Method for thinning FeNi alloy foil tape through chemical etching

A technology of chemical etching and alloy foil, which is applied in the field of non-ferrous metal foil processing, and can solve problems such as affecting etching processing, forming streaks on the surface of thin plates, and easy deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 A method of chemically etching thinned FeNi alloy foil strips provided in this embodiment includes:

[0033] The FeNi alloy sheet with a thickness of 100 μm is alkaline washed for 5 minutes with KOH aqueous solution with a concentration of about 0.5mol / L, and then dried with hot air at about 40°C;

[0034] Spray the FeNi alloy thin plate evenly with an etching solution at a temperature of 30°C. The etching solution contains a HCl concentration of 10mol / L and a FeCl concentration of 30g / L. 3 and the rest of the water, the spray pressure is 0.2MPa, and the spray time is 20 minutes;

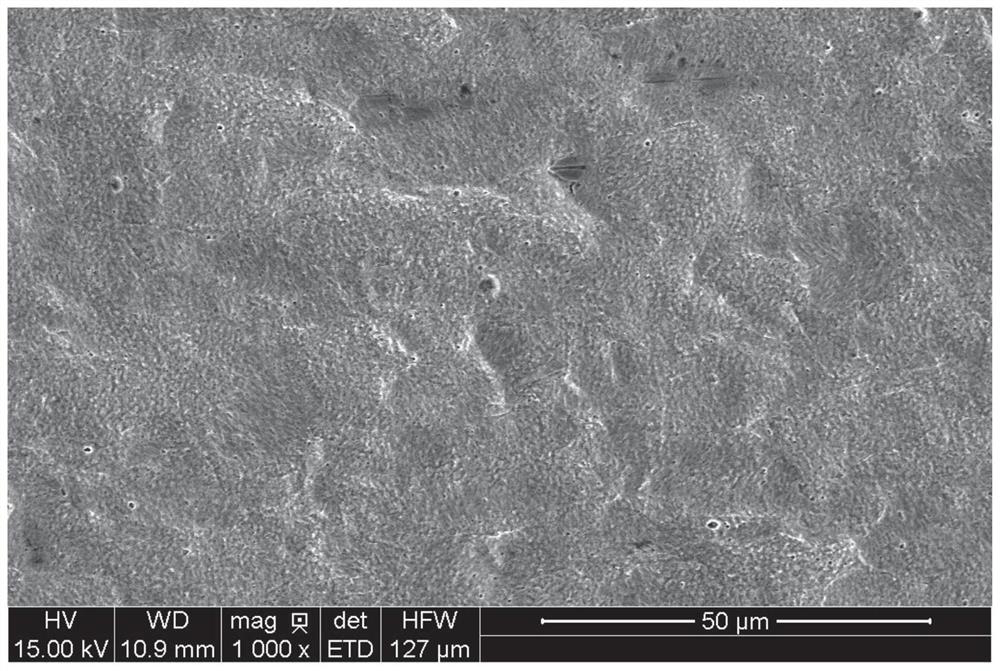

[0035] The obtained FeNi alloy foil strip was taken out, sprayed and cleaned with NaOH aqueous solution with a concentration of 0.5mol / L, and then dried in a drying oven at 40°C. The thickness of the obtained FeNi alloy foil strip was 50 μm, and its etched surface morphology was as follows: figure 1 shown, and its surface stress value does not exceed ±5MPa.

Embodiment 2

[0037] Embodiment 2 A method of chemically etching thinned FeNi alloy foil strips provided in this embodiment includes:

[0038] The FeNi alloy sheet with a thickness of 50 μm is alkaline washed for 5 minutes with KOH aqueous solution with a concentration of 0.6mol / L, and dried with hot air at about 50°C;

[0039] Spray the FeNi alloy thin plate evenly with an etching solution at a temperature of 30°C. The etching solution contains a HCl concentration of 10mol / L and a FeCl concentration of 30g / L. 3 and the rest of the water, the spray pressure is 0.2MPa, and the spray time is 10 minutes;

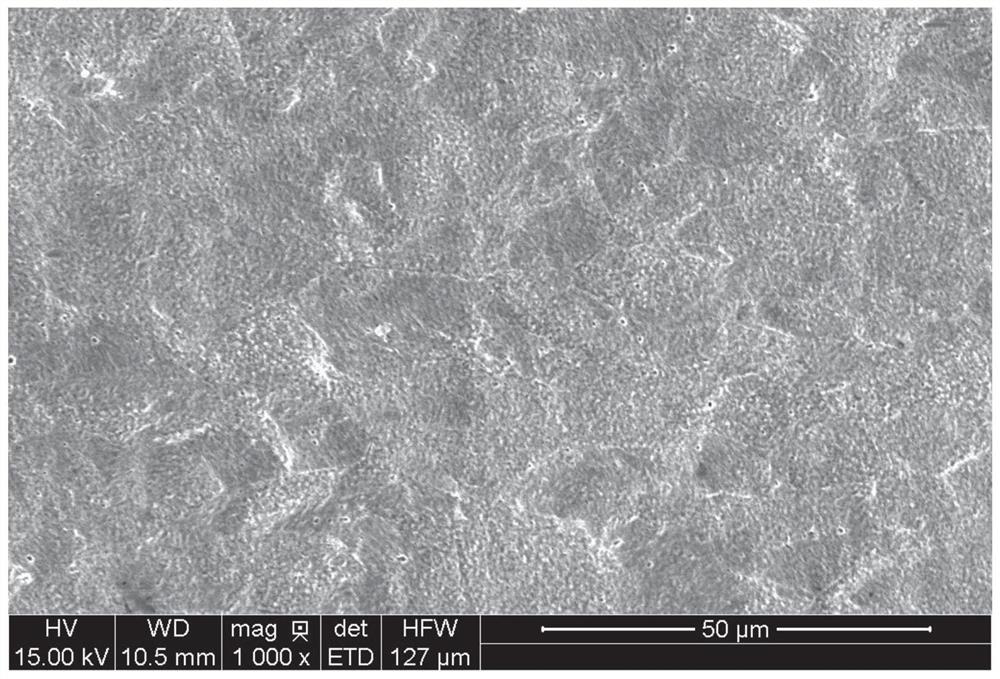

[0040] The obtained FeNi alloy foil strip was taken out, sprayed and cleaned with NaOH aqueous solution with a concentration of 0.5mol / L, and then dried in a drying oven at 60°C. The thickness of the obtained FeNi alloy foil strip was 25 μm, and its etched surface morphology was as follows: figure 2 shown.

Embodiment 3

[0041] Embodiment 3 A method of chemically etching thinned FeNi alloy foil strips provided in this embodiment includes:

[0042] The FeNi alloy sheet with a thickness of 40 μm is alkaline washed for 3 minutes with KOH aqueous solution with a concentration of 0.5mol / L, and dried with hot air at about 60°C;

[0043] Spray the FeNi alloy thin plate evenly with an etching solution at a temperature of 30°C. The etching solution contains a HCl concentration of 10mol / L and a FeCl concentration of 15g / L. 3 And the remaining water, the spray pressure is 0.1MPa, and the spray time is 10 minutes;

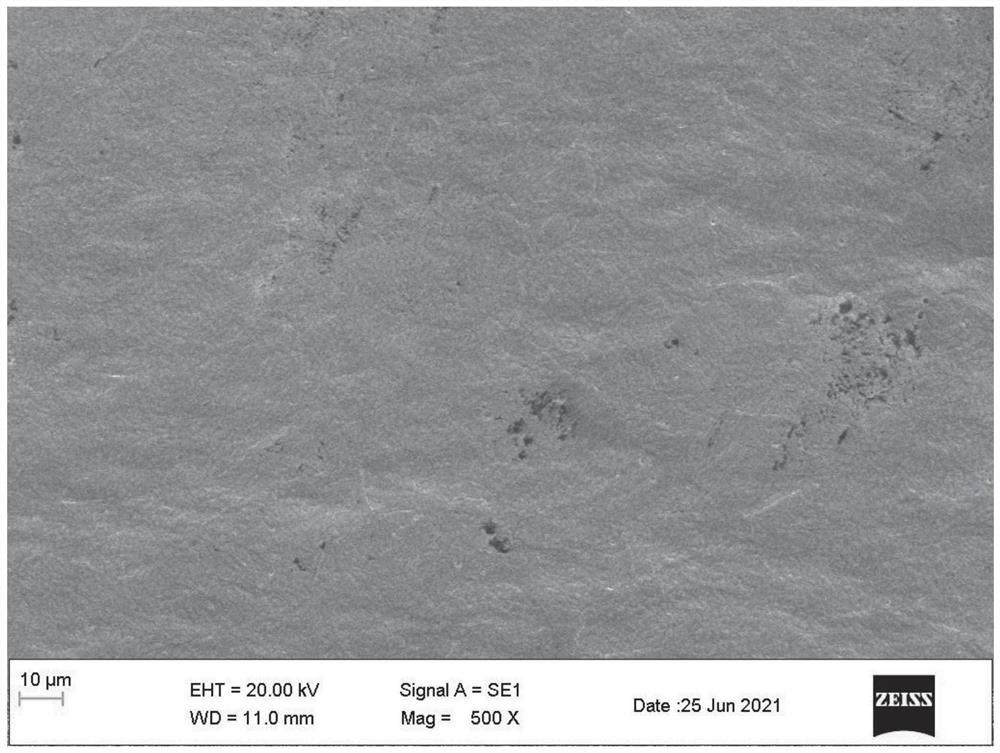

[0044]The obtained FeNi alloy foil strip was taken out, sprayed and cleaned with NaOH aqueous solution with a concentration of 0.5mol / L, and then dried in a drying oven at 50°C. The thickness of the obtained FeNi alloy foil strip was 20 μm, and its etched surface morphology was as follows: image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com