Erasable film variable-resistance memory unit adopting flexible paper base and preparation method thereof

A technology of storage unit and resistive variable memory, which is applied in the direction of electrical components, etc., can solve the problems of large number of transistors, low storage density, increased production cost, etc., and achieve the effects of wide application prospects, high deposition rate, and good resistive variable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be further described below through specific examples.

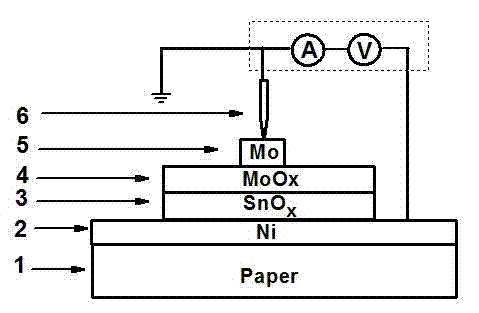

[0031] The metal Ni target is selected, and the vacuum of the reaction chamber is lowered to less than 3.0×10 before film deposition. -3 Pa, and then the Ar gas is passed into the reaction chamber through the variable gas guide valve, and the working pressure in the reaction chamber is controlled to be 2.0×10 -1Pa. The sputtering current and voltage were adjusted to 180 mA and 500 V, respectively, and the sputtering time was 20 minutes to form a metal nickel film on the ink paper substrate as the bottom electrode. Electrode square resistance is less than 10 ohms.

[0032] Select a metal tin target, and vacuum the reaction chamber to less than 3.0×10 before film deposition -3 Pa, the substrate is heated to 100°C, and then the O 2 and Ar gas are passed into the reaction chamber in turn, and the oxygen partial pressure in the reaction chamber is controlled to be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com