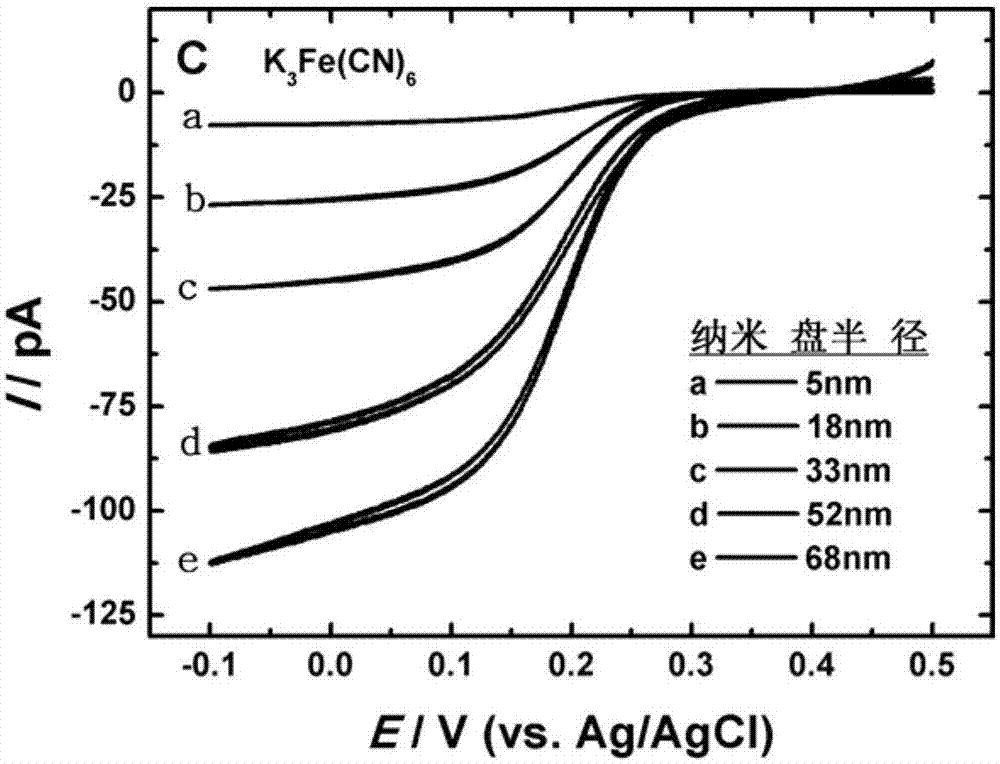

Au@Pt core-shell structure nano electrode, preparing method and application of Au@Pt core-shell structure nano electrode

InactiveCN107287596AUniform thinningExcellent electrode propertiesMaterial nanotechnologyTransportation and packagingPower flowEtching

The invention provides an Au@Pt core-shell structure nano electrode, a preparing method and application of the Au@Pt core-shell structure nano electrode. Compared with the prior art, the method for preparing a gold nano disk electrode is simple, the size can be controlled within the nano scale range, and the method can be used for preparing the gold nano disk electrode and is similarly applicable to nano disk electrodes of other metals. Meanwhile, about the technology for preparing the gold nano disk electrode, the Au@Pt core-shell structure nano electrode is obtained through etching and under potential deposition, very good electro-catalysis activity is achieved for hydrogen peroxide, the prepared Au@Pt core-shell structure nano electrode has very good response to the redox reaction for hydrogen peroxide catalysis, the current is obviously increased along with increasing of the concentration of hydrogen peroxide, and a linear relation between hydrogen peroxide concentration and current signals is constructed; and accordingly the concentration of the hydrogen peroxide solution is detected.

Owner:ANHUI NORMAL UNIV

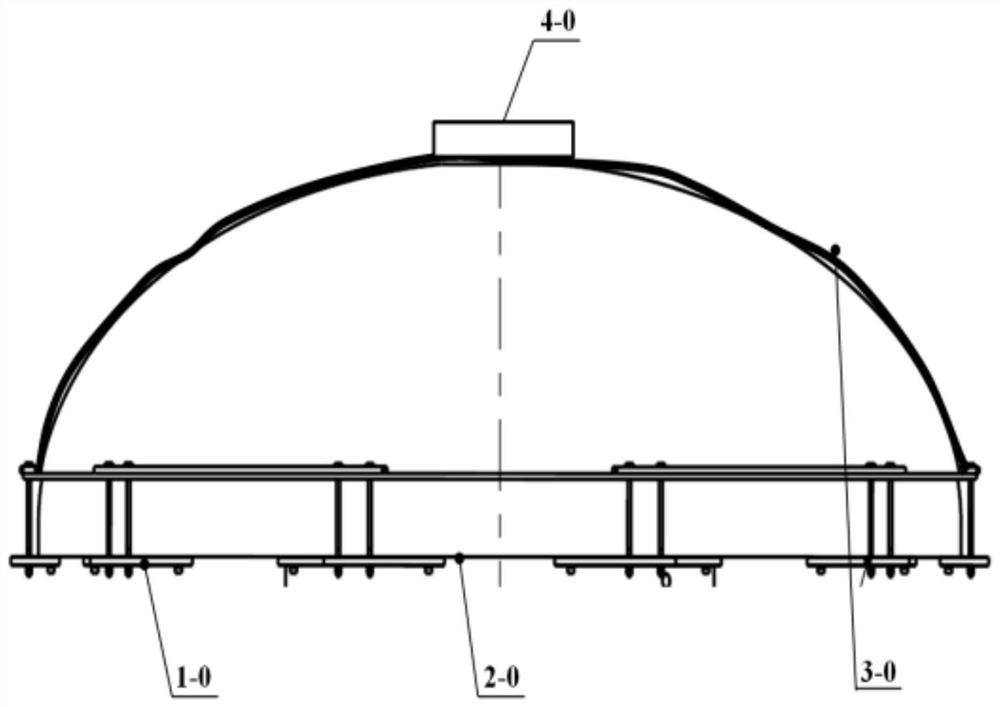

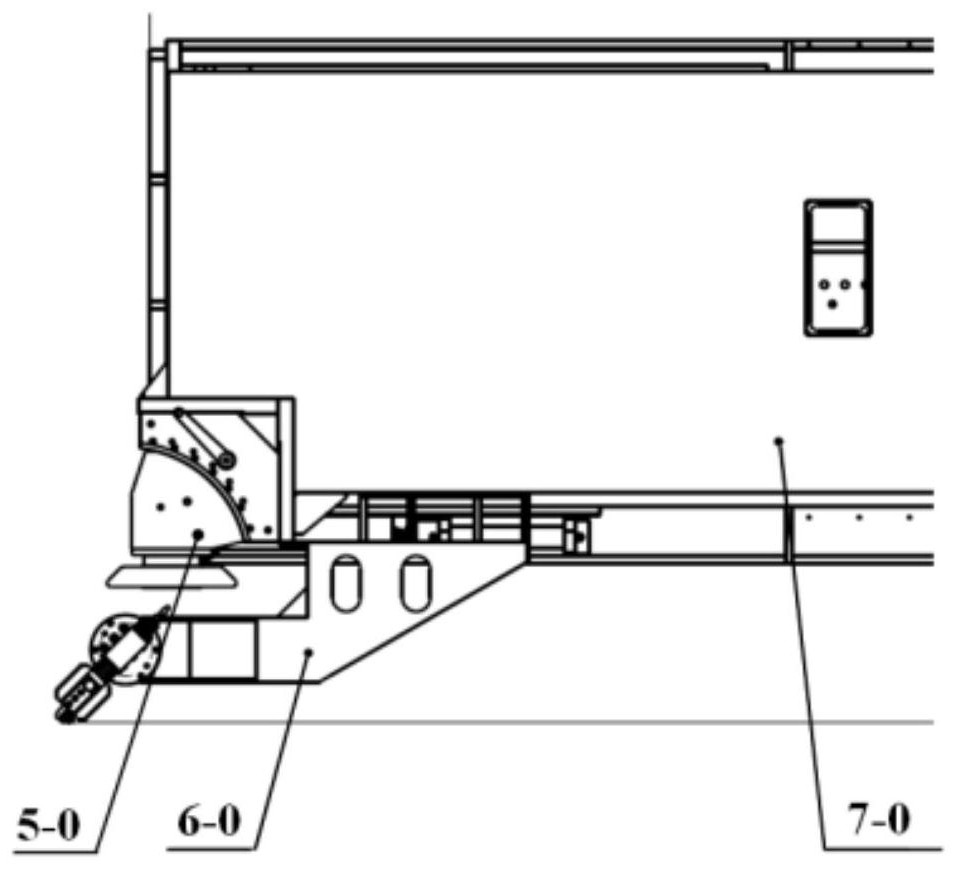

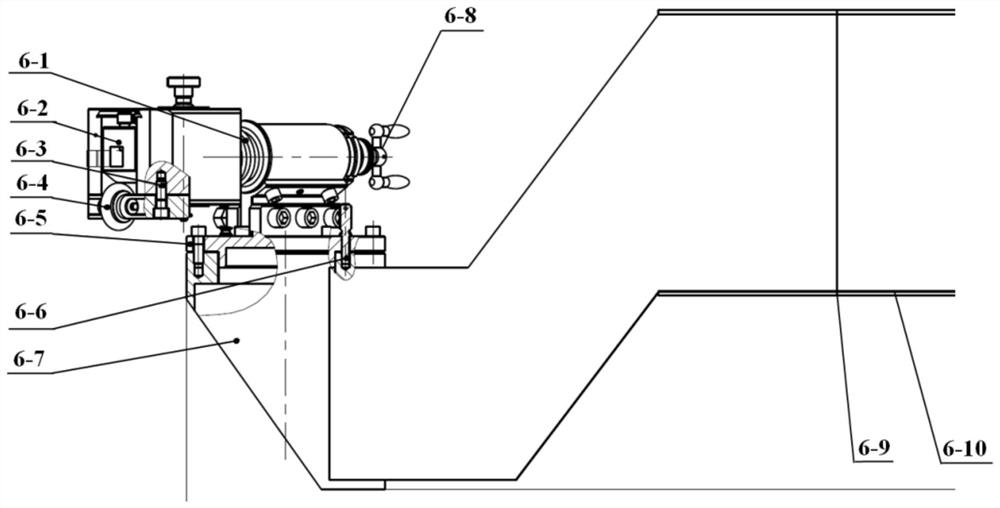

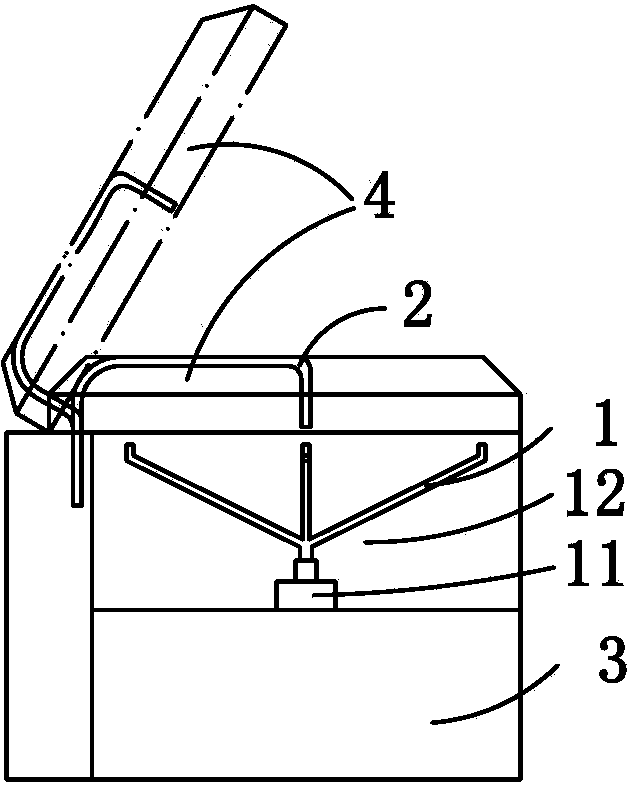

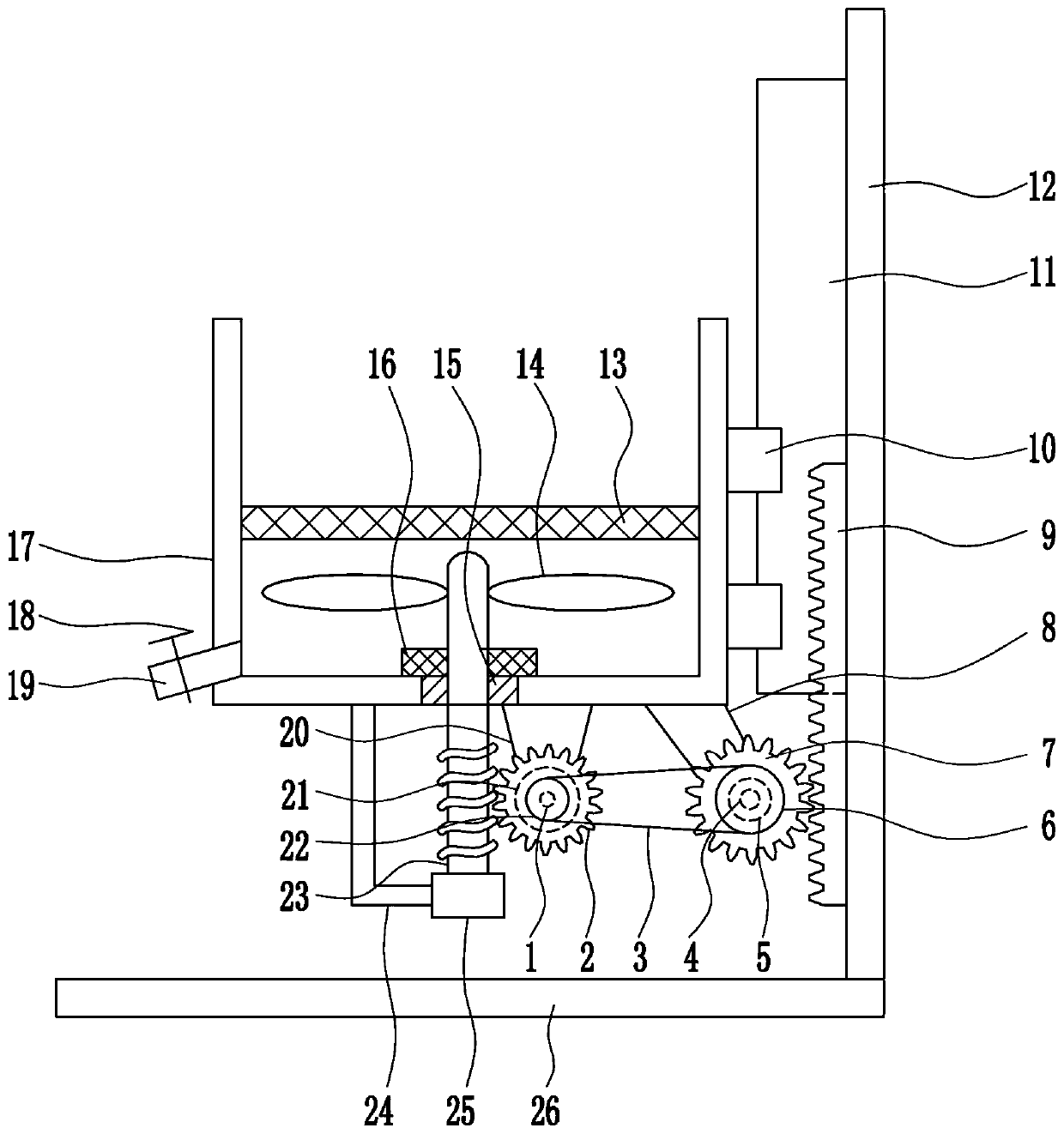

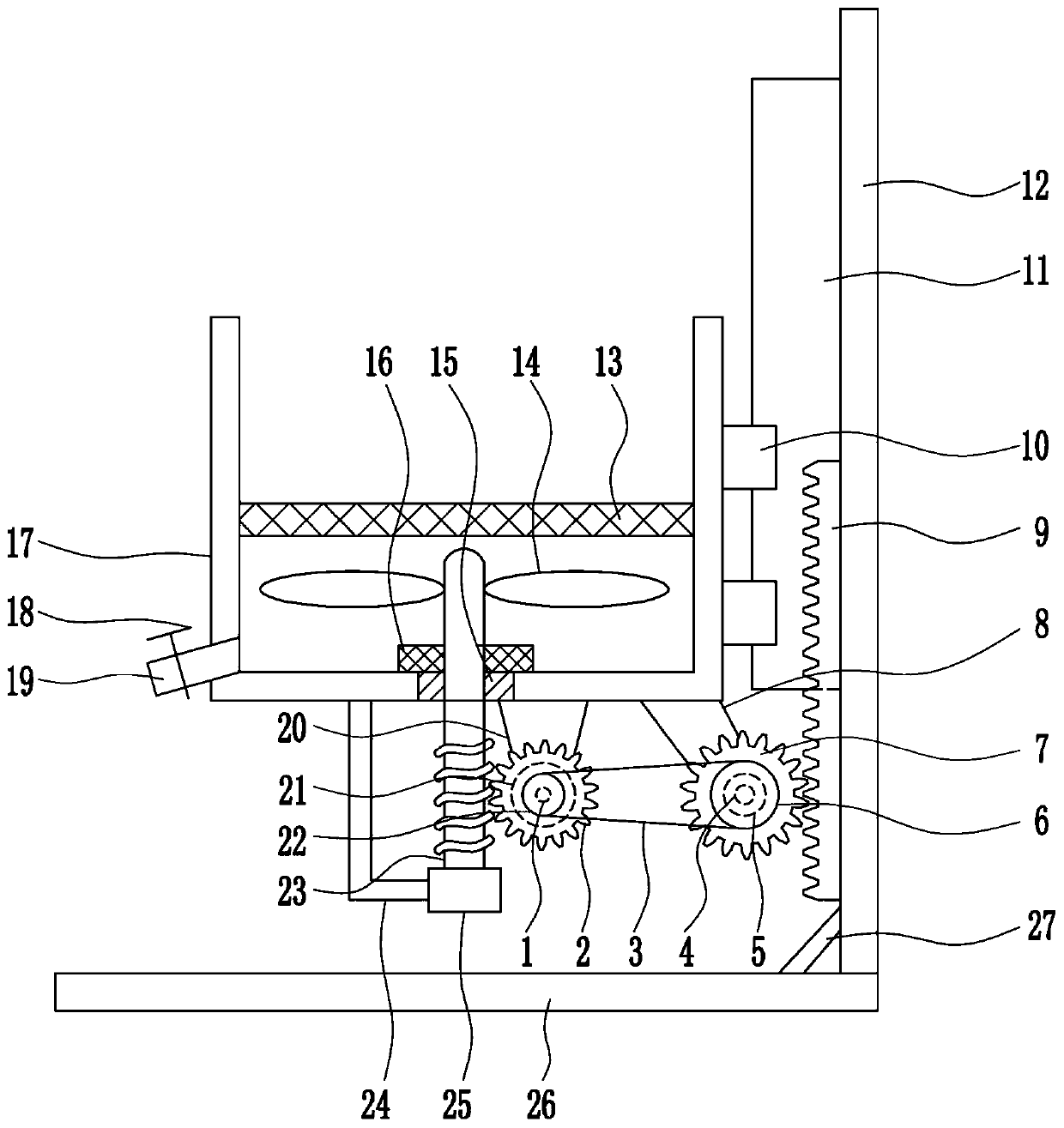

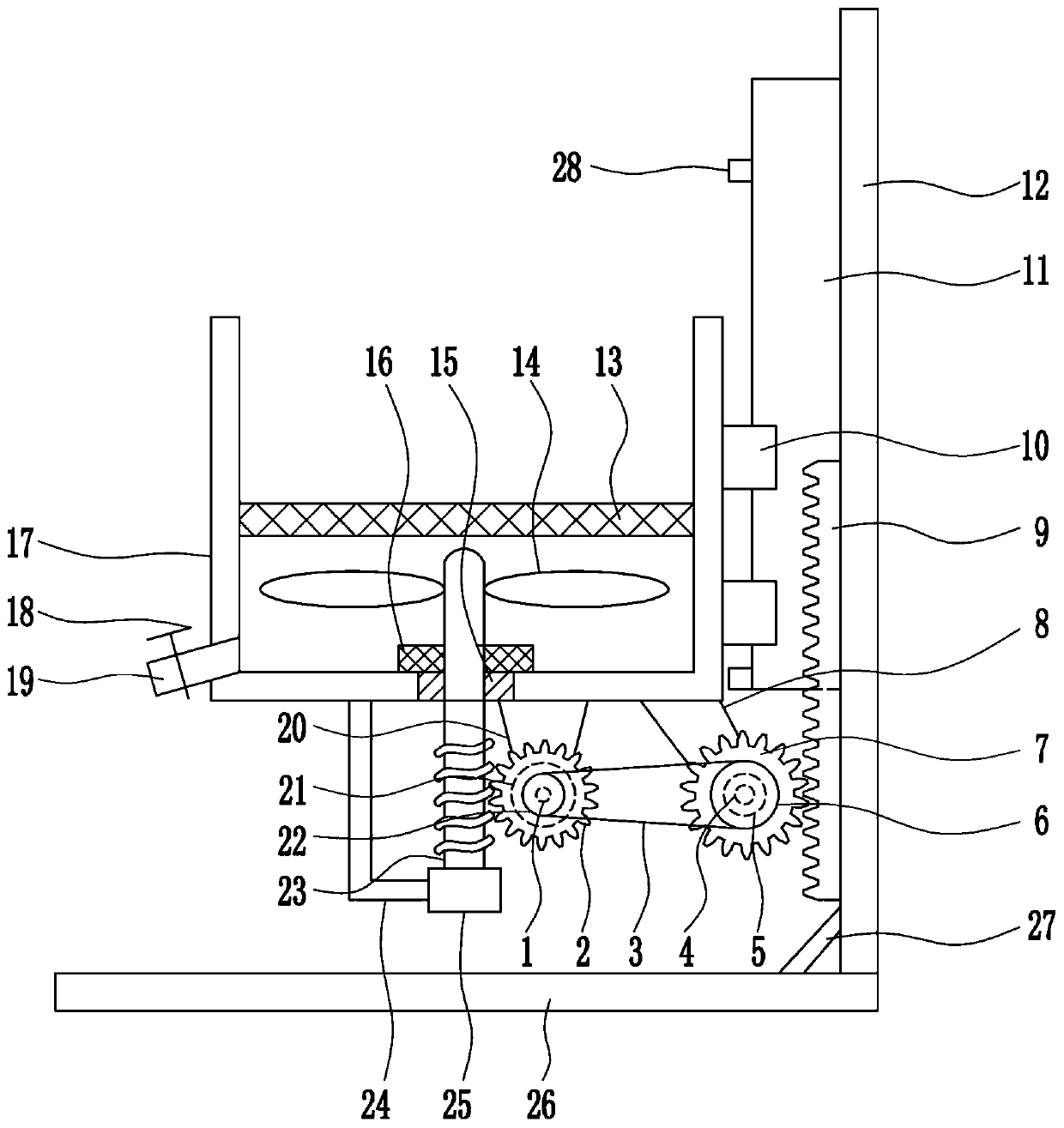

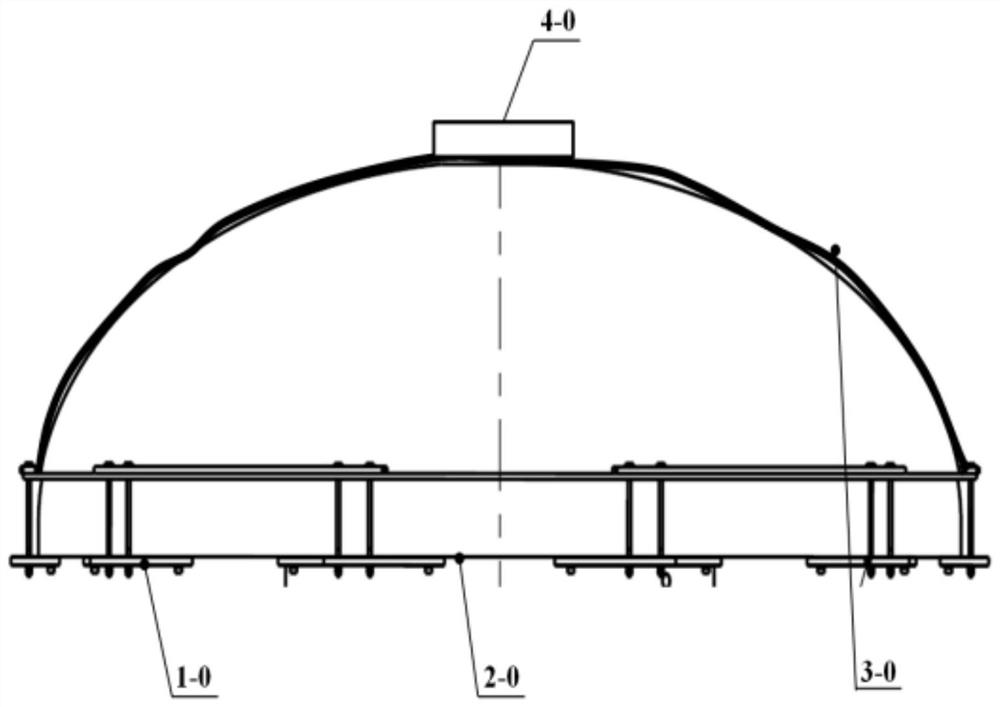

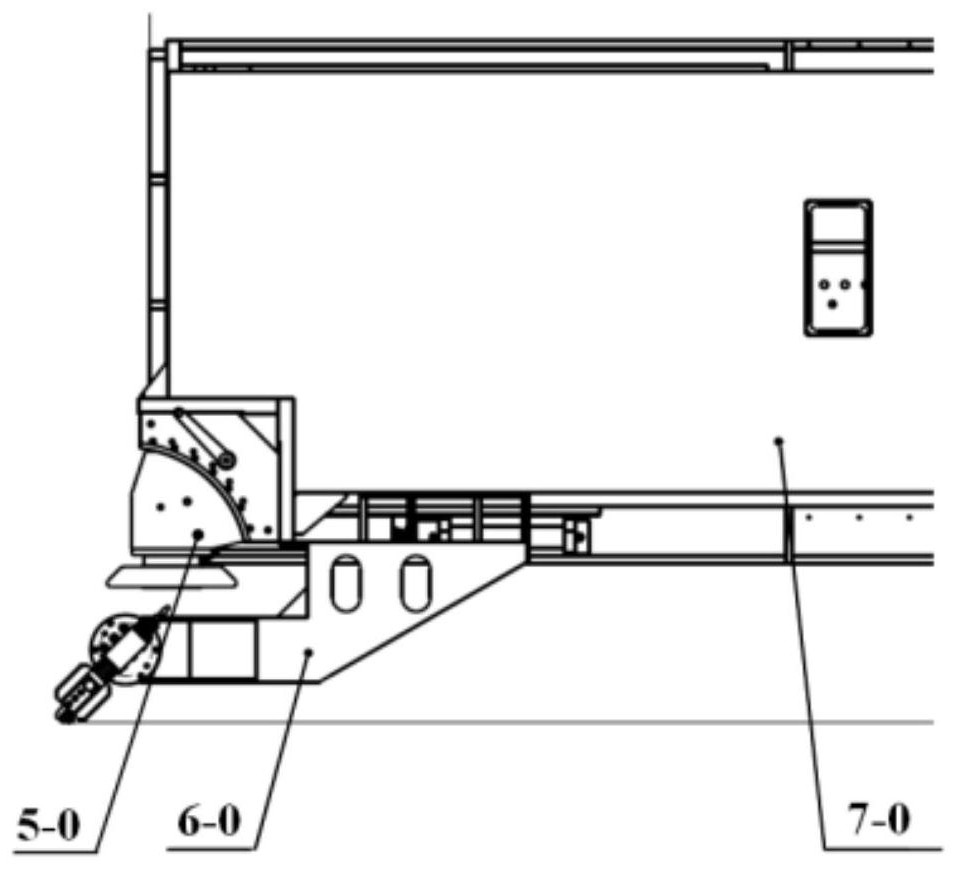

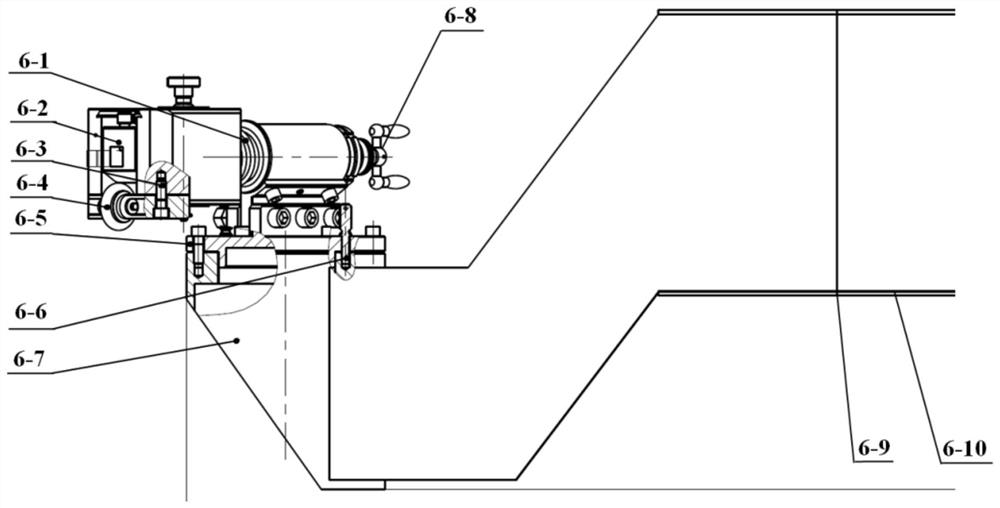

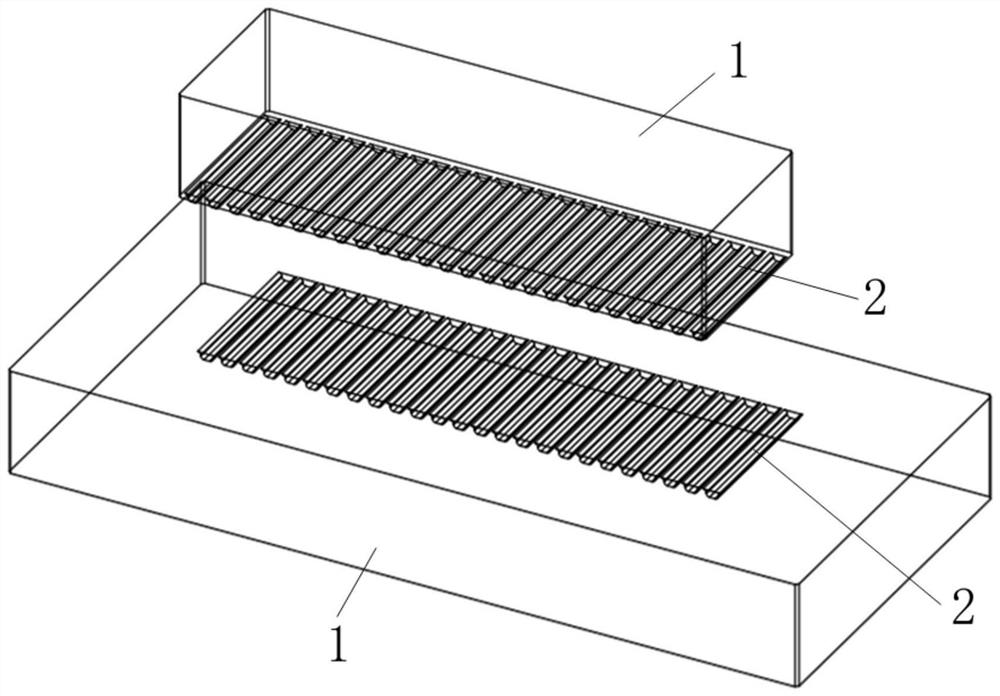

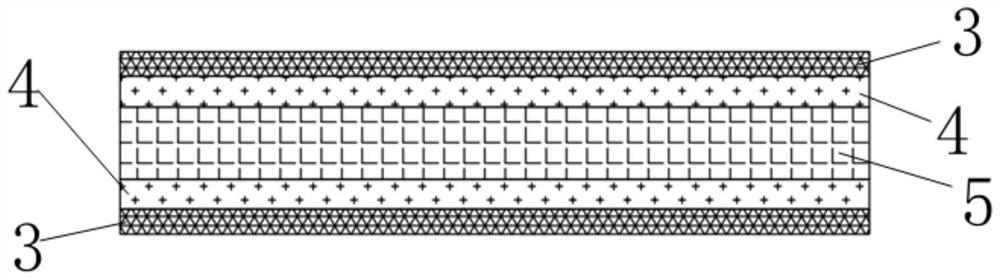

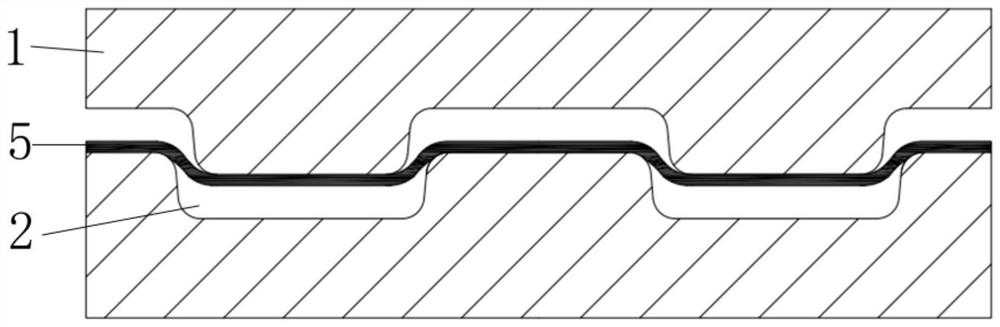

Large irregular bus-shaped surface shell uniform thinning machining method and device

ActiveCN112589133AUniform thinningThinning meetMeasurement/indication equipmentsLarge fixed membersNumerical controlSpinning

The invention discloses a large irregular bus-shaped surface shell uniform thinning machining method and device. According to the large irregular bus-shaped surface shell uniform thinning machining method and device, a programmable uniform thinning model is generated, the blank curvature change rule is combined, and a sectional type turning method and a layered turning method are utilized to complete a certain aluminum alloy dry cutting process; and a set of shell blank uniform thinning machining device system is designed and directly added on numerical control equipment, so that the requirements of uniform thinning machining of blanks in a forming mode such as spinning / casting can be met, the requirements of the sectional type turning process and the layered turning process are met, the requirements of the large-end rigid clamping process are met, the error caused by main shaft jumping in the turning process is solved, precision compensation is realized, uniform thinning machining ofparts is realized, the problems of low chemical milling efficiency and heavy pollution after the parts are taken down through spinning and subjected to heat treatment deformation are solved, and the requirements of weight and precision are met.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

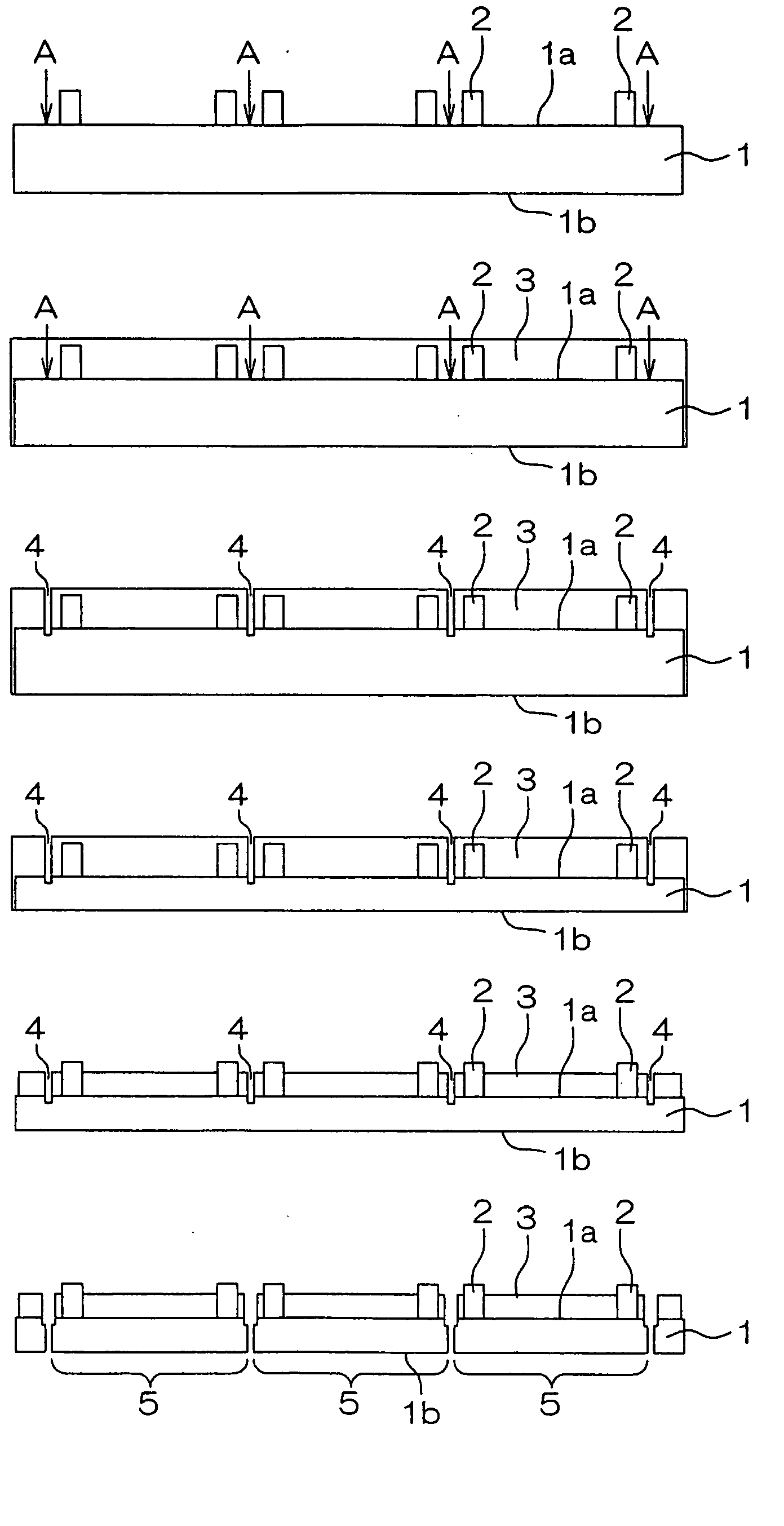

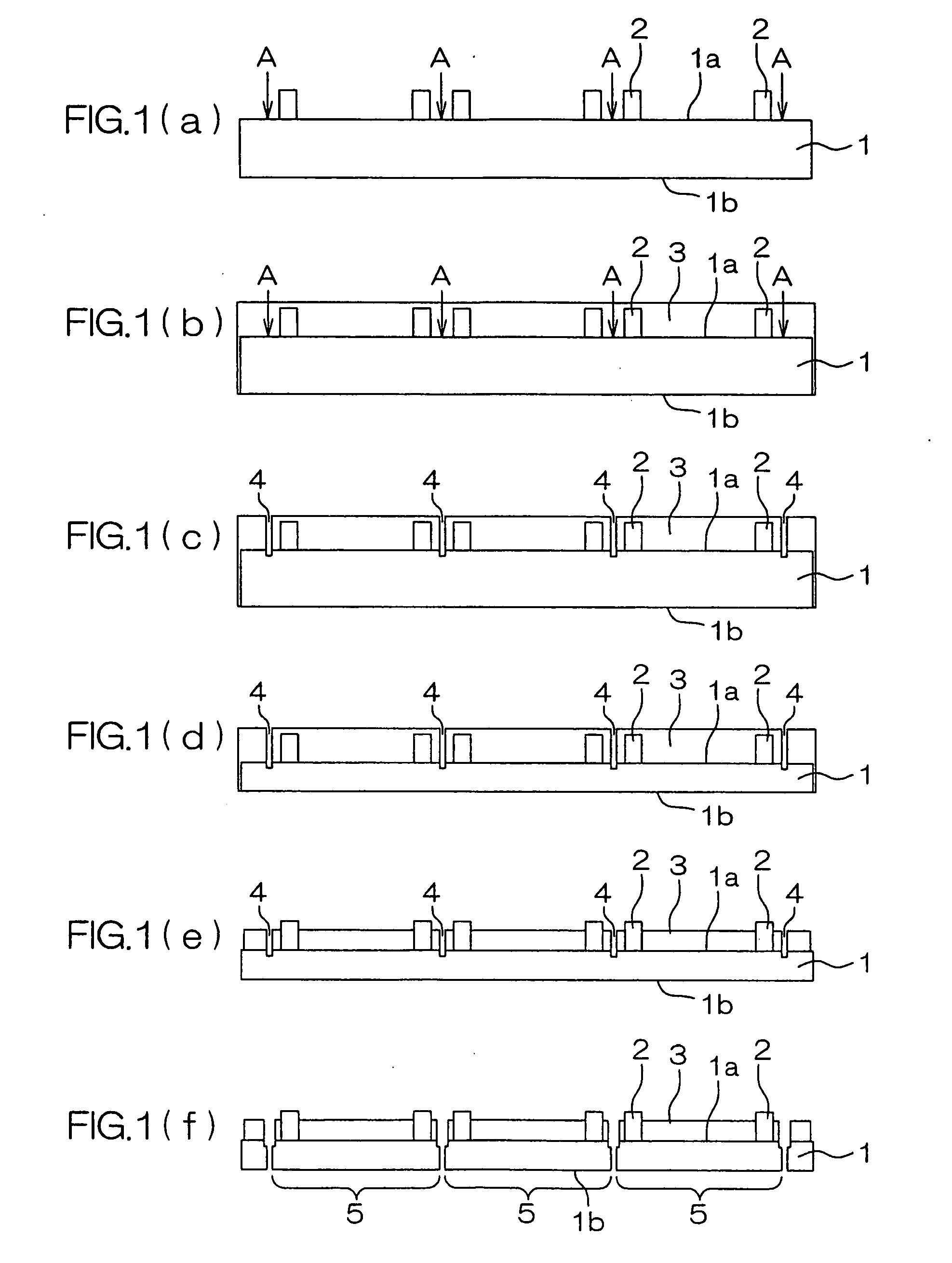

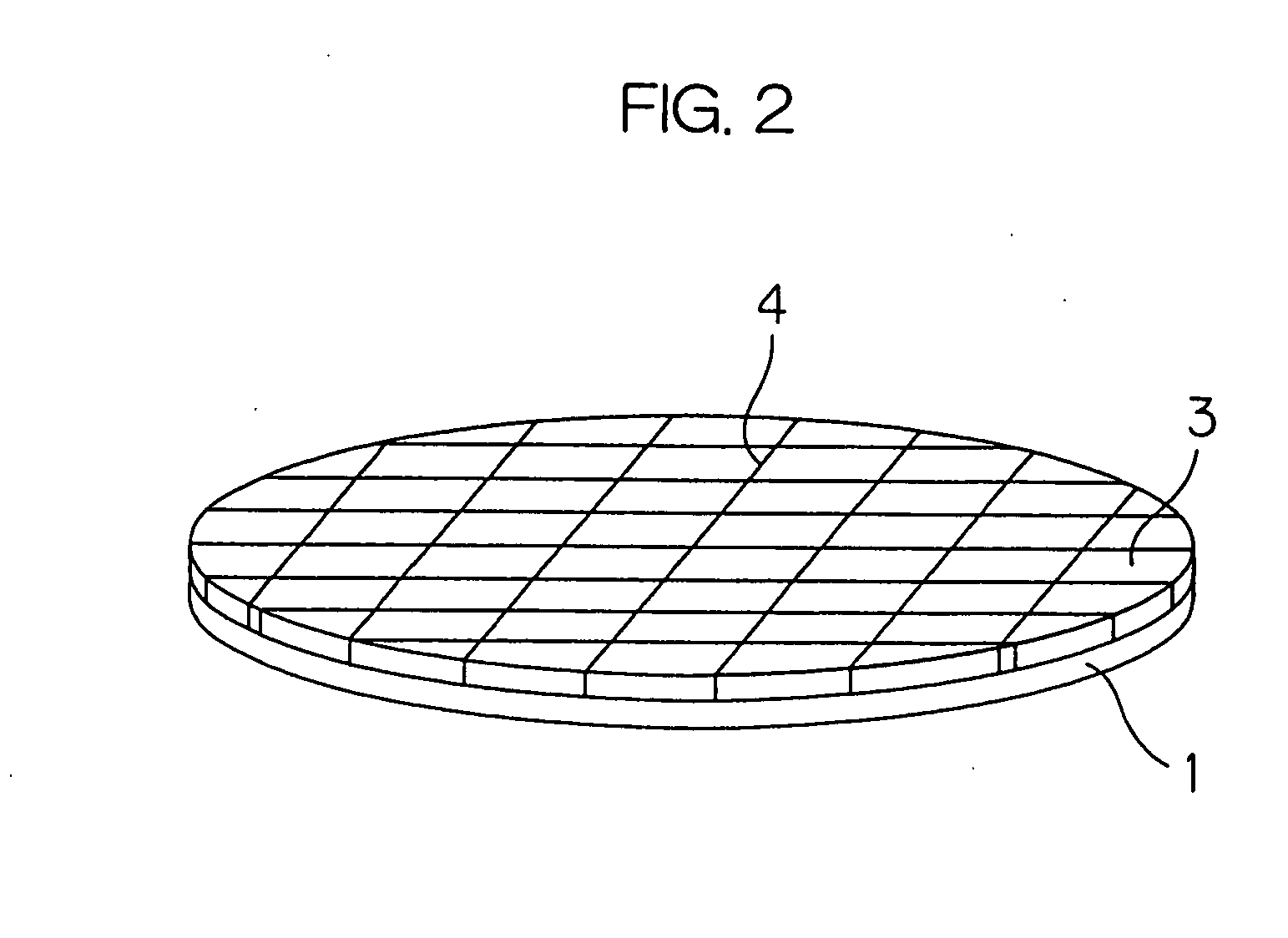

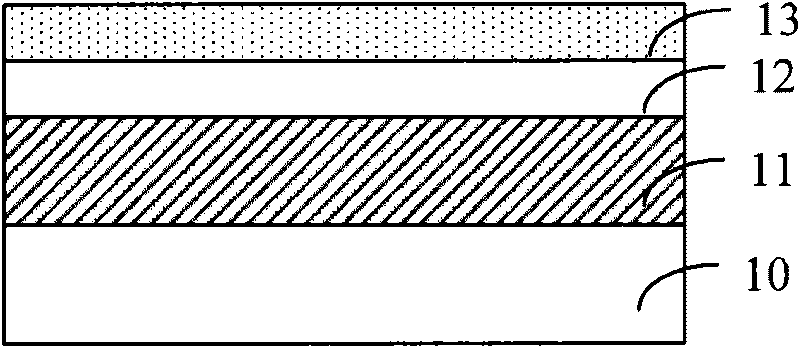

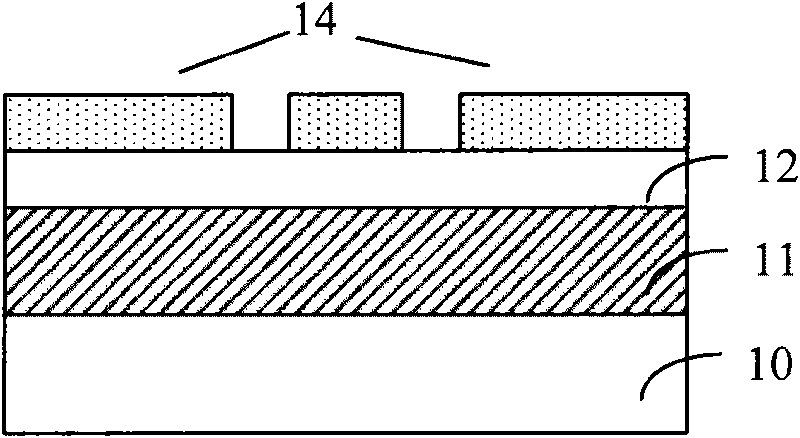

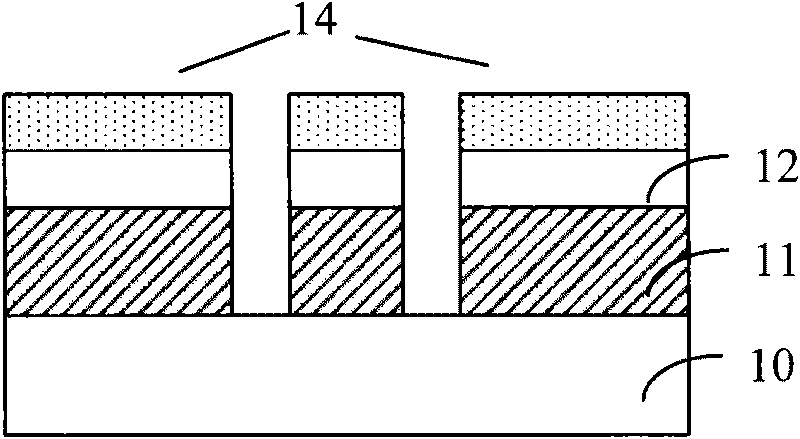

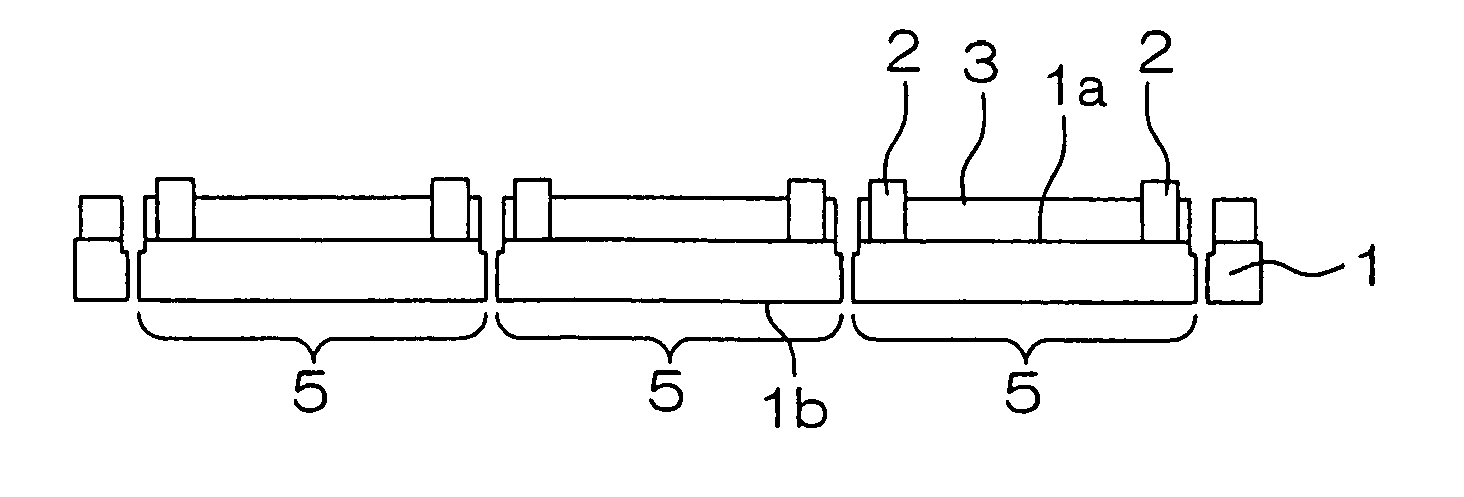

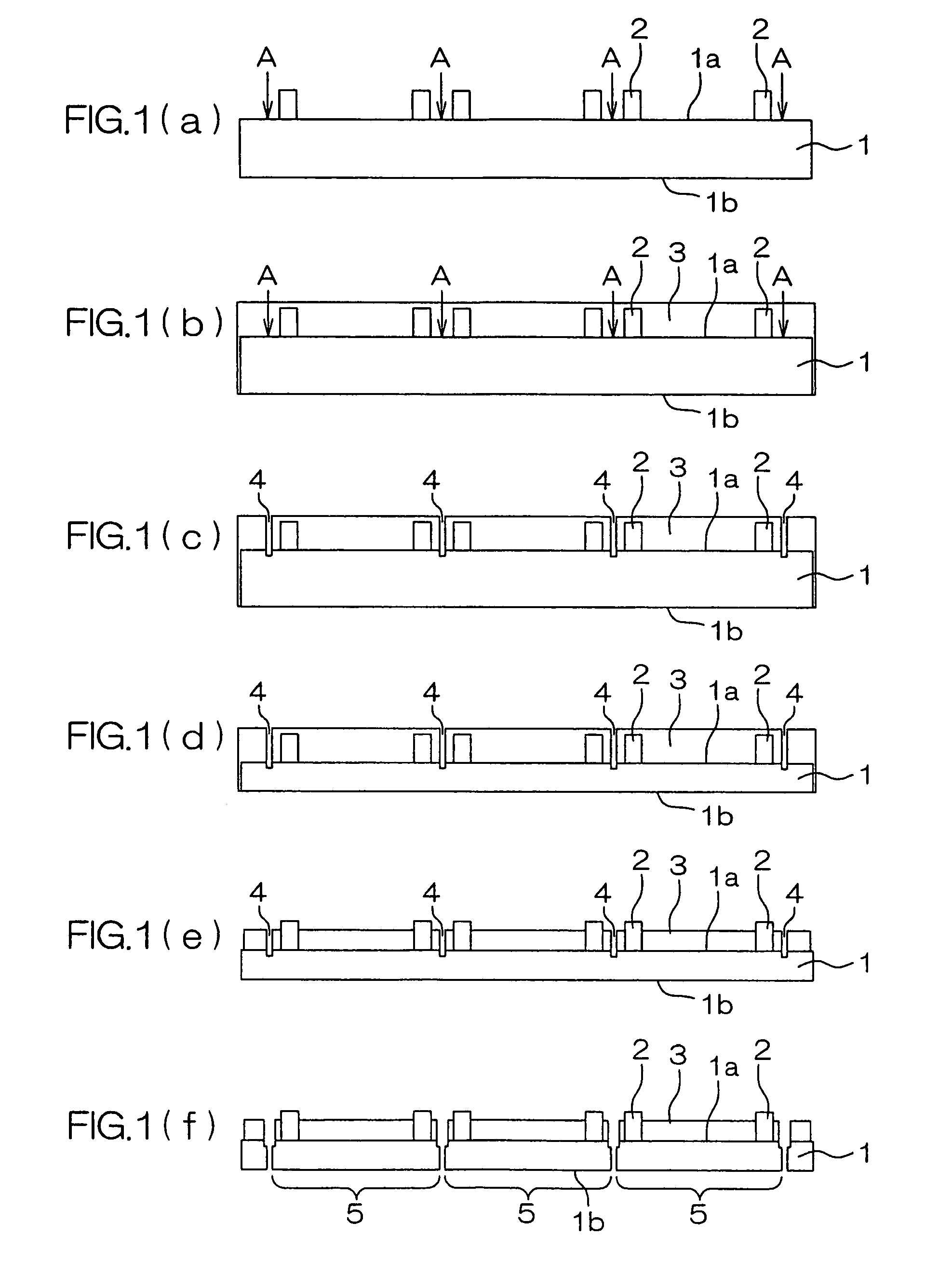

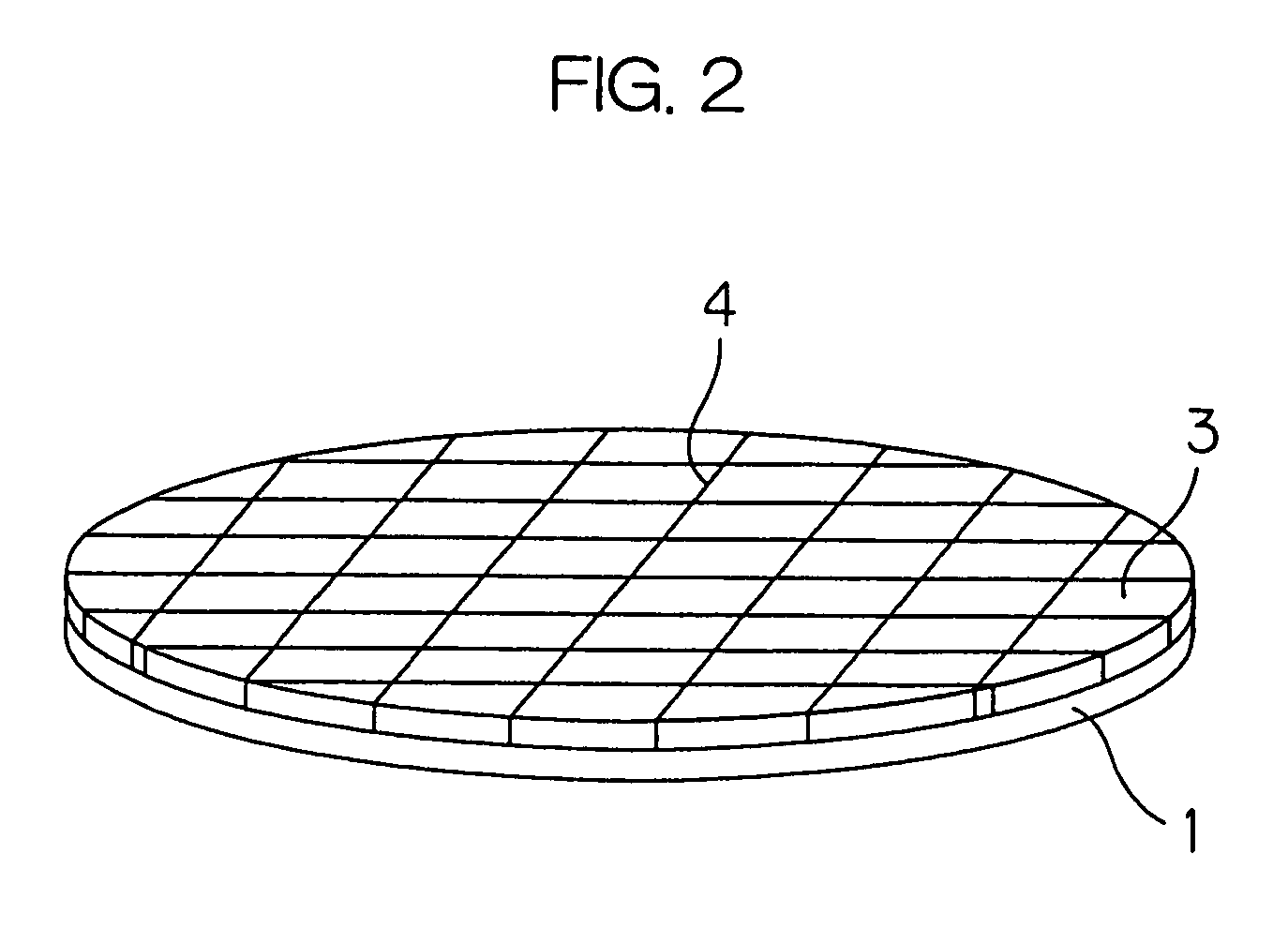

Semiconductor device and method for manufacturing the same

InactiveUS20050032334A1Evenly thickness-reducedGrind evenlySemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor chip

A method for manufacturing a semiconductor device which enables favorable back-surface grinding of a semiconductor substrate with preventing a warp in the substrate, thereby manufacturing a thickness-reduced semiconductor device. A projection electrode is formed on a surface of a wafer. A resin layer is formed on the wafer surface to a thickness to bury a top of the projection electrode. A cut groove is formed in the resin layer along a scribe line formed on the wafer. Thereafter, grinding is made on a back surface of the wafer by the use of a grinder or the like. A surface portion of the resin layer is removed by etching or the like, to expose the top of the projection electrode. The wafer is cut along the cut groove to obtain individual semiconductor chip pieces.

Owner:TAIWAN SEMICON MFG CO LTD

Method for manufacturing aluminum wiring

ActiveCN101740469AMake up for unetched etch defectsUniform thinningSemiconductor/solid-state device manufacturingIonEtching rate

The invention relates to a method for manufacturing aluminum wiring, comprising the following steps of: executing a first etching process on aluminum wiring, wherein the first etching process is a reactive ion etching process without applying bias voltage; after the first etching process is executed, executing a second etching process on the aluminum wiring to form an aluminum wiring diagram, wherein the second etching process is a reactive ion etching process applying the bias voltage. The method for manufacturing aluminum wiring remedies the etching defect that the aluminum wiring is not etched through due to the etch rate difference when the aluminum wiring diagram is formed by etching, thereby avoiding the influence on the quality of finally formed semiconductor devices due to the etching defect.

Owner:SEMICON MFG INT (SHANGHAI) CORP

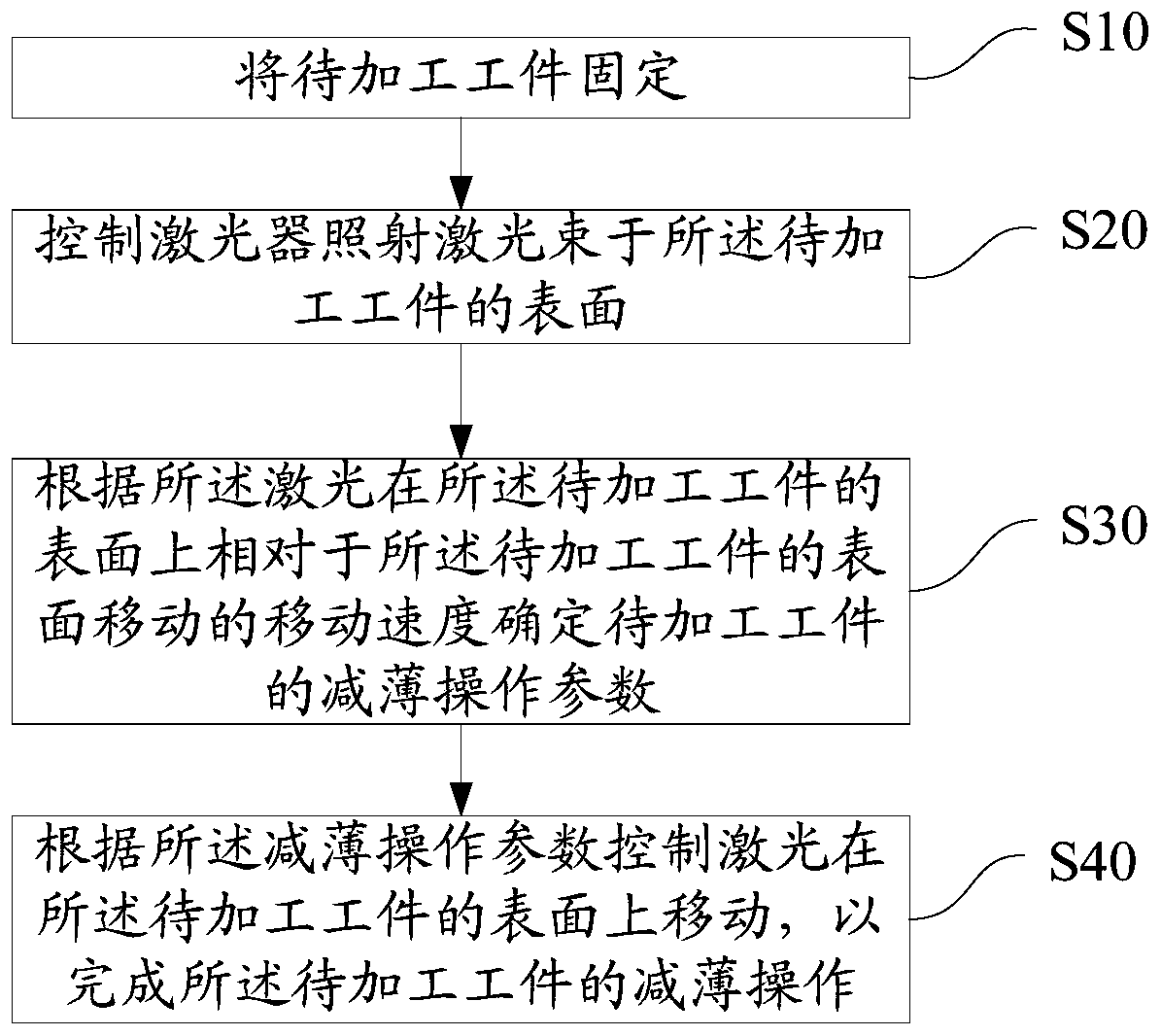

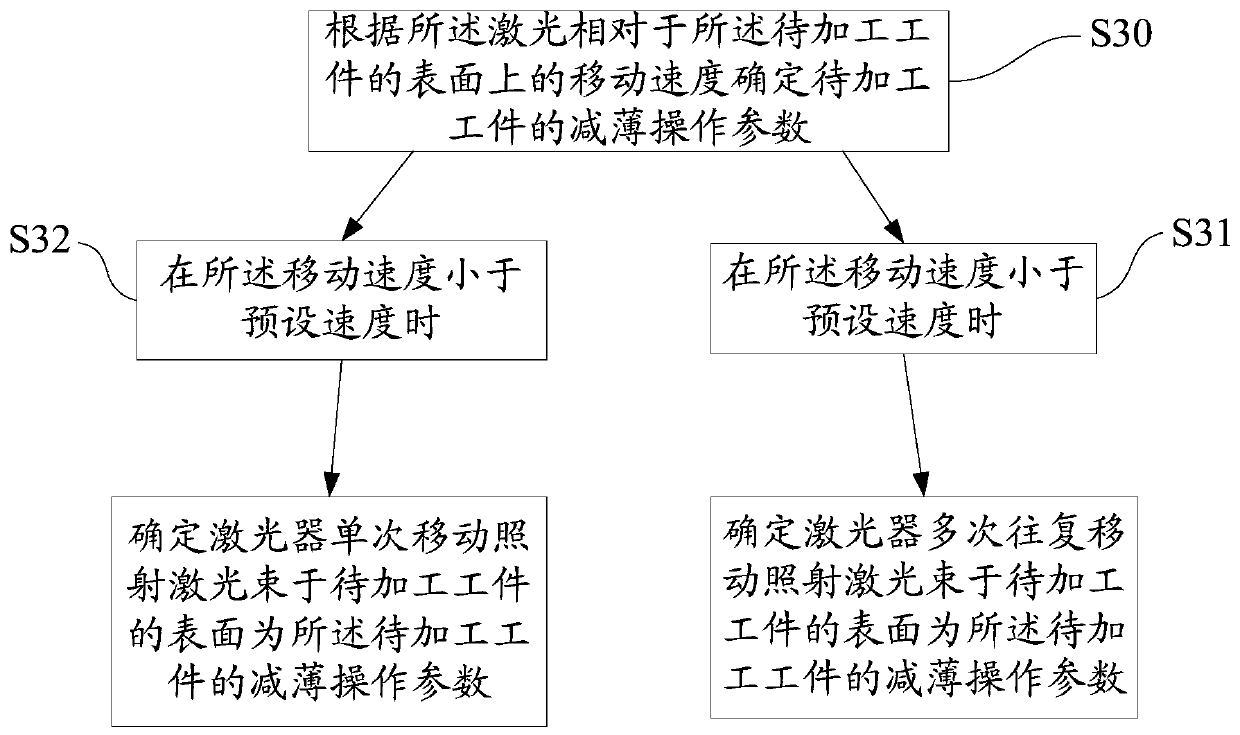

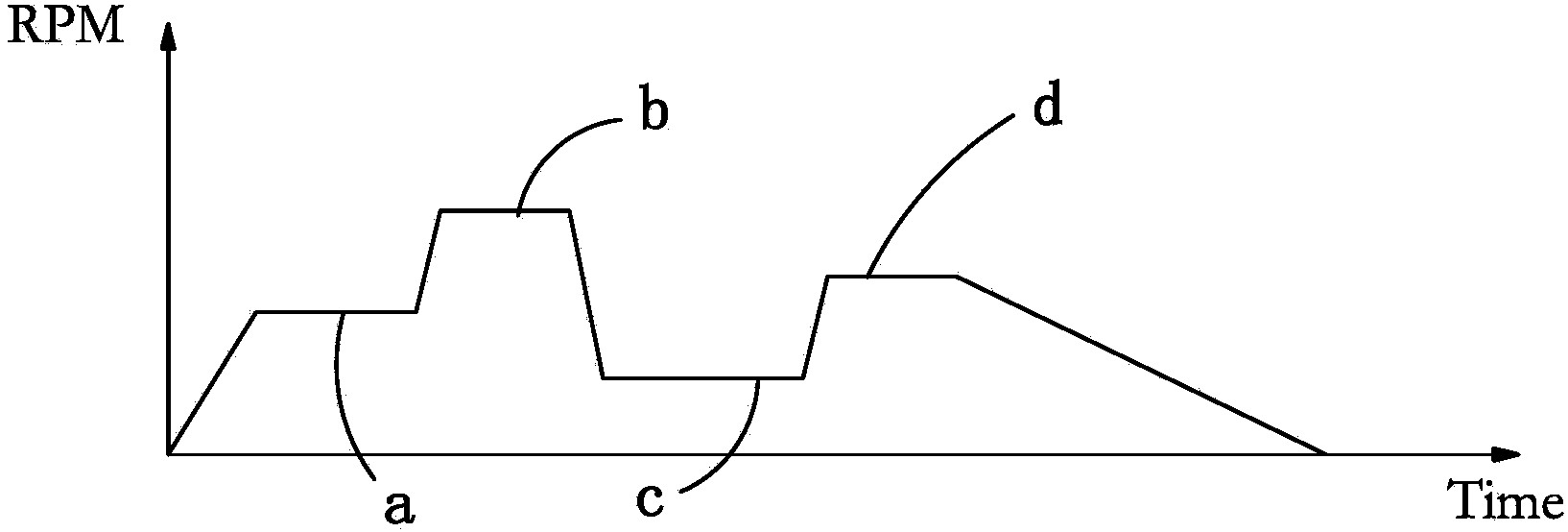

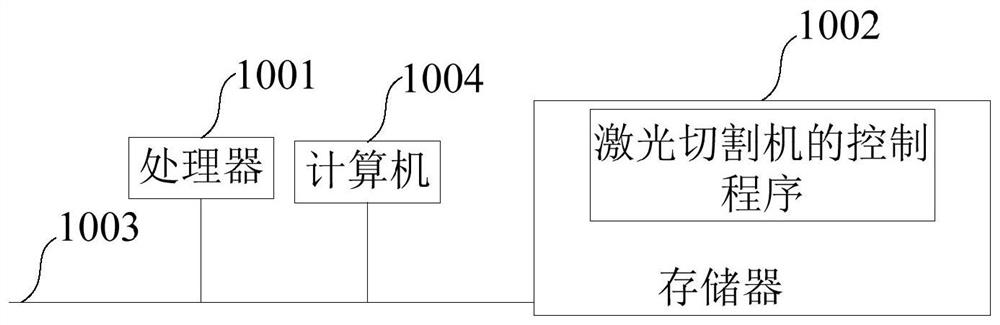

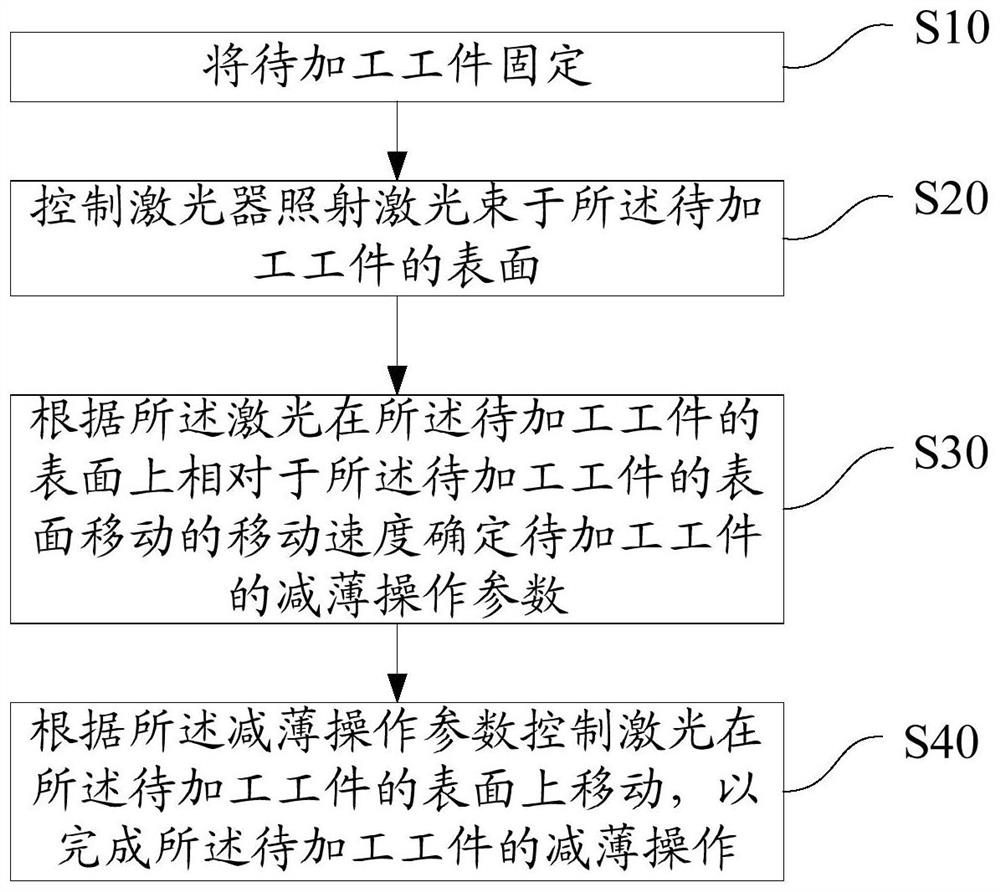

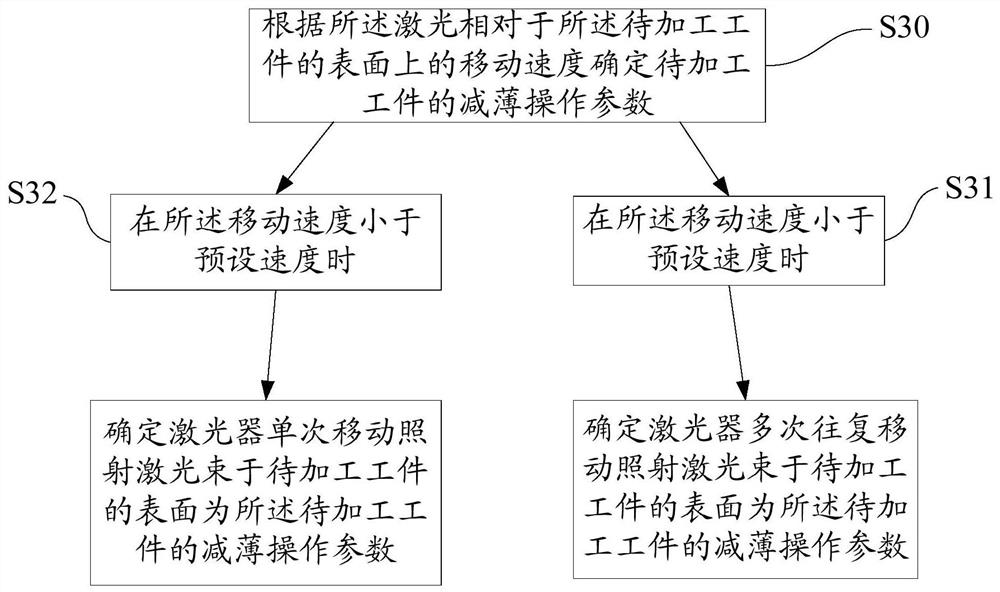

Laser thinning method and laser machine

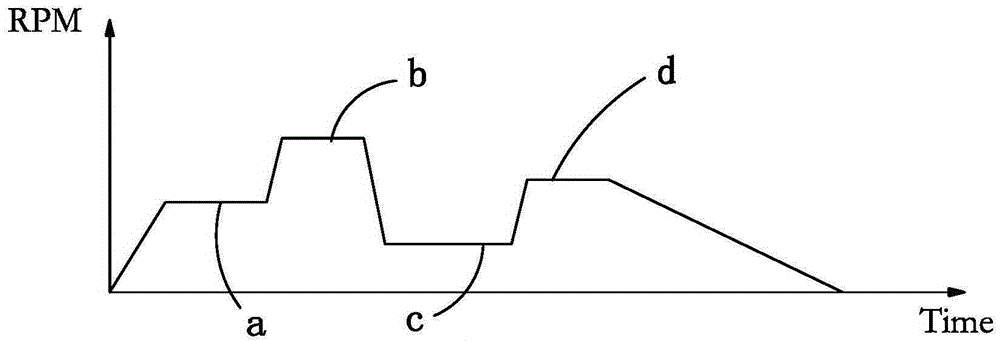

ActiveCN110238544AConsistent cutting volumeImprove flatnessLaser beam welding apparatusMoving speedOptoelectronics

The invention discloses a laser thinning method. The laser thinning method includes the following steps that a to-be-machined workpiece is fixed; laser is controlled to be irradiated to the surface of the to-be-machined workpiece; according to the moving speed of the laser on the surface of the to-be-machined workpiece relative to moving of the surface of the to-be-machined workpiece, thinning operation parameters of the to-be-machined workpiece are determined; and according to the thinning operation parameters, the laser is controlled to move on the surface of the to-be-machined workpiece, so that thinning operation of the to-be-machined workpiece is completed. The invention further discloses a laser machine. The laser thinning method and the laser machine guarantee that the surface evenness of the to-be-machined workpiece after thinning machining is good.

Owner:SHENZHEN H TECH CO LTD

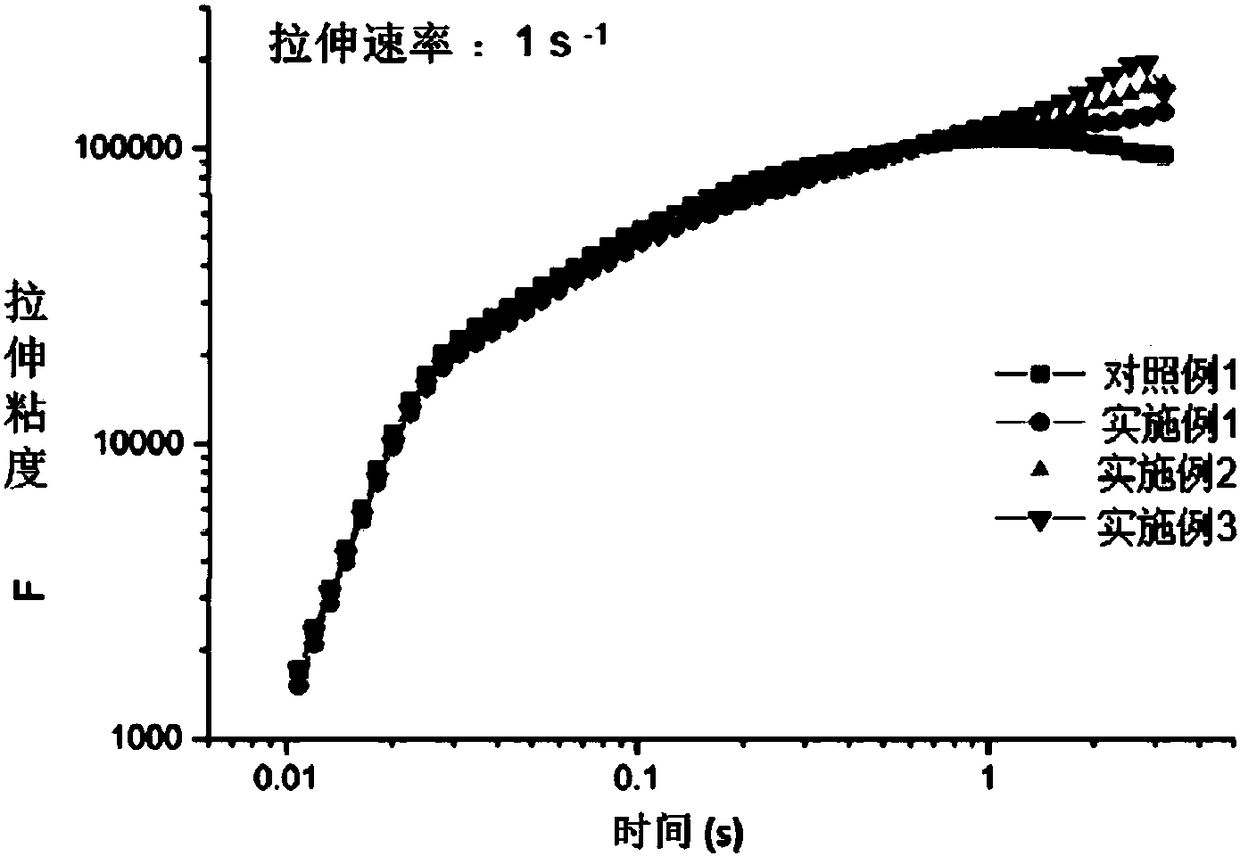

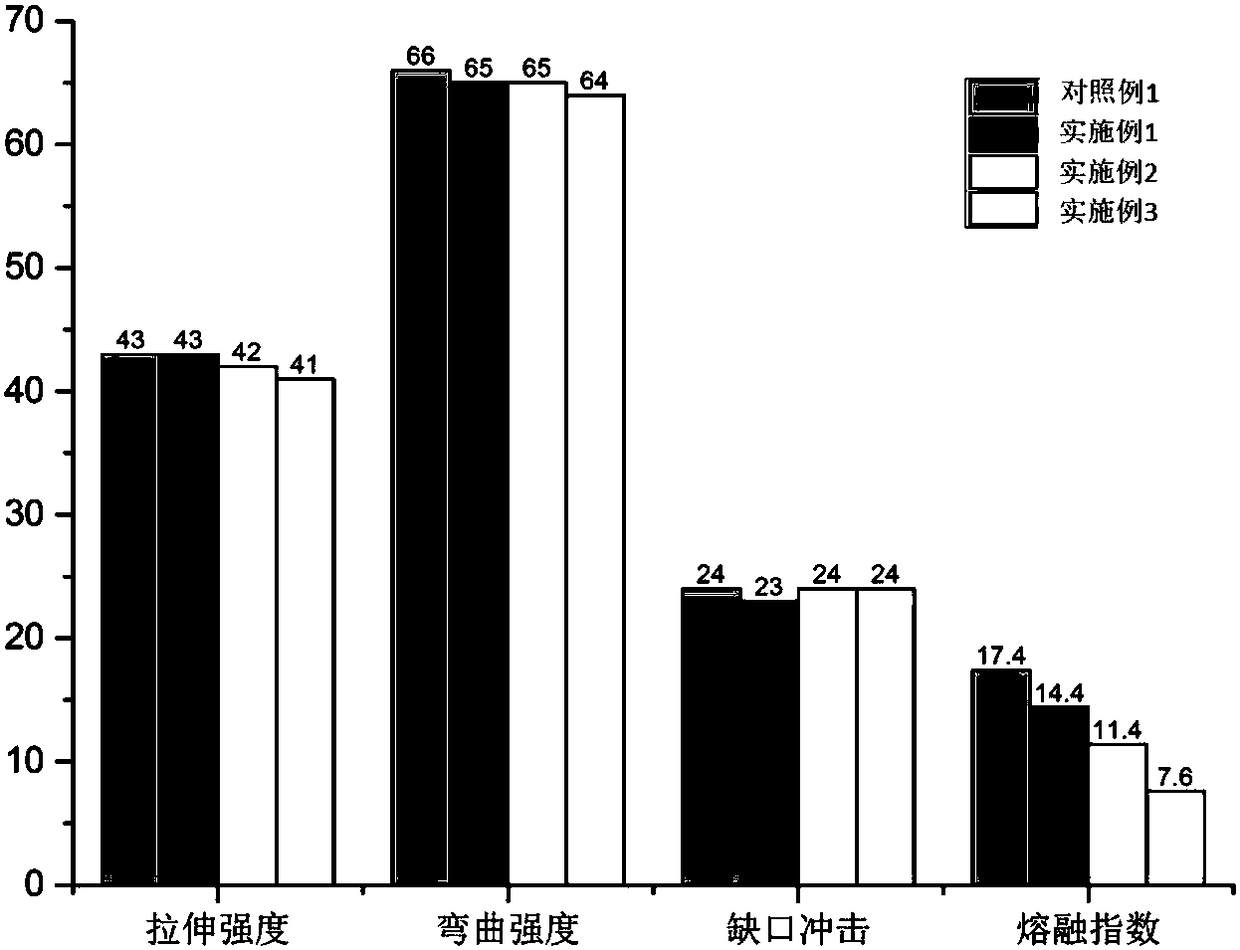

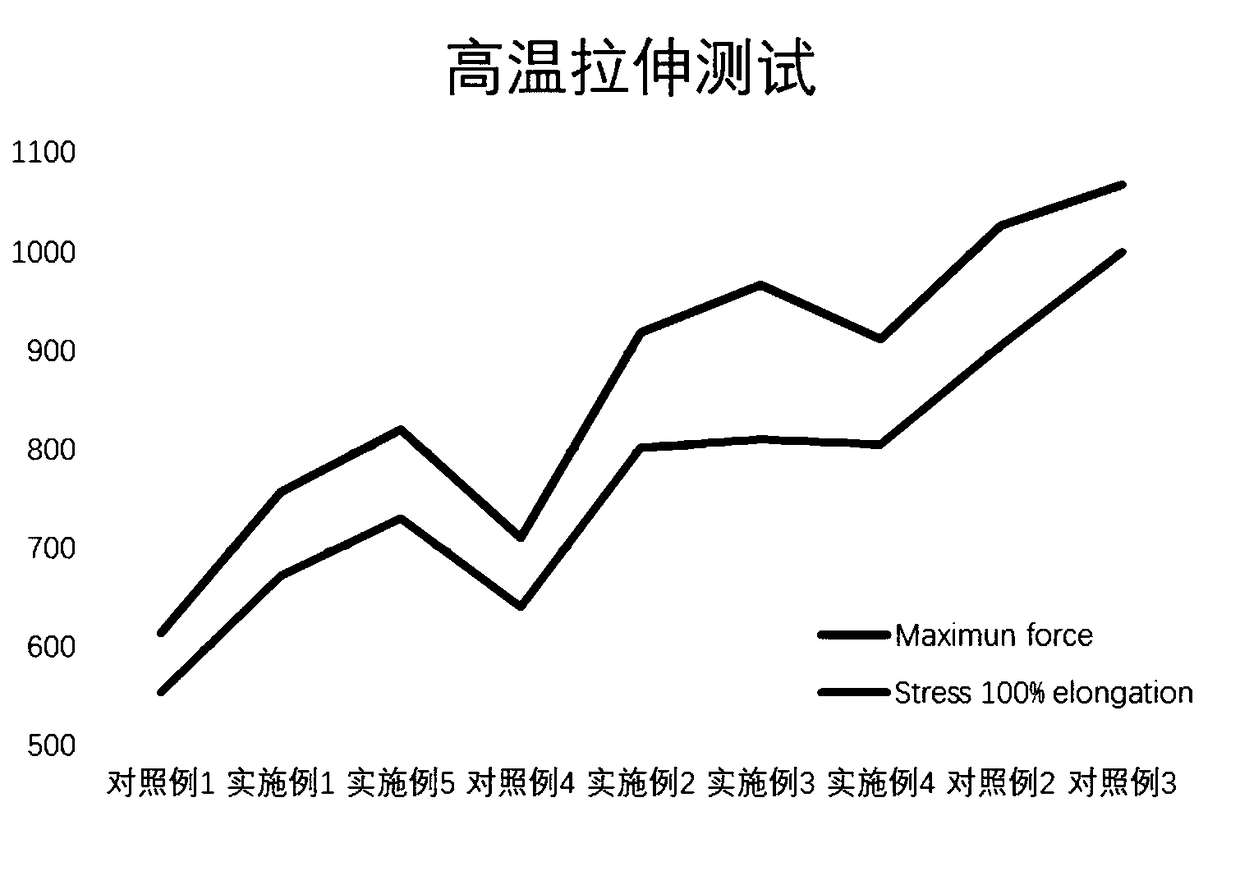

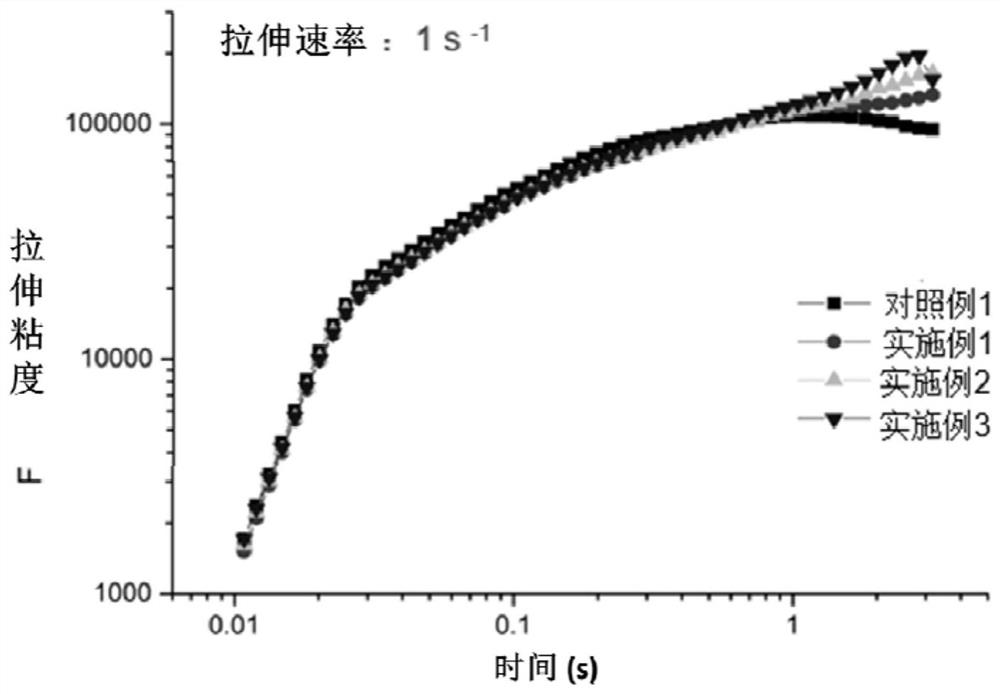

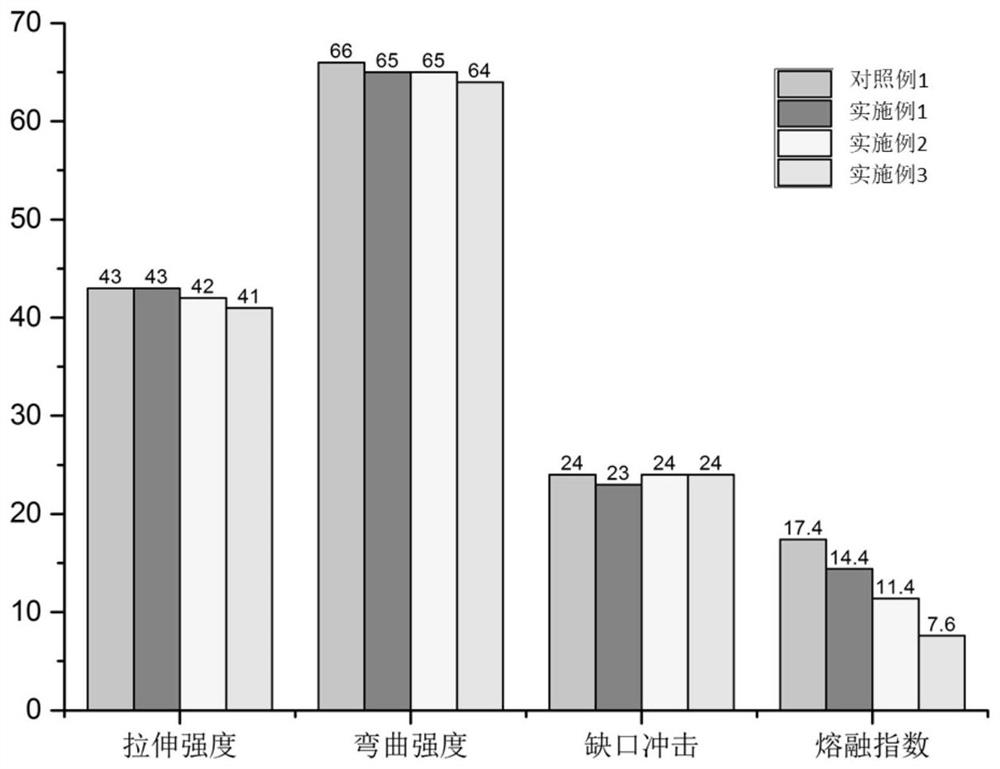

High-melt-strength styrene resin composition and preparation method thereof

The invention provides a high-melt-strength styrene resin composition. The composition comprises, by weight, styrene resin or styrene alloy, a tackifier, an antioxidant and a lubricant. Compared withthe prior art, the composition has the advantages that a random copolymer serving as the tackifier, the styrene resin and the styrene alloy are thermally compatible, phase separation is avoided, andthe mechanical property is excellent; the molecular weight of the random copolymer serving as the tackifier is moderate, and the random copolymer can be plasticized more easily compared with rubber powder, high-molecular-weight SAN powder, heat-resistant powder and the like, so that the processing performance is better, the thickness is uniform, the shrinkage rate is low, and surface defects are not likely to be generated.

Owner:FINE BLEND POLYMER SHANGHAI CO LTD

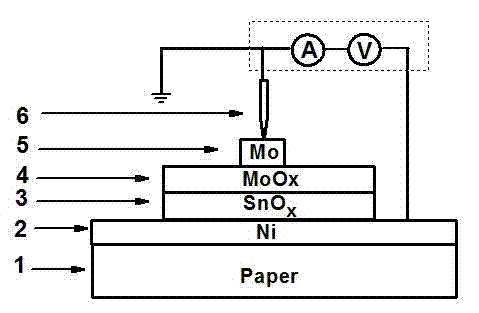

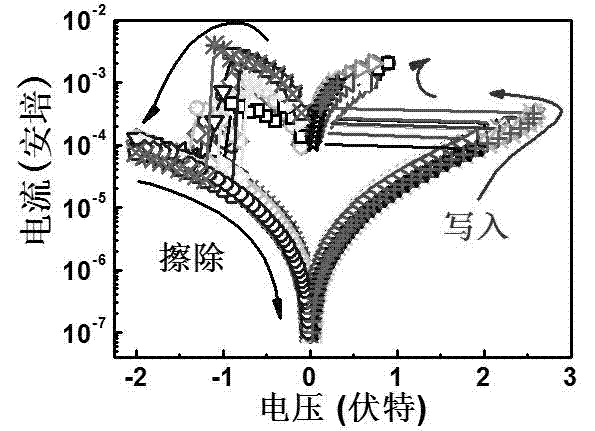

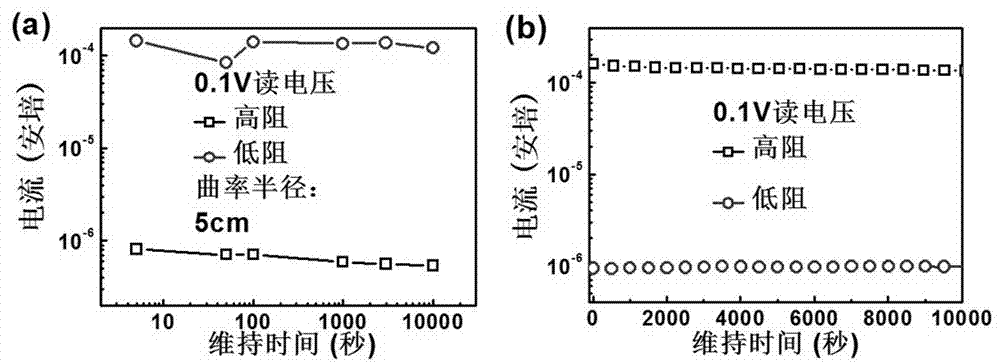

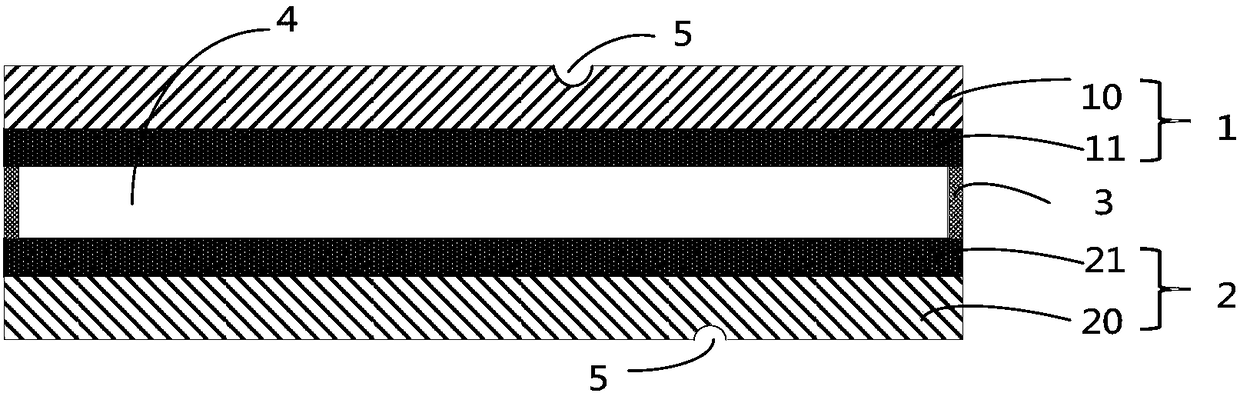

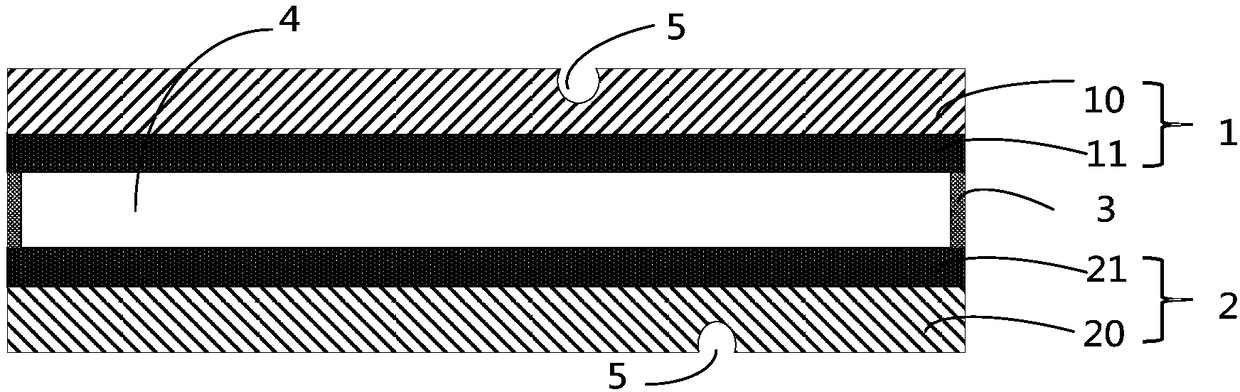

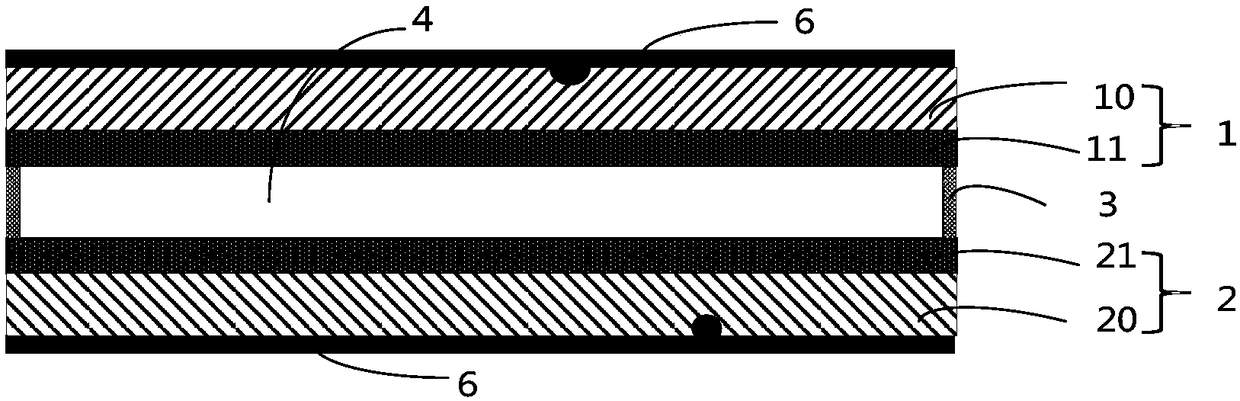

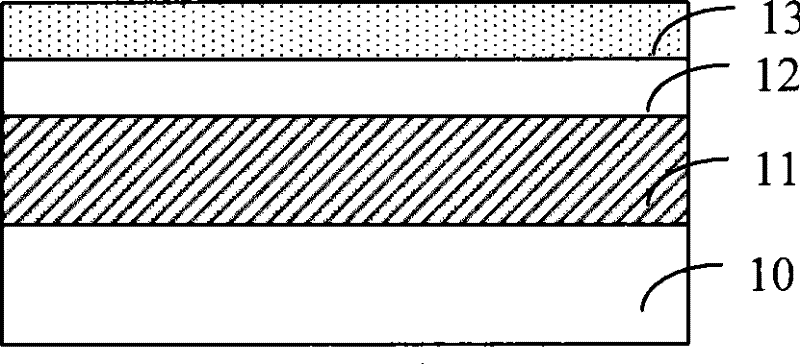

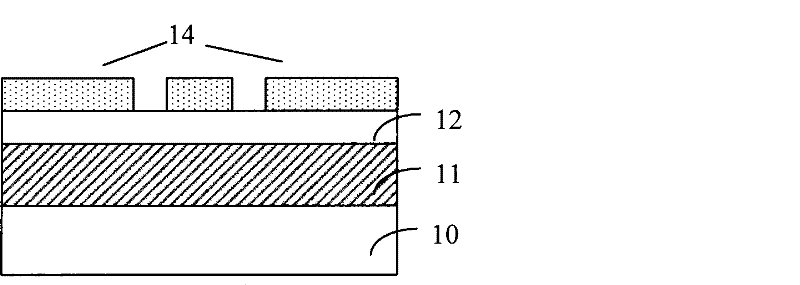

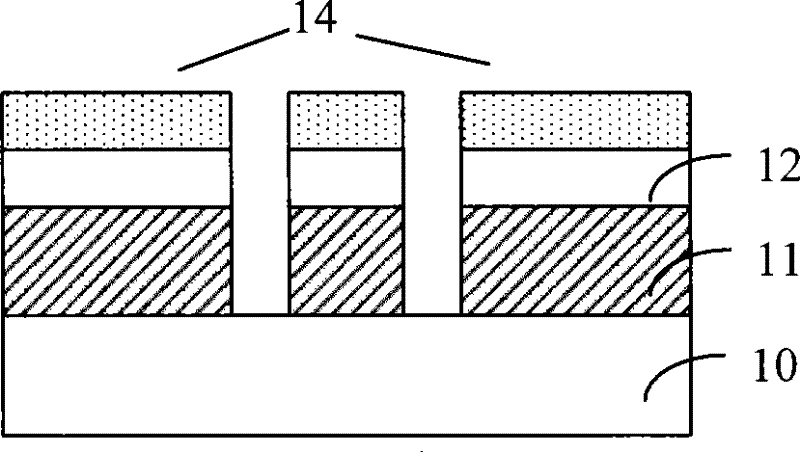

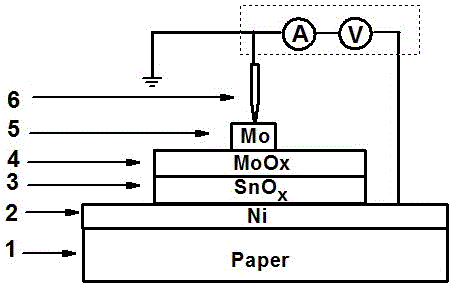

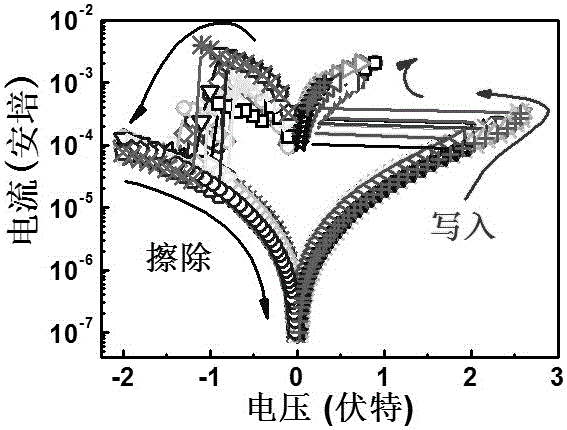

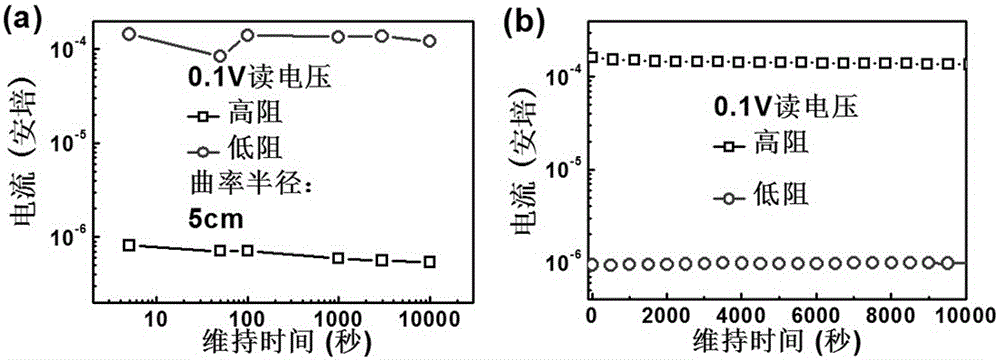

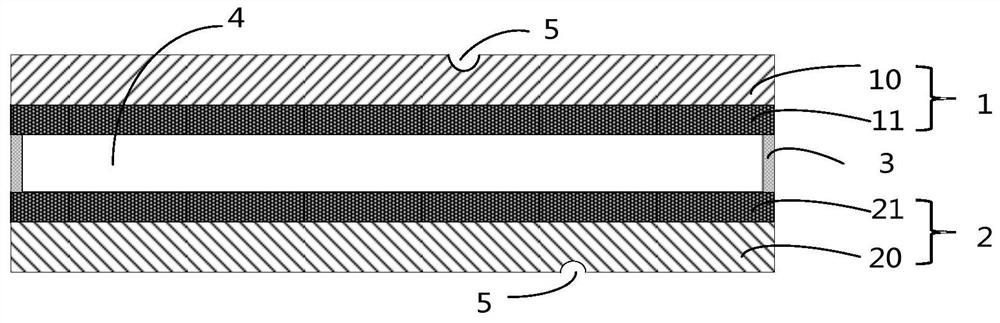

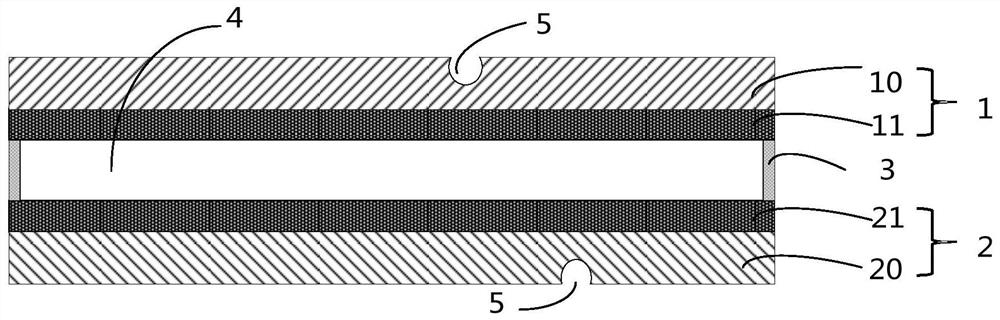

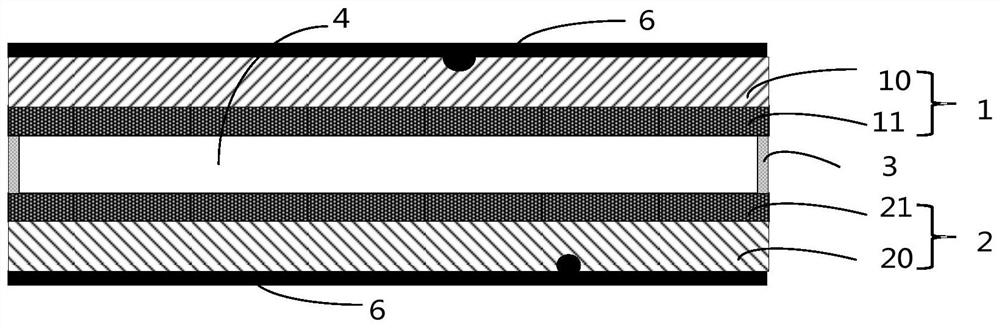

Erasable film variable-resistance memory unit adopting flexible paper base and preparation method thereof

InactiveCN103247758AGood controllabilityIncrease deposition rateElectrical apparatusColor printingMetal

The invention belongs to the technical field of nonvolatile memory devices, and particularly relates to an erasable film RRAM (resistive random access memory) memory unit. The memory unit is characterized in that a piece of flexible and bendable printing ink color printing paper is used as a substrate, a tin oxide film is used as a variable-resistance layer, and a molybdenum oxide film is used as an oxygen storage layer; and a specific structure comprises the printing ink color printing paper substrate, a metallic nickel film serving as a bottom electrode, the tin oxide film, the molybdenum oxide film and a metallic molybdenum film serving as a top electrode in sequence. According to the invention, a direct current magnetron sputtering technology is used at the low temperature (subzero 100 DEG C), and the metallic nickel film, the tin oxide film, the molybdenum oxide film and the metallic molybdenum film are prepared on the substrate sequentially. The variable-resistance memory unit prepared by the invention has the characteristics of good bending durability and the like, and has a wide application prospect in the fields of nonvolatile memory and flexible electron devices.

Owner:FUDAN UNIV

Process method for treating and thinning middle-high voltage anode aluminum foil

ActiveCN112863879AAvoid uneven thicknessLarge specific surface areaElectrolytic capacitorsO-Phosphoric AcidHigh voltage

The invention discloses a process method for treating and thinning a middle-high voltage anode aluminum foil. The method comprises the steps of pretreatment, first-stage hole forming corrosion, middle treatment corrosion, second-stage hole expanding corrosion, post-treatment and the like, and comprises the following steps: soaking aluminum foil in a mixed solution of hydrochloric acid and sulfuric acid, applying current to the mixed solution of hydrochloric acid and sulfuric acid to carry out direct-current hole-forming corrosion and carry out first-stage direct-current hole-forming corrosion, soaking the aluminum foil in a mixed solution of silicon hydrofluoric acid and phosphoric acid, then applying current to the aluminum foil in a nitric acid solution to carry out second-stage direct-current hole-forming corrosion, repeating the processes of intermediate treatment corrosion and second-stage hole-forming corrosion many times, soaking the aluminum foil in the nitric acid solution for post-treatment, finally cleaning the aluminum foil with tap water, cleaning the aluminum foil with pure water, and then drying and rolling the aluminum foil to obtain the corroded foil. The method can effectively remove the porous layer on the surface of the finished corrosion foil, reduces the residual thickness of the corrosion foil, does not reduce the specific volume, and improves the specific volume of the corrosion foil in unit thickness.

Owner:GUANGXI HEZHOU GUIDONG ELECTRONICS TECH

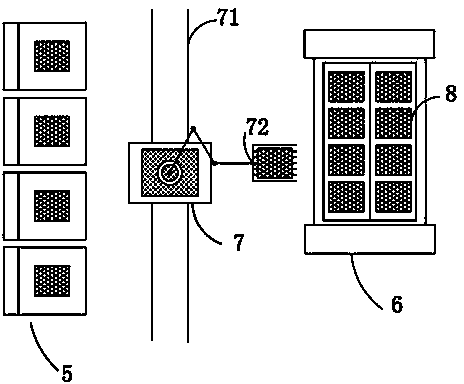

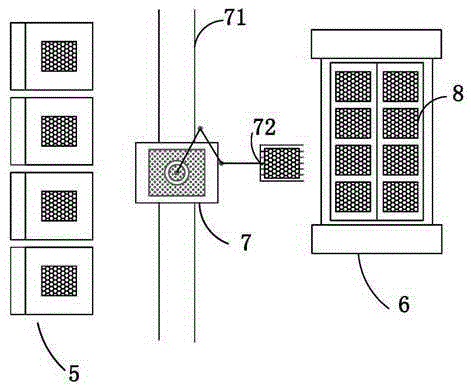

Organic light emitting diode (OLED) panel thinning device, system and method

InactiveCN103456766AUniform etchUniform thinningSolid-state devicesSemiconductor/solid-state device manufacturingRotary machineSurface plate

The invention discloses an organic light emitting diode (OLED) panel thinning device, system and method. The OLED panel thinning device mainly comprises a rotary machine frame, a fluid guide tube and a rotary machine frame cavity, wherein the rotary machine frame is fixedly installed in the rotary machine frame cavity, and a port of the fluid guide tube is located right above the central position of the rotary machine frame. A principle is that etching liquid evenly diffuses from the center of an OLED panel to the outside by utilizing centrifugal force produced by the rotary machine frame in rotation, and then etching and thinning of the OLED panel are achieved. The invention further discloses the OLED panel thinning method based on the OLED panel thinning device. The OLED panel thinning device and method overcomes the shortcoming that the etching liquid for immersion-type thinning is polluted and accordingly the thinning quality is reduced, and meanwhile overcomes the problem that concave spots are easily formed and the etching thickness is uneven and the like in the spraying-type thinning.

Owner:SICHUAN CCO DISPLAY TECH

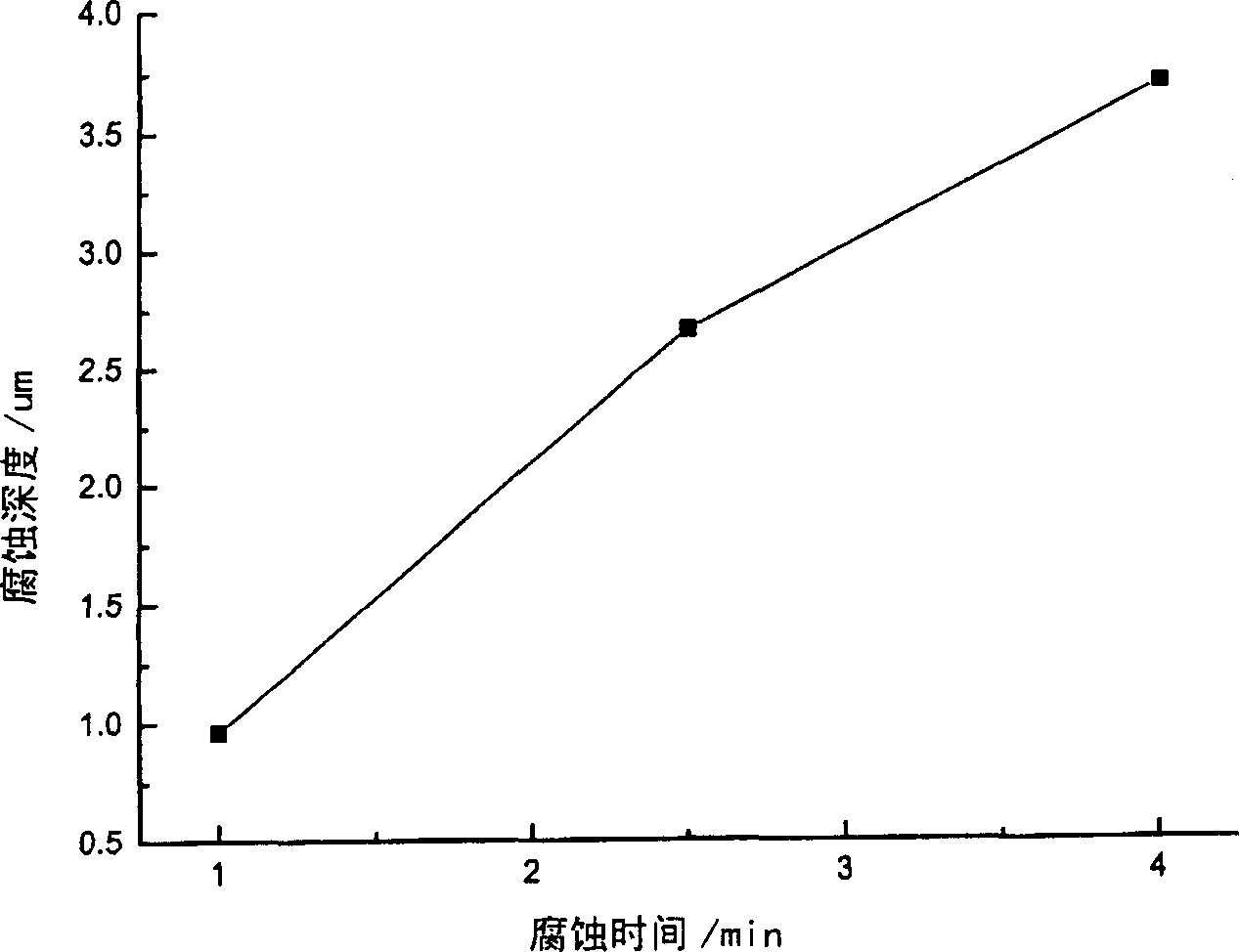

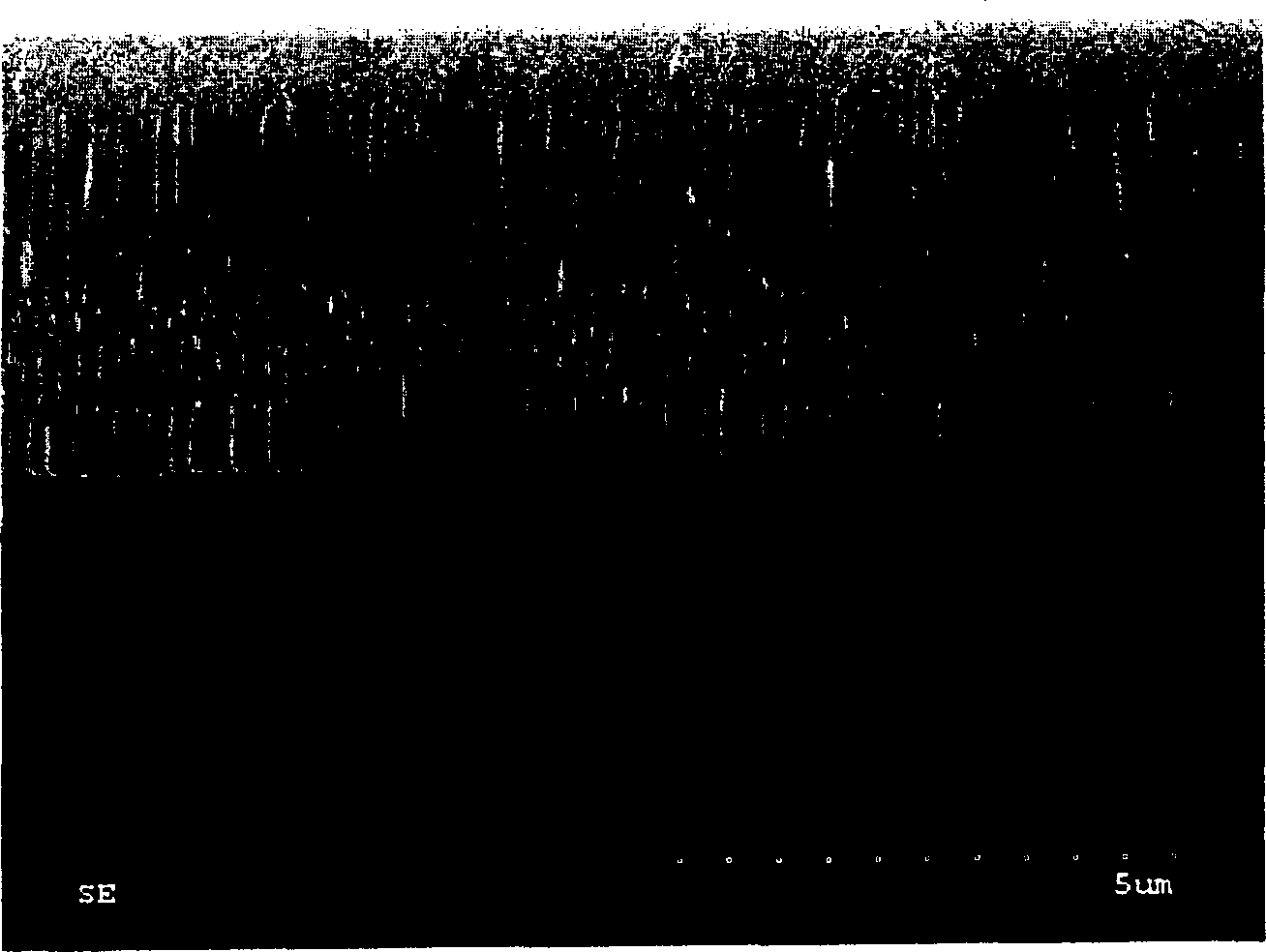

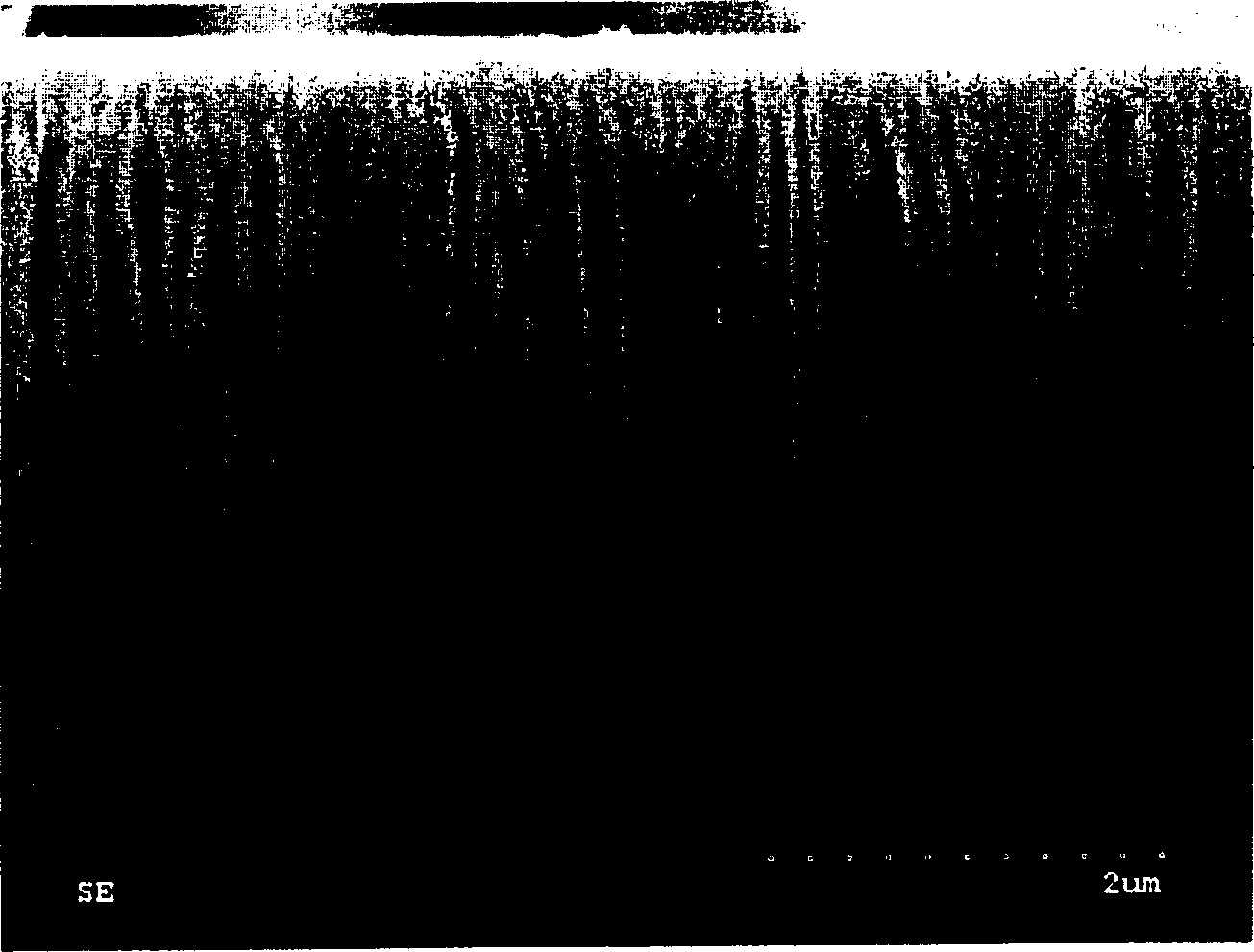

Porous indium phosphide barrier layer, corrosion liquid of porous indium phosphide and use method

This invention relate to a multi-hole indium phosphide barrier layer and its corrosive liquor and its using method. It includes the mixed liquor of hydrobromic acid, nitric acid and water. The weight amount is that hydrobromic acid: 1-2, water 10-20. the procedures are that 1: a multi-hole indium phosphide material is selected, 2: the multi-hole indium phosphide material is soaked into the mixed liquor said in claim of right 1, 3: the barrier layer of the indium phosphide surface and part of the multi-hole indium phosphide layer is eroded, so the material is thinned.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Liquid crystal display panel processing method

ActiveCN108072989AImprove display qualityAvoid display unevennessNon-linear opticsLiquid-crystal displayColor film

The invention provides a liquid crystal display panel processing method. The method comprises the steps that a liquid display panel is provided, the liquid display panel comprises a thin film transistor array substrate, a color film substrate and a liquid crystal layer clamped between the thin film transistor array substrate and the color film substrate, and pits exist on surfaces, facing away from the liquid crystal layer, of the thin film transistor array substrate and the color film substrate; an organic silicon resin film layer or a silicon oxide film layer is formed respectively on the surfaces, facing away from the liquid crystal layer, of the thin film transistor array substrate and the color film substrate to fill the existed pits on the two substrates of the liquid crystal displaypanel to obtain a flattened liquid crystal display panel; thinning treatment is conducted on the flattened liquid crystal display panel. The existence of the organic silicon resin film layer or the silicon oxide film layer can fill the pits which might exist on the panel, and probability that the pits are deteriorated when the thinning treatment is conducted on the panel is reduced to improve display quality of the panel.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

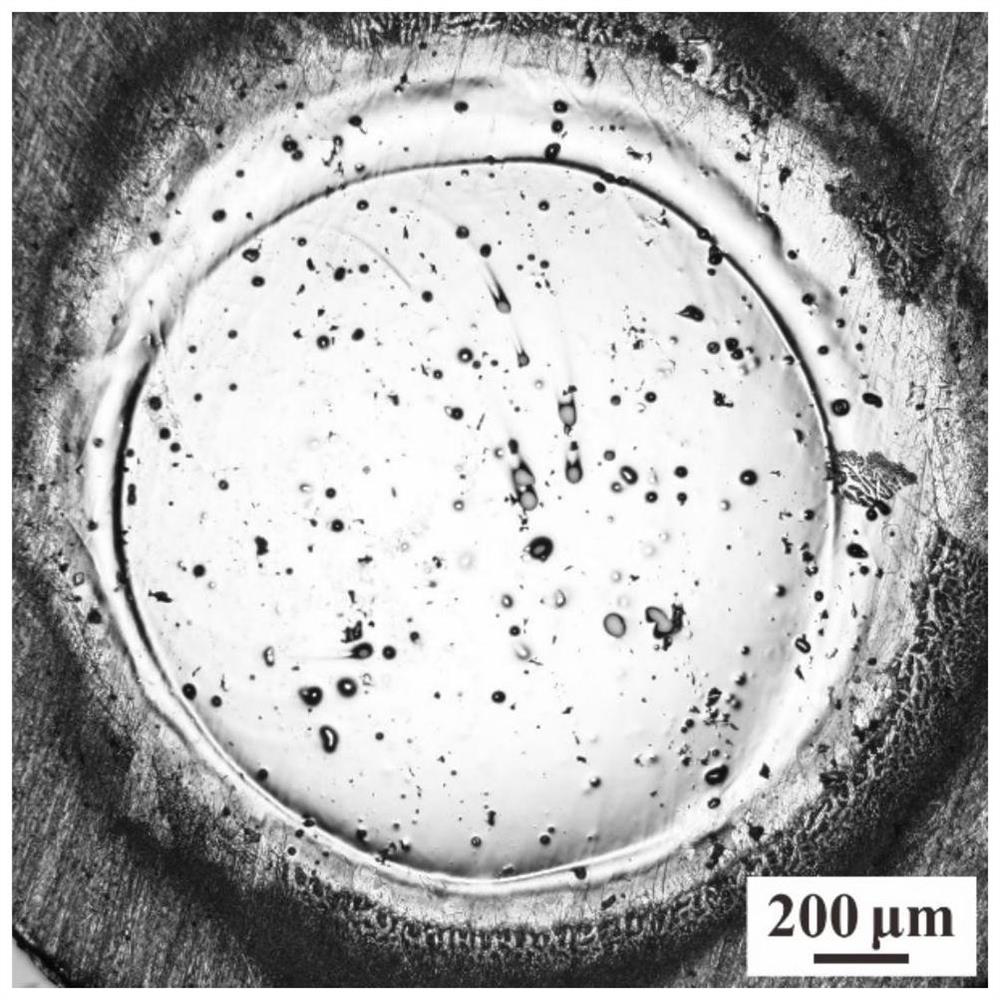

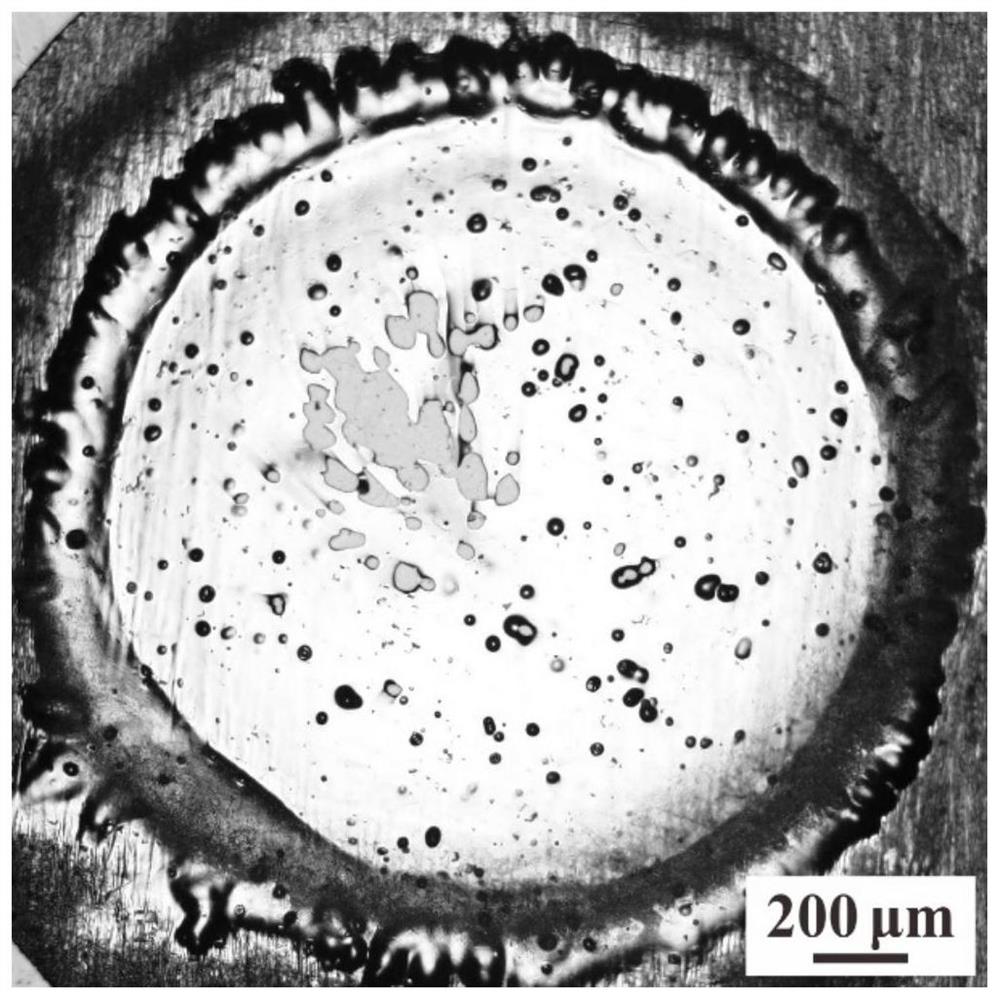

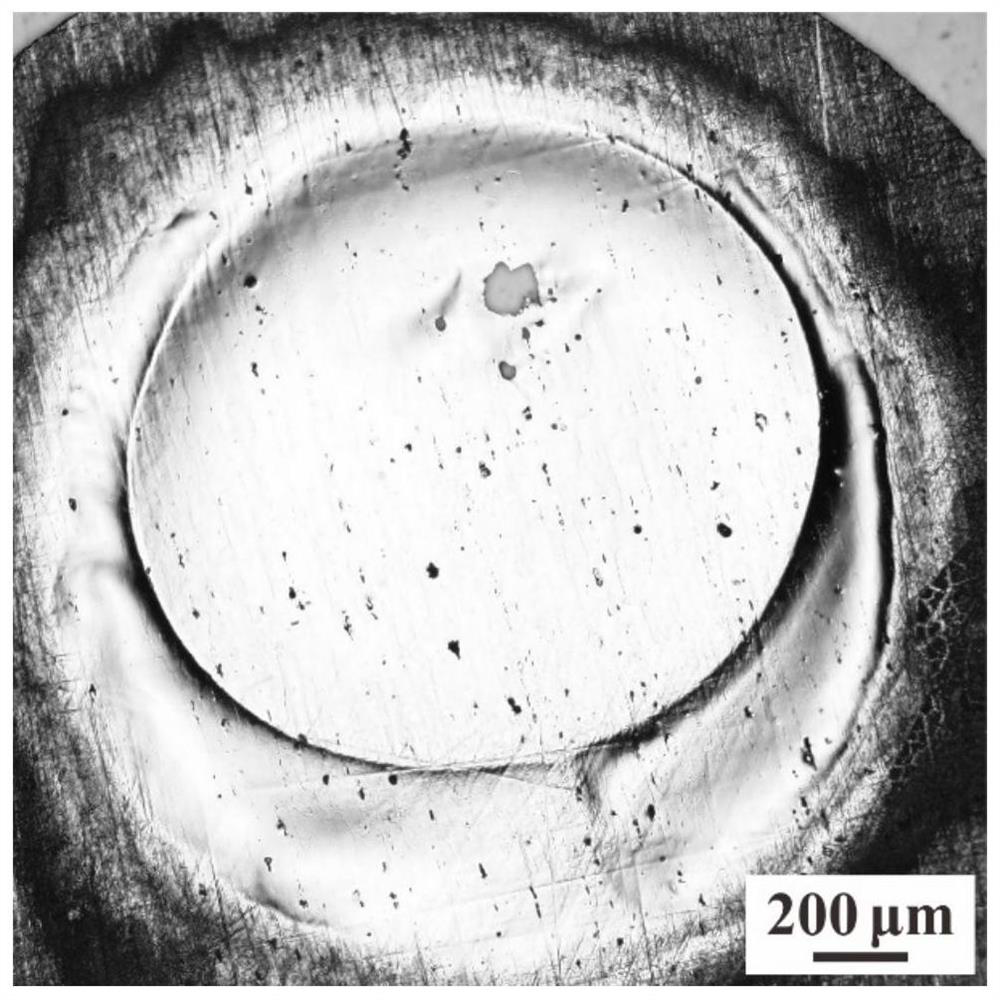

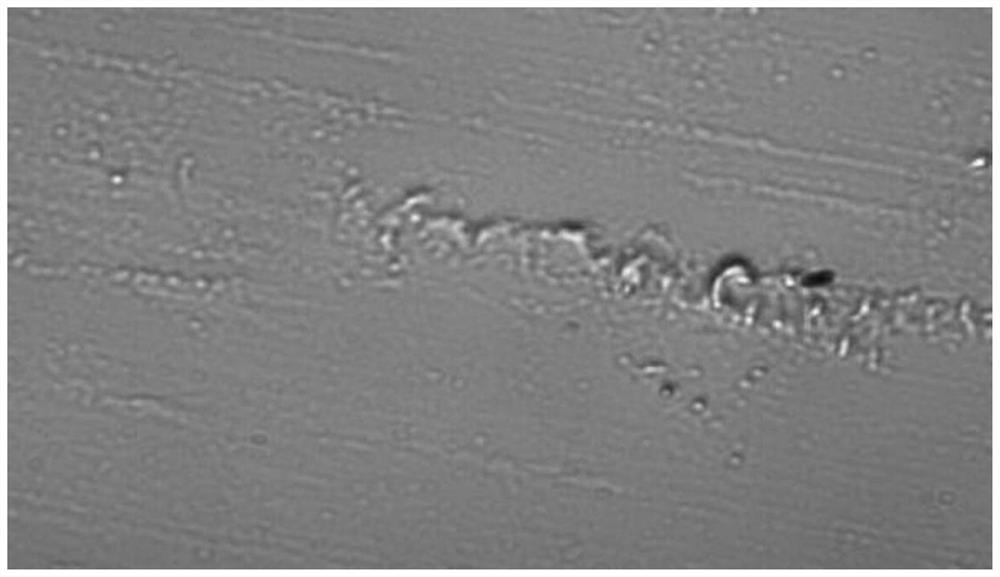

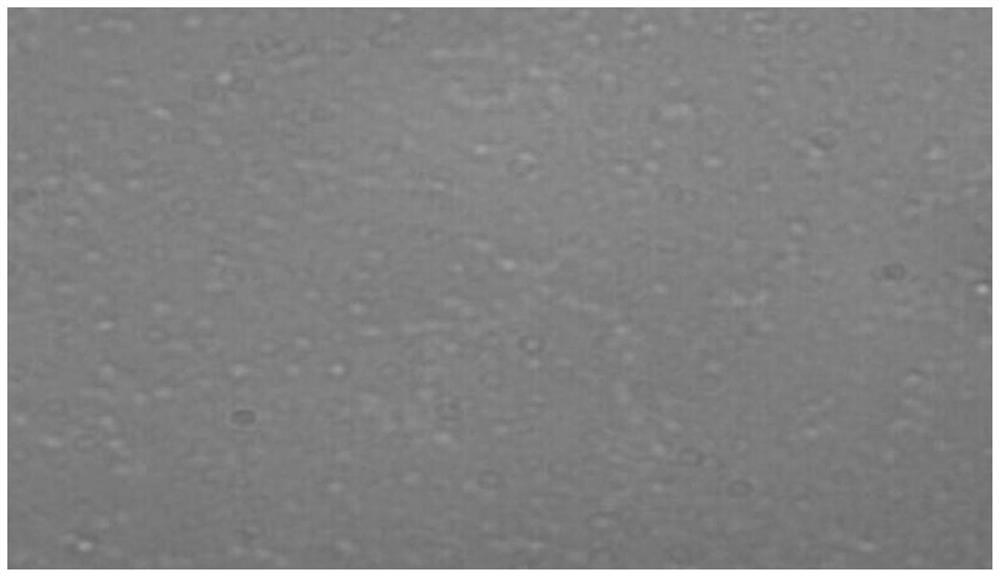

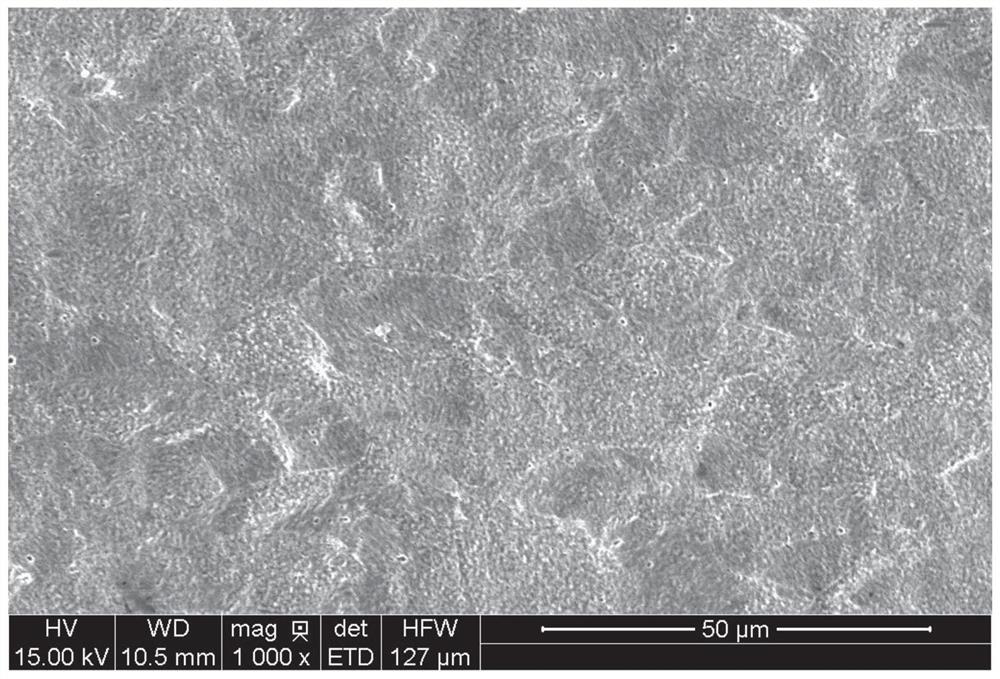

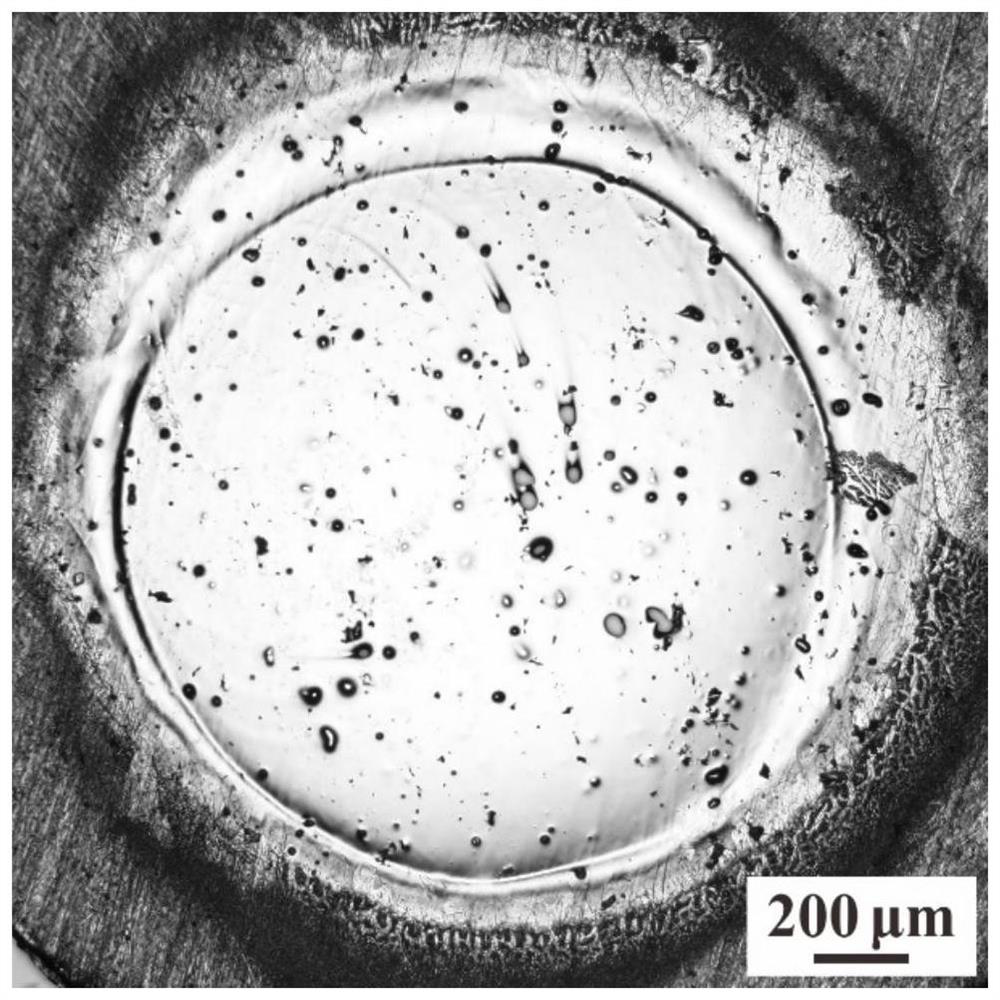

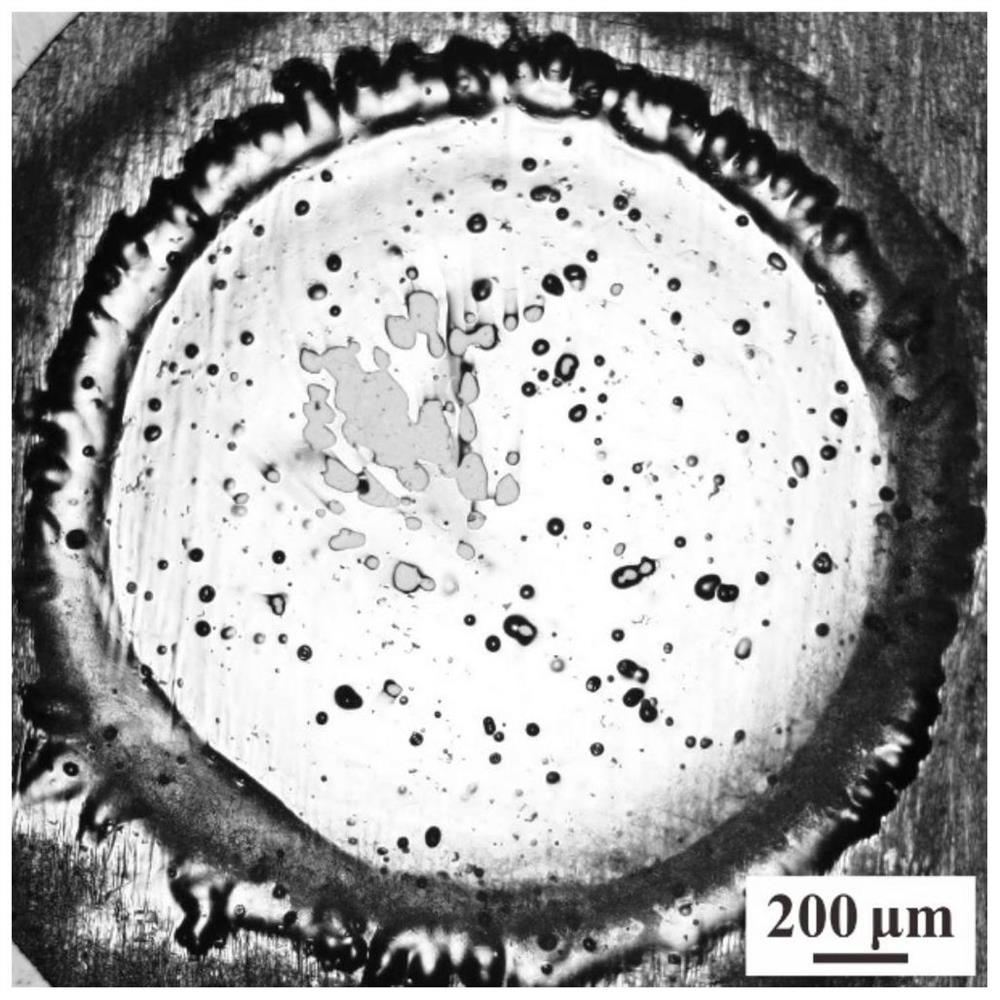

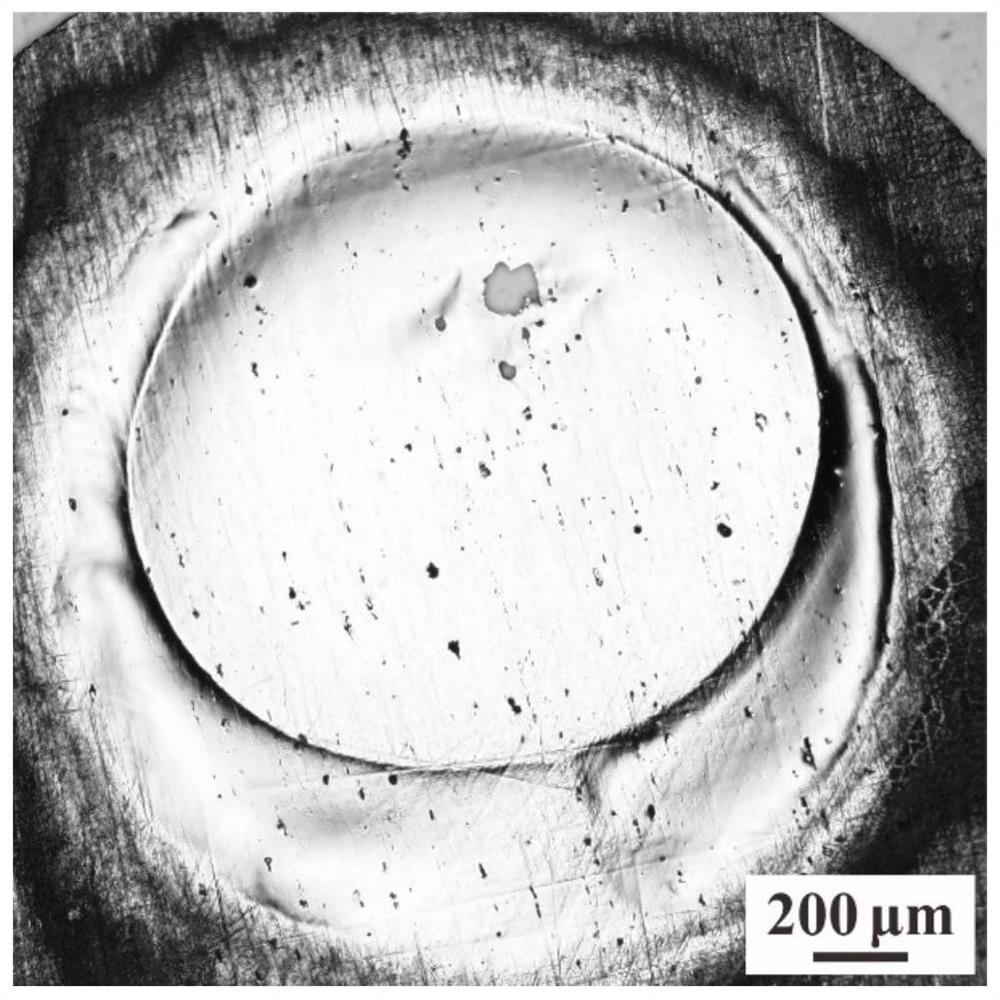

Preparation method of 2xxx series aluminum alloy transmission electron microscope sample

ActiveCN112595565AShort cycleQuality improvementMaterial analysis using wave/particle radiationPreparing sample for investigationElectrolysisPotential difference

The invention discloses a preparation method of a 2xxx series aluminum alloy transmission electron microscope sample, and belongs to the technical field of transmission electron microscope sample preparation. The method comprises the following steps: selecting a double-spraying liquid formed by mixing nitric acid and methanol with a certain concentration according to a volume ratio of 1:3, controlling the double-spraying voltage to be 18-22V and the double-spraying temperature to be 5-10 DEG C, and thinning a sample on a double-spraying electrolytic thinning instrument. Due to the selection ofproper double-spraying liquid, double-spraying voltage and double-spraying temperature, the surface of a sample is bright, the potential difference between a second phase and a base body is reduced,sieve pores are effectively avoided, uniform thinning is achieved, the thinning effect can be achieved within 10-20 s, the efficiency is greatly improved, no stress or heat is input in the thinning process, and the invention provides a rapid and reliable sample preparation method. By utilizing the method, the transmission sample without sieve pores and with a larger thin area can be conveniently and simply prepared, and the method has important reference significance for preparing the metal material transmission sample containing the thick second phase.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Repairing paste for slight scratches of optical glass

PendingCN111925126AEliminate the consequences of slight distortionUniform thinningOXALIC ACID DIHYDRATEAmmonium bifluoride

The invention relates to the field of optical glass repair, and particularly relates to repairing paste for slight scratches of optical glass. The repairing paste is prepared from the following components in parts by weight: 1.5 to 2.5 parts of ammonium bifluoride, 2 to 3 parts of water, 0.2 to 0.5 part of hydrofluoric acid, 0.5 to 1.5 parts of nitric acid, 0.5 to 1 part of phosphoric acid, 1 to 5parts of oxalic acid, 1.5 to 2.5 parts of monocalcium phosphate and 0.05 to 0.2 part of Arabic gum. The repairing paste provided by the invention can be widely applied to each production process of optical products, eliminates slight scratches in the production process of each process, and achieves the purpose of improving the yield of the optical products; the repairing paste product can realizerepairing work of slight scratches of the optical glass, has the advantages of simple process method, high repairing efficiency, low repairing cost and the like, and improves the product yield of theoptical glass in the production process.

Owner:ZHENGZHOU HIHO OPTICAL TECH CO LTD

High melt strength styrenic resin composition and preparation method thereof

The invention provides a high-melt-strength styrenic resin composition, which comprises the following components proportioned in certain parts by weight: styrenic resin or styrenic alloy, tackifier, antioxidant, lubricating agent agent. Compared with the prior art, the present invention has the following beneficial effects: 1, as the random copolymer of tackifier in the present invention, has thermodynamic compatibility with styrene resin and its alloy, phase separation does not take place, mechanical Excellent performance; 2. The molecular weight of the random copolymer used as a tackifier in the present invention is moderate, and it is easier to plasticize than resins such as rubber powder, high molecular weight SAN powder, heat-resistant powder, etc., so it has better processability, thickness Uniform, low shrinkage, not easy to produce surface defects.

Owner:FINE BLEND POLYMER SHANGHAI CO LTD

OLED panel thinning device, thinning system and thinning method

InactiveCN103456766BUniform thinningTo achieve the purpose of thinningSolid-state devicesSemiconductor/solid-state device manufacturingCentrifugal forceThinning

The invention discloses an organic light emitting diode (OLED) panel thinning device, system and method. The OLED panel thinning device mainly comprises a rotary machine frame, a fluid guide tube and a rotary machine frame cavity, wherein the rotary machine frame is fixedly installed in the rotary machine frame cavity, and a port of the fluid guide tube is located right above the central position of the rotary machine frame. A principle is that etching liquid evenly diffuses from the center of an OLED panel to the outside by utilizing centrifugal force produced by the rotary machine frame in rotation, and then etching and thinning of the OLED panel are achieved. The invention further discloses the OLED panel thinning method based on the OLED panel thinning device. The OLED panel thinning device and method overcomes the shortcoming that the etching liquid for immersion-type thinning is polluted and accordingly the thinning quality is reduced, and meanwhile overcomes the problem that concave spots are easily formed and the etching thickness is uneven and the like in the spraying-type thinning.

Owner:SICHUAN CCO DISPLAY TECH

Method for manufacturing aluminum wiring

ActiveCN101740469BMake up for unetched etch defectsUniform thinningSemiconductor/solid-state device manufacturingDevice materialWiring diagram

The invention relates to a method for manufacturing aluminum wiring, comprising the following steps of: executing a first etching process on aluminum wiring, wherein the first etching process is a reactive ion etching process without applying bias voltage; after the first etching process is executed, executing a second etching process on the aluminum wiring to form an aluminum wiring diagram, wherein the second etching process is a reactive ion etching process applying the bias voltage. The method for manufacturing aluminum wiring remedies the etching defect that the aluminum wiring is not etched through due to the etch rate difference when the aluminum wiring diagram is formed by etching, thereby avoiding the influence on the quality of finally formed semiconductor devices due to the etching defect.

Owner:SEMICON MFG INT (SHANGHAI) CORP

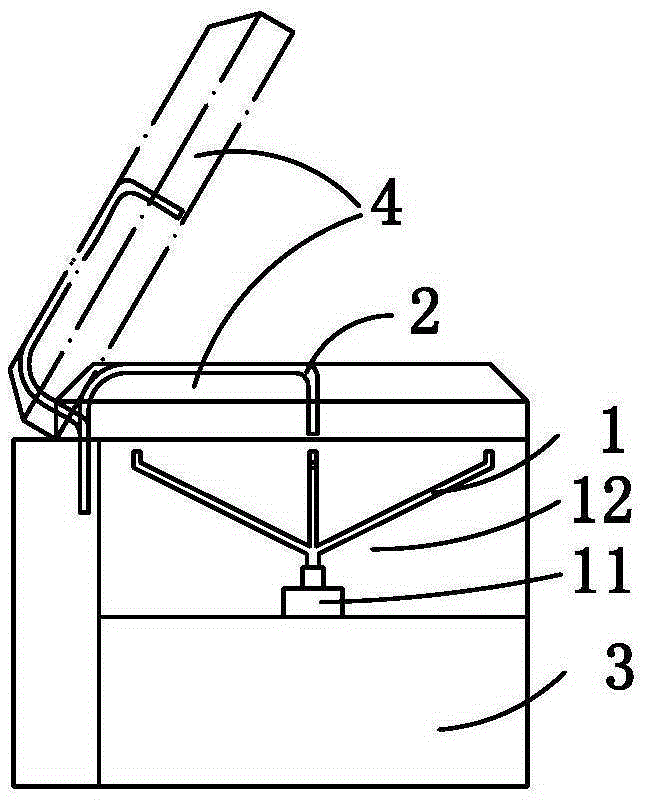

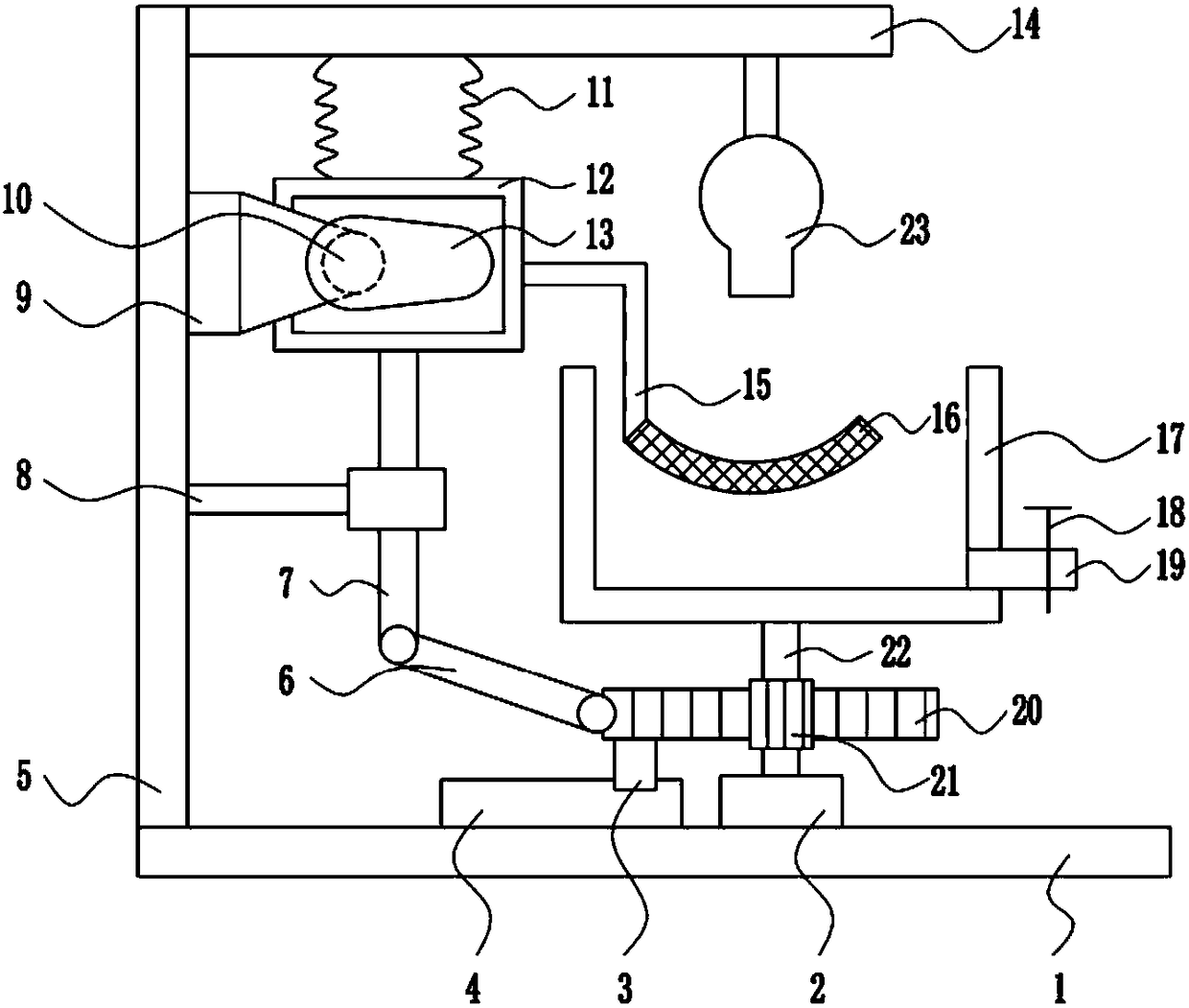

A silicon wafer thinning equipment for monocrystalline silicon cell production process

ActiveCN106783670BFast thinningEasy to operateFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringThinning

The invention belongs to the technical field of monocrystalline silicon cell production, and especially relates to silicon chip thinning equipment for the monocrystalline silicon cell production technology. A to-be-solved technical problem is to provide the silicon chip thinning equipment which is high in thinning speed, is simple in operation and is uniform in reduced thickness. In order to solve the above problem, the invention provides the silicon chip thinning equipment, and the silicon chip thinning equipment comprises a first rotating shaft, a worm gear, a flat belt, a second rotating shaft, a first bearing seat, a big belt pulley, a gear, a first installation seat, a rack, a sliding block, a sliding rail, and a right frame. The right end of the top of the bottom plate is provided with the right frame through welding, and the upper part of the left side of the right frame is connected with a sliding rail in a mode of bolt connection. The equipment is quick in thinning speed, is simple in operation, is uniform in thinning thickness, plays an important role in thinning, also improves the work efficiency, and is high in safety.

Owner:ANHUI FENGYANG COUNTY QIANLI GLASSWORK CO LTD

Meteorologic balloon and production method thereof

ActiveCN101526630BGood anti-aging performanceImprove uniformityBalloon aircraftsHollow articlesMedicineSulfur

The invention relates to a meteorological balloon and a production method thereof. The meteorological balloon has the quality of 700g to 800g, the length of a balloon body is 205 cm to 255 cm, and a balloon handle has a width of 9 cm to 10 cm and a length of 10 cm to 14 cm. The meteorological balloon comprises a solid raw material, an oil raw material and a colloid raw material, wherein the solid raw material comprises the ingredients by weight ratio: 100 parts of centrifugal concentrated natural latex, 0 part to 0.30 part of potassium hydroxide, 0 part to 0.15 part of casein, 0 part to 0.10 part of leveling agent O, 1.00 part to 3 parts of sulfur, 1.00 part to 2 parts of antioxidant D, 1.00 part to 2 parts of 4010NA, 1.50 parts to 3 parts of rubber accelerator PX and 0.20 part to 5 parts of zinc oxide; the oil raw material comprises 7.00 parts to 10.0 parts of mechanical oil by weight ratio; and the colloid raw material comprises neoprene latex which is added by the mixed weight ratio of the mixture of the solid raw material and the oil raw material to the neoprene latex, namely 1 to 10. The neoprene latex is added in a raw material formulation so as to improve the anti-aging performance and the whole processing performance of the meteorological balloon, ensure the streamlined appearance of the meteorological balloon, improve the evenness degree of a balloon surface and enable the balloon surface to swell evenly in the discharge process.

Owner:CHEMCHINA ZHUZHOU RUBBER RES & DESIGN INST

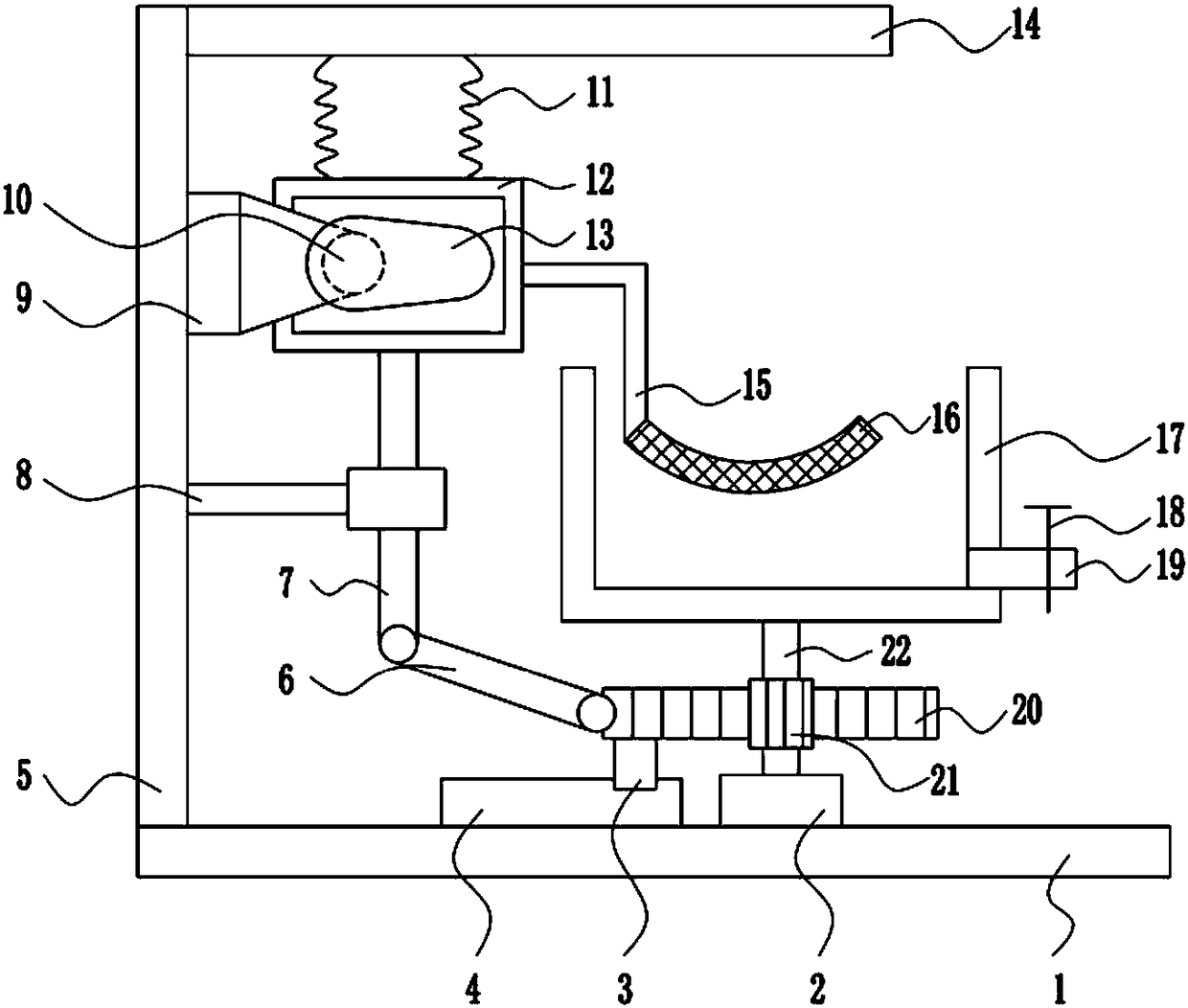

A device for rapid thinning of silicon wafers for solar cell production process

ActiveCN106191863BFast thinningEasy to operatePolycrystalline material growthAfter-treatment detailsEngineeringWafer thinning

The invention relates to a silicon wafer thinning device, in particular to a rapid silicon wafer thinning device for a solar cell production technology, and aims to provide a rapid silicon wafer thinning device which is used for the solar cell production technology and is high in thinning speed, simple to operate and uniform in thinning thickness. The rapid silicon wafer thinning device comprises a bottom plate, a bearing block, a sliding block, a sliding rail, a left frame, a swing rod, a lifting rod, a guiding sleeve, a mounting seat, a motor, springs, a moving frame, a cam, a top plate, an L-shaped connecting rod, an arc-shaped net plate, a processing frame, an electric control valve, a liquid outlet pipe, a rack, a gear and a rotating shaft, wherein the left frame, the sliding rail and the bearing block are arranged at the top of the bottom plate sequentially from left to right; the sliding block is glidingly connected onto the sliding rail; and the rack is arranged on the sliding block. The device has the effects of being high in thinning speed, simple to operate and uniform in thinning thickness.

Owner:江西宇泰新能源有限公司

Semiconductor device with multi-staged cut side surfaces

InactiveUS7180194B2Uniform thinningGrind evenlySemiconductor/solid-state device detailsSolid-state devicesWaferingDevice material

Owner:TAIWAN SEMICON MFG CO LTD

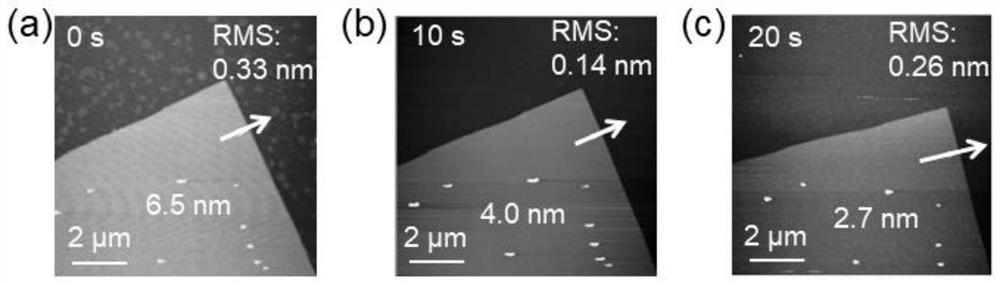

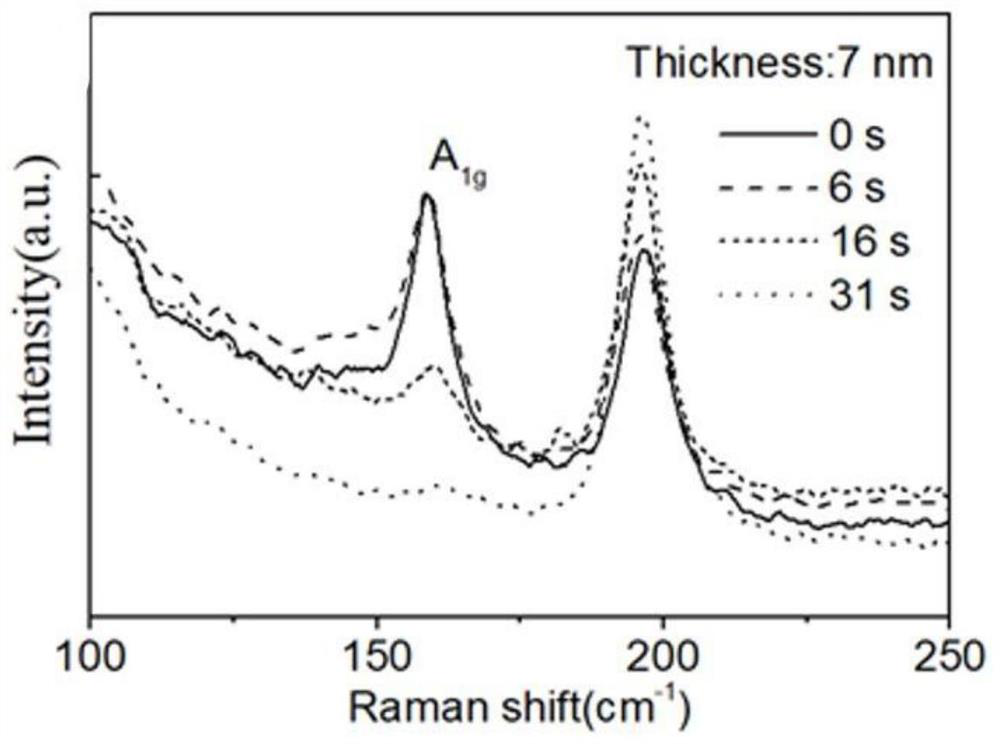

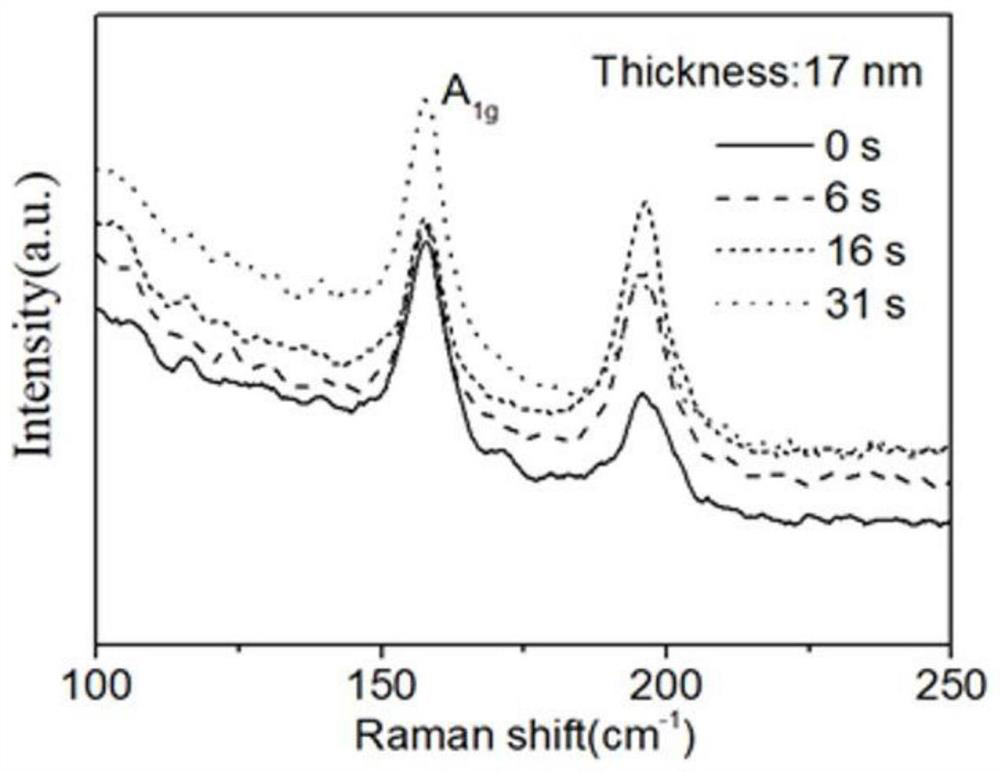

Method for regulating and controlling thickness of two-dimensional Bi2O2Se thin film

PendingCN113690145AEasy to operateGood repeatabilitySemiconductor/solid-state device manufacturingSemiconductor devicesRadio frequencyThin membrane

The invention discloses a method for regulating and controlling the thickness of a two-dimensional Bi2O2Se thin film. The method comprises the following steps that the two-dimensional Bi2O2Se thin film with a first thickness is prepared on a first substrate through a chemical vapor deposition method; the thickness of the two-dimensional Bi2O2Se thin film is regulated and controlled to be a second thickness through a plasma etching process, the vacuum degree of etching equipment of the plasma etching process is 6.4*10<-4> Pa, the radio frequency power is 120 W, the current of a neutralizer is 500 mA, the current range of an ion beam is 80 mA to 100 mA, the voltage of the ion beam is 200 V to 280 V, the Ar flow is 10 sccm, the O2 flow is 6 sccm, and the etching time is 6-20 seconds. The method is simple to operate and good in repeatability, and realizes uniform thinning of the two-dimensional Bi2O2Se thin film material.

Owner:NANJING UNIV OF SCI & TECH

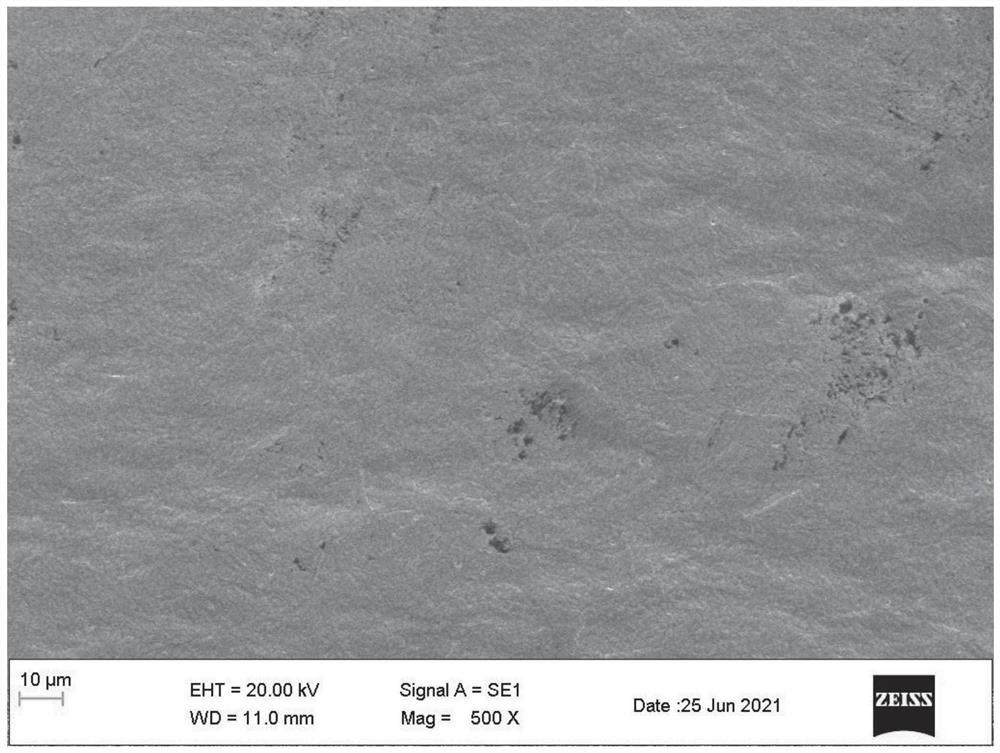

Method for thinning FeNi alloy foil tape through chemical etching

The invention discloses a method for thinning a FeNi alloy foil tape through chemical etching. The method comprises the following steps of: pretreating a FeNi alloy thin plate, uniformly spraying an etching solution on the FeNi alloy thin plate to etch and thin the FeNi alloy thin plate to form an FeNi alloy foil tape, and post-treating the FeNi alloy foil tape, wherein the etching solution is prepared from FeCl3, HCl and water. The method is simple and easy to operate, the thickness of the FeNi alloy thin plate can be further rapidly and uniformly reduced, a rolled hardened layer on the surface of the FeNi alloy thin plate can be further removed, and the internal plastic strain and residual stress of the FeNi alloy thin plate can be reduced, so that deformation during etching and material reduction is inhibited, the flexibility of the FeNi alloy foil tape is effectively improved, the yield of mask manufacturing is remarkably improved, and post-treatment does not need. The method is suitable for FeNi alloy thin plates with various components, sizes and thicknesses, and the obtained FeNi alloy foil strip is uniform in thickness and low in surface roughness.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

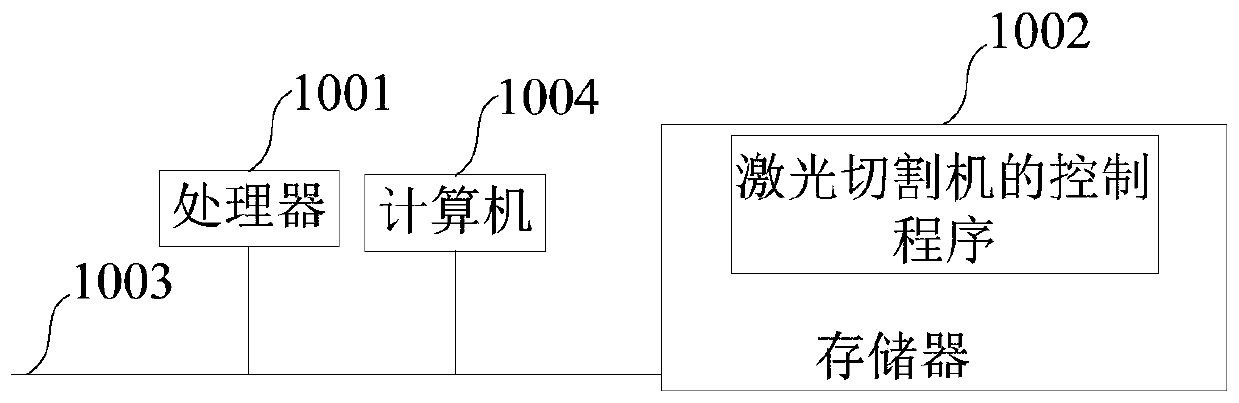

Laser thinning method and laser machine

ActiveCN110238544BUniform thinningConsistent cutting volumeLaser beam welding apparatusMechanical engineeringLaser

The invention discloses a laser thinning method. The laser thinning method comprises the following steps: fixing the workpiece to be processed; controlling the laser to irradiate the surface of the workpiece to be processed; The moving speed on the surface of the workpiece relative to the surface of the workpiece to be processed determines the thinning operation parameters of the workpiece to be processed; according to the thinning operation parameters, the laser is controlled to move on the surface of the workpiece to be processed to complete the workpiece to be processed. Thinning operations for machining workpieces. The invention also discloses a laser machine. The invention ensures that the surface smoothness of the workpiece to be processed is better after the thinning process.

Owner:SHENZHEN H TECH CO LTD

Rewritable film resistive memory unit using flexible paper base and preparation method thereof

InactiveCN103247758BImprove controllabilityIncrease deposition rateElectrical apparatusStatic random-access memoryColor printing

The invention belongs to the technical field of nonvolatile memory devices, and particularly relates to an erasable film RRAM (resistive random access memory) memory unit. The memory unit is characterized in that a piece of flexible and bendable printing ink color printing paper is used as a substrate, a tin oxide film is used as a variable-resistance layer, and a molybdenum oxide film is used as an oxygen storage layer; and a specific structure comprises the printing ink color printing paper substrate, a metallic nickel film serving as a bottom electrode, the tin oxide film, the molybdenum oxide film and a metallic molybdenum film serving as a top electrode in sequence. According to the invention, a direct current magnetron sputtering technology is used at the low temperature (subzero 100 DEG C), and the metallic nickel film, the tin oxide film, the molybdenum oxide film and the metallic molybdenum film are prepared on the substrate sequentially. The variable-resistance memory unit prepared by the invention has the characteristics of good bending durability and the like, and has a wide application prospect in the fields of nonvolatile memory and flexible electron devices.

Owner:FUDAN UNIV

A kind of preparation method of 2xxx series aluminum alloy transmission electron microscope sample

ActiveCN112595565BShort cycleQuality improvementMaterial analysis using wave/particle radiationPreparing sample for investigationElectrolysisPotential difference

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A method and device for uniformly thinning a large-scale irregular busbar-shaped surface shell

ActiveCN112589133BUniform thinningThinning meetMeasurement/indication equipmentsLarge fixed membersNumerical controlEngineering

The invention discloses a method and a device for uniformly thinning a large-scale irregular busbar-shaped shell. The invention completes a certain aluminum alloy dry cutting process by generating a programmable uniform thinning model, combining with the change rule of the curvature of the blank, and using the segmented and layered turning methods; design and directly add a set of shell blanks on the numerical control equipment The uniform thinning processing device system can meet the uniform thinning processing of blanks in forming methods such as spinning / casting, meet the requirements of segmented and layered turning processes, meet the requirements of large-end rigid clamping processes, and solve the problem of spindle runout during turning. The resulting errors can be compensated for precision, and the parts can be uniformly thinned. It can replace the problems of low efficiency and heavy pollution such as the use of chemical milling after the parts are spinned to remove heat treatment deformation, and meet the weight and precision requirements.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

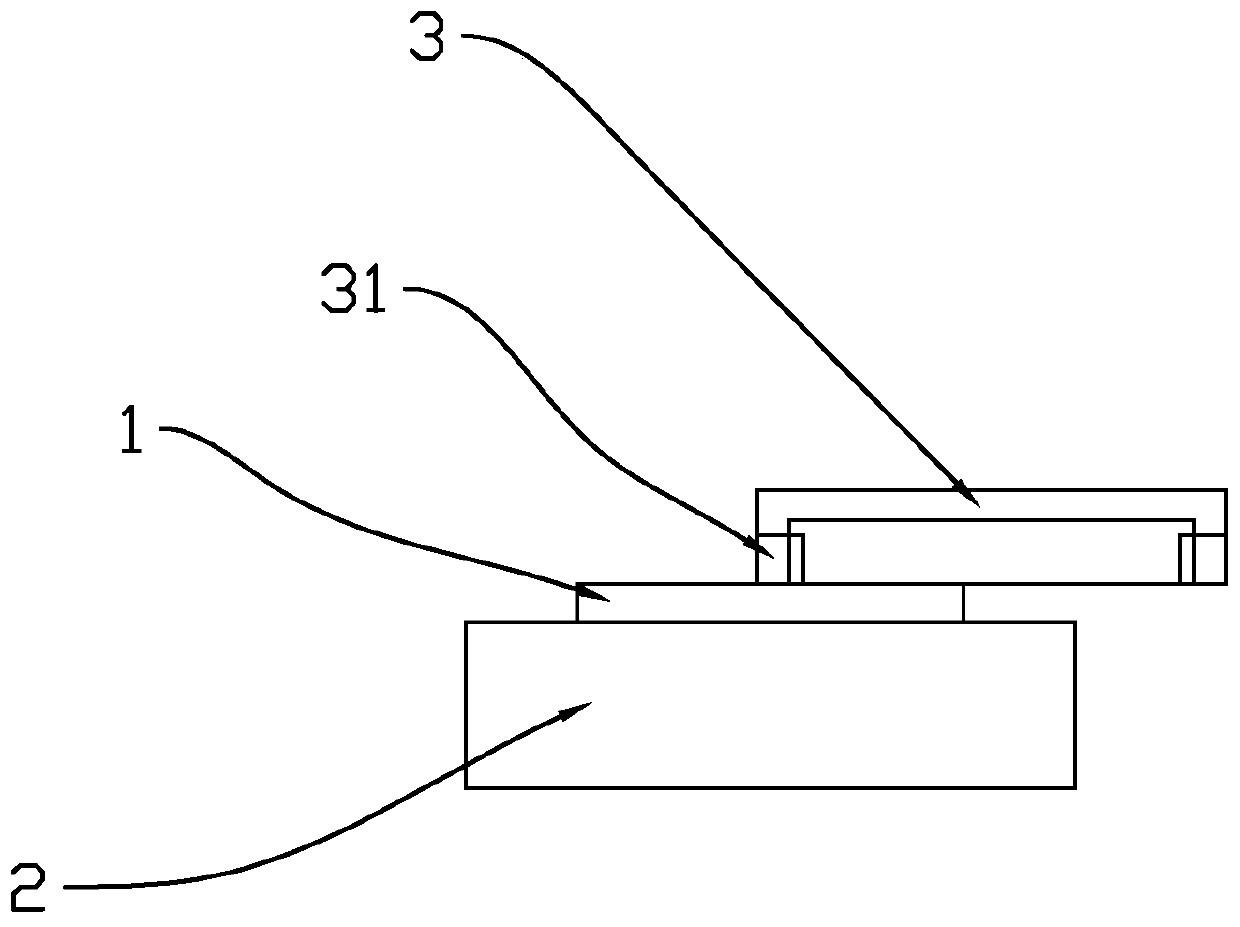

Fuel cell metal polar plate lubricating and stamping method and polar plate workpiece

PendingCN114472724AGuaranteed lubrication effectReduce stress concentrationShaping toolsCollectors/separatorsFuel cellsThin membrane

The invention provides a fuel cell metal polar plate lubricating and stamping method and a polar plate workpiece, and relates to the field of stamping methods.The surface of a plate is coated with a lubricant, and the coating position is covered with a film; the thin film and the plate are fixed along the edge, and the thin film and the plate are punched together; the film is attached to the plate and deforms together with the plate under the action of the mold, so that the plate forms a characteristic structure; in order to solve the problem of insufficient forming precision caused by poor lubricating effect during plate stamping forming at present, the plate surface is coated with a lubricant and then covered with a deformable thin film, the thin film is attached to the plate through the lubricant, distribution of the lubricant can be kept in the extrusion process, meanwhile, the thin film can also achieve a solid lubricating effect, and the forming precision is improved. Therefore, the lubricating effect of the die on all positions during plate stamping is guaranteed, stress concentration is reduced, and the forming precision is improved.

Owner:SHANDONG UNIV

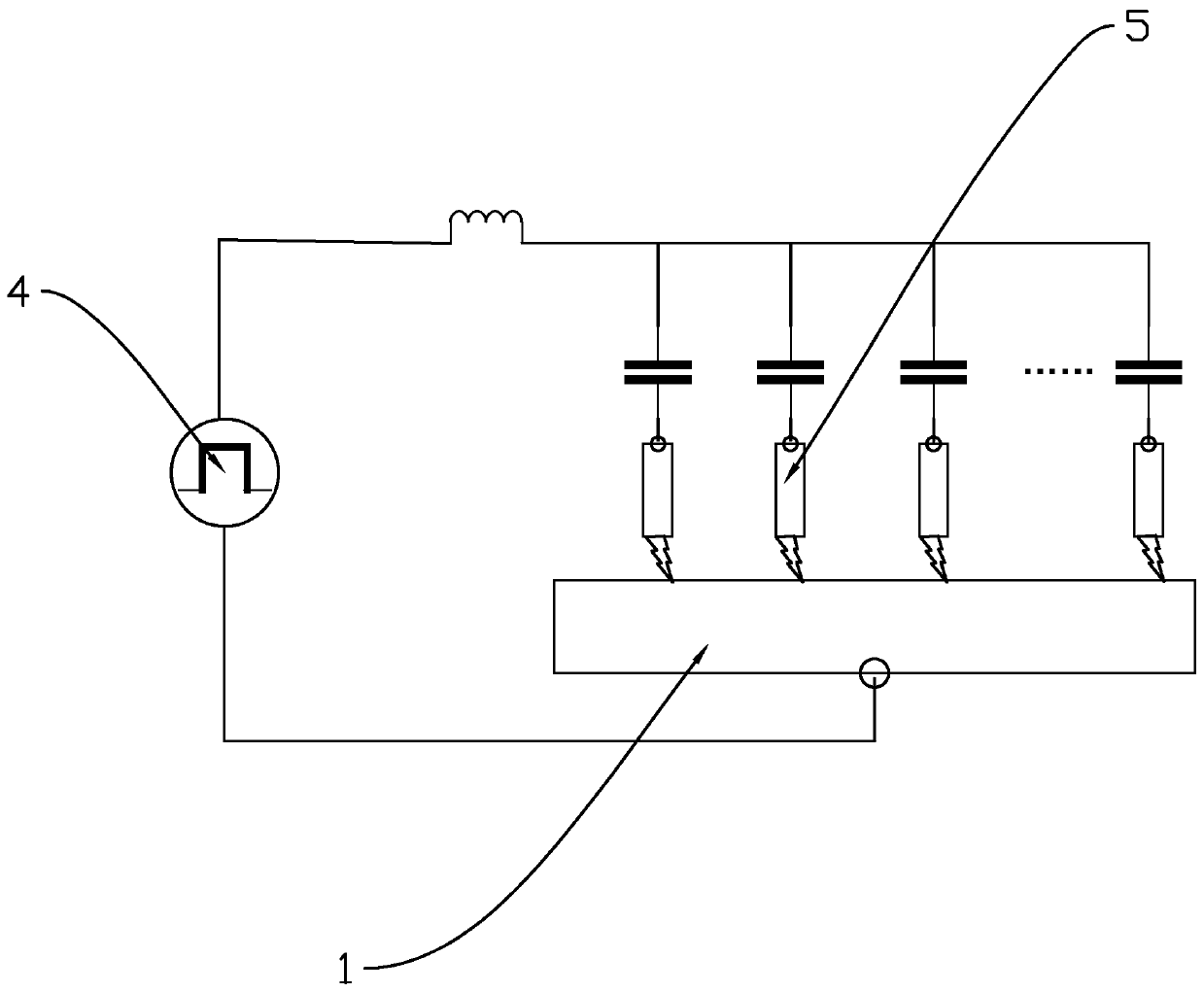

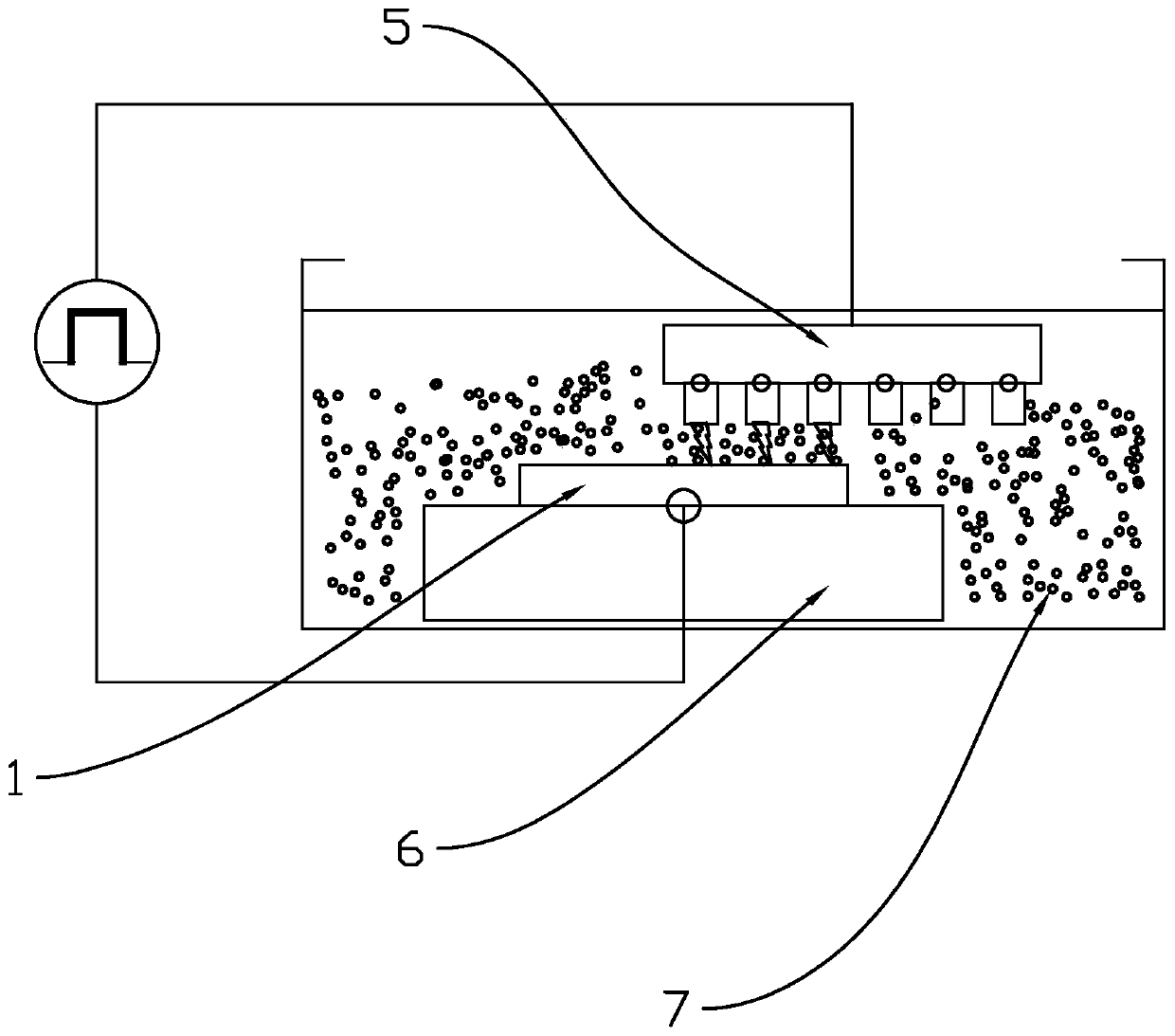

Wafer thinning device

PendingCN111300671ANo contact forceUniform thinningSemiconductor/solid-state device manufacturingFine working devicesElectrical connectionWafer thinning

The invention relates to the technical field of wafer thickness reduction and discloses a wafer thinning device. The wafer thinning device comprises a power supply and a tool electrode. One pole of the power supply is electrically connected with the tool electrode. The other pole of the power supply can be electrically connected with a wafer to be processed. The tool electrode is provided with a plurality of discharge terminals. Through the electric spark machining principle, the tool electrode and the wafer are connected with the two poles of the power supply correspondingly, and the space between the tool electrode and the wafer is broken down through voltage to form a discharge channel between the tool electrode and the wafer, and then the surface of the wafer at the discharge channel is thinned. The whole process belongs to non-contact type machining. No contact acting force exists between the tool electrode and the wafer. Thus, the wafer has no risk of breakage caused by excess contact force.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Liquid crystal display panel processing method

ActiveCN108072989BImprove display qualityAvoid display unevennessNon-linear opticsLiquid-crystal displayColor film

The invention provides a liquid crystal display panel processing method. The method comprises the steps that a liquid display panel is provided, the liquid display panel comprises a thin film transistor array substrate, a color film substrate and a liquid crystal layer clamped between the thin film transistor array substrate and the color film substrate, and pits exist on surfaces, facing away from the liquid crystal layer, of the thin film transistor array substrate and the color film substrate; an organic silicon resin film layer or a silicon oxide film layer is formed respectively on the surfaces, facing away from the liquid crystal layer, of the thin film transistor array substrate and the color film substrate to fill the existed pits on the two substrates of the liquid crystal displaypanel to obtain a flattened liquid crystal display panel; thinning treatment is conducted on the flattened liquid crystal display panel. The existence of the organic silicon resin film layer or the silicon oxide film layer can fill the pits which might exist on the panel, and probability that the pits are deteriorated when the thinning treatment is conducted on the panel is reduced to improve display quality of the panel.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com