A kind of preparation method of 2xxx series aluminum alloy transmission electron microscope sample

A technology for transmission electron microscope samples and aluminum alloys, which is applied in the preparation of test samples, sampling, and material analysis using wave/particle radiation. It can solve problems such as poor quality and long sample cycle, and achieve high thinning rate and improved The effect of large quality and thin area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

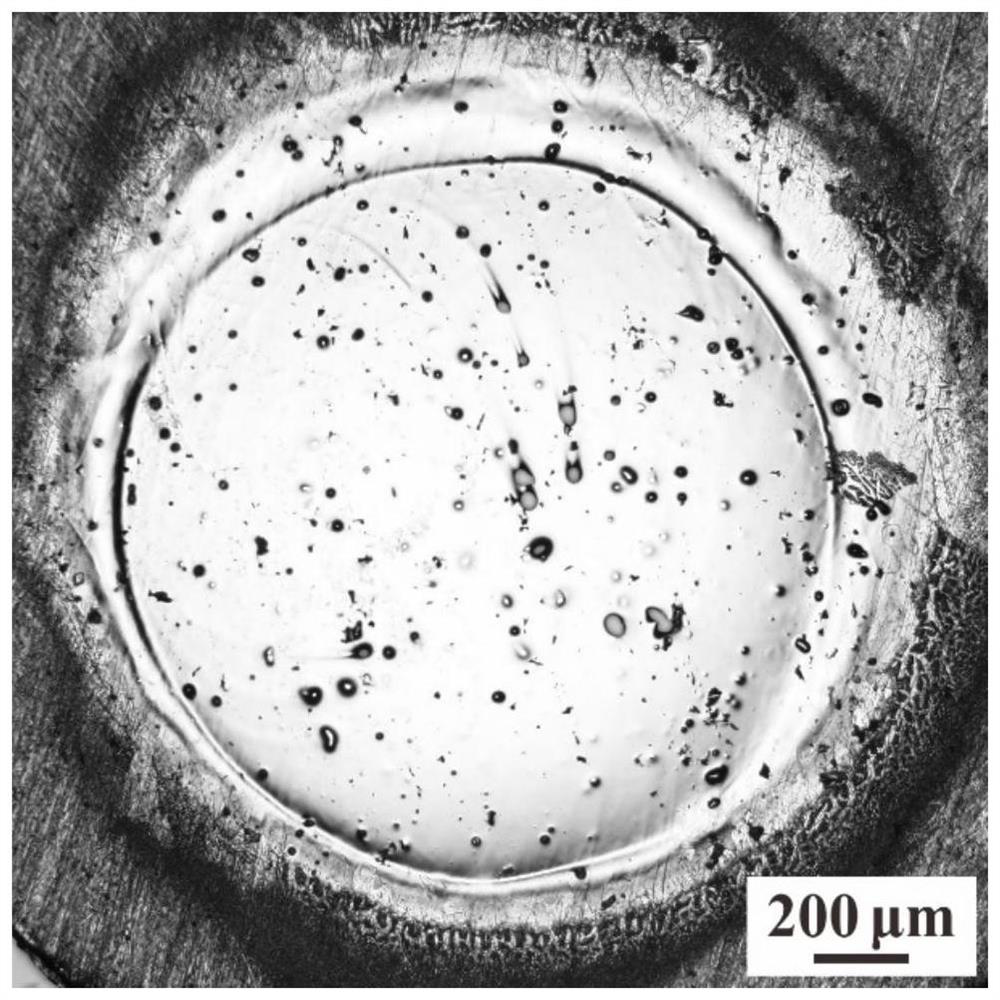

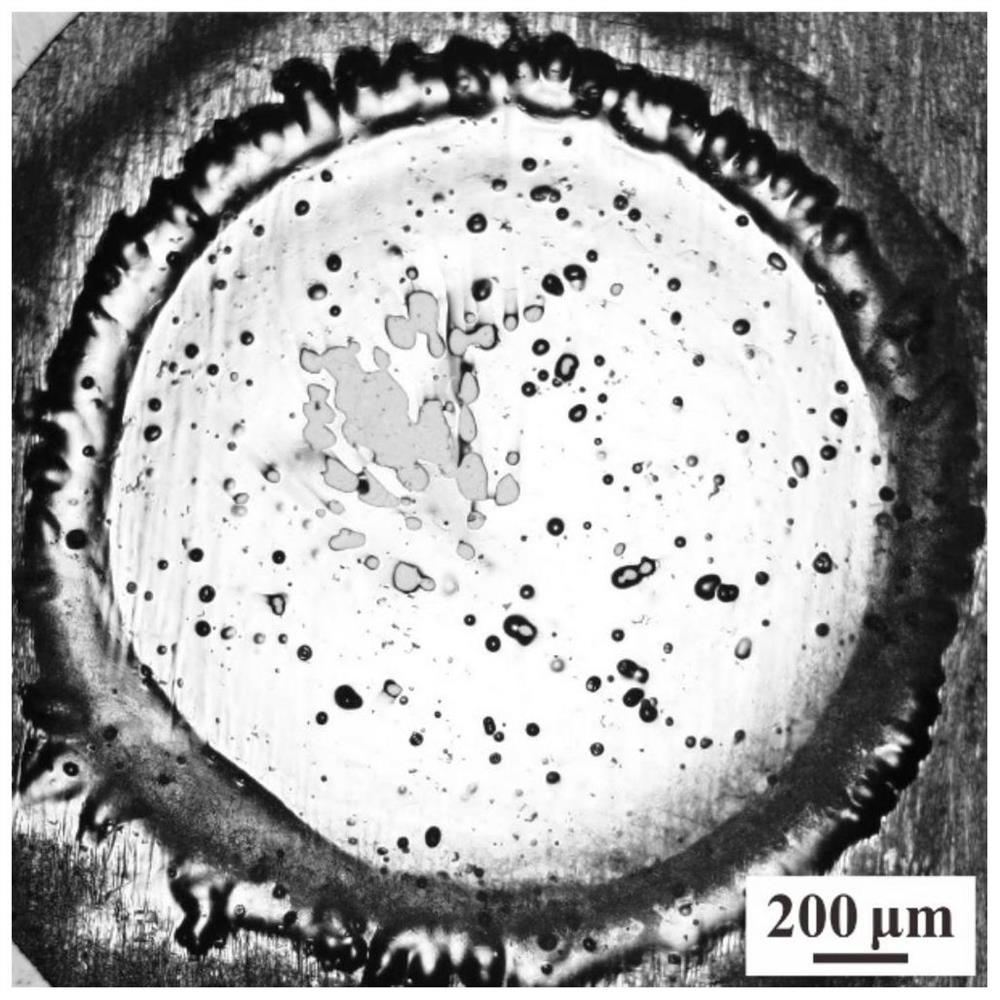

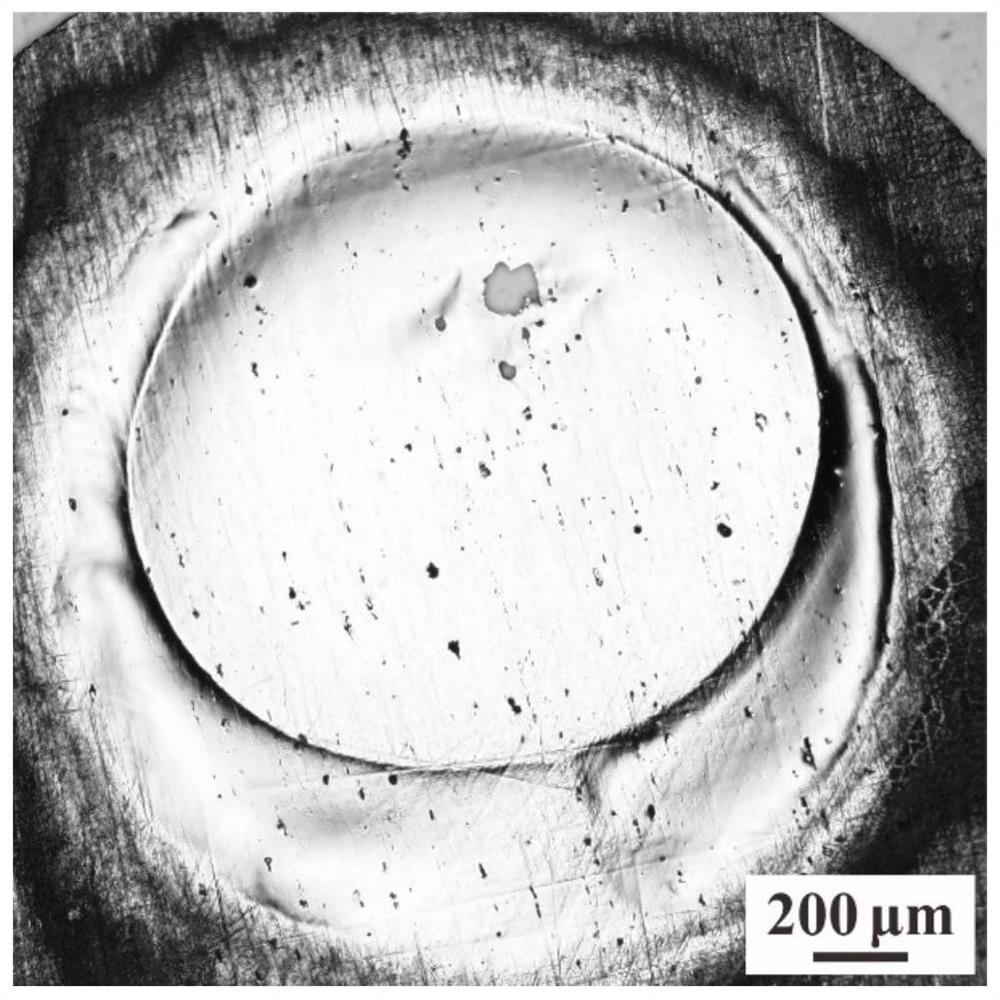

[0030] The present invention will be described in more detail below with reference to the embodiments. In this example, a sample of 2024 aluminum alloy over-aged at 180°C for 120h is used as an example to prepare a transmission sample. The specific steps are as follows:

[0031] Step 1: Use an EDM wire cutting machine to cut a metal sheet with a thickness of 500um from the block sample, and then use 400#, 800#, 1200#, 2000# sandpaper to mechanically thin the sample to a thickness of 40um ~ 50um, In the process of sample grinding, place a smooth and flat glass plate under the sandpaper and use a rubber to drag the sample to grind on the sandpaper with an "8"-shaped trajectory. metal disc;

[0032] Step 2: In this example, the TenuPol-5 electrolytic double-spraying apparatus of Struers Company is used to carry out the double-spraying experiment. In the electrolytic cell of the double jet thinning apparatus, a double jet liquid is formed by mixing nitric acid with a concentrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com